Overall grinding device for cylindrical workpiece

A cylindrical and workpiece technology, applied in the field of the overall grinding device for cylindrical workpieces, can solve problems such as looseness, uneven marble reception, affecting the quality of cylindrical workpiece polishing and grinding, etc., to achieve the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail in conjunction with the accompanying drawings. This specific embodiment is only an explanation of the present invention, and it is not a limitation of the present invention. After reading this specification, those skilled in the art can make modifications to this embodiment without creative contribution according to needs, but as long as they are within the scope of the present invention All claims are protected by patent law.

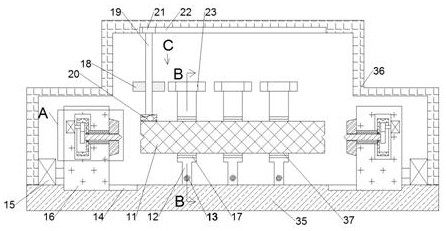

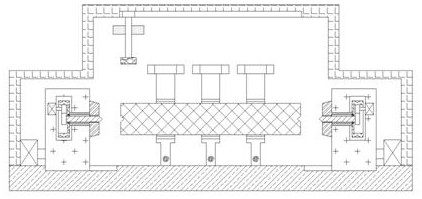

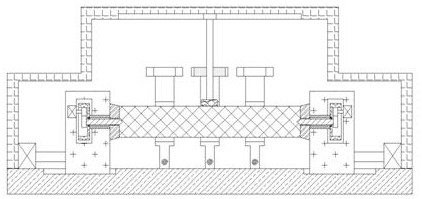

[0026] A cylindrical workpiece overall grinding device according to the present invention includes a base 35 and a frame 36, the base 35 is fixed on the ground, the frame 36 is fixed on the base 35, the base Six sliding plates 12 are slidably arranged on the upper end surface of the seat 35, and the six sliding plates 12 are arranged linearly along the axial direction of the workpiece 11. The six sliding plates 12 are divided into three groups, and the two sliding plates 12 of the same gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com