Patents

Literature

34results about How to "Good fretting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fixed fly jib stepless amplitude-variation control system for crane and crane

ActiveCN104071709AWide speed rangeGood fretting performanceCranesLoad-engaging elementsControl systemReversing valve

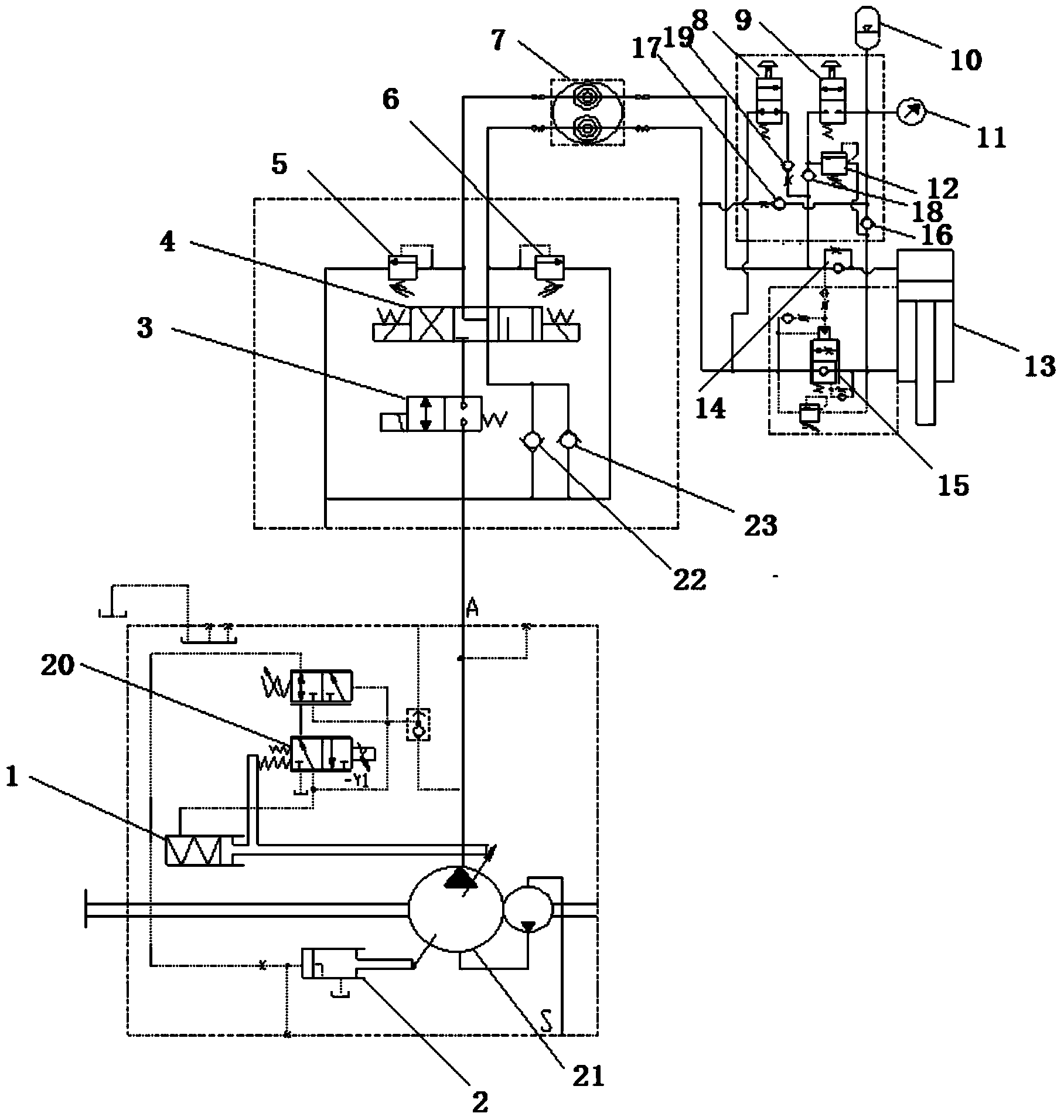

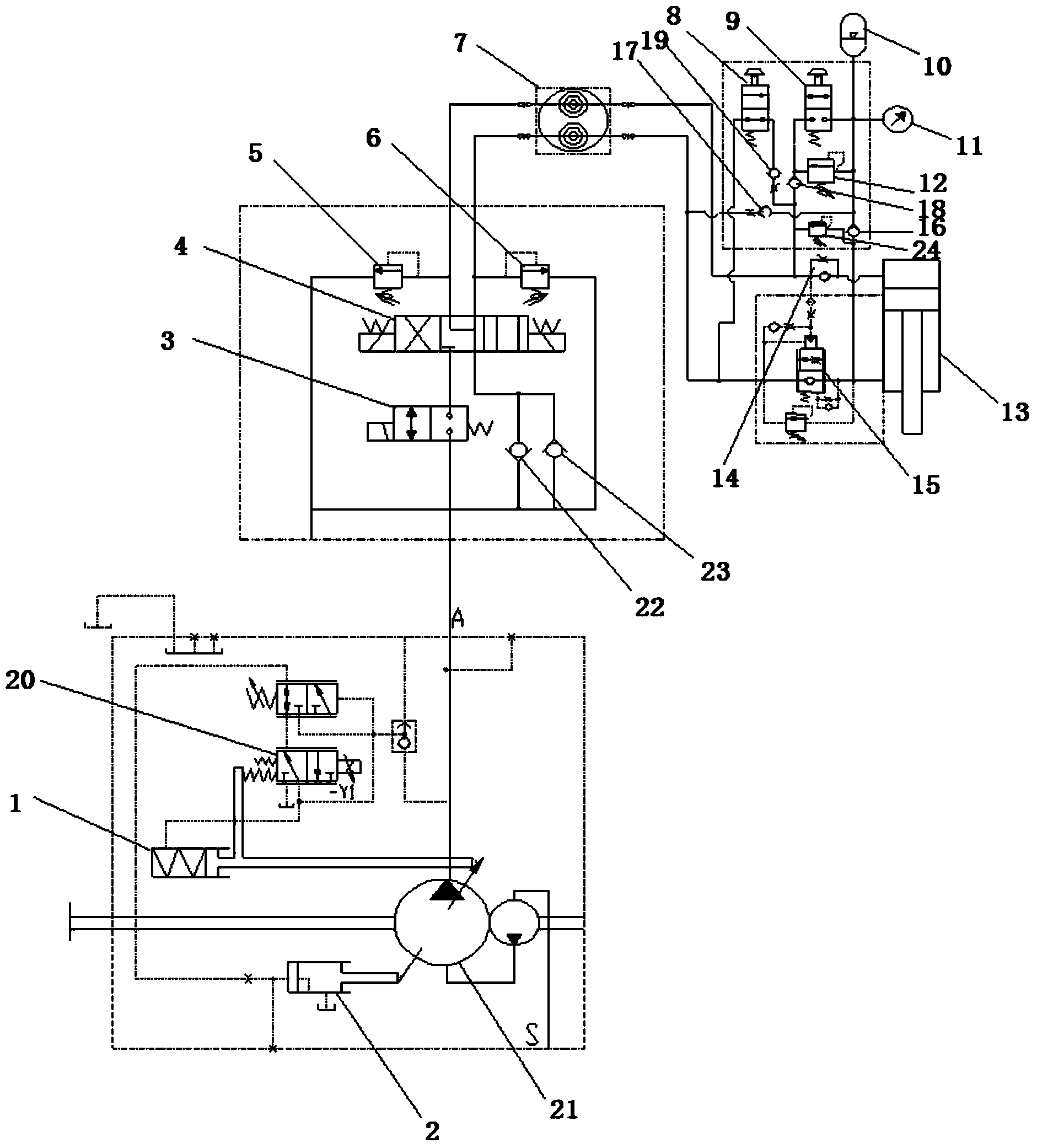

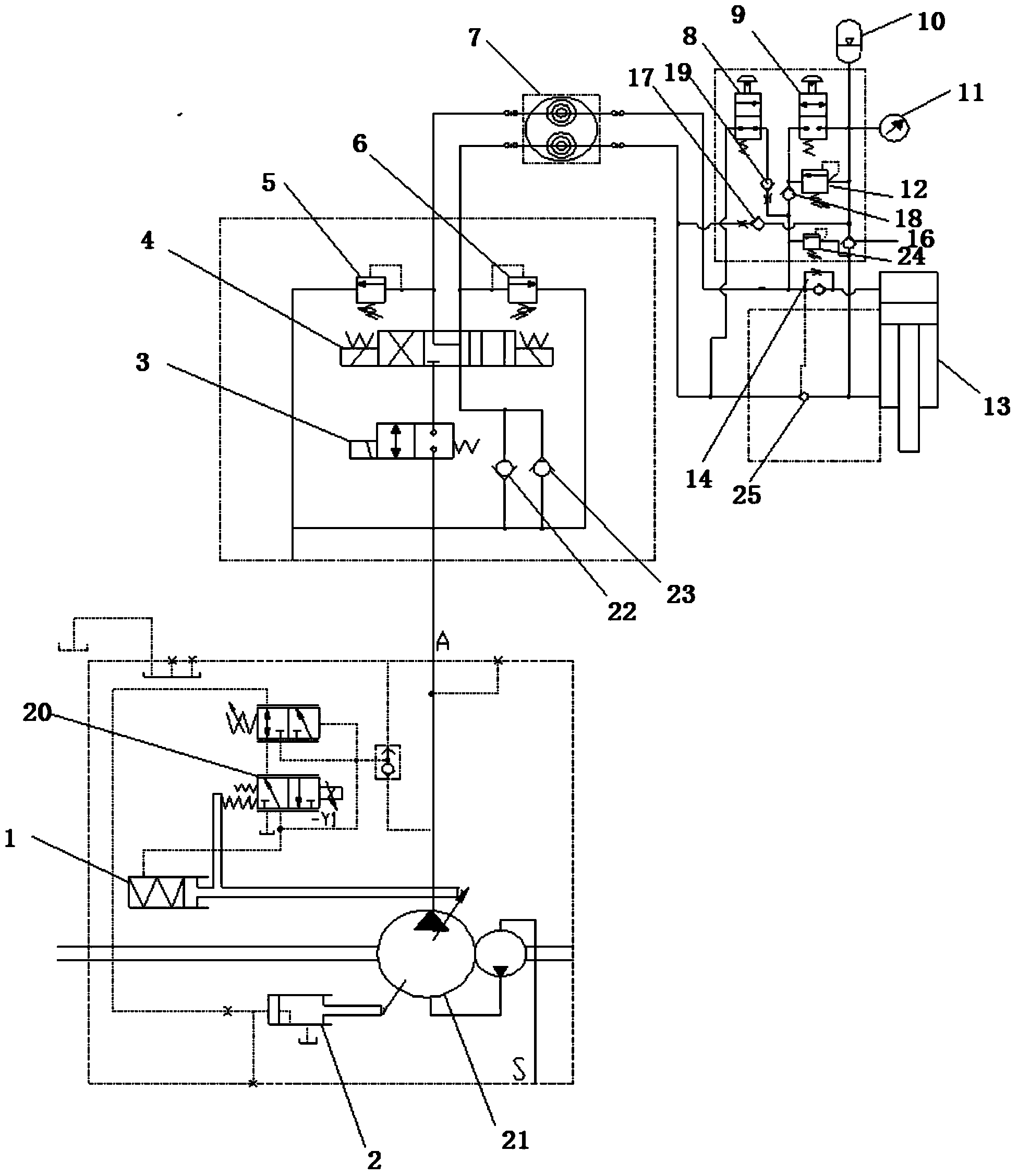

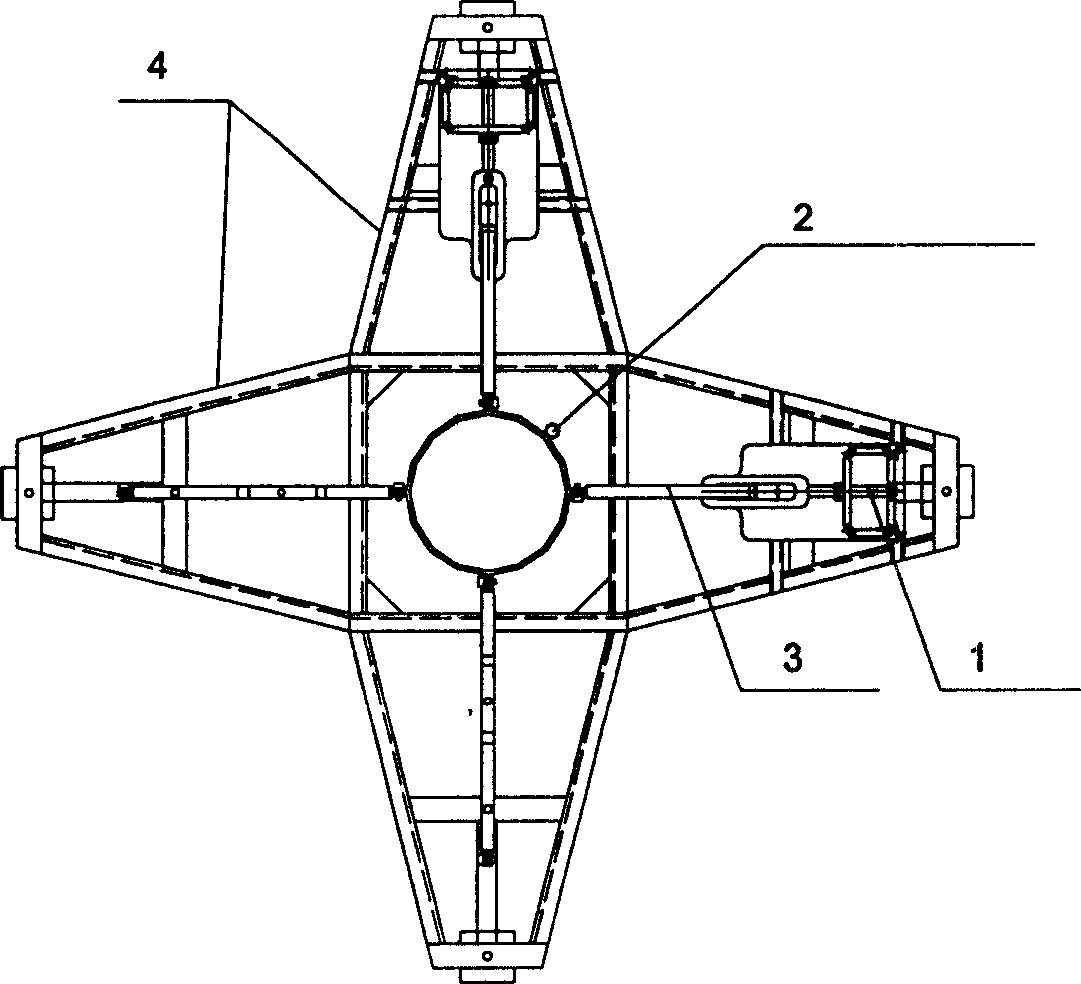

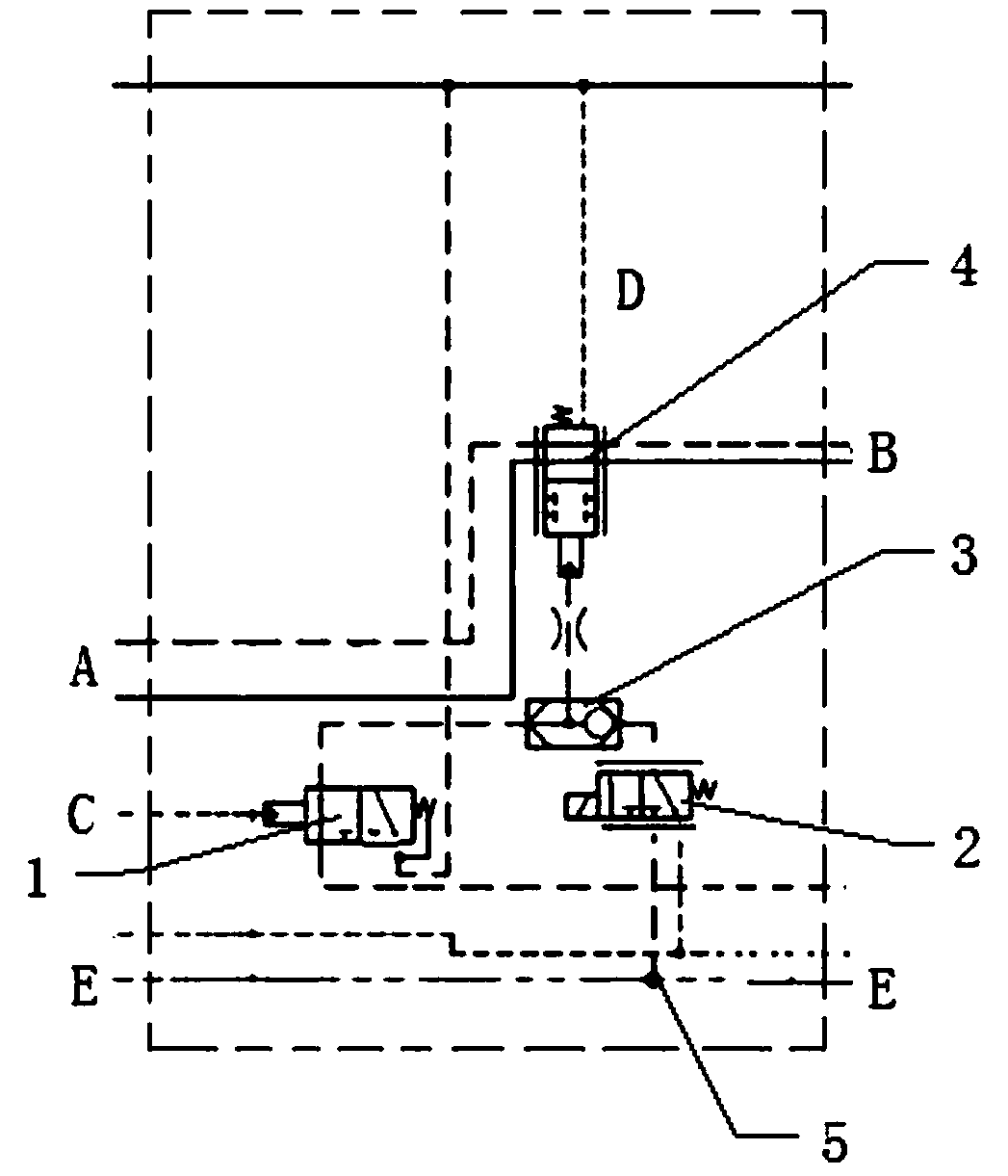

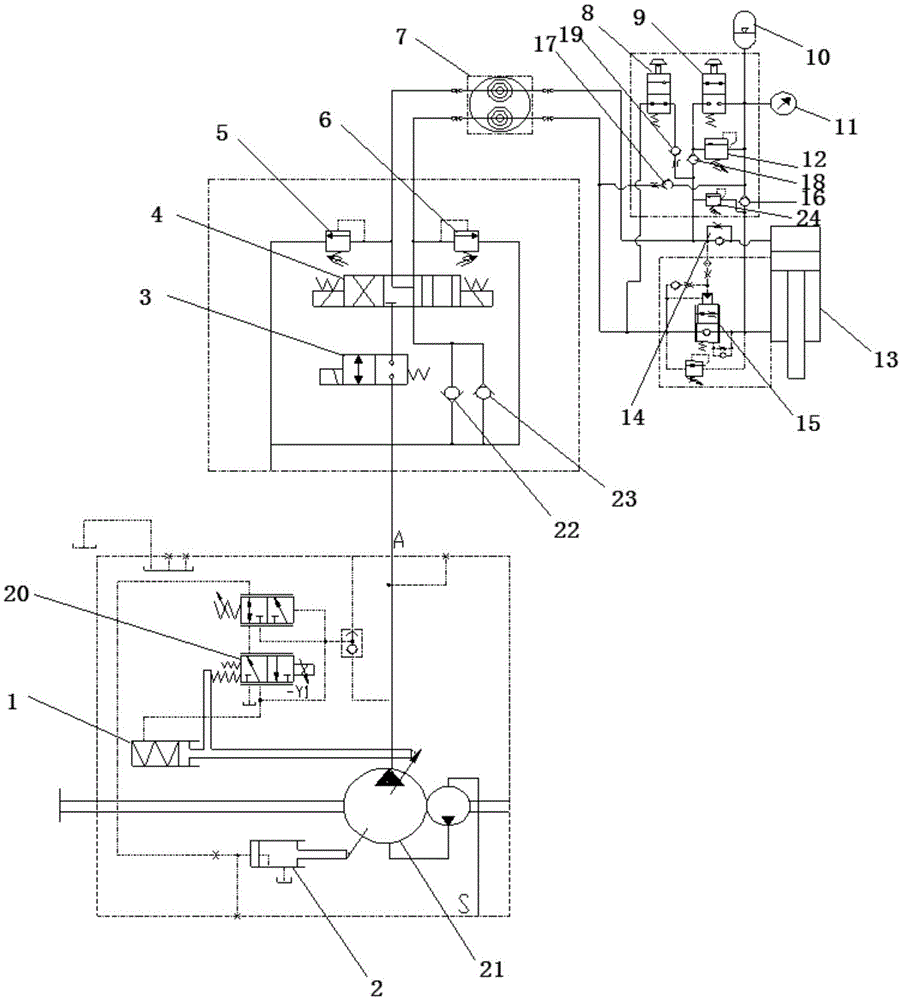

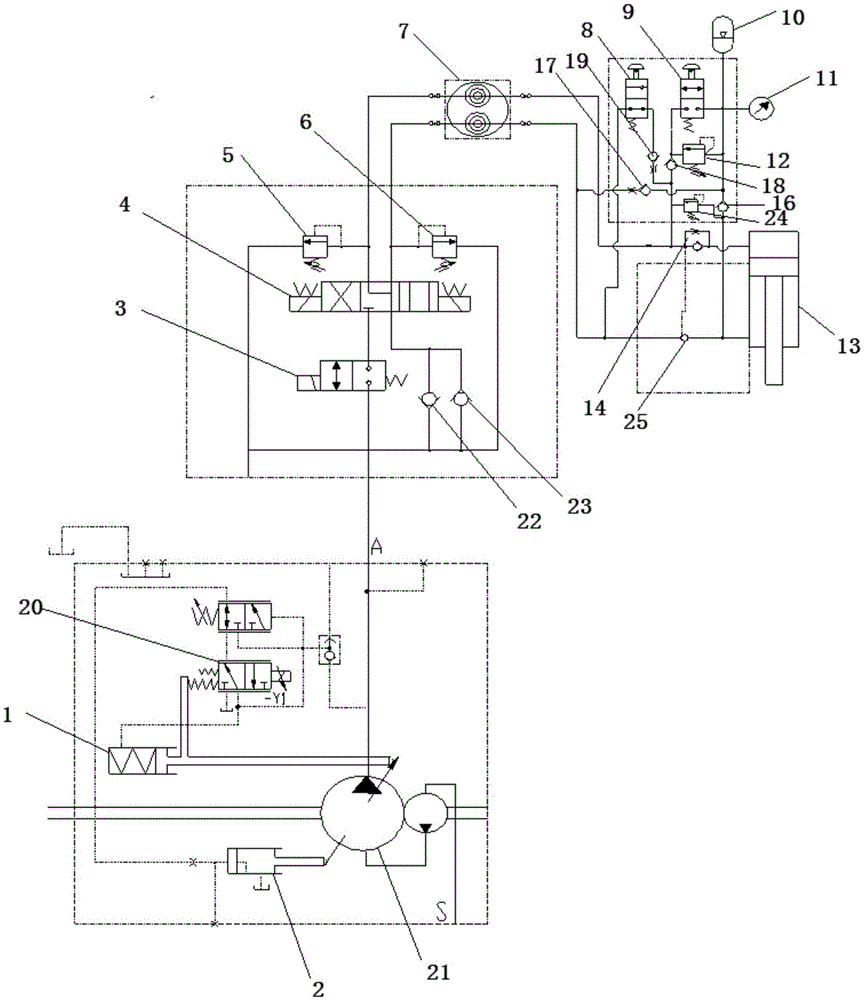

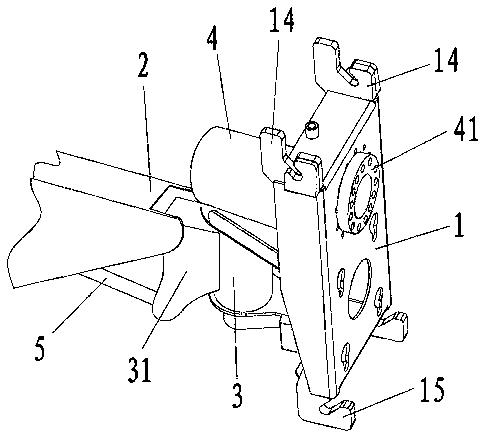

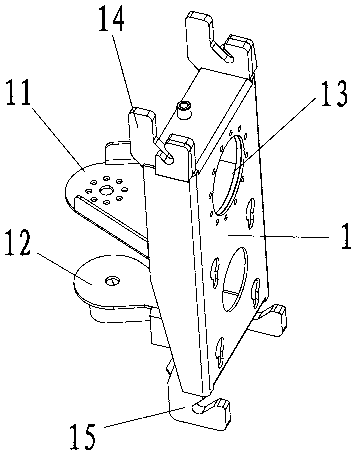

The invention relates a fixed fly jib stepless amplitude-variation control system for a crane and the crane. The control system comprises an electronic proportional pressure-reducing valve, a variable pump, a first reversing valve, and a hydraulic oil cylinder for varying the amplitude of a fixed fly jib, wherein the first reversing valve is positioned on an oil line between the variable pump and the hydraulic oil cylinder; the pressure oil output by the variable pump is input in the hydraulic oil cylinder via the first reversing valve; the electronic proportional pressure-reducing valve controls the discharge volume of the output pressure oil of the variable pump. The control system provided by the invention utilizes the electronic proportional pressure-reducing valve for controlling the discharge volume of the variable pump so as to realize the continuous variation of the discharge value of the variable pump, and is wide in speed regulating range and good in jogging property.

Owner:XUZHOU HEAVY MASCH CO LTD

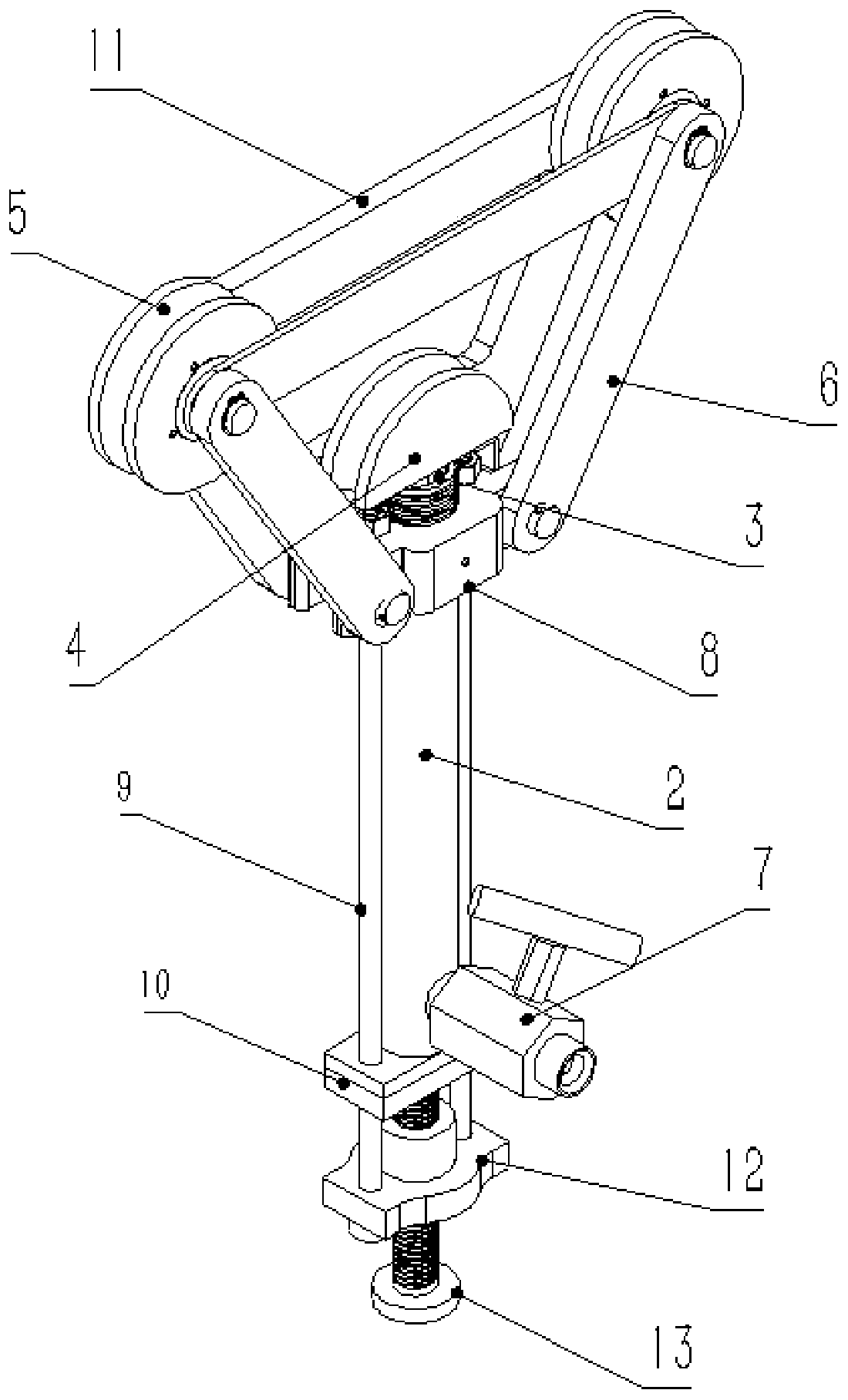

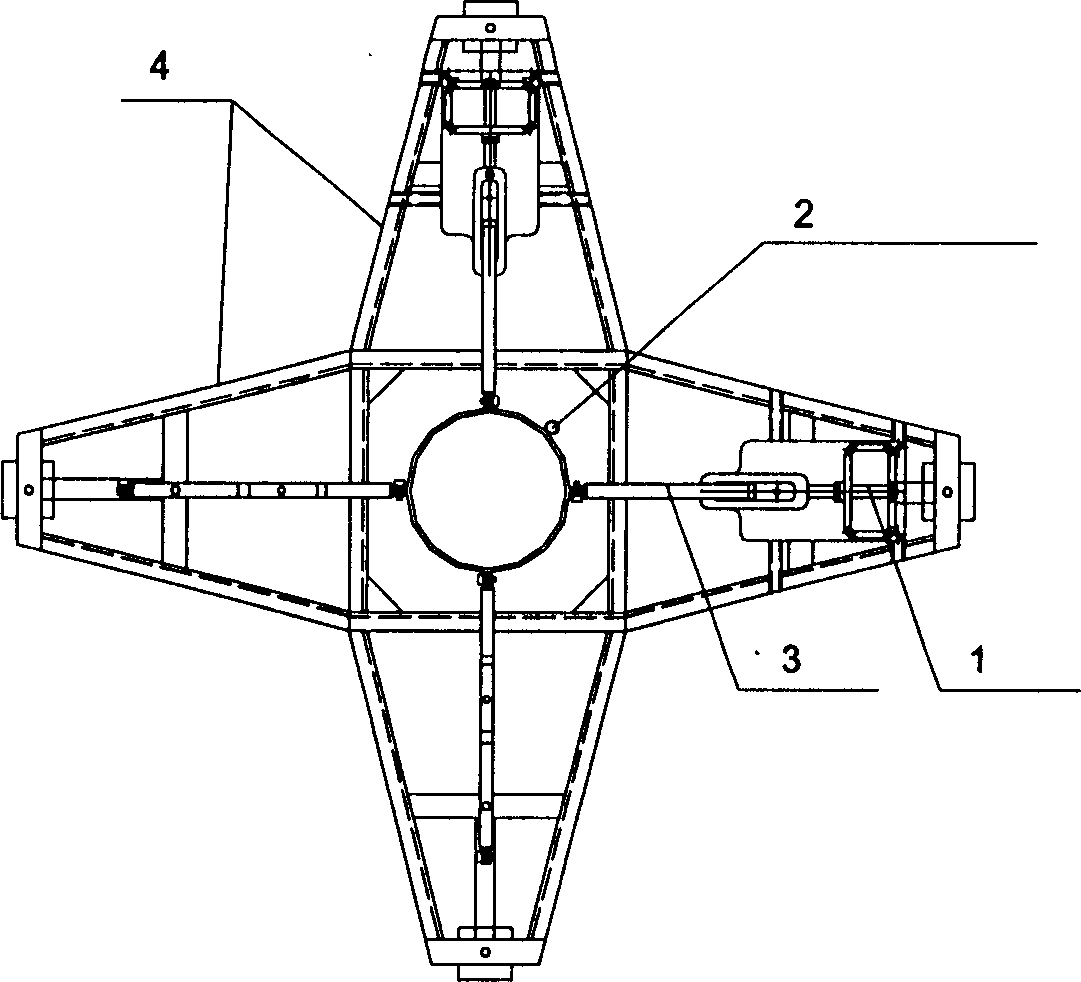

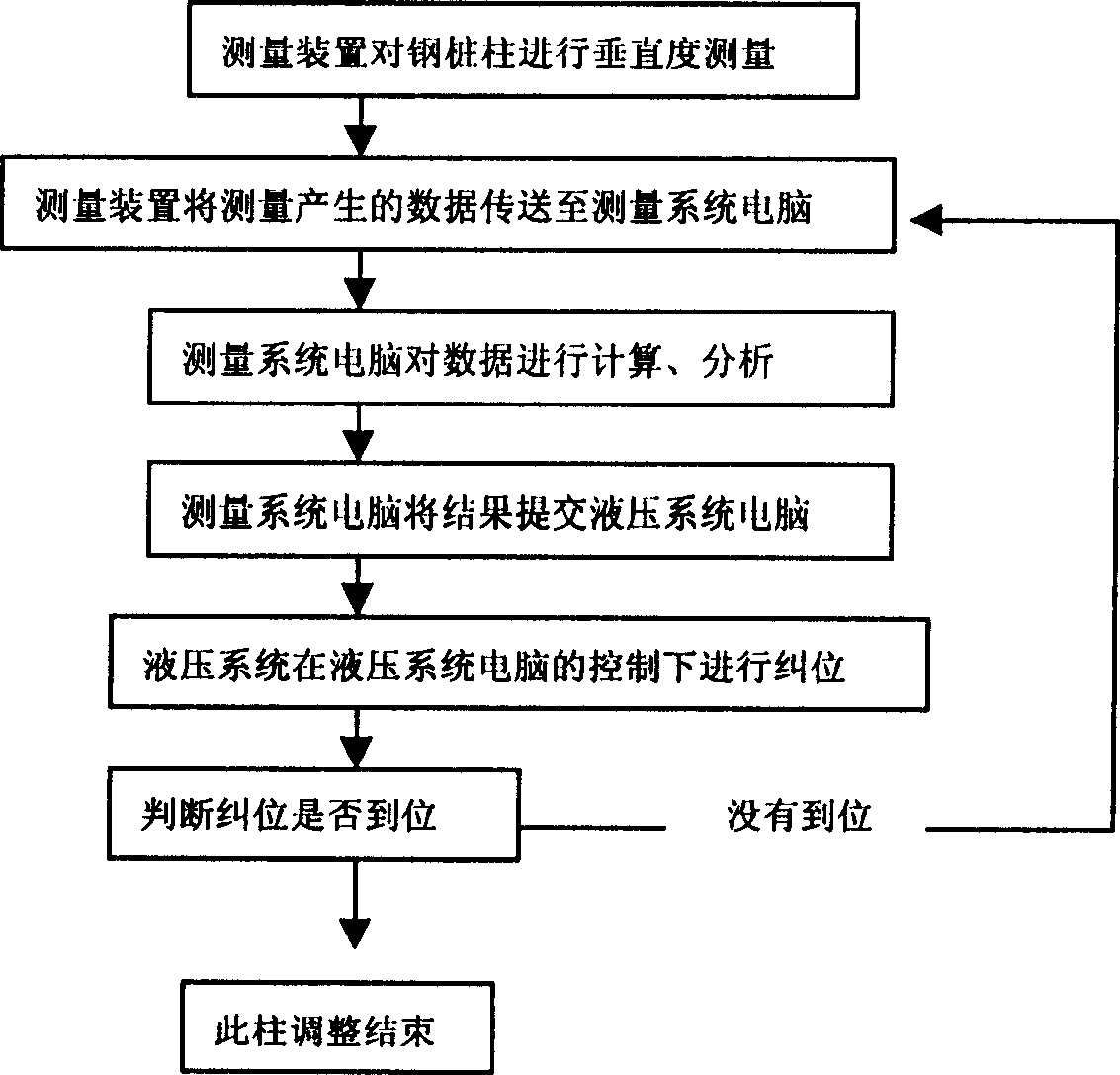

Automatic verticality regulating method for piling bar post and system thereof

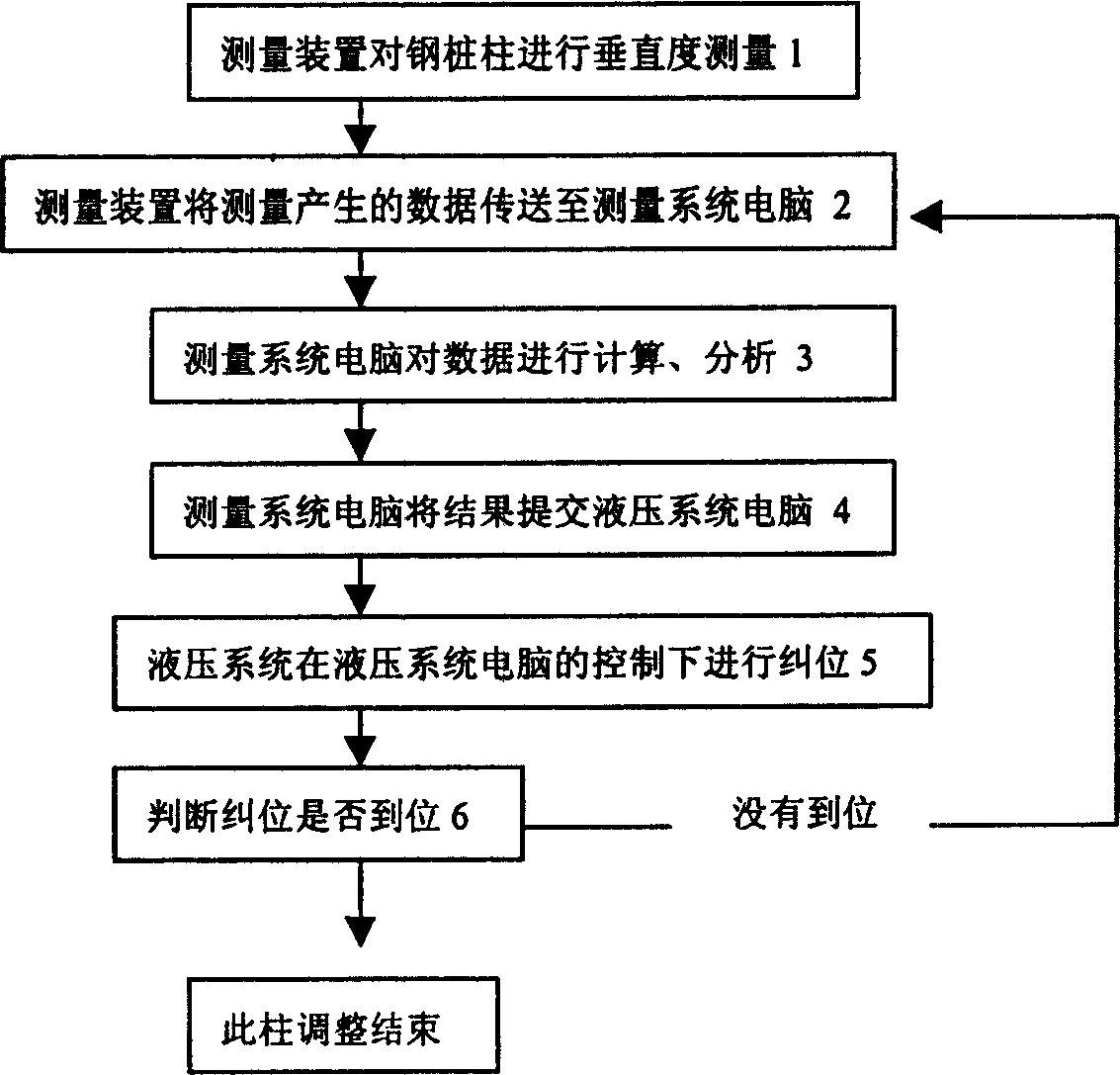

The present invention provides a steel pile column full-automatic verticality regulation and control system and its method. Its method includes the following steps: (1) making verticality measurement of steel pile column by using measuring device; (2) transferring measured data into measurement system computer; (3). measuring system computer can be used for calculating and analyzing said data; (4). transferring said result into the hydraulic system cmputer by means of measurement system computer; (5) hydraulic system can be used for correcting position under the control of hydraulic system computer; and (6). judging that the above-mentioned corrected position is in place or not, if it is not in place, returning step (2). Said system is high in accuracy, smooth and stable in operation, good in micromotion property and can implement step-by-step operation less than 0.2 mm.

Owner:SHANGHAI CONSTR NO 1 GRP +1

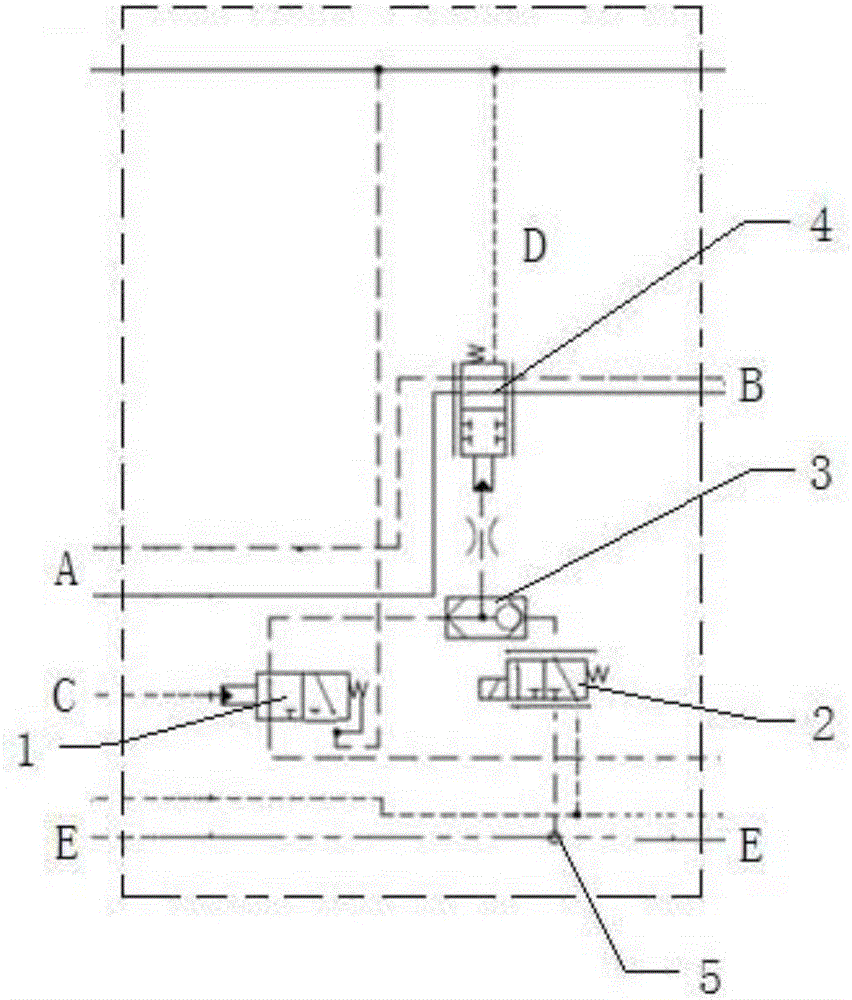

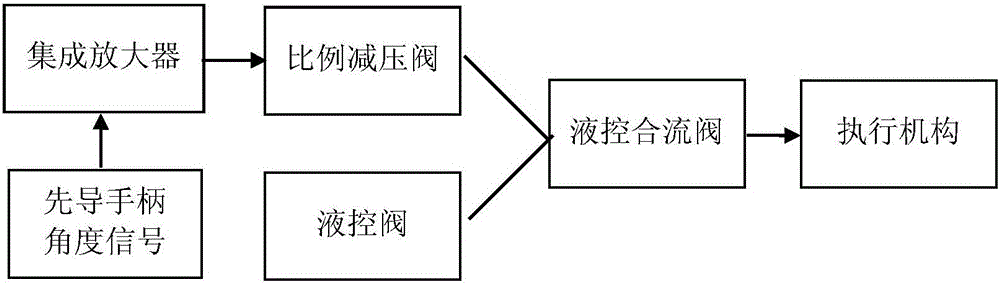

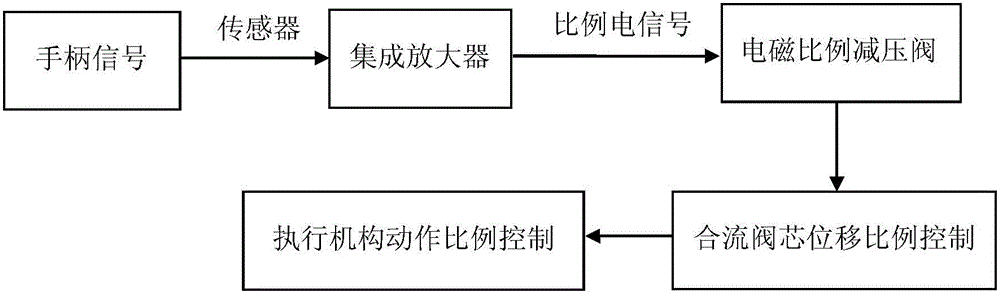

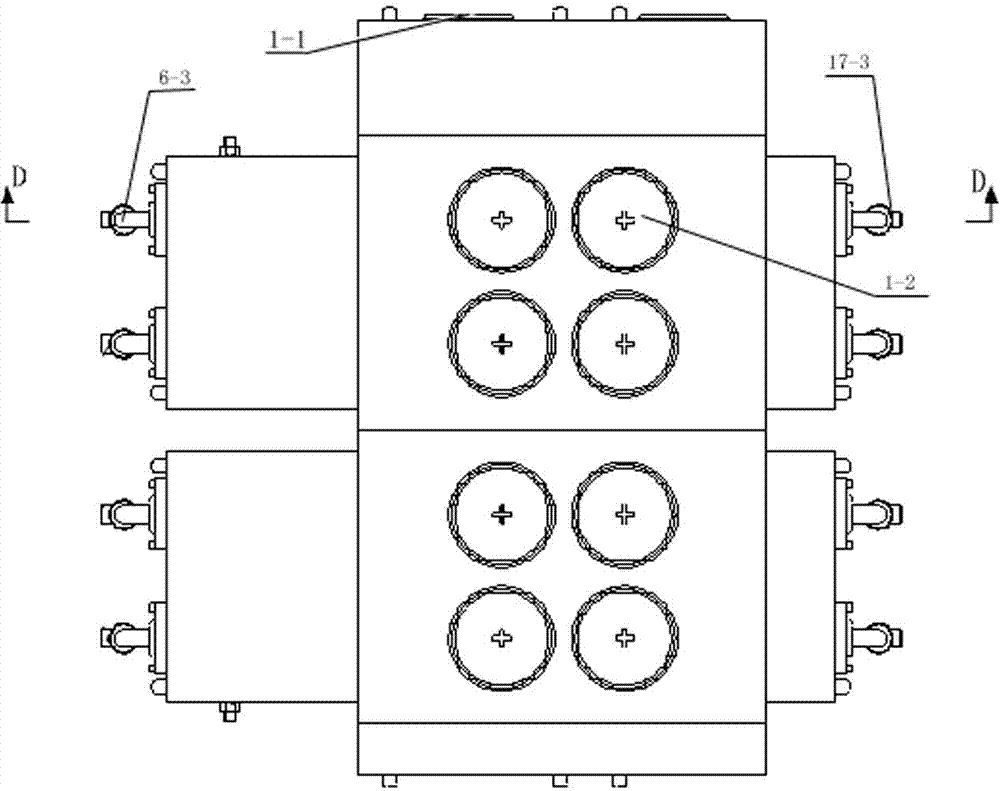

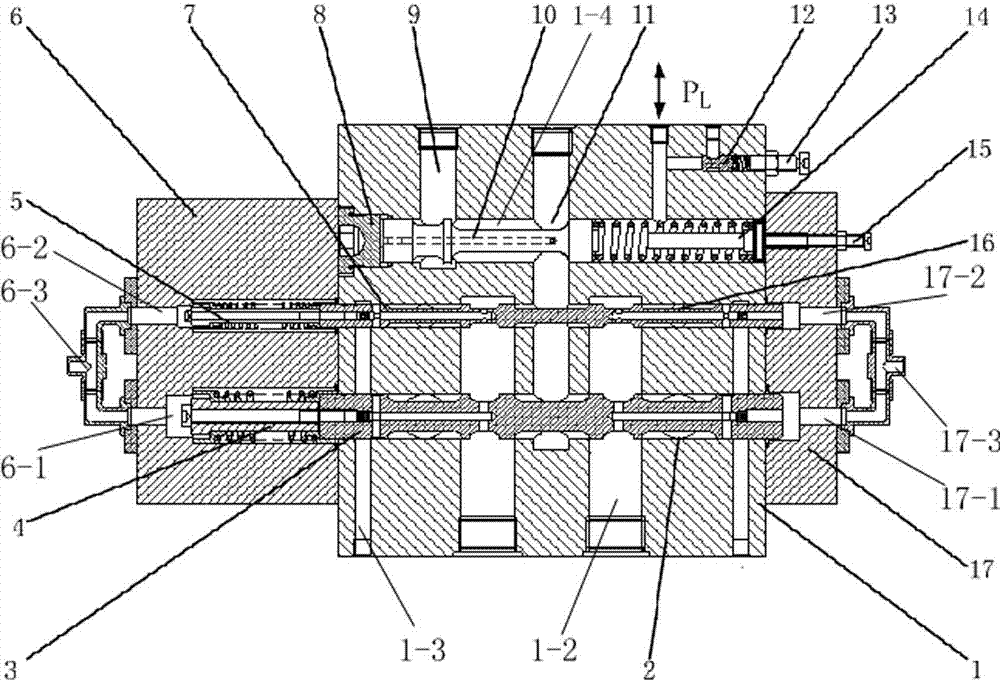

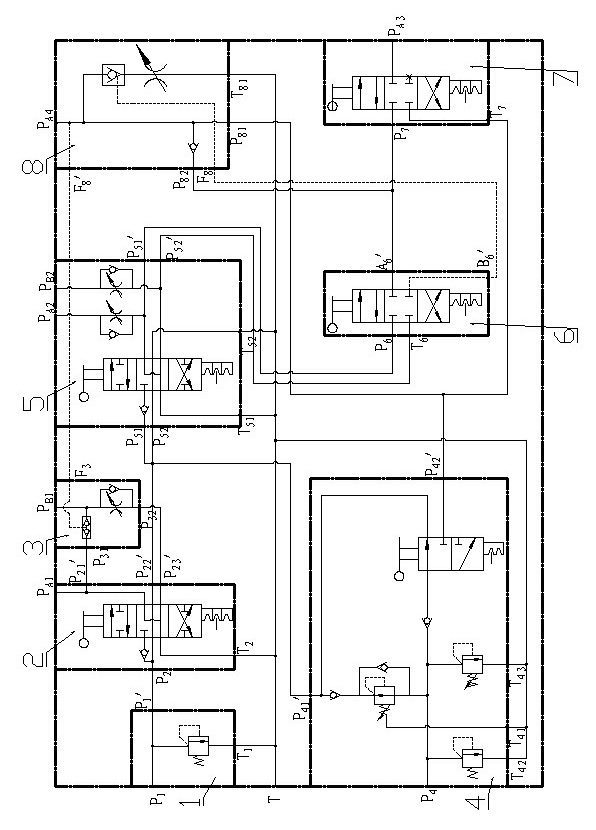

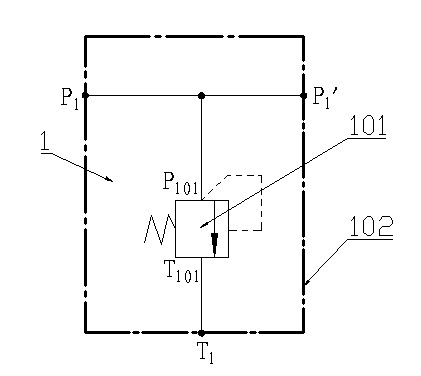

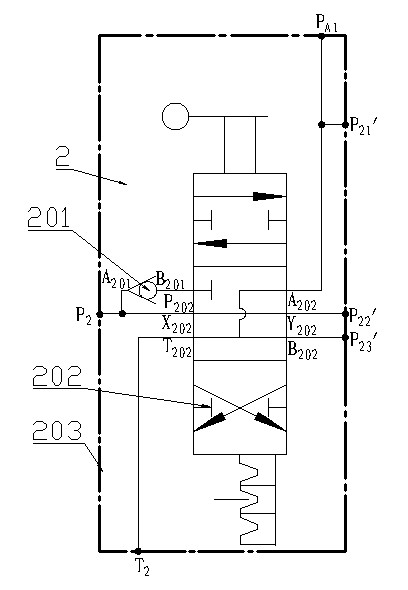

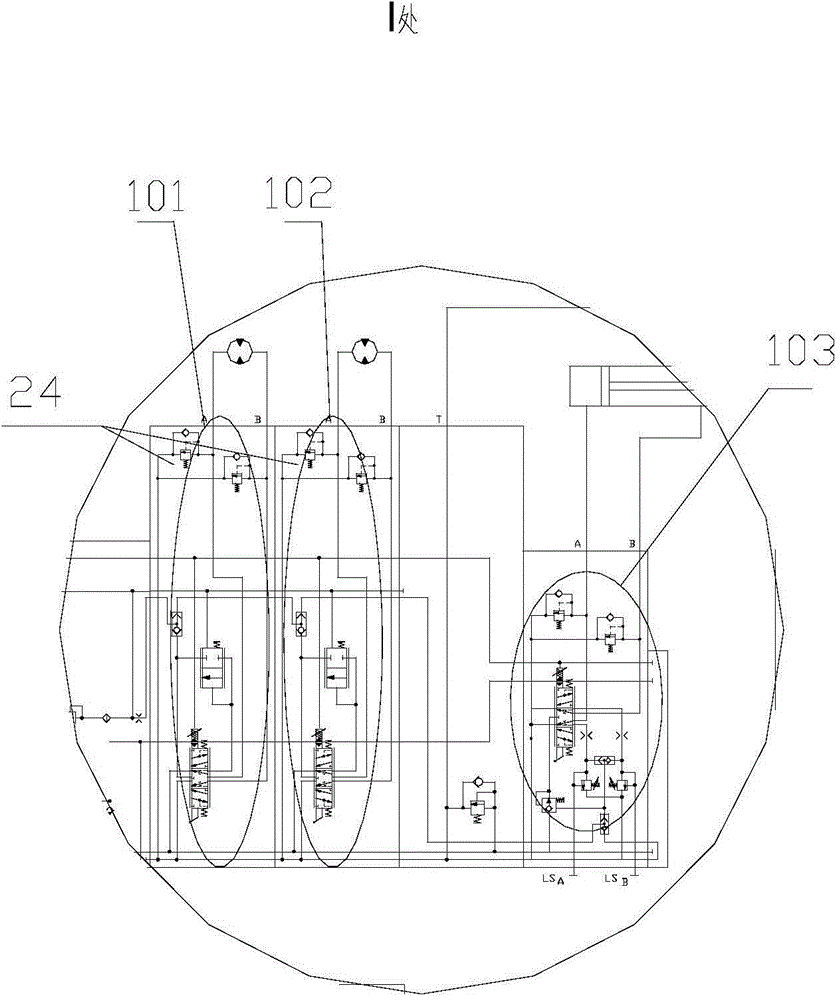

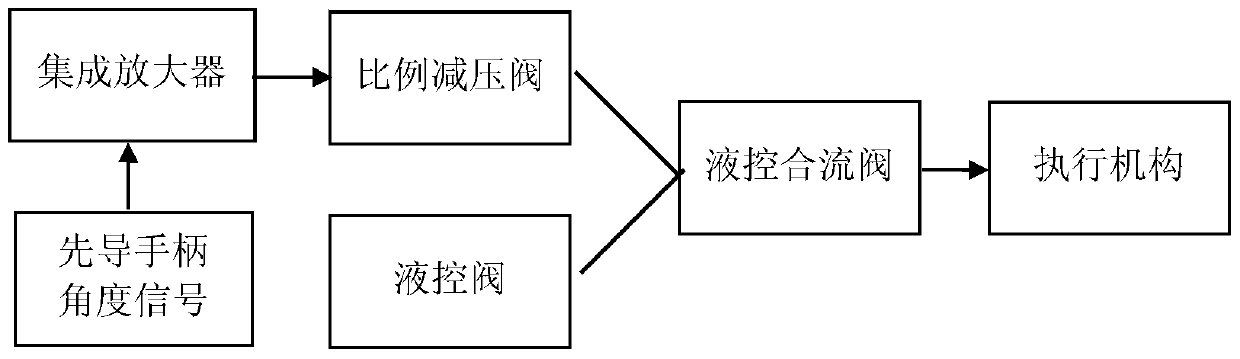

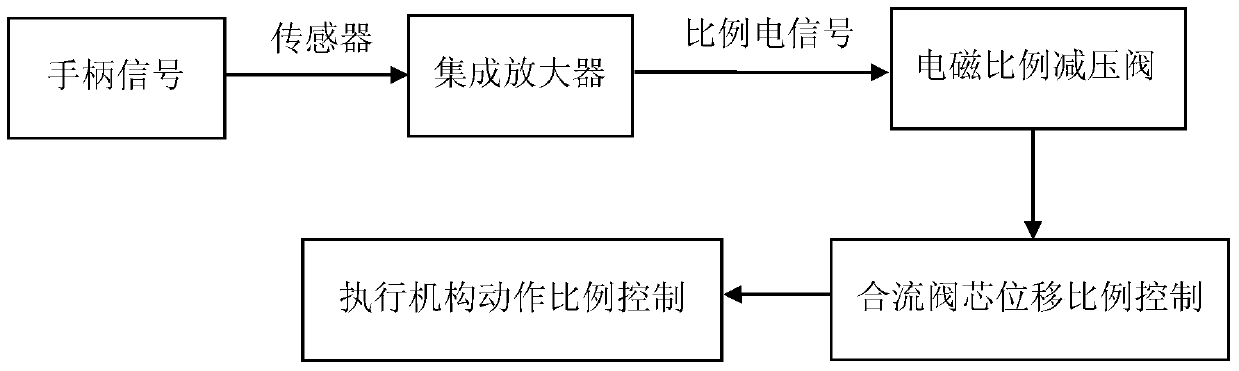

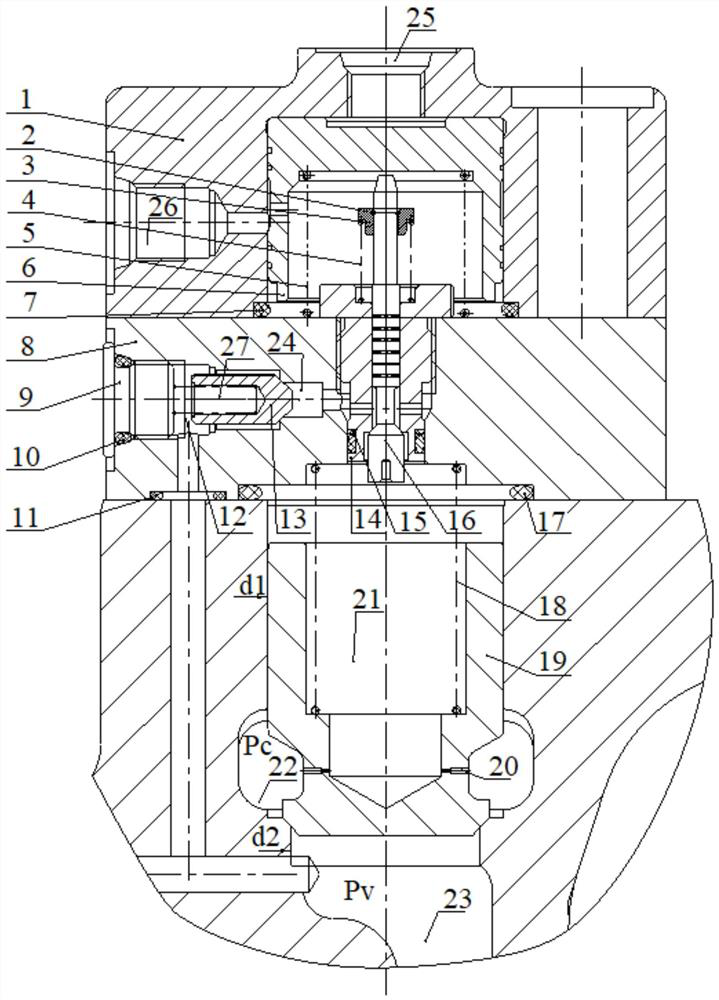

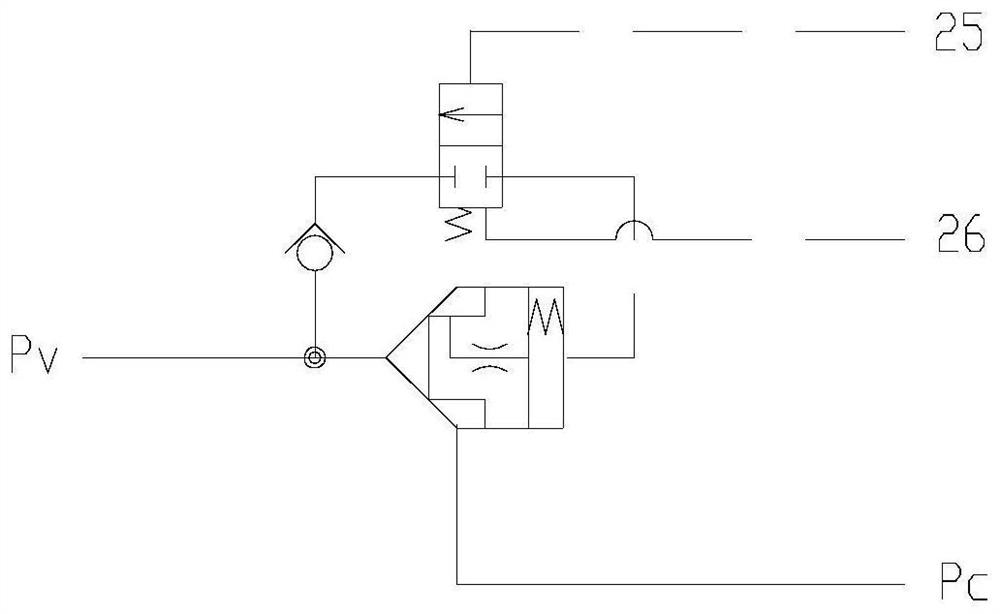

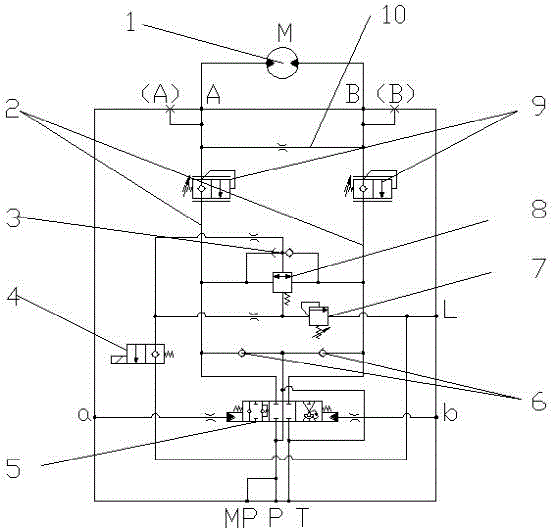

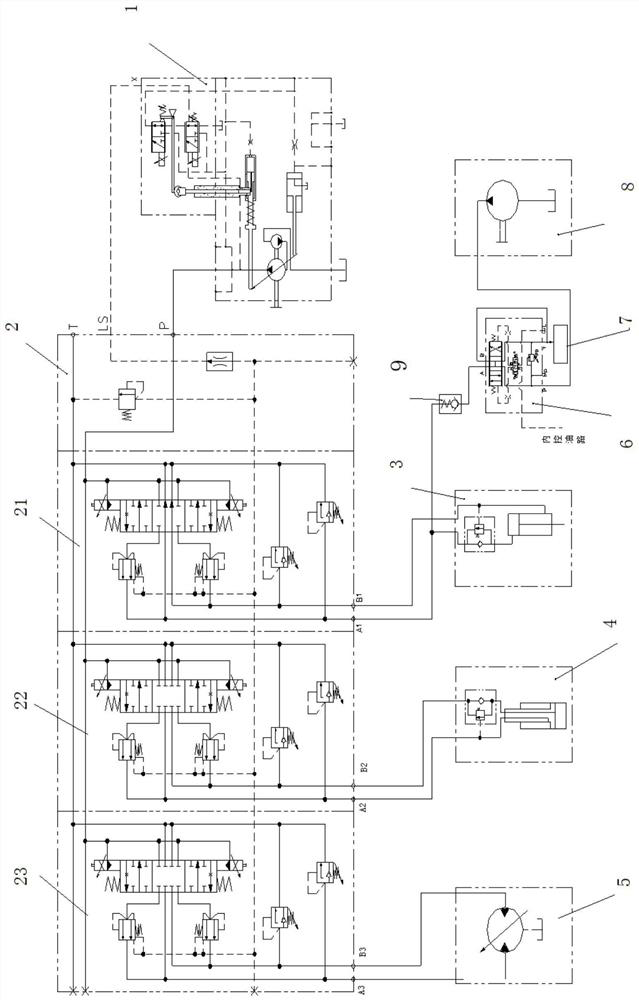

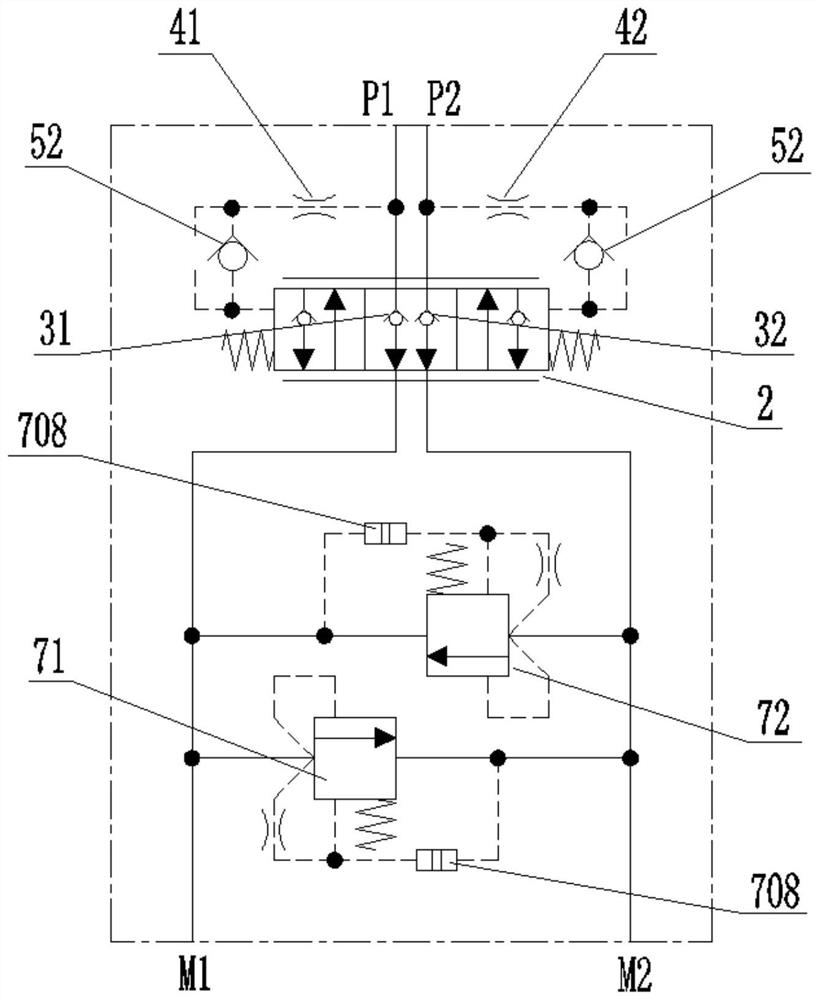

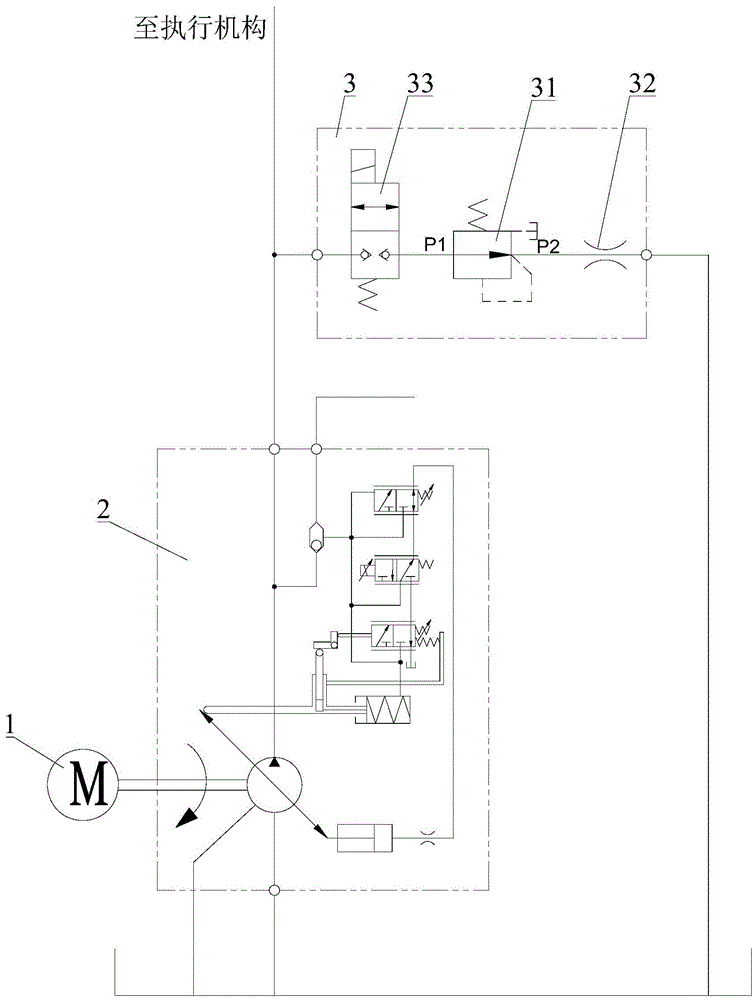

Confluence control device of hydraulic crane

ActiveCN105110192AGood fretting performanceImprove operabilityServomotor componentsLoad-engaging elementsControl modeElectricity

The invention discloses a confluence control device of a hydraulic crane. The pilot-operated hydraulic control mode and the proportional electromagnetic valve pilot control mode are adopted for controlling confluence and flow on the two sides. Connection of a confluence device is decided by the one, with higher pressure, of a hydraulic control pilot oil channel and an electric proportion control pilot oil channel, and the combined work flow of the left side and the right side is decided by the continuous change condition of the deflection angle of a pilot handle or the pressure condition on the two sides of a system. Left-to-right confluence or right-to-left confluence is selected according to the pressure flow requirement of systems on the two sides of combined confluence. Confluence impact generated when the crane acts is reduced by controlling moving of a confluence valve core. According to the invention, impact generated in the confluence process of a main hydraulic valve of the crane is reduced, the confluence process can be controlled, the micro-motion property in the process of winching small flow by the crane is guaranteed, and the confluence process can be smooth; by adopting the electronic control confluence mode, the feasibility performance of confluence is improved, and the requirements of hydraulic actuating mechanisms of engineering machinery for hydraulic system confluence on different work conditions can be met.

Owner:XCMG HYDRAULICS CO LTD

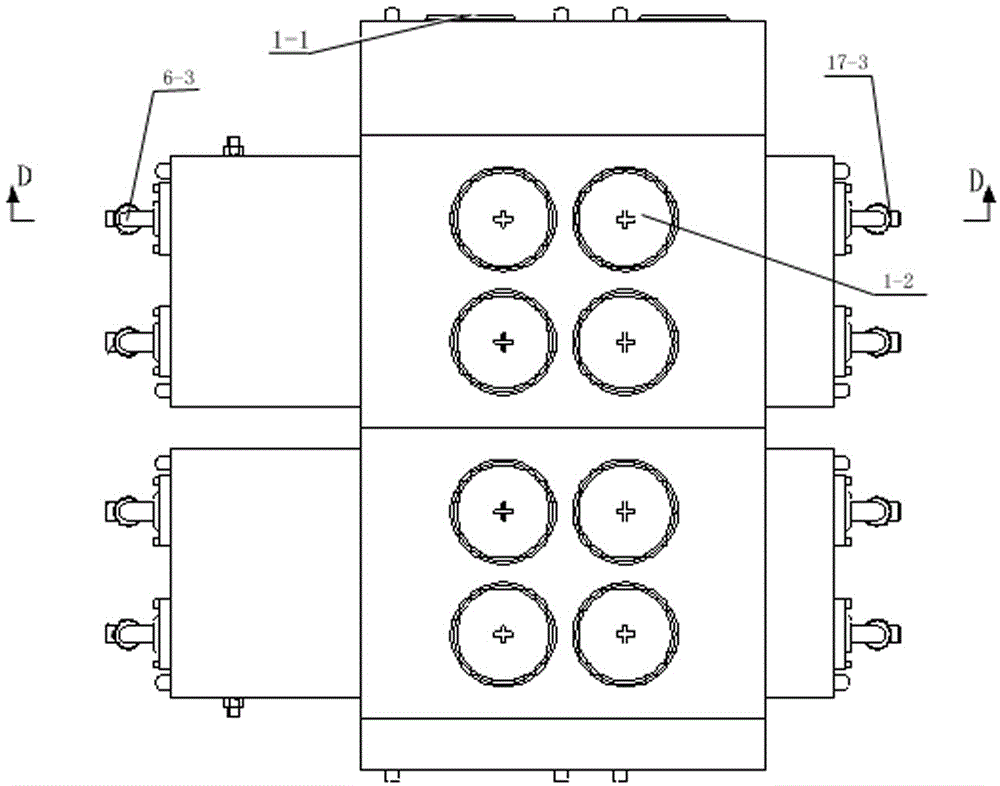

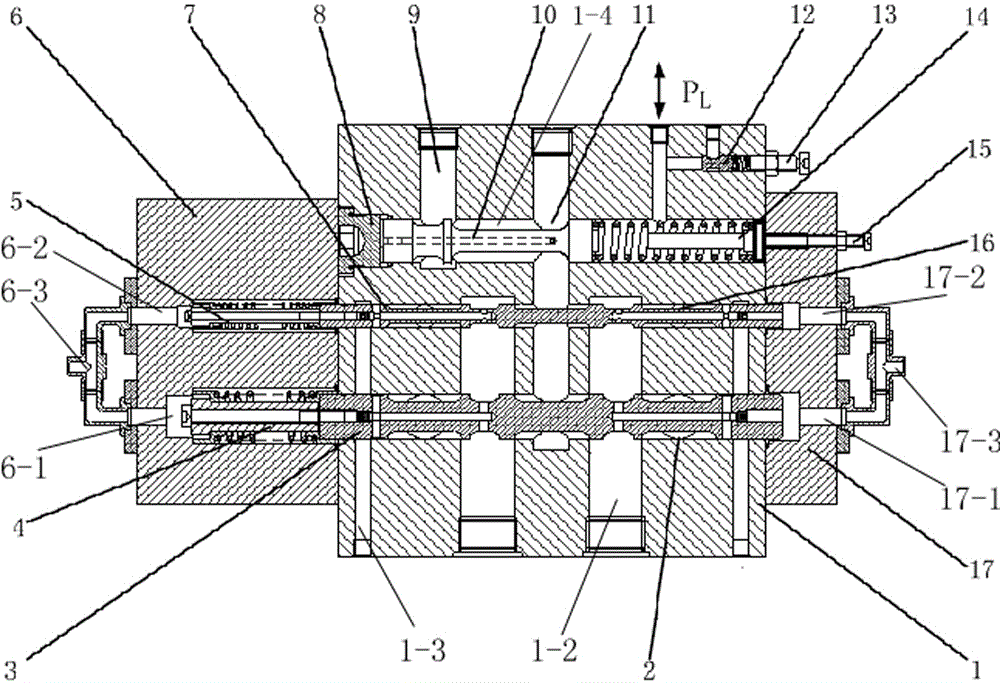

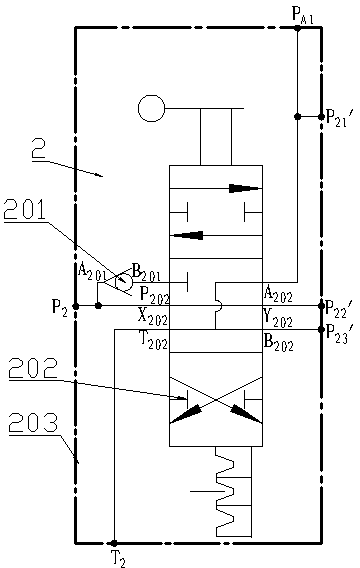

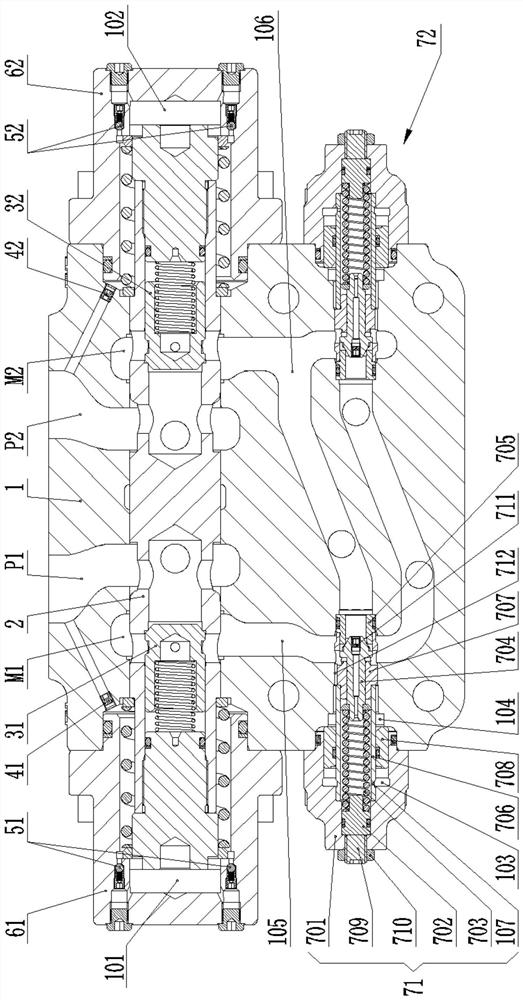

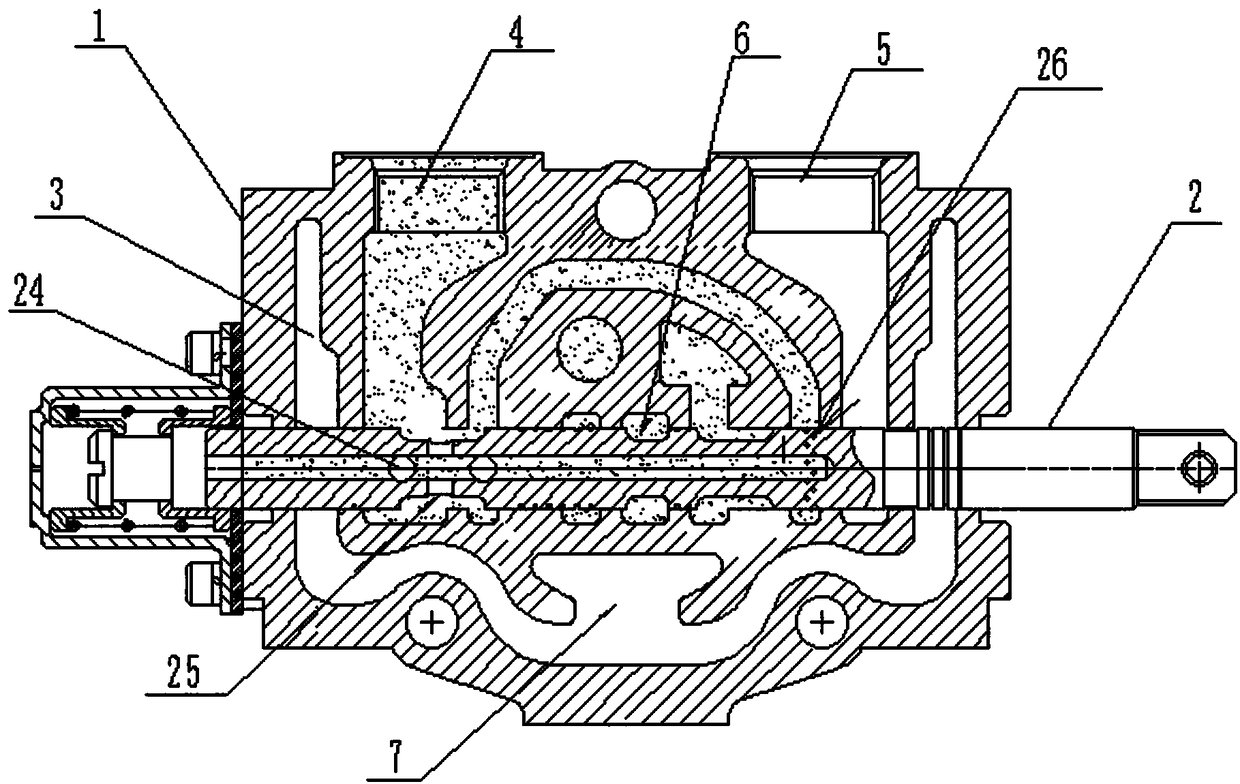

Load-sensitive multiway valve with micromotion valve element

The invention provides a load-sensitive multiway valve with a micromotion valve element. The load-sensitive multiway valve with the micromotion valve element comprises at least one valve body, wherein the valve body is provided with one group or multiple groups of valve blocks and an oil inlet hole; two ends of the valve body are respectively provided with a control end cover and a control piston end cover; each valve block comprises a main valve element hole, a micromotion valve element hole, a compensation valve element hole, an oil inlet path, a multiway valve oil inlet cavity, a plurality of oil outlet holes and oil leakage holes; a main valve element, a micromotion valve element and a compensation valve element are respectively installed in each main valve element hole, each micromotion valve element hole and each compensation valve element hole; each he oil inlet path is communicated with the corresponding oil inlet hole of the valve body and is communicated with a multiway valve oil inlet cavity via the corresponding compensation valve element hole; each multiway valve oil inlet cavities are communicated with the oil outlet holes and the oil leakage holes via the main valve element holes and the micromotion valve element holes. The load-sensitive multiway valve is provided with the micromotion valve elements, so that the load-sensitive multiway valve has the advantages of better multiway valve micromotion performance and convenience in the small-flow regulation of a system, system pressure loss is reduced, and an energy use ratio is improved. According to the load-sensitive multiway valve, the processing of a valve element throttling groove is reduced, and the difficulty of a processing technology is lowered.

Owner:XIANGTAN UNIV

Combined-type multi-way reversing valve for coal-mine full-hydraulic underground drilling machine

The invention discloses a combined-type multi-way reversing valve for a coal-mine full-hydraulic underground drilling machine. The combined-type multi-way reversing valve consists of an oil feeding valve body, a motor direction control valve body, a motor rotating-speed control valve body, an auxiliary control valve body, an oil cylinder direction and speed control valve body, a hydraulic chuck control valve body, a gripper control valve body and a hydraulic chuck oil return valve body which are communicated in sequence. The combined-type multi-way reversing valve has the advantages that since the original hydraulic oil pipe is replaced by an oil path block, the oil path is shortened, and leaking points possibly existing on the oil path are reduced; all the valve bodies are integrated into one valve block, the structure is more compact, the stroke of hydraulic oil is short, the pressure and power loss is less, the micro-motion performance is good, and the accuracy is high, the system efficiency is high; and all hydraulic elements are arranged orderly, concentrated control is easy to implement, the operation is convenient, and the reliability of a main machine is good.

Owner:锦州力特液压科技有限公司

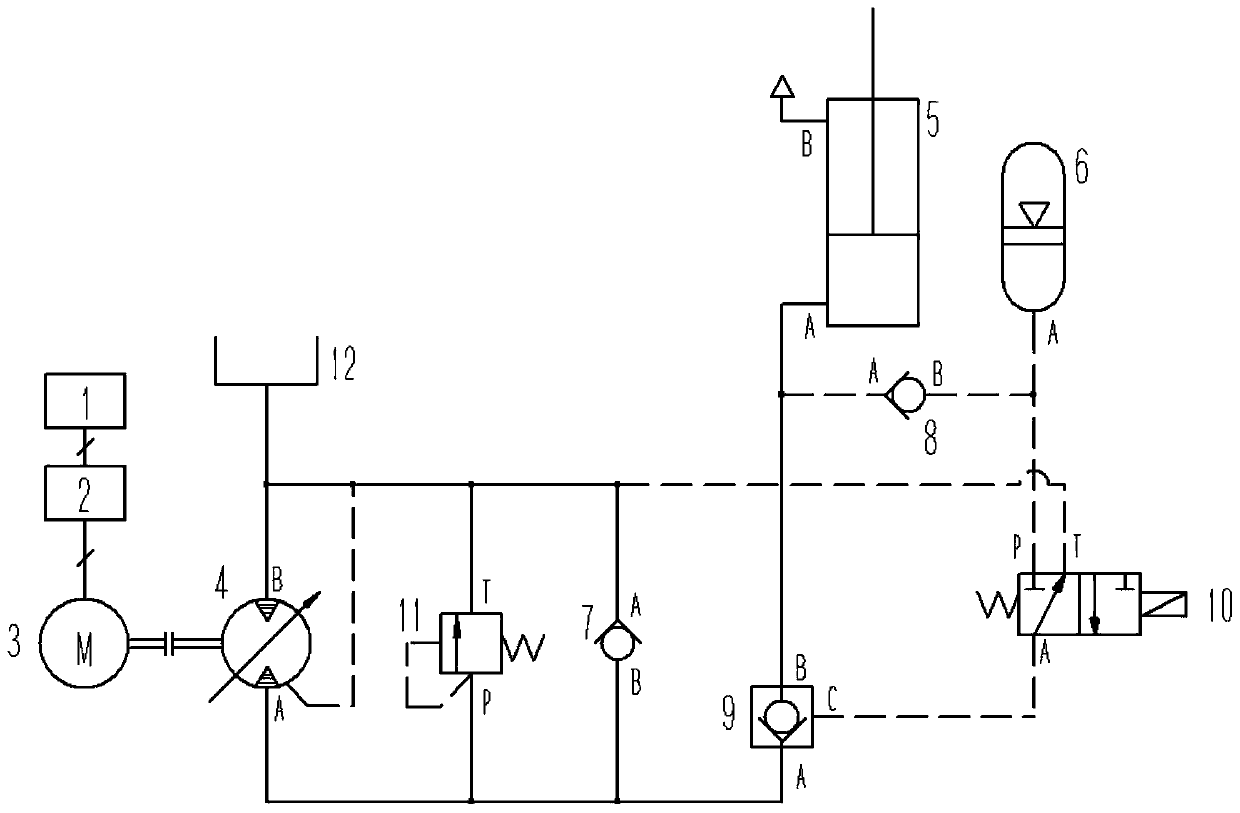

Motor-driven hydraulic system for crane amplitude changing mechanism and action method thereof

ActiveCN111396378AReduce volumeReduce noiseServomotor componentsServomotorsElectric driveHydraulic cylinder

The invention discloses a motor-driven hydraulic system for a crane amplitude changing mechanism and an action method thereof, and belongs to the field of construction machinery. The motor-driven hydraulic system comprises an electric driving device and a hydraulic device; a battery supplies power to a controller, the controller adjusts the rotation direction and rotating speed of an electromotor,the electromotor drives a hydraulic motor, and when the hydraulic motor reversely drags the electromotor, the electric driving device can achieve the reversing drag power generation energy recovery;when the amplitude is increased, the electromotor rotates forward to drive the motor, pressure oil is output to be supplied to a rodless cavity of a hydraulic cylinder, a piston rod extends out, and the electricity energy is converted into the gravitational potential energy in the process; and when the amplitude in decreased, the electromotor rotates reversely, the pressure oil of the rodless cavity of the hydraulic cylinder drives the electromotor through the hydraulic motor, the electromotor is in a reversing drag power generation condition, the generated electric energy is stored in the battery, and the energy can be reused when the amplitude is increased. According to the motor-driven hydraulic system, the gravitational potential energy of a jib and the sling load is recovered and utilized when the amplitude is decreased, the energy consumption can be significantly lowered, the system efficiency is improved, and the heating is reduced.

Owner:抚顺海创电子科技有限公司

Tool bit holder micrometer feed device

A tool bit holder micrometer feed device comprises a lead screw, a fixing nut, a movable nut, linear slide rails and a driving motor, wherein the lead screw is provided with two thread sections, and the two thread sections are in the same rotary direction but are different in lead; the fixing nut is arranged on the lead screw and matched with the thread section with the larger lead of the lead screw; the movable nut is arranged on the lead screw and matched with the thread section with the smaller lead of the lead screw; a tool bit holder is mounted on the movable nut; the linear slide rails are arranged in the axial direction of the lead screw in parallel; the movable nut is slidably connected with the linear slide rails through a nut sliding block; and a rotation output part of the driving motor is fixedly connected with the lead screw. Accordingly, the smaller the lead different of the two thread sections, the smaller the feed amount of the movable nut, and micrometer feed of the tool bit holder can be achieved more easily; and action response of the tool bit holder can be quite smooth.

Owner:东莞市埃弗米数控设备科技有限公司

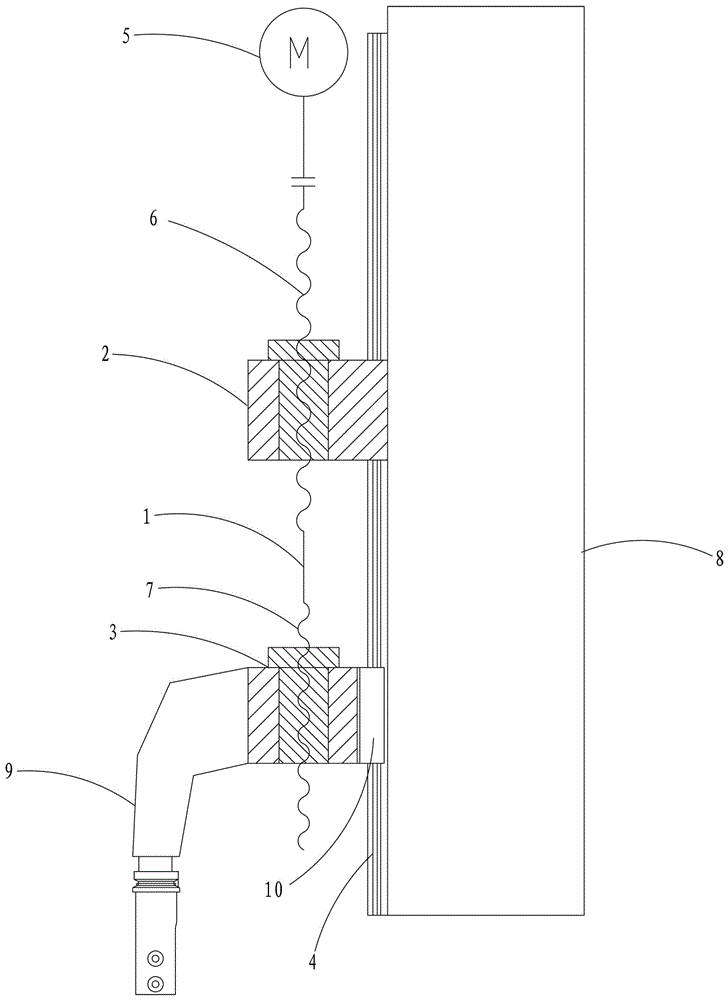

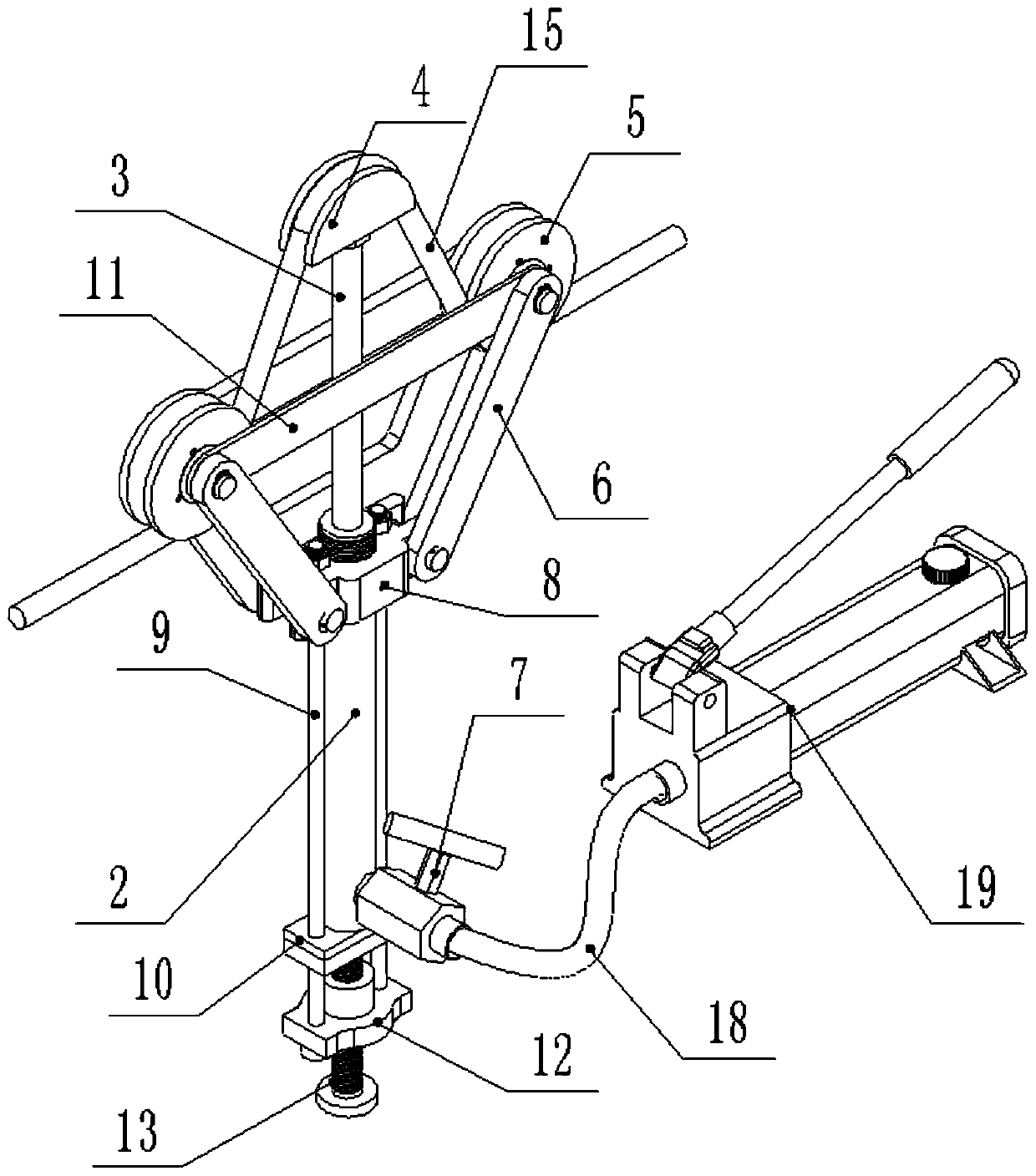

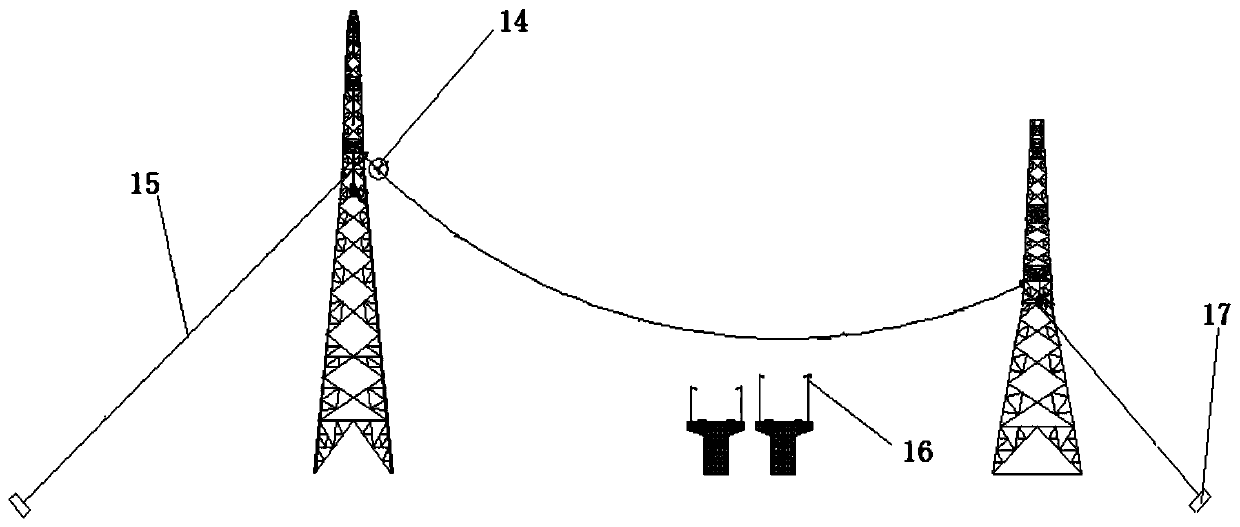

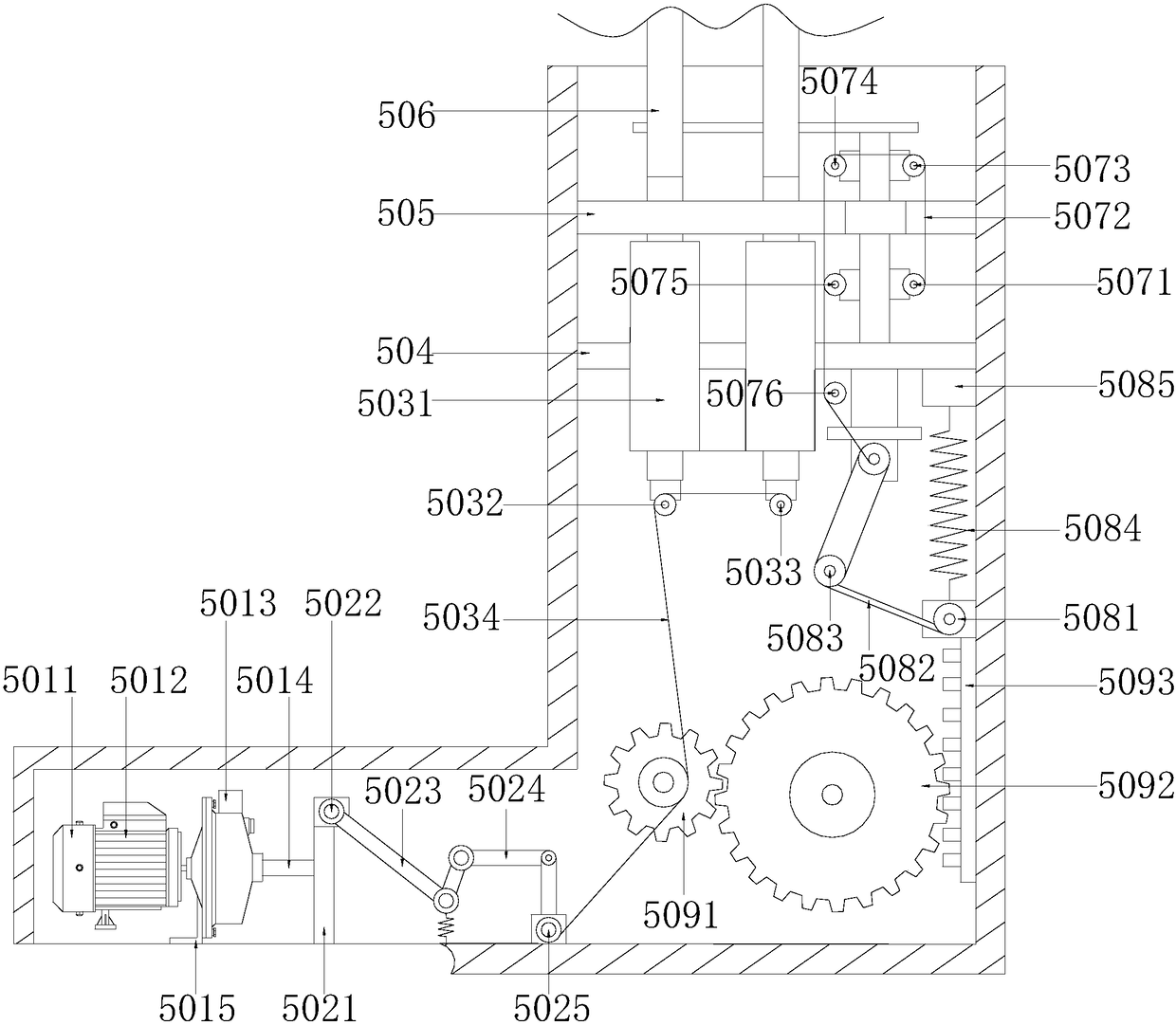

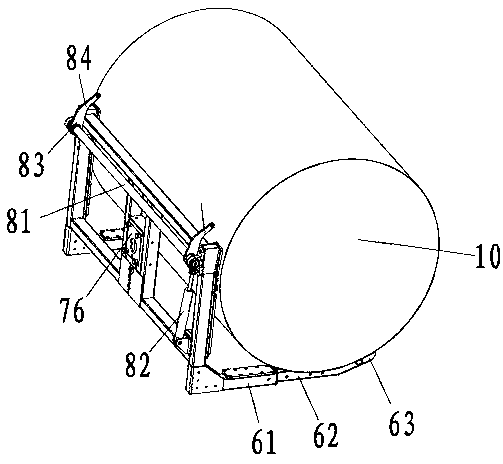

High-altitude tightening device for Dyneema rope

PendingCN109713612AGood tightening effectReduce labor intensityApparatus for overhead lines/cablesEngineeringMicro motion

The invention discloses a high-altitude tightening device for a Dyneema rope, and the device comprises a main body supporting frame. Two sets of rolling wheels are respectively connected to the two sides of the main body supporting frame, and a telescopic mechanism is arranged in the main body supporting frame. A telescopic end of the telescopic mechanism is connected with a pushing wheel, and thepushing wheel moves up and down between the two sets of rolling wheels. The telescopic mechanism drives the pushing wheel to move up and down, so the manpower is saved. The pushing wheel and the rolling wheels cooperate with each other to enable the Dyneema rope to freely roll between the rolling wheels, thereby reducing mechanical damages to the Dyneema rope while effective tightening is achieved, and enabling the tightening to be smooth and effective. The small-size telescopic mechanism is adopted, so the micro-motion performance is good, and operation is convenient. The split type structure is good in detachability and convenient to maintain and upgrade.

Owner:STATE GRID CORP OF CHINA +2

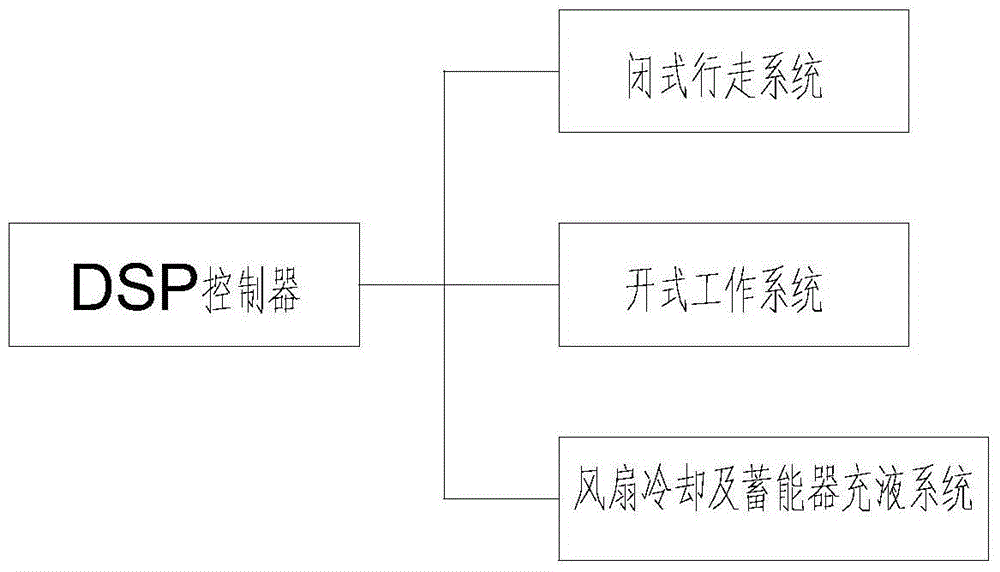

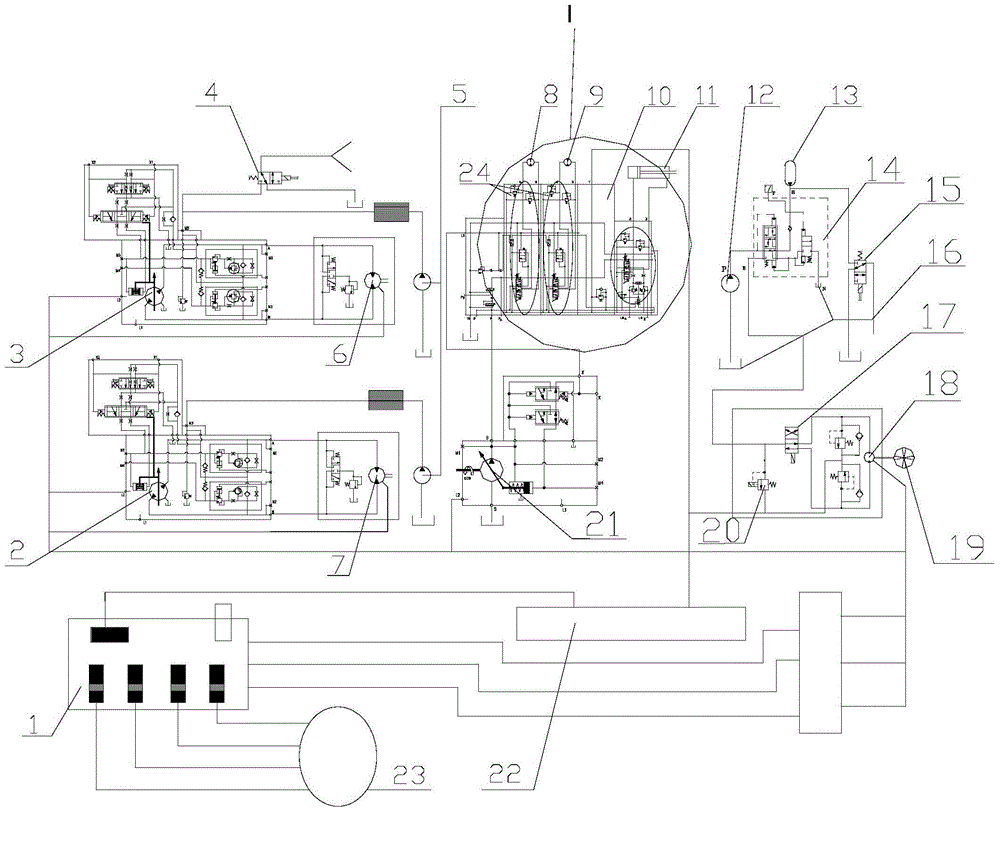

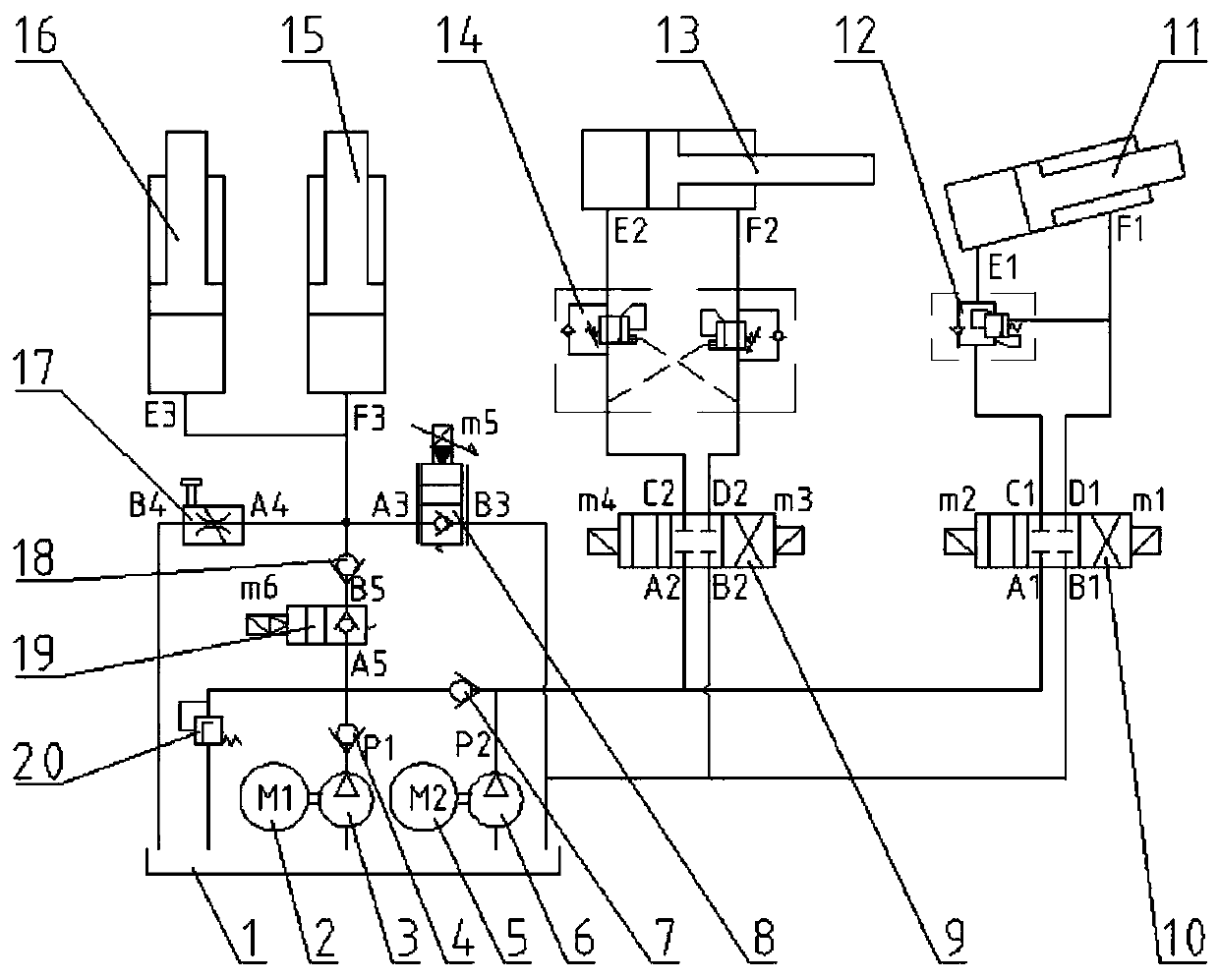

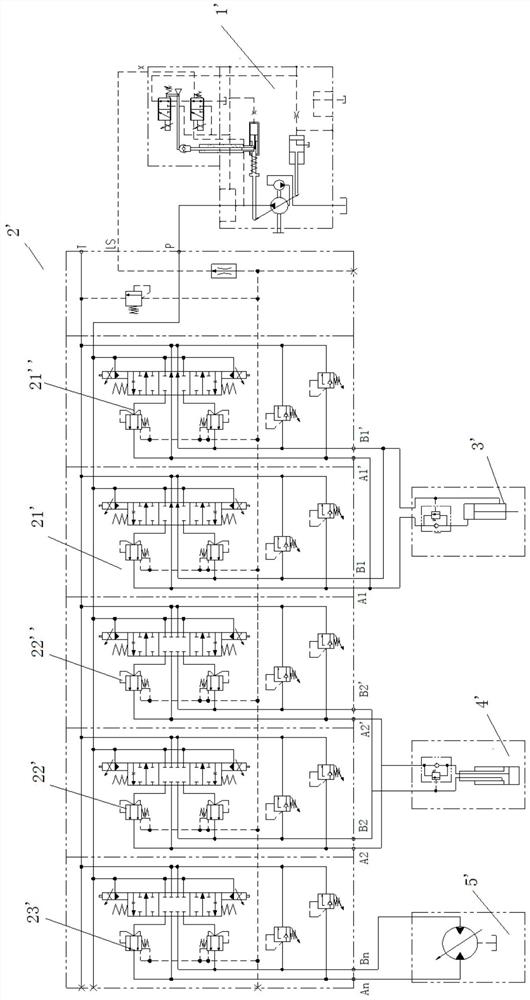

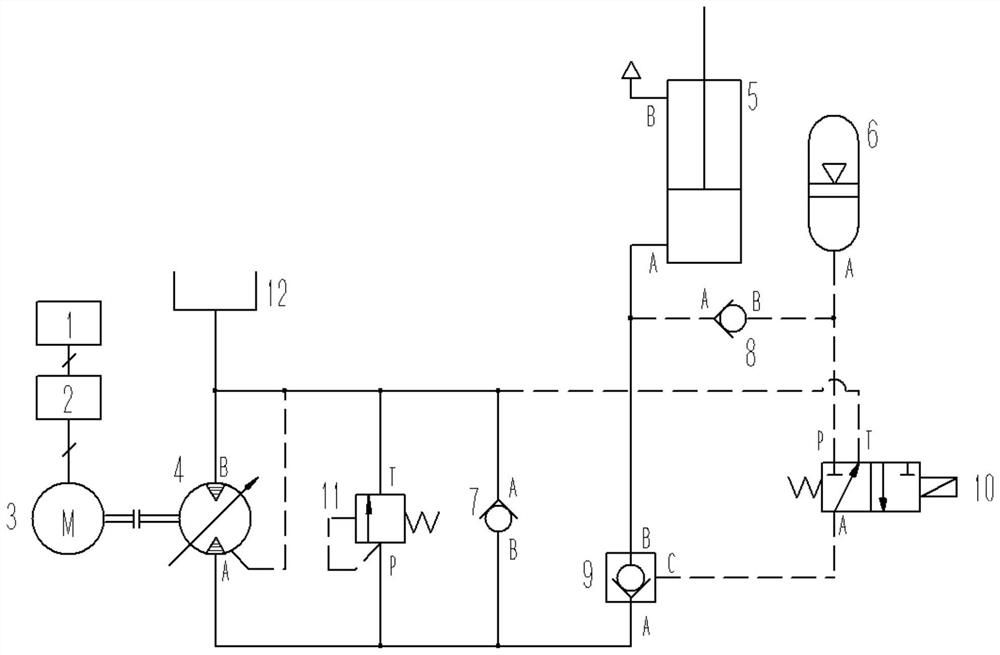

Full-hydraulic digitized synergetic linkage control pipe lifting machine

InactiveCN106032259AWorking condition real-time monitoringRealize linkage and synergyAccumulator installationsServomotorsMulti machineWork performance

The invention relates to a full-hydraulic digitized synergetic linkage control pipe lifting machine, and provides a full-hydraulic digitized synergetic linkage control pipe lifting machine with advantages of high work precision, excellent work performance, low energy consumption, strong operability and high safety. The full-hydraulic digitized synergetic linkage control pipe lifting machine comprises a wireless communication module and an electric-hydraulic control system, wherein the plurality of the pipe lifting machines communicate through the wireless communication module, and the electric-hydraulic control system comprises a DSP controller, a closed walking system, an opened working system, and a fan cooling and accumulator liquid filling system. With the full-hydraulic digitized synergetic linkage control pipe lifting machine of the present invention, the working condition of the pipe lifting machine can be real-timely monitored, the host machine anti-tipping alarm function is provided, the counterweight opening angle can be automatically matched so as to achieve the optimal dynamic balance state, and the operation has the excellent micro-mobility through the high precision electric proportional signal; and with the wireless communication module, the synergetic linkage action of the multiple machines can be achieved.

Owner:JIANGSU TIANPU HEAVY IND

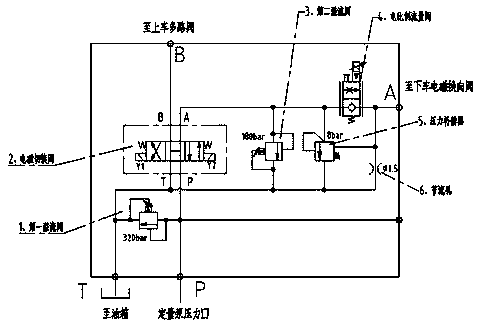

Loading and unloading switching valve for lorry-mounted crane

PendingCN109185241AEasy to operateAvoid High Voltage ShockServomotor componentsServomotorsProportional controlFuel tank

The invention relates to a loading and unloading switching valve for a lorry-mounted crane. The loading and unloading switching valve for the lorry-mounted crane comprises a first overflowing valve, an electromagnetic switching valve, a second overflowing valve, an electric proportional flow valve, a pressure compensator and a throttling hole; the first overflowing valve is arranged between a quantifying pump pressure port pipeline and an oil tank pipeline; the quantifying pump pressure port pipeline is connected with the electromagnetic switching valve through a P port; the oil tank pipelineis connected with an electromagnetic valve through a T port; the electromagnetic switching valve is connected with a loading multi-way valve through a B port; and the electromagnetic valve is connected with an unloading supporting leg control system through an A port. The loading and unloading switching valve for the lorry-mounted crane has the following advantages: 1, the loading and unloading switching valve for the lorry-mounted crane is simple to operate, a single switching valve is not needed, loading and unloading switching depends on electric control, and error operation possibility isavoided; 2, each oil path system is provided with an independent overflowing protecting valve, pressure setting is conducted according to respective needed pressure, and high-pressure impact generatedby the supporting leg system is effectively avoided; and 3, the supporting leg control system adopts a load sensitive proportional control mode, the flow is distributed according to requirements, theoperation micromotion property is high, and the system is efficient in throttling.

Owner:江苏宏昌天马物流装备有限公司

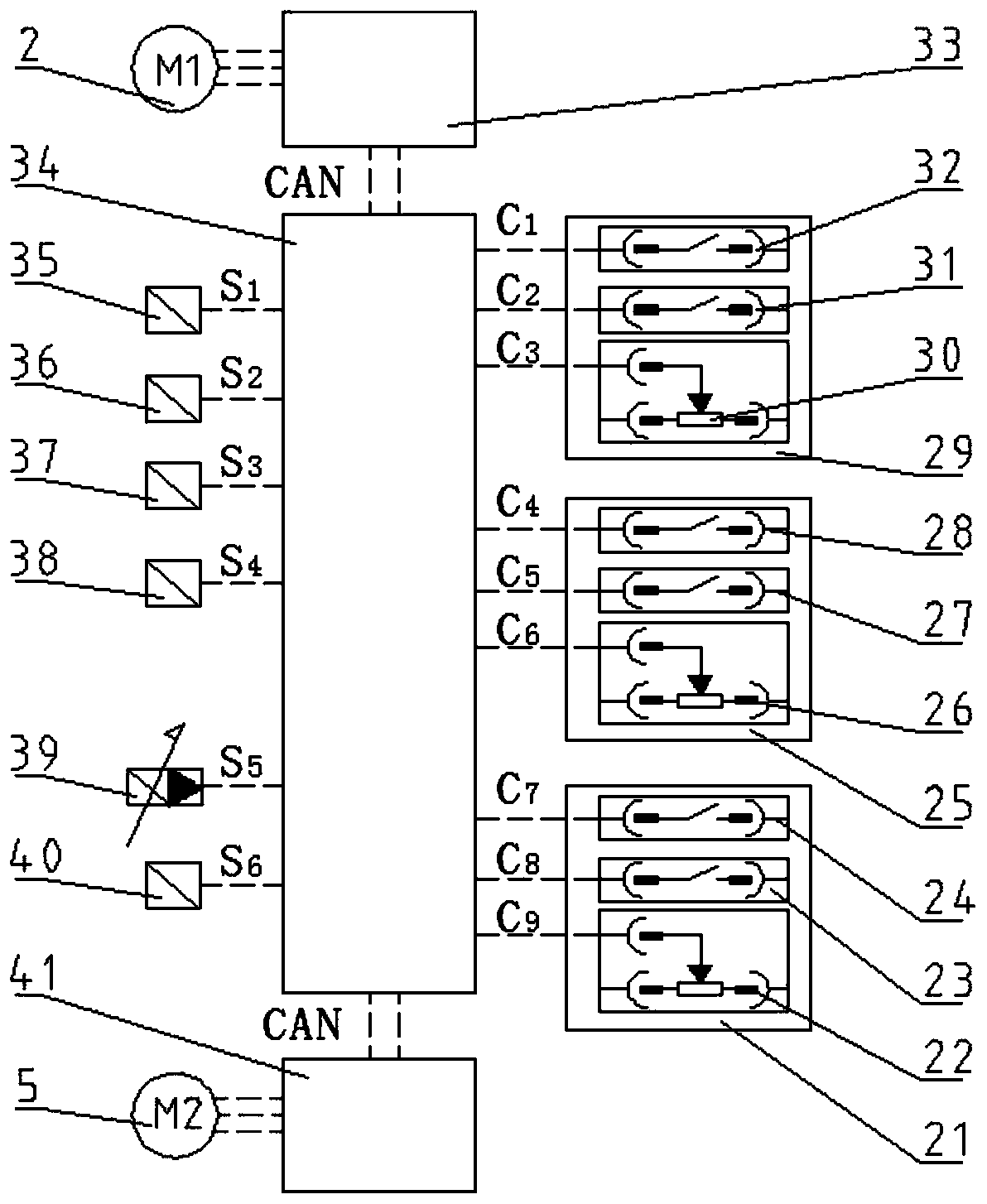

Reach forklift hydraulic system and control method

ActiveCN109911820AGuaranteed lifting speedGood frettingServomotorsLifting devicesMotor controllerControl theory

The invention relates to a reach forklift hydraulic system and a control method. The technical problems that when a reach forklift supplies oil to a forward and backward oil cylinder and a tilting oilcylinder, a motor and an oil pump work at a low-rotating-speed area, working efficiency is low and lifting micromotion performance is poor can be solved. The reach forklift hydraulic system comprisesa large-displacement oil pump motor controller and a small-displacement oil pump motor controller. The large-displacement oil pump motor controller controls a large-displacement oil pump motor to operate. The small-displacement oil pump motor controller controls a small-displacement oil pump motor to operate. The reach forklift hydraulic system further comprises a valve controller. The large-displacement oil pump motor controller and the small-displacement oil pump motor controller are in communication connection with the valve controller through a CAN bus. The valve controller is in communication connection with a lifting thumb switch, a forward and backward thumb switch and a tilting thumb switch of the reach forklift. According to the reach forklift hydraulic system provided by the invention, a small-displacement oil pump is adopted to supply oil to the forward and backward oil cylinder and the tilting oil cylinder independently, working efficiency is high and energy can be saved;and meanwhile the small-displacement oil pump is used for oil supplying during lifting micromotion operation, and the micromotion performance is good.

Owner:ANHUI HELI CO LTD

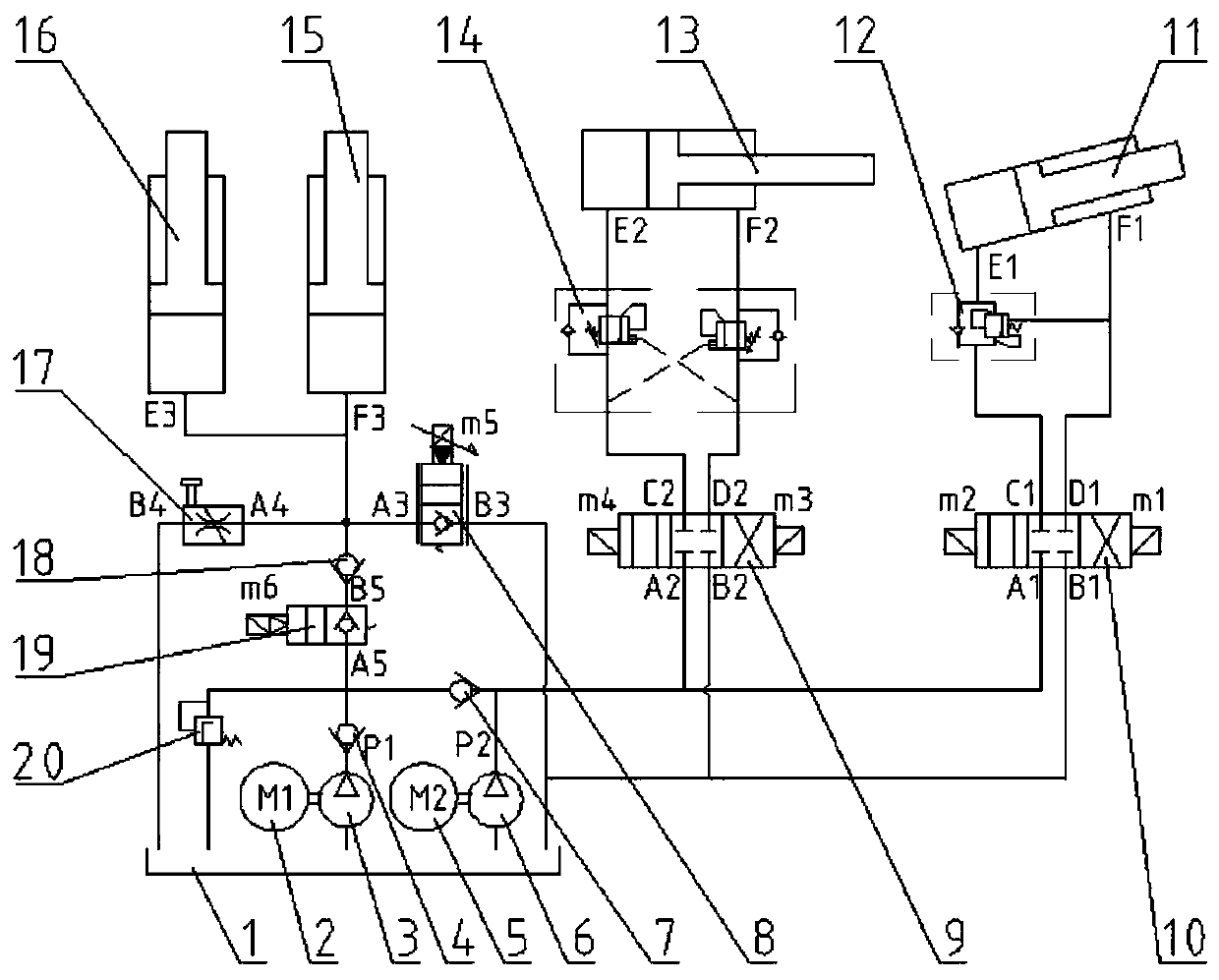

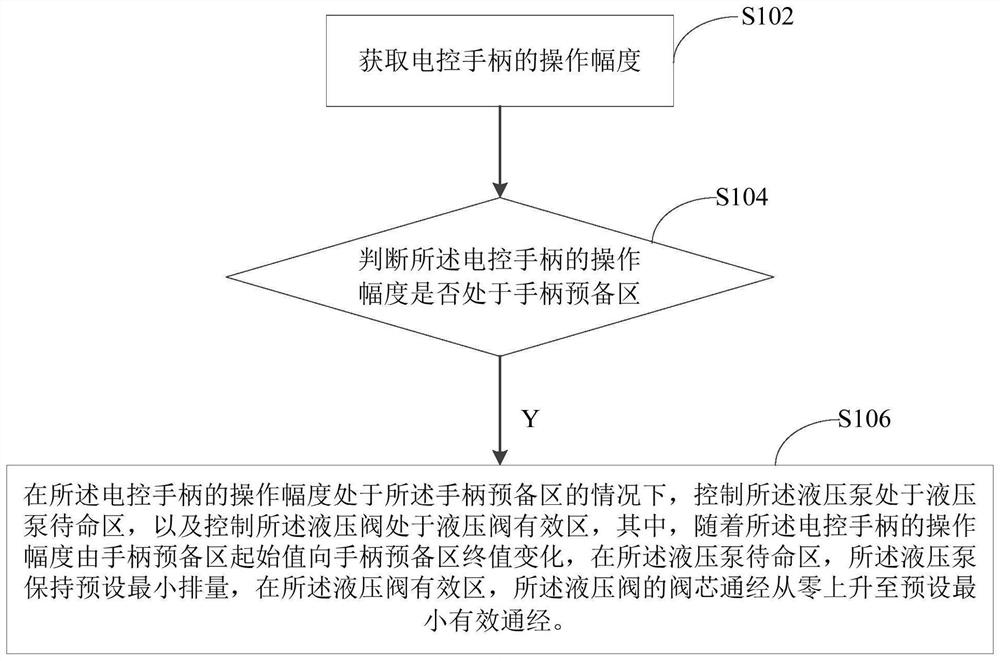

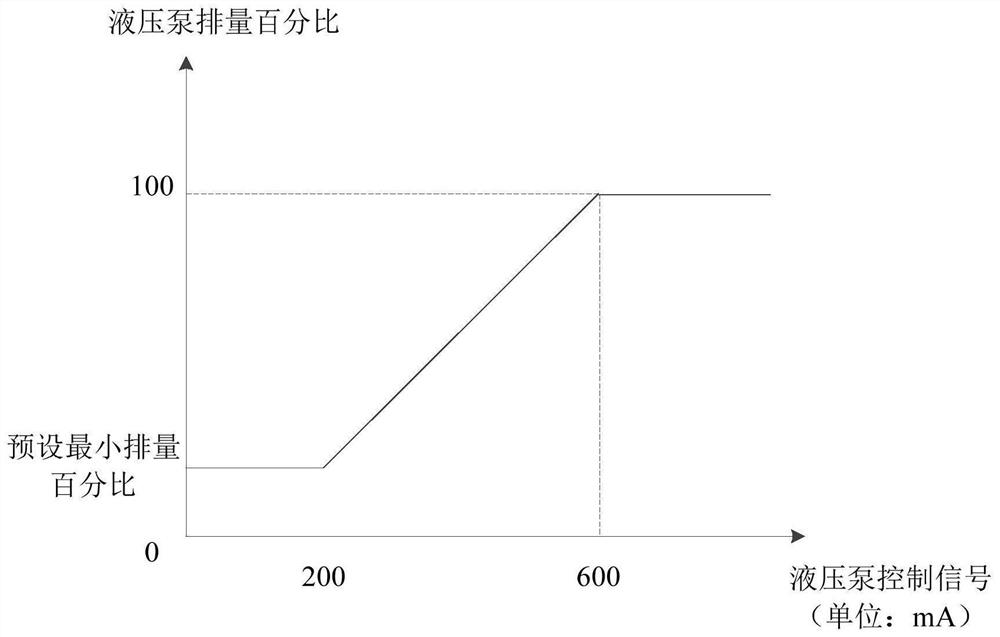

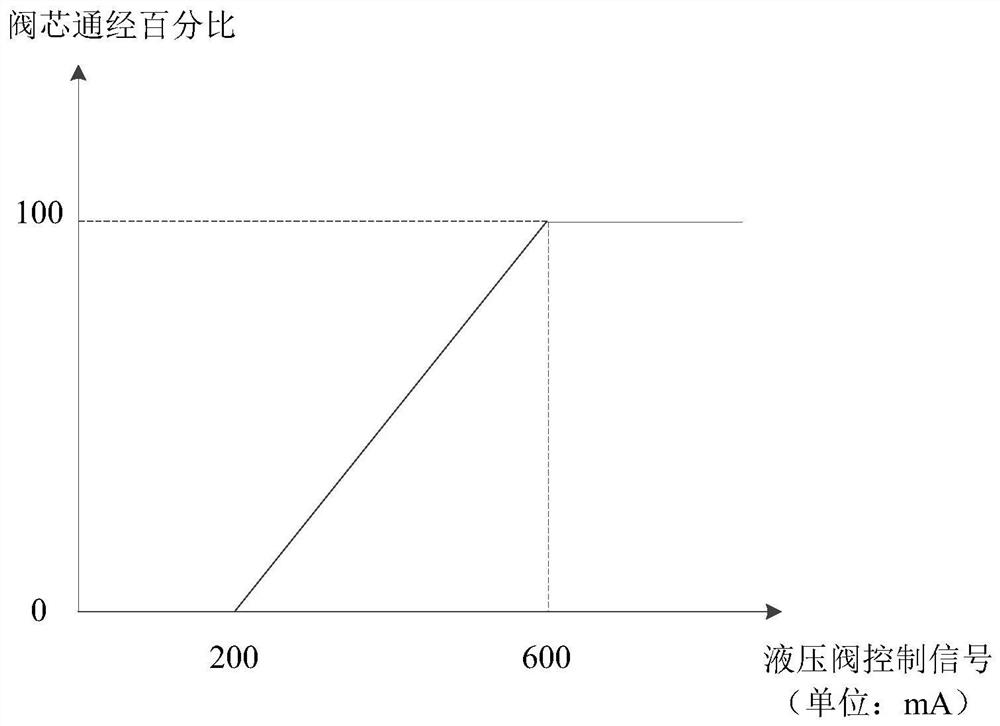

Control method for engineering machinery hydraulic system, controller and storage medium

ActiveCN111677724ALarge displacementGood frettingServometer circuitsFluid-pressure actuator componentsControl engineeringHydraulic pump

The embodiment of the invention provides a control method for an engineering machinery hydraulic system, a controller and a storage medium, and belongs to the field of engineering machinery. The control method for the engineering machinery hydraulic system comprises the steps that the operation amplitude of an electric control handle is obtained; whether the operation amplitude of the electric control handle is in a handle preparation area or not is judged; and under the condition that the operation amplitude of the electric control handle is located in the handle preparation area, a hydraulicpump is controlled to be located in a hydraulic pump standby area, a hydraulic valve is controlled to be located in a hydraulic valve effective area, the hydraulic pump keeps the preset smallest displacement in the hydraulic pump standby area along with the change of the operation amplitude of the electric control handle from an initial value of the handle preparation area to a final value of thehandle preparation area, and the valve element opening diameter of the hydraulic valve rises from zero to the preset minimum effective opening diameter in the hydraulic valve effective area. According to the control method for the engineering machinery hydraulic system, the controller and the storage medium, staged composite control is carried out according to the actual operation amplitude of the electric control handle, and it is guaranteed that equipment has good micro-motion performance during micro-motion.

Owner:SHANGHAI ZOOMLION HEAVY IND PILING MACHINERYCO

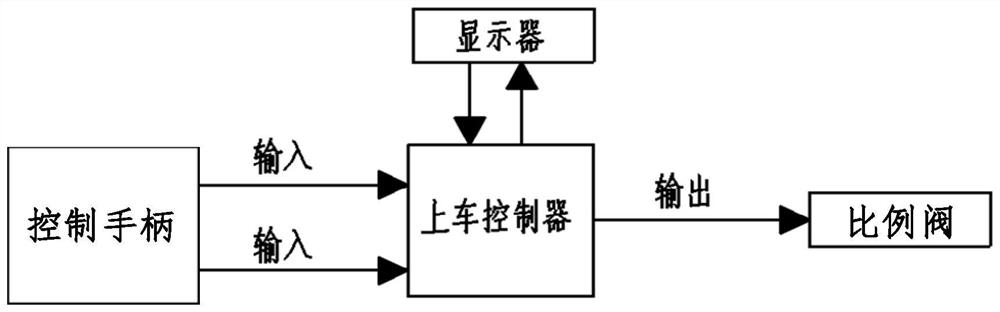

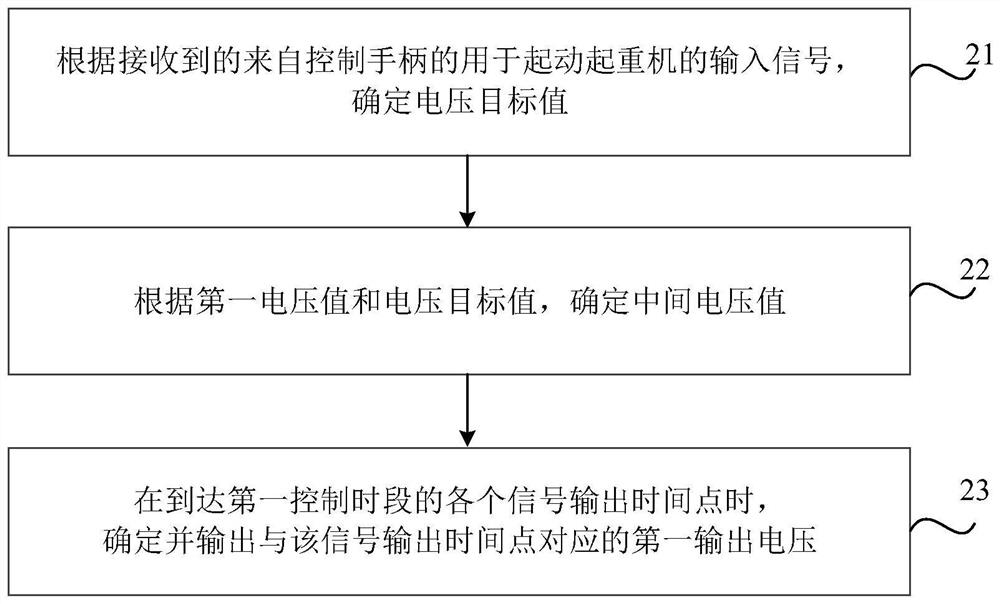

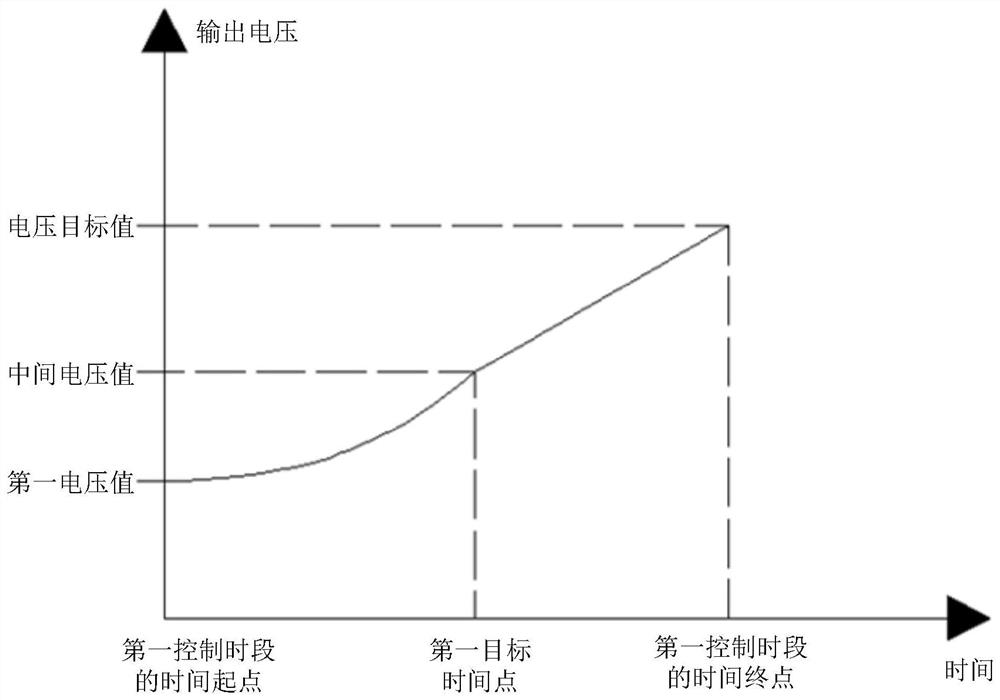

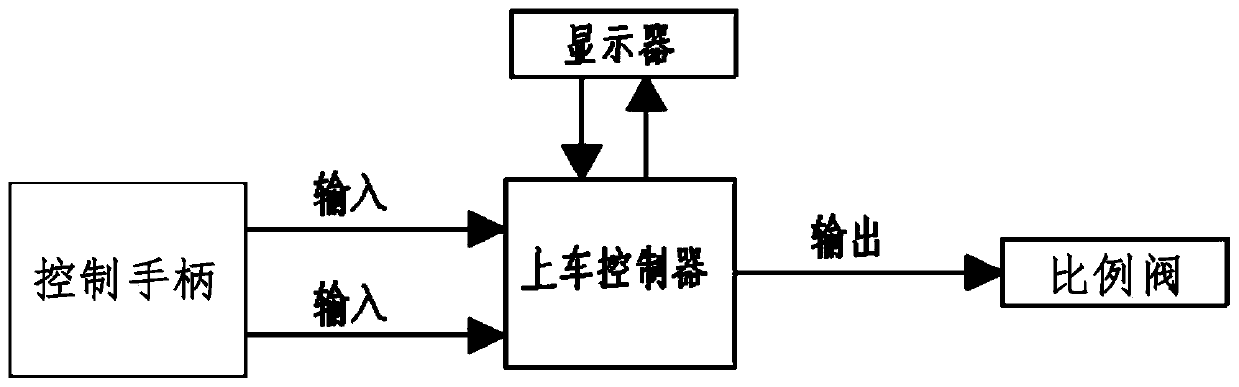

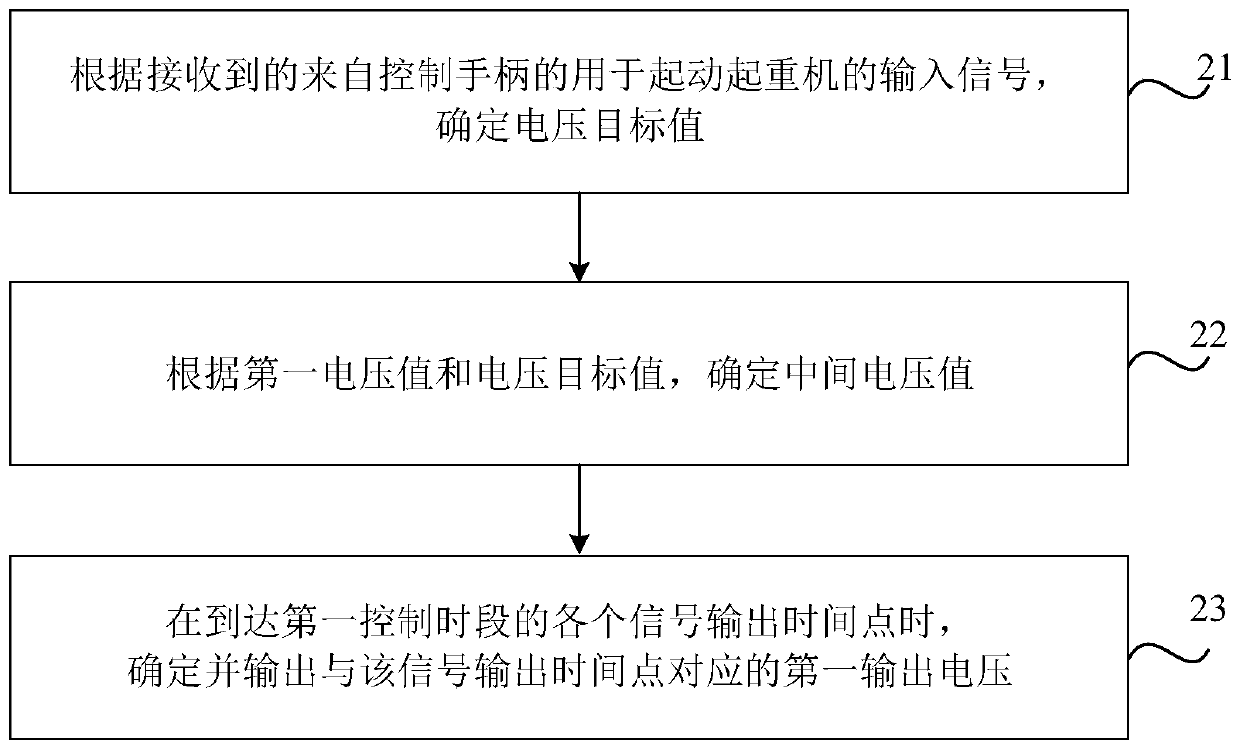

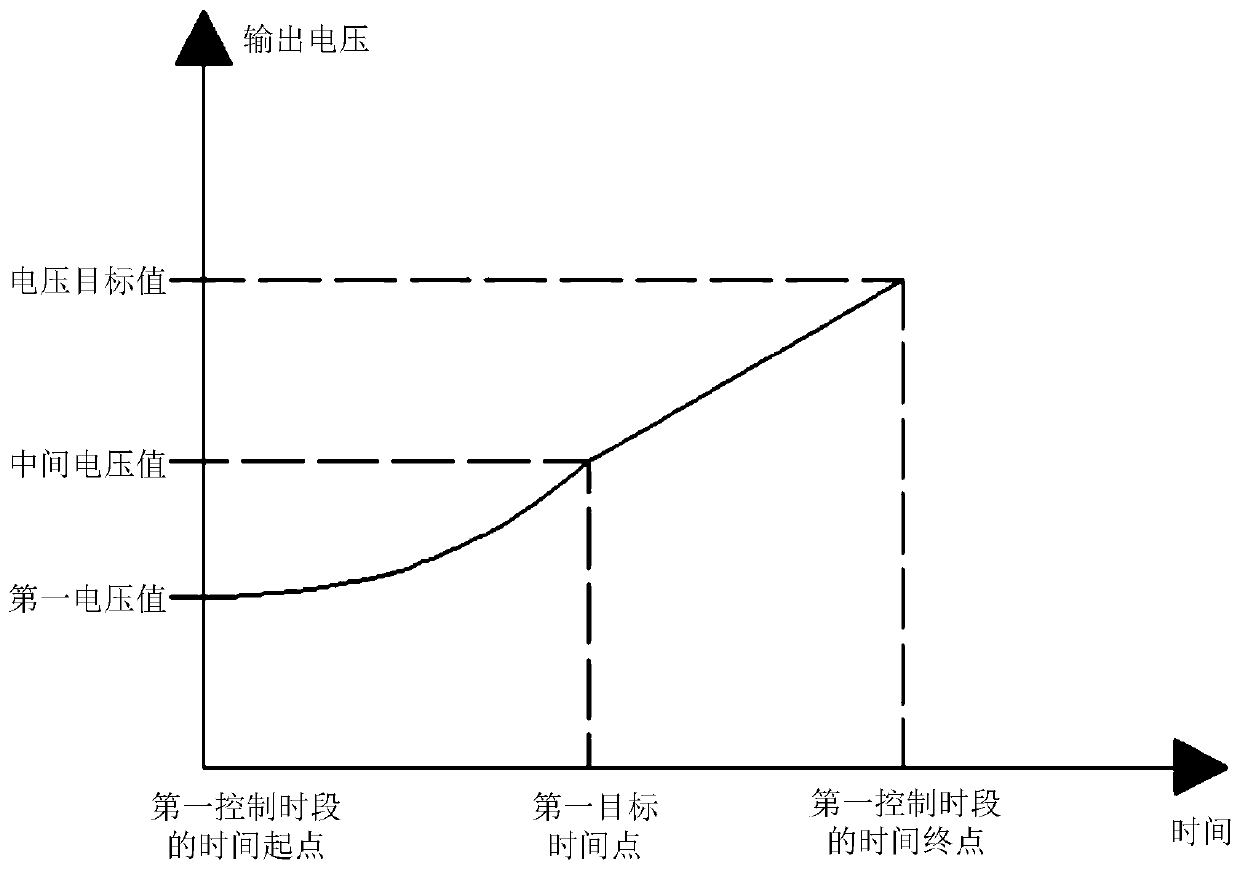

Vehicle crane control method, device and vehicle crane

ActiveCN111039178BGuaranteed stabilityImprove experienceLoad-engaging elementsControl engineeringControl theory

The invention relates to a vehicle crane control method and device, and a vehicle crane. The method comprises the following steps of determining a voltage target value according to a received input signal for starting a crane from a control handle; determining an intermediate voltage value according to a first voltage value and the voltage target value; and when each signal output time point of afirst control time period is reached, determining and outputting a first output voltage corresponding to the signal output time point, wherein the first output voltage at a first target time point isthe intermediate voltage value, the first output voltage of a time end point of a first control time period is a voltage target value, and in the first time period formed by a time starting point of the first control time period and the first target time point, an increasing amplitude of the first output voltage corresponding to a latter signal output time point is increased along with the increase of time compared with the increasing amplitude of the first output voltage corresponding to a former signal output time point. Therefore, good micro-motion performance is achieved on control of thecrane, and large shaking in a starting process is prevented.

Owner:河北雷萨重型工程机械有限责任公司

A confluence control device for a hydraulic crane

ActiveCN105110192BEasy to operateWith two-way merge functionServomotor componentsLoad-engaging elementsElectricityEngineering

The invention discloses a confluence control device of a hydraulic crane. The pilot-operated hydraulic control mode and the proportional electromagnetic valve pilot control mode are adopted for controlling confluence and flow on the two sides. Connection of a confluence device is decided by the one, with higher pressure, of a hydraulic control pilot oil channel and an electric proportion control pilot oil channel, and the combined work flow of the left side and the right side is decided by the continuous change condition of the deflection angle of a pilot handle or the pressure condition on the two sides of a system. Left-to-right confluence or right-to-left confluence is selected according to the pressure flow requirement of systems on the two sides of combined confluence. Confluence impact generated when the crane acts is reduced by controlling moving of a confluence valve core. According to the invention, impact generated in the confluence process of a main hydraulic valve of the crane is reduced, the confluence process can be controlled, the micro-motion property in the process of winching small flow by the crane is guaranteed, and the confluence process can be smooth; by adopting the electronic control confluence mode, the feasibility performance of confluence is improved, and the requirements of hydraulic actuating mechanisms of engineering machinery for hydraulic system confluence on different work conditions can be met.

Owner:XCMG HYDRAULICS CO LTD

Load holding valve for excavator

ActiveCN112879365ASimple and reliable partsReliable structureServomotor componentsPhysicsPilot valve

The invention discloses a load holding valve for an excavator. The load holding valve is characterized by comprising a first valve body, a second valve body and a main valve body, and two ends of the second valve body are respectively sealed and fixedly connected with the first valve body and the main valve body. The required parts such as the valve element, the valve body and the valve sleeve are simple and reliable, and the structure that a spring seat and a steel wire check ring compress the valve element is stable and reliable. The area ratio of the pilot valve element to the valve sleeve is very large and reaches about 80, the micro-motion performance is very good, a pilot control valve element can be opened only through small pressure in pilot control, and internal leakage is very low and reaches 2 cc / min or below.

Owner:龙工(上海)精工液压有限公司

A load-sensing multi-way valve with a micro-movement spool

Owner:XIANGTAN UNIV

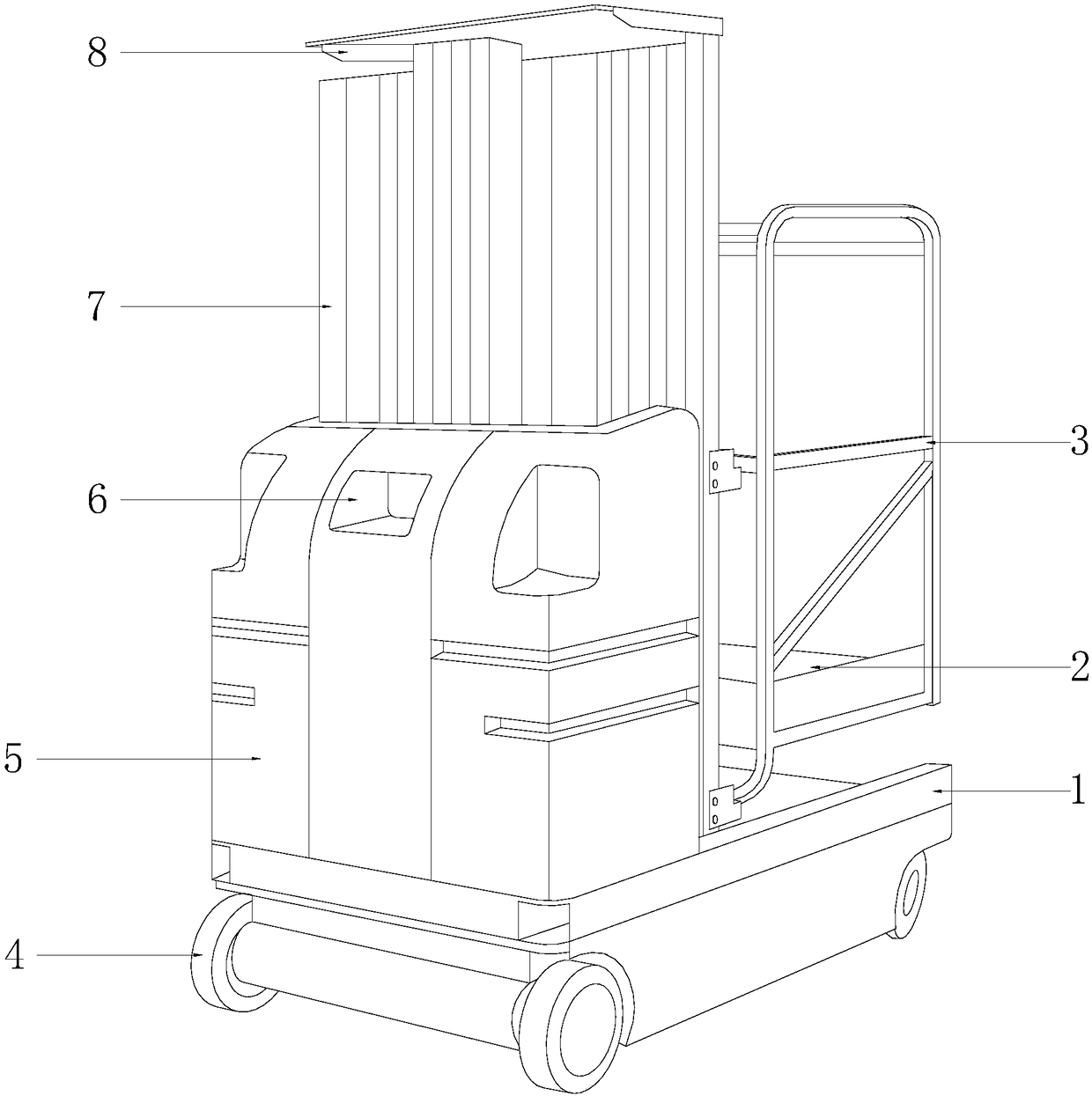

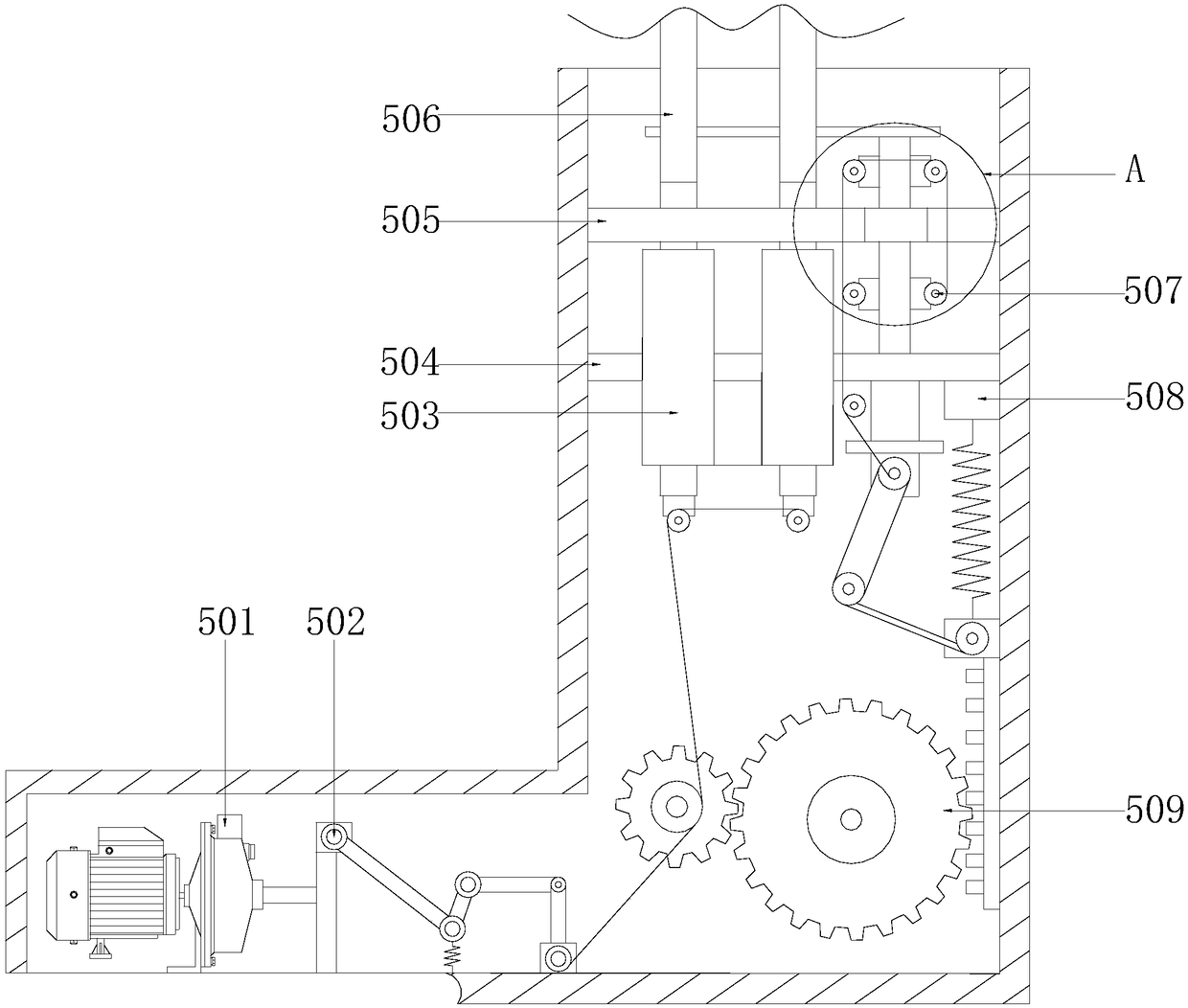

Mast type overhead working truck with working platform capable of moving transversely

InactiveCN108466986AReduce offsetIncrease stiffnessSafety devices for lifting equipmentsTruckRolling chassis

The invention discloses a mast type overhead working truck with a working platform capable of moving transversely. The mast type overhead working truck structurally comprises a pedestal, a footboard,a lifting type guardrail device, traceless solid rubber wheels, a mast lifting mechanism, a charger port, a high-strength aluminum alloy mast set and a mast cover. The pedestal is vertically installedat the lower end of the footboard and is in interference fit with the traceless solid rubber wheels; the section of the footboard is of a rectangle structure, and the footboard is vertically fixed tothe upper end of the pedestal and fixed to the lifting type guardrail device through nuts; the lifting type guardrail device is vertically installed at the upper end of the footboard and welded to the high-strength aluminum alloy mast set; and the lifting type guardrail device and the footboard are of an integral structure. By means of the mast lifting mechanism, shifting of the gravity center can be reduced, the rigidity of an integral chassis is improved, and stability, achieved in the running process and the operation process, of a complete machine is guaranteed; the speed is controlled precisely and sensitively, and in addition, the fine motion performance is good; and the overhead working requirement is met.

Owner:谢秀铅

A rotary buffer valve

ActiveCN104214154BReduce leakageEliminate pressure fluctuationsServomotor componentsSolenoid valveRotary valve

The invention discloses a rotary buffer valve used in a hydraulic system of a crane. It includes a valve body with two main oil passages. The valve body also has a pilot control oil port a, a pilot control oil port b, an oil inlet P, an oil return port T, an oil drain port L and a rotary motor connected to the oil inlet and outlet. The oil port A and oil port B of the port; the valve body is mainly equipped with a three-position six-way hydraulic control reversing valve, a main relief valve and a free-slip solenoid valve; two main oil passages leading to A and B oil ports Each is equipped with an adjustable back pressure valve; there is a throttling oil passage connecting the two main oil passages between the two main oil passages, and the intersection point of the throttling oil passage and the main oil passage is more Closer to port A and port B. The invention has the advantages of compact structure, small volume, low cost, convenient installation and operation, strong adaptability, wide application, good fretting performance, precise rotary positioning and stable stop.

Owner:XCMG HYDRAULICS CO LTD

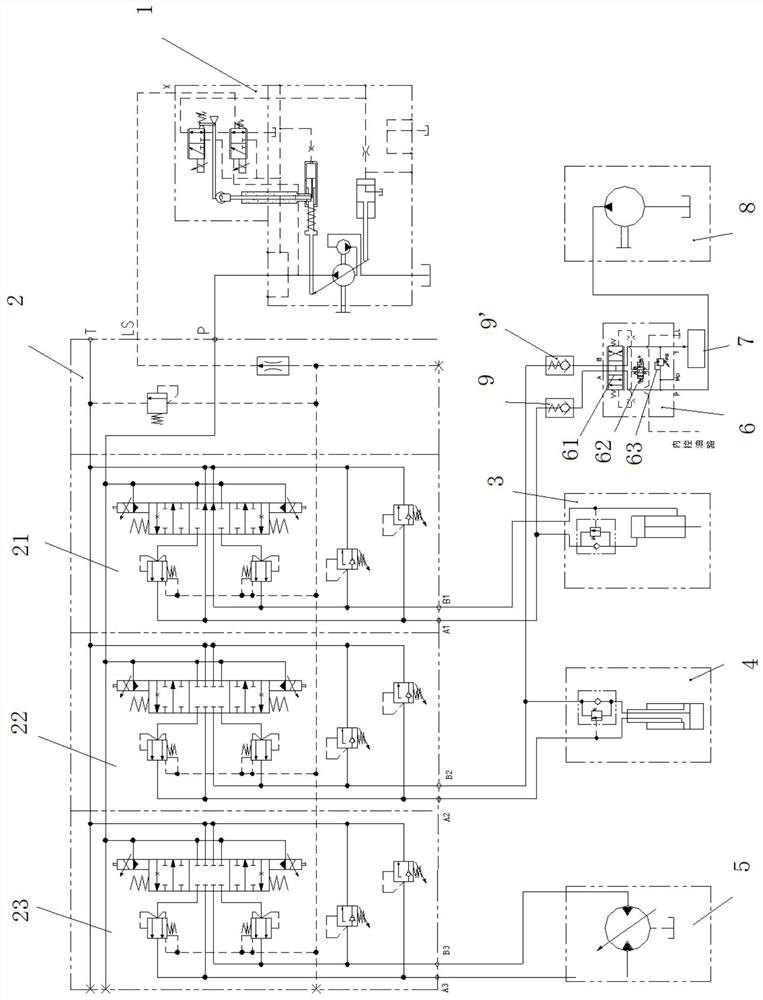

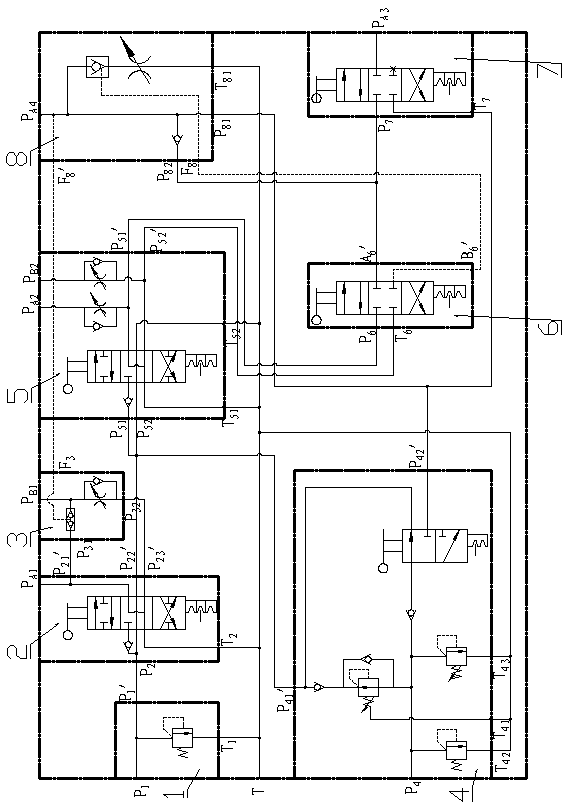

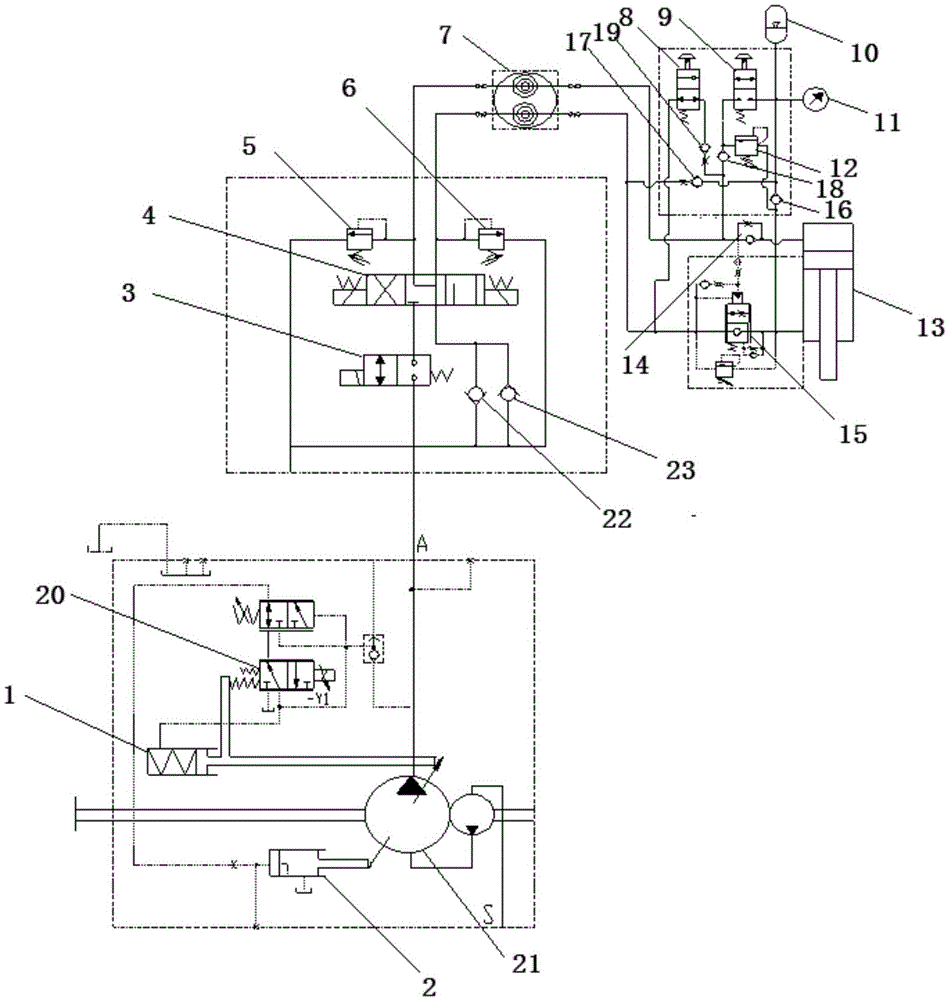

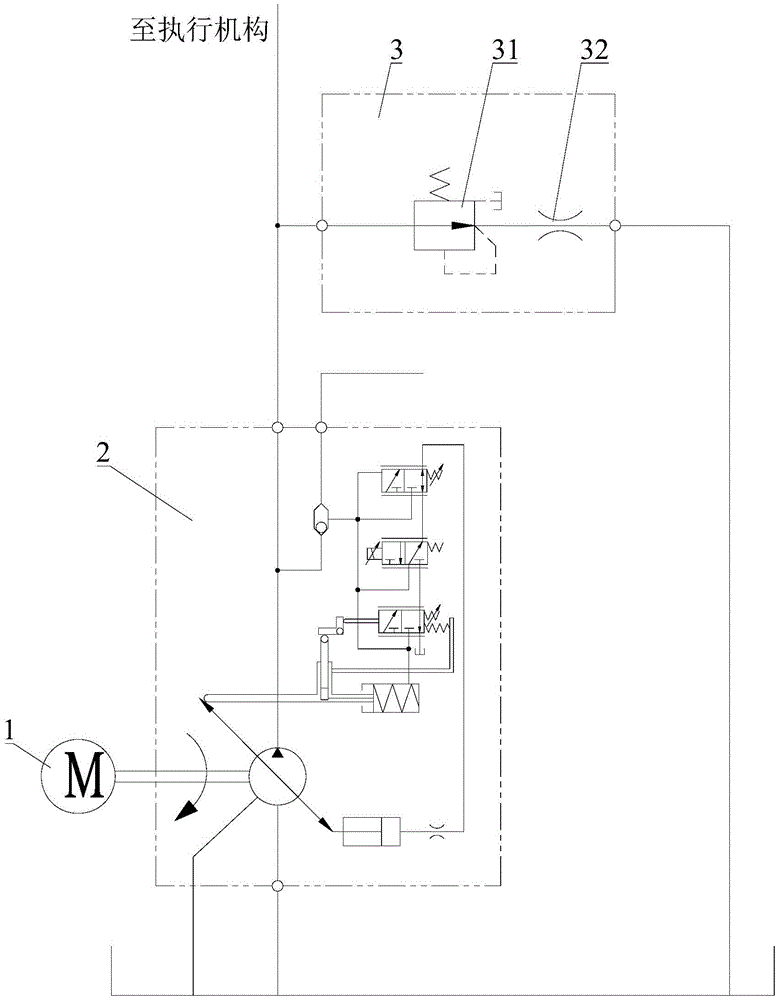

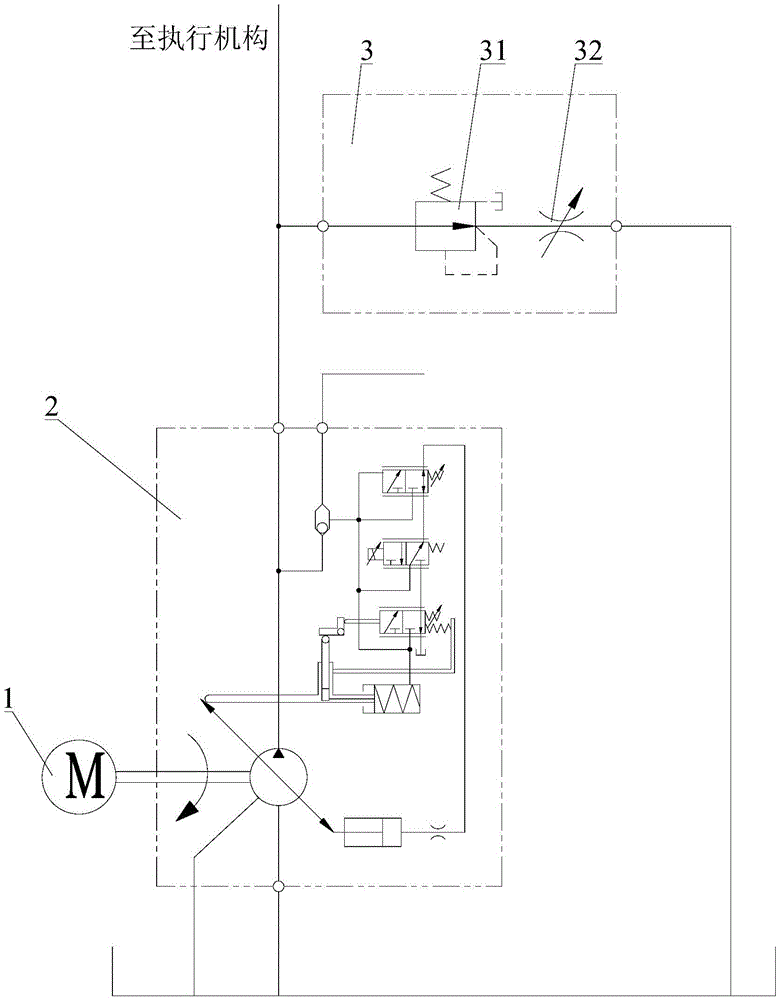

Hydraulic transmission system and crane

ActiveCN110848181BGood frettingMeet high-speed requirementsServomotor componentsServomotorsControl engineeringProcess engineering

The invention relates to the technical field of engineering machinery, and discloses a hydraulic transmission system and a crane. The hydraulic transmission system includes a main control oil circuit and an auxiliary control oil circuit; the main control oil circuit includes a first power unit (1) and an execution unit and is connected between the first power unit (1) and the execution unit The first control module (2) used to control the action of the execution unit; the hydraulic oil output from the auxiliary control oil circuit can merge with the hydraulic oil output from the first control module (2) to control the execution unit. The hydraulic transmission system can not only ensure that the equipment using the hydraulic transmission system has good micro-movement performance under heavy load, but also meet the high-speed requirements under light load and no load, and can save costs.

Owner:ZOOMLION HEAVY IND CO LTD

Combined multi-way reversing valve for coal mine full hydraulic tunnel drilling rig

The invention discloses a combined-type multi-way reversing valve for a coal-mine full-hydraulic underground drilling machine. The combined-type multi-way reversing valve consists of an oil feeding valve body, a motor direction control valve body, a motor rotating-speed control valve body, an auxiliary control valve body, an oil cylinder direction and speed control valve body, a hydraulic chuck control valve body, a gripper control valve body and a hydraulic chuck oil return valve body which are communicated in sequence. The combined-type multi-way reversing valve has the advantages that since the original hydraulic oil pipe is replaced by an oil path block, the oil path is shortened, and leaking points possibly existing on the oil path are reduced; all the valve bodies are integrated into one valve block, the structure is more compact, the stroke of hydraulic oil is short, the pressure and power loss is less, the micro-motion performance is good, and the accuracy is high, the system efficiency is high; and all hydraulic elements are arranged orderly, concentrated control is easy to implement, the operation is convenient, and the reliability of a main machine is good.

Owner:锦州力特液压科技有限公司

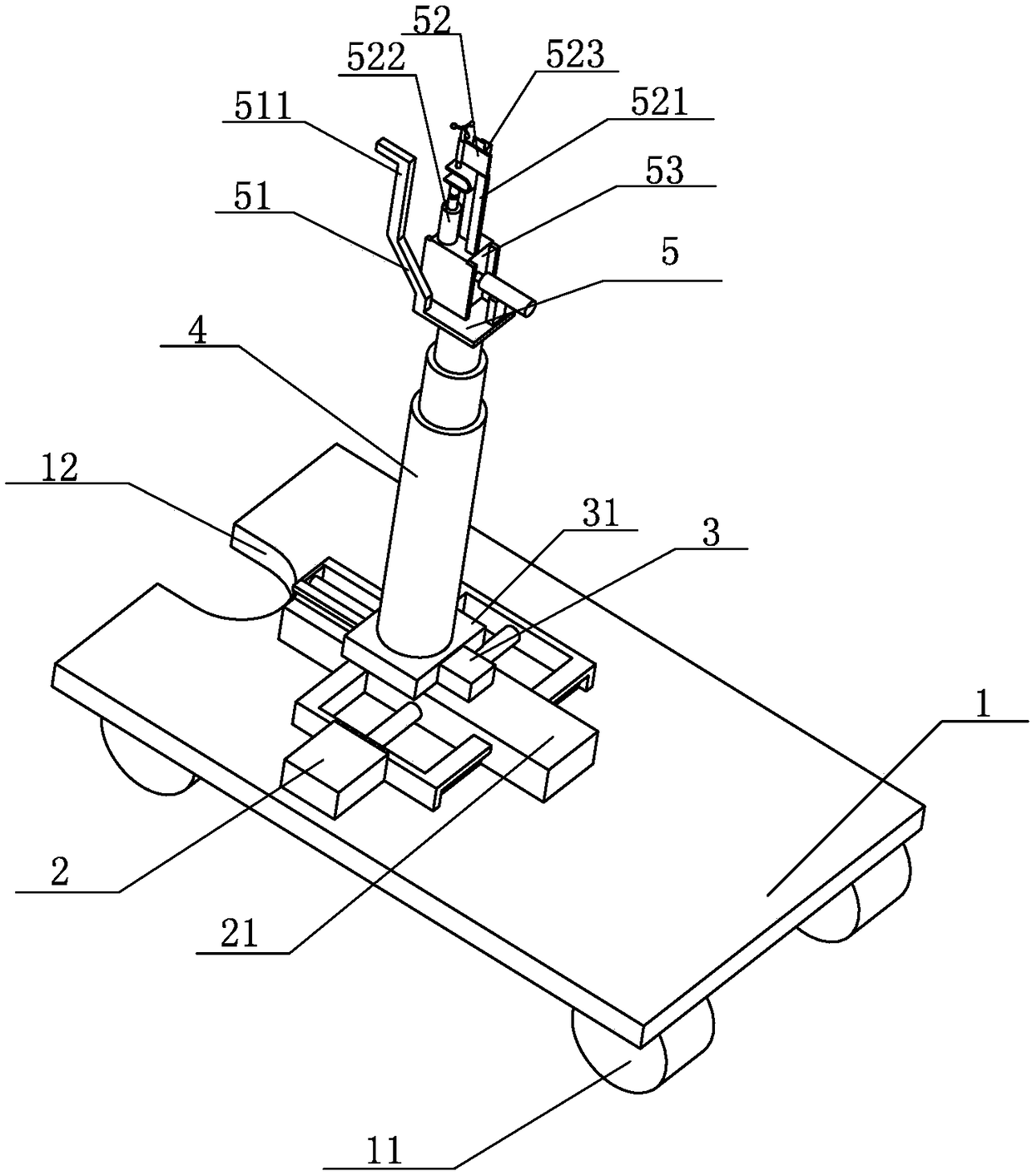

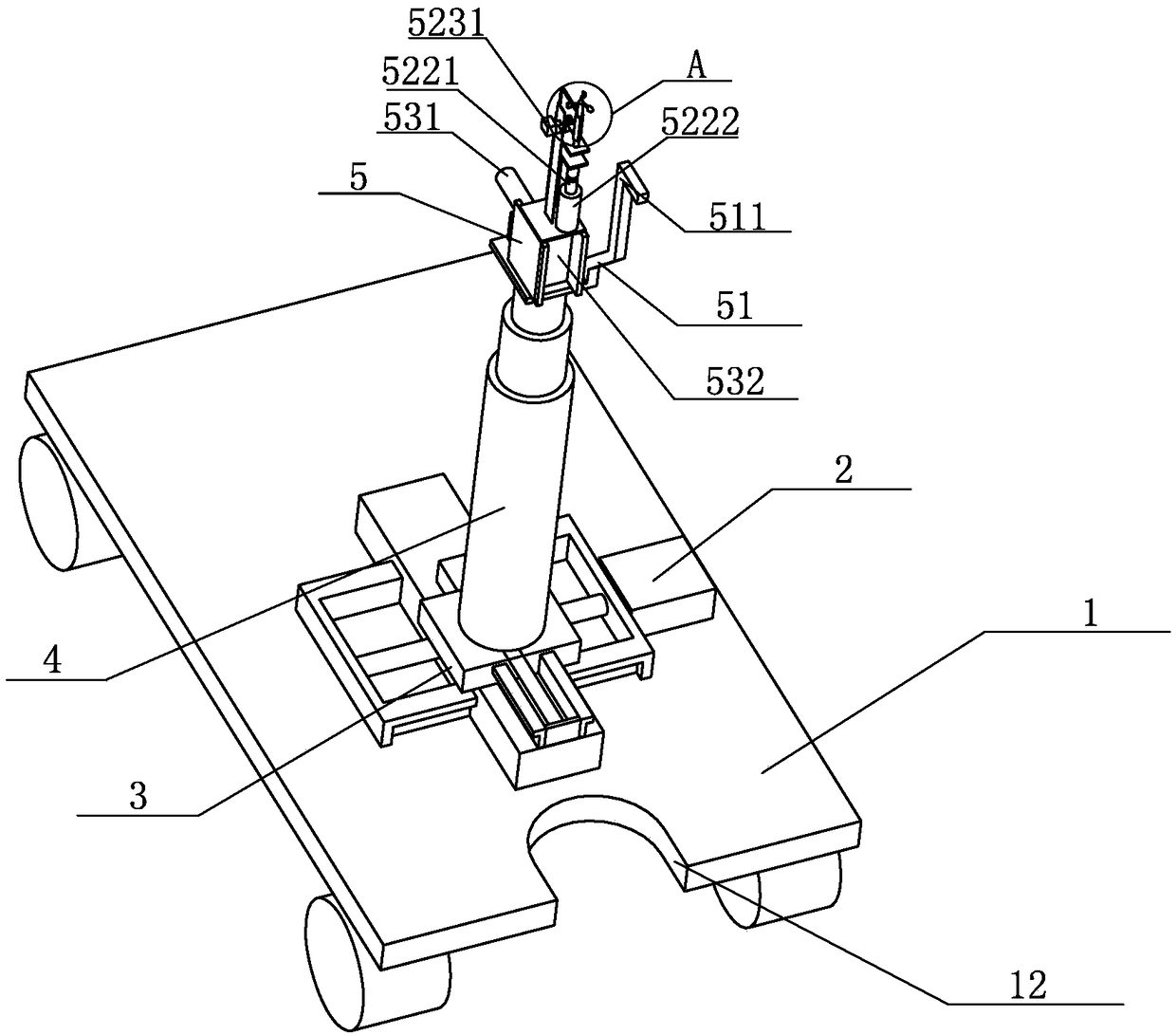

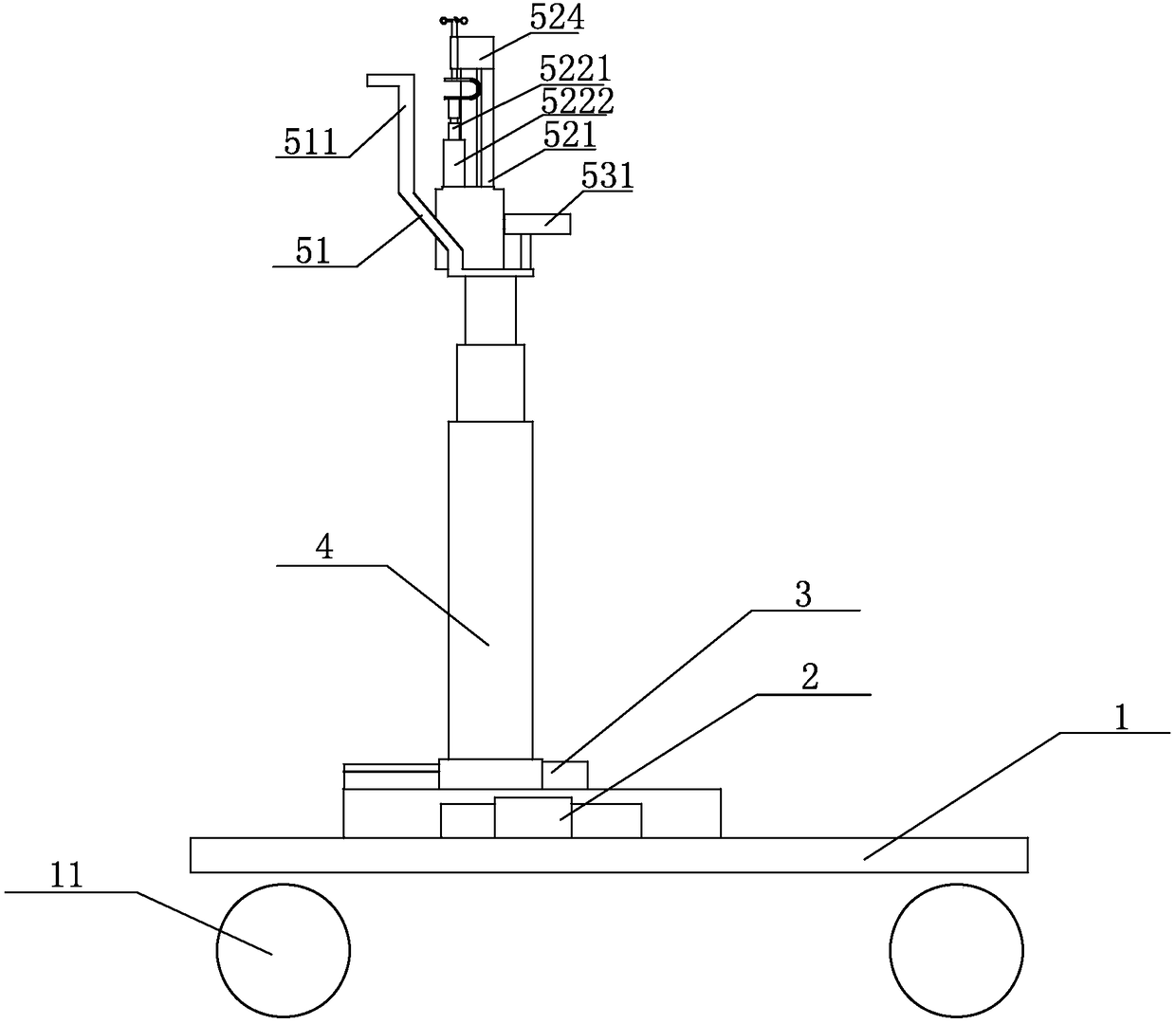

Bird repellent installation device

InactiveCN106058732BReduce work intensityHeight adjustableAnimal repellantsApparatus for overhead lines/cablesEngineeringMechanical engineering

The invention provides an installation apparatus for bird driving device which comprises a base, a horizontally moving mechanism, a longitudinally moving mechanism, a multi-stage elevation oil cylinder and a positioning device. Four walking wheels are arranged under the base; a U type groove is provided in the central position of the base back end. Both the horizontally moving mechanism and the longitudinally moving mechanism adopt a screw drive principle. And longitudinally moving mechanism is mounted on the sliding block of the horizontally moving mechanism; the multistage elevation oil cylinder is arranged on the sliding block of the longitudinally moving mechanism. The positioning device is arranged on the top of the multistage elevation oil cylinder. The apparatus, with a simple structure, is convenient to operate. With the apparatus, it is possible to install a bird driving device without having to cut off power supply or climbing a rod. This not only reduces the labor intensity, but also improves the safety of installation of a bird driving device.

Owner:国网山东省电力公司茌平县供电公司 +1

Extra-large flow two-way balance valve

ActiveCN113898628AImprove stabilityImprove consistencyServomotor componentsMechanical engineeringPetroleum engineering

The invention relates to an ultra-large flow two-way balance valve. The ultra-large flow two-way balance valve comprises a valve body, a valve element, a first buffering overflow valve and a second buffering overflow valve; one-way valves are integrated in the two ends of the valve element respectively; a first oil port, a second oil port, a third oil port, a fourth oil port, a first oil channel and a second oil channel are formed in the valve body; the left and right of the valve element are opened and closed in a two-way manner, pressure oil from the first oil port or the second oil port is connected or disconnected with the third oil port or the fourth oil port; if a walking motor generates negative load, the valve element automatically adjusts the size of the throttling port, the load is effectively balanced, the micro-motion performance is good, and the through-flow capacity is high. When impact pressure is generated under the working conditions of walking start and stop, uphill and downhill and the like, impact pressure oil from the walking motor flows into the first oil channel or the second oil channel through the third oil port or the fourth oil port, and motor start and stop pressure impact is reduced through the arranged first buffering overflow valve or the second buffering overflow valve; the slope two-way walking speed of the walking mechanism is effectively controlled, and stable operation of the walking mechanism is guaranteed.

Owner:JIANGSU ADVANCED CONSTR MASCH INNOVATION CENT LTD

Vehicle crane control method and device, and vehicle crane

ActiveCN111039178AGuaranteed stabilityImprove experienceLoad-engaging elementsControl engineeringControl theory

The invention relates to a vehicle crane control method and device, and a vehicle crane. The method comprises the following steps of determining a voltage target value according to a received input signal for starting a crane from a control handle; determining an intermediate voltage value according to a first voltage value and the voltage target value; and when each signal output time point of afirst control time period is reached, determining and outputting a first output voltage corresponding to the signal output time point, wherein the first output voltage at a first target time point isthe intermediate voltage value, the first output voltage of a time end point of a first control time period is a voltage target value, and in the first time period formed by a time starting point of the first control time period and the first target time point, an increasing amplitude of the first output voltage corresponding to a latter signal output time point is increased along with the increase of time compared with the increasing amplitude of the first output voltage corresponding to a former signal output time point. Therefore, good micro-motion performance is achieved on control of thecrane, and large shaking in a starting process is prevented.

Owner:河北雷萨重型工程机械有限责任公司

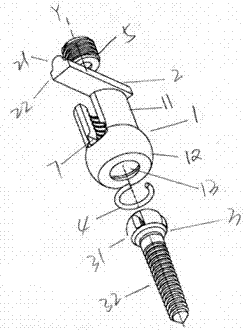

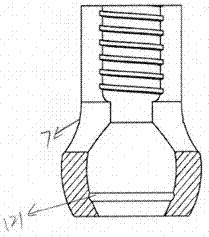

A spinal rod system

ActiveCN104873309BGuaranteed stabilityStability impactInternal osteosythesisSpinal implantsSpinal columnFretting

The invention provides a spinal screw rod system, including a receiver, a rod, an anchor and a locking screw. The rod passes through the locking member and is locked by the locking screw. Through the unique connection between the receiving member and the anchor The method realizes the stability of the screw-rod system and can also produce a certain amount of micro-motion. This system can effectively improve the fusion rate and long-term stability of spinal products, and it is easy to install, which can reduce surgical operation steps and greatly shorten surgical operation time. .

Owner:BEIJING NATON TECH GRP CO LTD +2

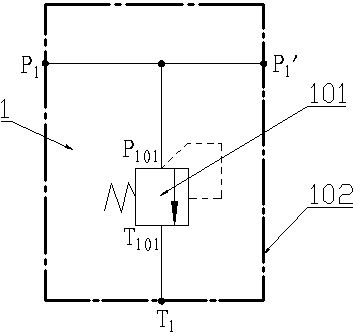

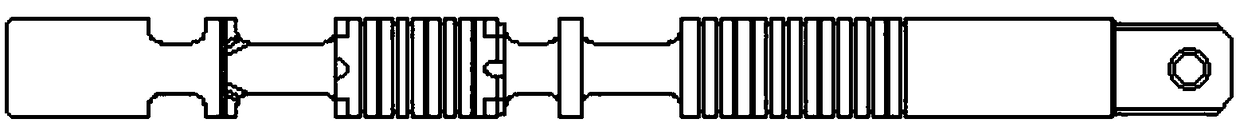

A fixed jib stepless variable amplitude control system for a crane and the crane

ActiveCN104071709BWide speed rangeGood frettingServomotorsLoad-engaging elementsHydraulic cylinderControl system

The invention relates to a fixed jib stepless variable amplitude control system for a crane and the crane. The control system includes an electric proportional pressure reducing valve, a variable pump, a first reversing valve and a hydraulic oil cylinder for making the fixed jib variable amplitude; A reversing valve is located on the oil circuit between the variable pump and the hydraulic cylinder, the pressure oil output by the variable pump enters the hydraulic cylinder through the first reversing valve, and the electric proportional pressure reducing valve controls the displacement of the output pressure oil of the variable pump. The fixed jib stepless variable amplitude control system for a crane provided by the invention utilizes an electric proportional pressure reducing valve to control the displacement of a variable pump, realizes continuous variation of the displacement of the variable pump, has a wide speed regulation range, and has good fretting performance.

Owner:XUZHOU HEAVY MASCH CO LTD

Multifunctional three-dimensional-rotating aerial work platform

ActiveCN102627246BIncrease flexibilityPrecise and sensitive controlLifting devicesThree-dimensional spaceAerial work platform

The invention belongs to the field of aerial work, and particularly relates to a multifunctional three-dimensional-rotating aerial work platform which is applied to a straight arm type aerial working vehicle and capable of automatically performing material lifting, installation and manned operation. The multifunctional three-dimensional-rotating aerial work platform comprises a support arm, a rotary connecting device and a bracket which are connected in sequence. The bracket comprises a horizontal propping support and a lateral leaning support which are vertical to each other. An installing seat is arranged in the middle of the lateral leaning support. The installing seat can be rotatably connected with the rotary connecting device. The rotary connecting device is provided with a horizontal rotating oil cylinder for driving the horizontal propping support to rotate on a horizontal surface and a vertical rotating oil cylinder for driving the horizontal propping support to rotate on the gravity surface. The support arm is provided with a swing telescopic oil cylinder for driving the propping support to lift and decline. The propping support of the multifunctional three-dimensional-rotating aerial work platform can be adjusted at any position in a three-dimensional space in any direction in a rotating mode by a wide margin, and the aerial work platform can work in a narrow space.

Owner:ZHEJIANG DINGLI MACHINERY CO LTD

Motor driven hydraulic system for crane luffing mechanism and its working method

ActiveCN111396378BReduce volumeReduce noiseServomotor componentsServomotorsDrive motorEnergy recovery

The invention discloses a motor-driven hydraulic system for a crane amplitude changing mechanism and an action method thereof, and belongs to the field of construction machinery. The motor-driven hydraulic system comprises an electric driving device and a hydraulic device; a battery supplies power to a controller, the controller adjusts the rotation direction and rotating speed of an electromotor,the electromotor drives a hydraulic motor, and when the hydraulic motor reversely drags the electromotor, the electric driving device can achieve the reversing drag power generation energy recovery;when the amplitude is increased, the electromotor rotates forward to drive the motor, pressure oil is output to be supplied to a rodless cavity of a hydraulic cylinder, a piston rod extends out, and the electricity energy is converted into the gravitational potential energy in the process; and when the amplitude in decreased, the electromotor rotates reversely, the pressure oil of the rodless cavity of the hydraulic cylinder drives the electromotor through the hydraulic motor, the electromotor is in a reversing drag power generation condition, the generated electric energy is stored in the battery, and the energy can be reused when the amplitude is increased. According to the motor-driven hydraulic system, the gravitational potential energy of a jib and the sling load is recovered and utilized when the amplitude is decreased, the energy consumption can be significantly lowered, the system efficiency is improved, and the heating is reduced.

Owner:抚顺海创电子科技有限公司

Hydraulic valve for forklift lifting

PendingCN108468668AStable handlingGood frettingServomotor componentsLifting devicesEngineeringMechanical engineering

The invention discloses a hydraulic valve for forklift lifting. The hydraulic valve for forklift lifting comprises a valve body and a valve element, wherein an oil path channel is formed in the valvebody; the valve element penetrates through the valve body and is arranged in the middle of the valve body; a working port A and a working port B are separately formed in the upper surface of the valvebody; an oil inlet cavity is formed in the valve body; an oil return cavity is formed in the lower end of the oil inlet cavity through the valve element; the valve element comprises a valve element a, a valve element b and a valve element c; two vertical through holes are vertically formed in the tail end of the valve element b, and the valve elements a, b and c are integrally formed. The hydraulic valve provided by the invention is steady in lifting operation and safe and reliable and has a good micro-motion property.

Owner:江苏海洲液压件制造有限公司

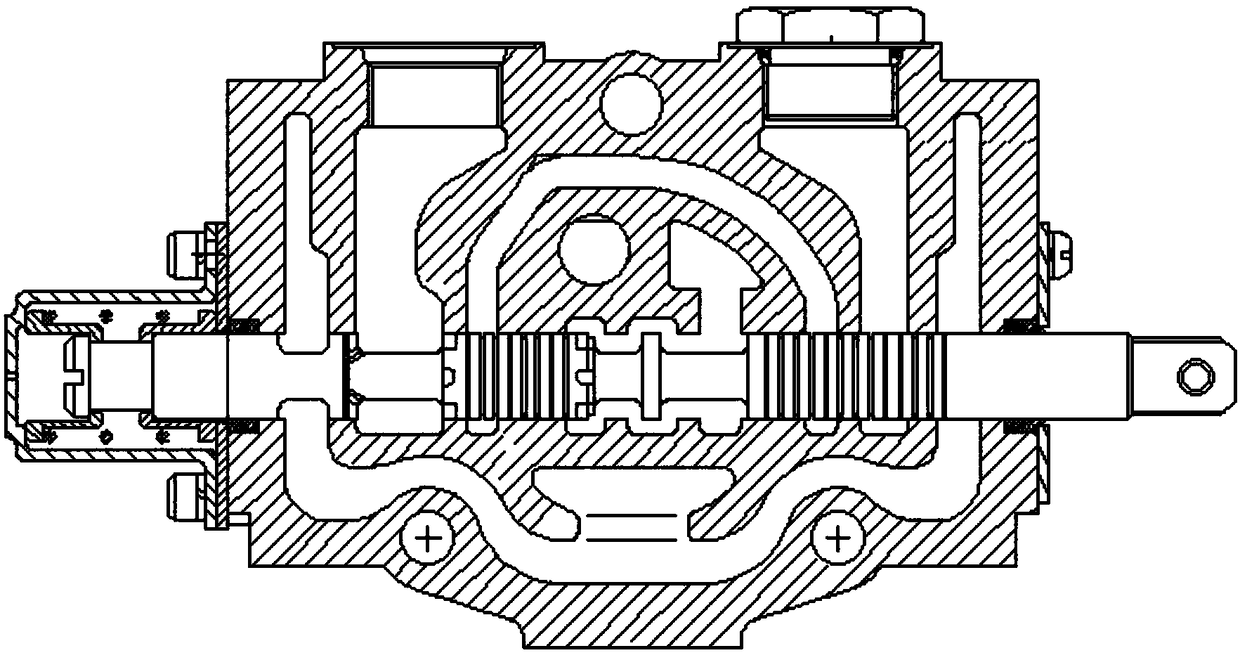

Variable pump hydraulic circuit and construction machinery

ActiveCN103527542BFretting stabilityReduce adverse effectsServomotor componentsServomotorsHydraulic circuitFuel tank

The invention discloses a variable pump hydraulic circuit and engineering machinery. The variable pump hydraulic circuit includes an oil tank, a variable pump, a constant pressure reducing valve and damping. The oil inlet of the variable displacement pump is connected to the oil tank, the oil outlet is connected to the oil inlet of the constant pressure reducing valve, and the oil outlet of the constant pressure reducing valve is connected to the oil inlet of the damper , the oil outlet end of the damping is connected to the oil tank. When the variable pump hydraulic circuit of the present invention is used to supply pressure oil to the actuator, since the constant pressure relief valve and damping cooperation can provide a stable bypass throttling for the variable pump, the variable pump does not need to work in an unstable range of flow and can be used for the actuator. The micro-movement of the mechanism provides a stable flow rate, which can effectively ensure the stability of the micro-motion performance of the actuator, and avoid the adverse effects of the unstable flow characteristics on the micro-motion performance of the actuator under the small displacement working condition of the variable displacement pump.

Owner:SANY AUTOMOBILE HOISTING MACHINERY

Automatic verticality regulating method for piling bar post and system thereof

The present invention provides a steel pile column full-automatic verticality regulation and control system and its method. Its method includes the following steps: (1) making verticality measurement of steel pile column by using measuring device; (2) transferring measured data into measurement system computer; (3). measuring system computer can be used for calculating and analyzing said data; (4). transferring said result into the hydraulic system cmputer by means of measurement system computer; (5) hydraulic system can be used for correcting position under the control of hydraulic system computer; and (6). judging that the above-mentioned corrected position is in place or not, if it is not in place, returning step (2). Said system is high in accuracy, smooth and stable in operation, good in micromotion property and can implement step-by-step operation less than 0.2 mm.

Owner:SHANGHAI CONSTR NO 1 GRP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com