A lift-drag combined double-chain water turbine

A combination of lift and drag, water turbine technology, applied in water wheels, circular chain machinery, mechanical equipment, etc., can solve the problems of low proportion of windward side, low efficiency, etc., to increase energy utilization coefficient, reduce hysteresis effect, high energy The effect of utilizing the coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is described in further detail below in conjunction with accompanying drawing:

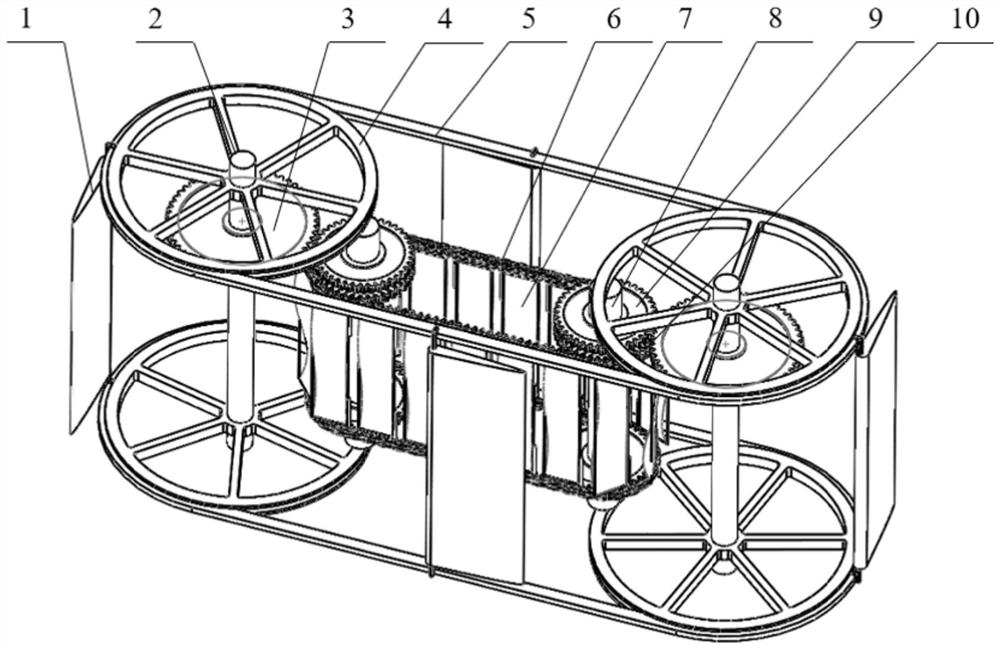

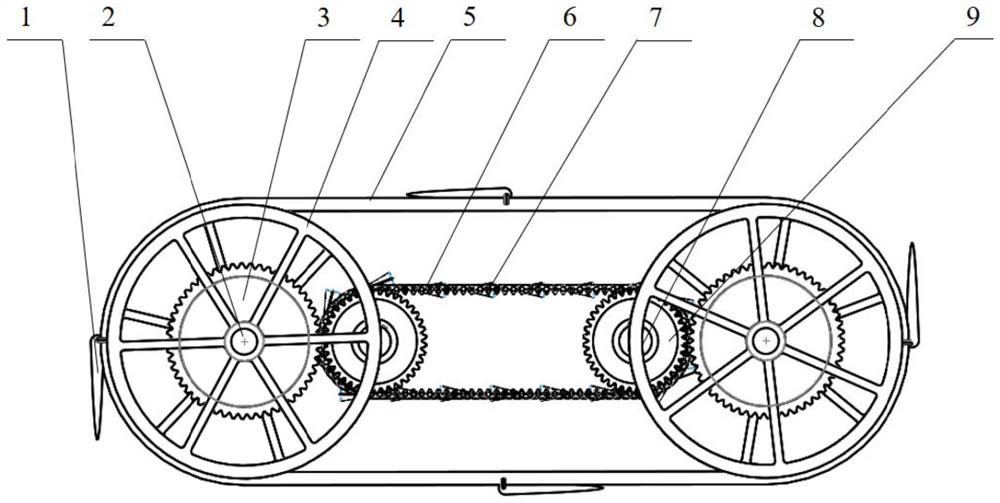

[0034] Such as Figure 1 to Figure 3 As shown, a lift-drag combination double-chain water turbine includes a lift water wheel structure and an internal resistance water wheel structure; the lift water wheel structure includes two lift water turbine shafts 2 arranged in parallel, and the two lift water turbine shafts 2 are equipped with Two supporting pulleys 4, the supporting pulleys 4 on the shaft 2 of the two lift turbines are connected by two lift transmission belts 5 arranged in parallel, there are a number of lift blades 1 arrayed between the two lift transmission belts 5, on the shaft 2 of the lift turbine A lift transmission gear 3 is provided;

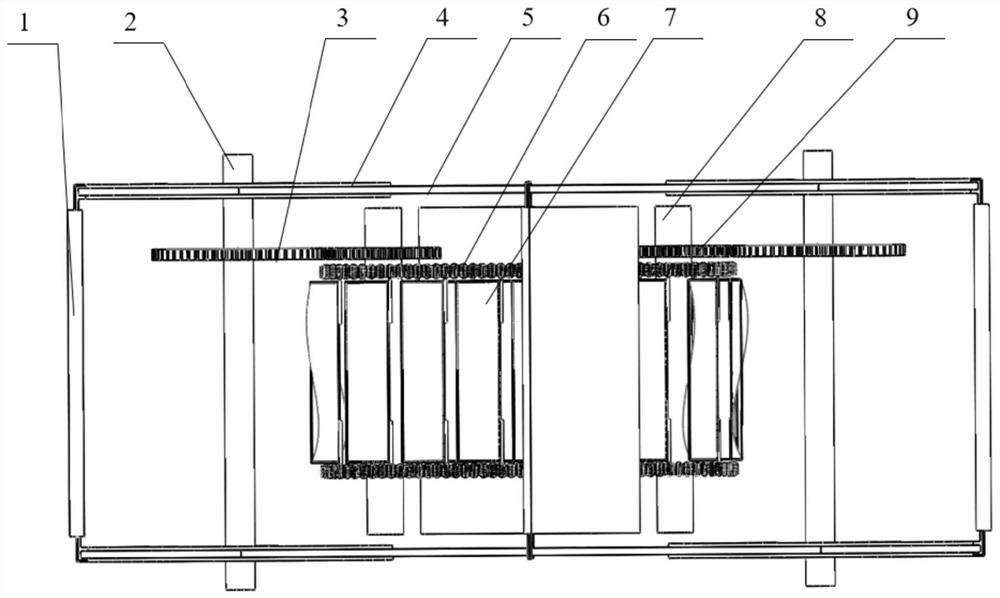

[0035] Such as Figures 7 to 9 As shown, the internal resistance water wheel structure includes two internal resistance water wheel transmission shafts 8 arranged in parallel, each internal resistance water wheel tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com