A method for testing heat dissipation performance of electronic devices and its thermal resistance tester

A technology of electronic devices and testers, applied in the direction of measuring resistance/reactance/impedance, instruments, measuring electricity, etc., can solve the problem that the heat dissipation effect of electronic devices cannot be measured, and achieve the effect of avoiding heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

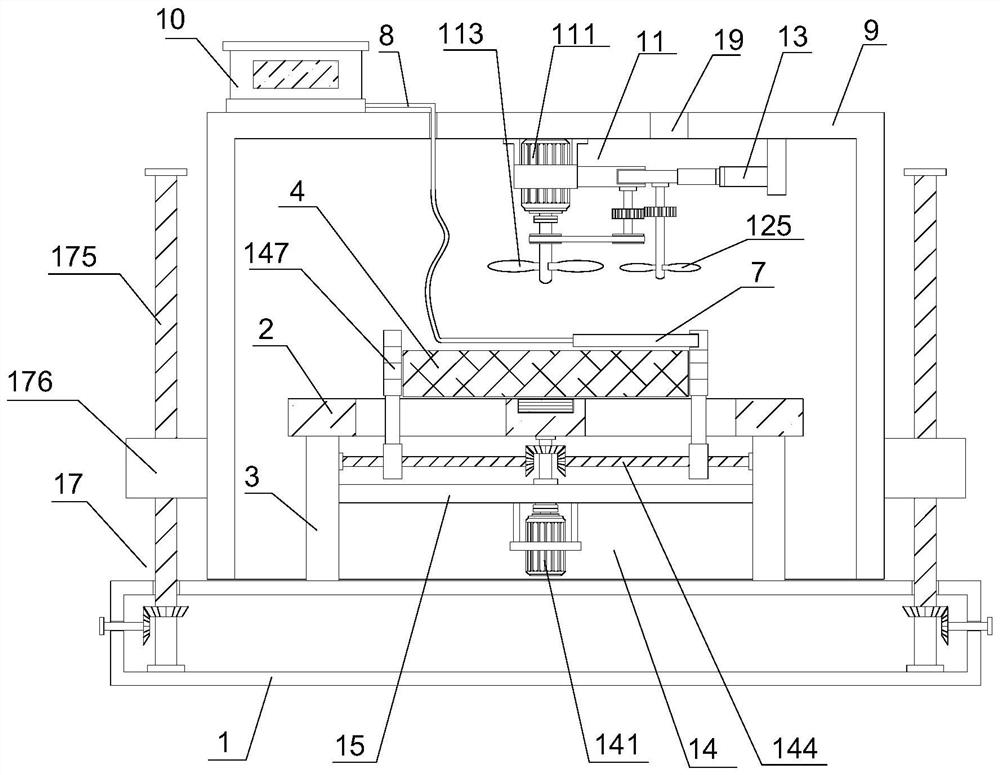

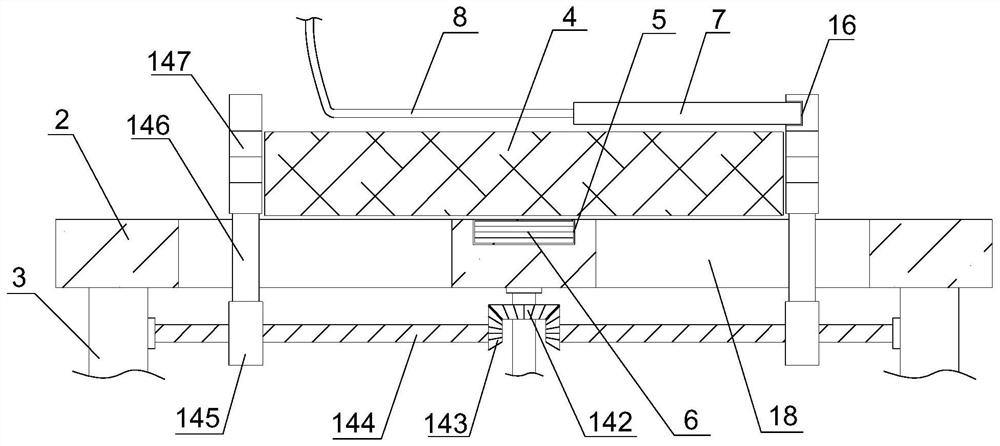

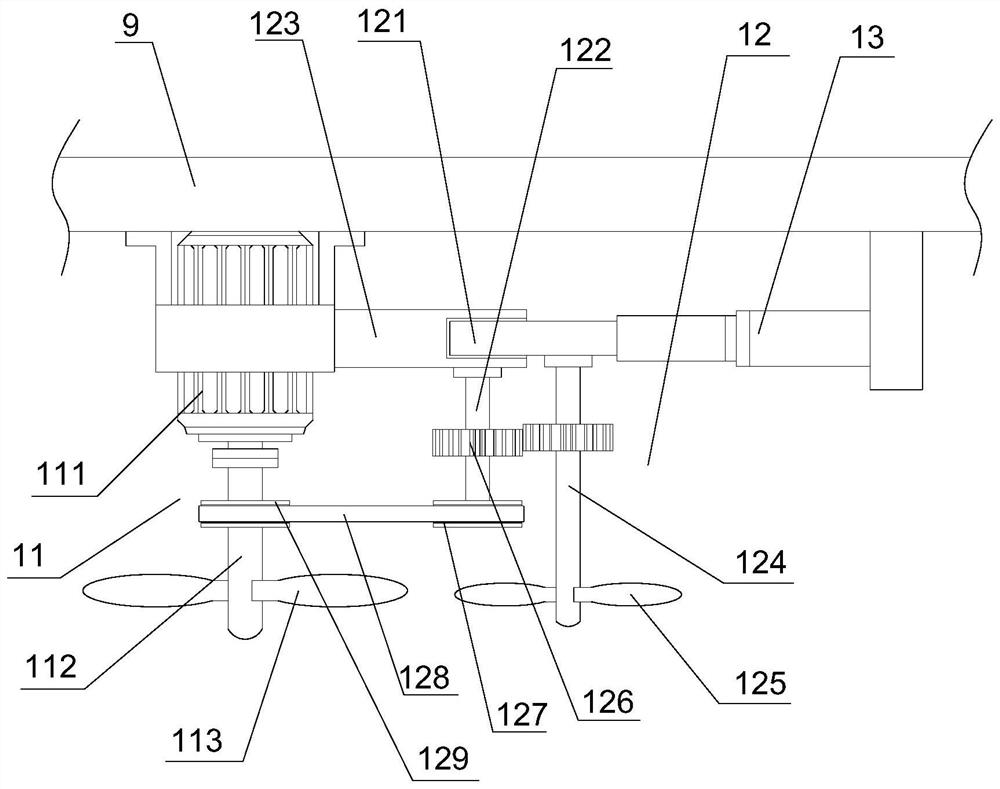

[0028] see Figure 1-5 , the present embodiment provides a method for testing the heat dissipation performance of an electronic device and a thermal resistance tester thereof, including a workbench 1 and a placement platform 2, bottom columns 3 are welded in the middle of both sides of the top of the workbench 1, and the bottom of the placement platform 2 The two sides of the end are respectively welded to the upper ends of the two bottom columns 3, the electronic device body 4 is placed in the middle of the top of the placing table 2, the heat conducting plate 7 is placed on one side of the upper end of the electronic device body 4, and the frame body 9 is placed on the upper end of the workbench 1. The top of the frame 9 away from the side of the heat conduction plate 7 is fixedly connected with the thermal resistance tester body 10 by bolts, the terminal of the heat conduction plate 7 is connected with a wire 8, the upper end of the wire 8 runs through the top of the frame 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com