Load holding valve for excavator

A load-holding valve and excavator technology, applied in the field of hydraulic valves, can solve the problems of complex structure, high production cost, large internal leakage, etc., and achieve the effects of good fretting performance, simple and reliable parts, and stable and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the present invention more obvious and comprehensible, preferred embodiments are described in detail below with reference to the accompanying drawings.

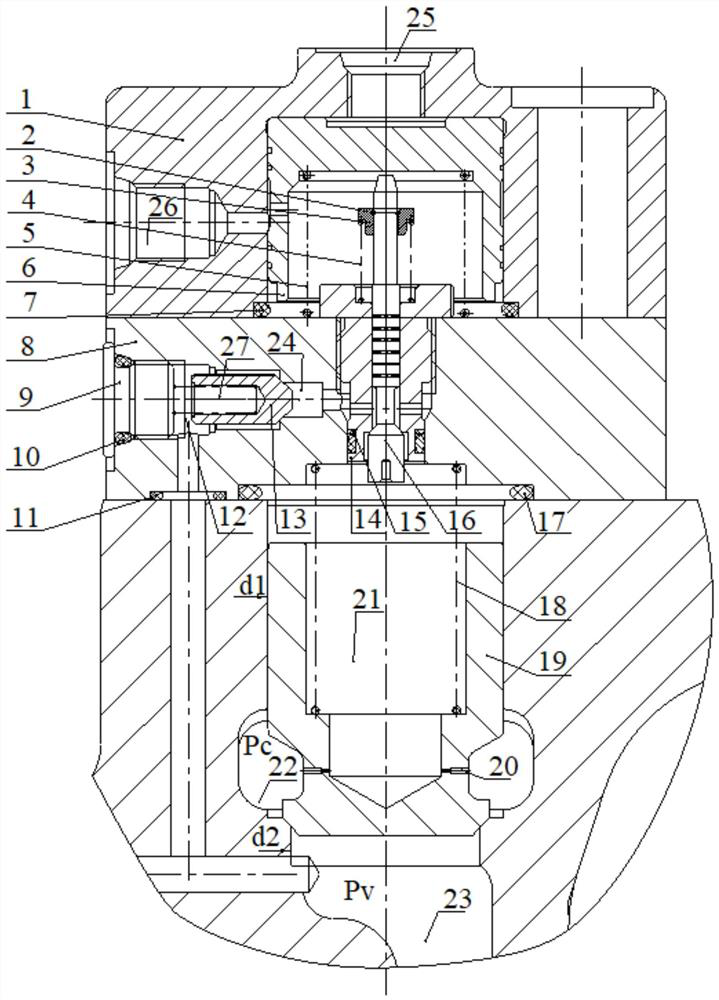

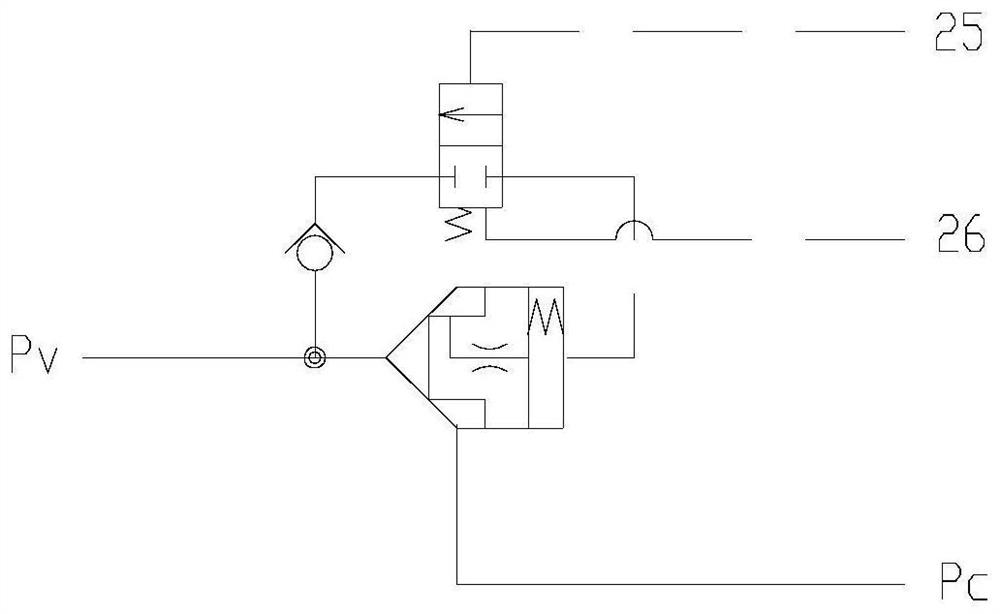

[0022] The present invention provides a load holding valve for an excavator, such as figure 1 As shown, it includes a first valve body 1, a second valve body 8, and a main valve body. The second valve body 8 is matched and sealed with the main valve body through the third O-ring 11 and the fourth O-ring 17. The first valve body The body 1 cooperates and seals with the second valve body 8 through the first O-ring 7 and is fastened by bolts.

[0023] The main valve body is provided with a main valve body hole, the large cone valve core 19 is installed in the main valve body hole, the large cone valve core 19 and the main valve body hole are precisely matched, and the outer cone surface of the large cone valve core 19 is fitted with the main valve body hole. The inner wall cone surface is sealed and matc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com