Full-hydraulic digitized synergetic linkage control pipe lifting machine

A pipelayer, full-hydraulic technology, applied in the direction of cranes, mechanical equipment, fluid pressure actuation devices, etc., can solve the problems of increased demand for pipelayer products, poor working accuracy of compound actions, and low power utilization. Achieve the effects of avoiding low power utilization, high action accuracy and high power utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

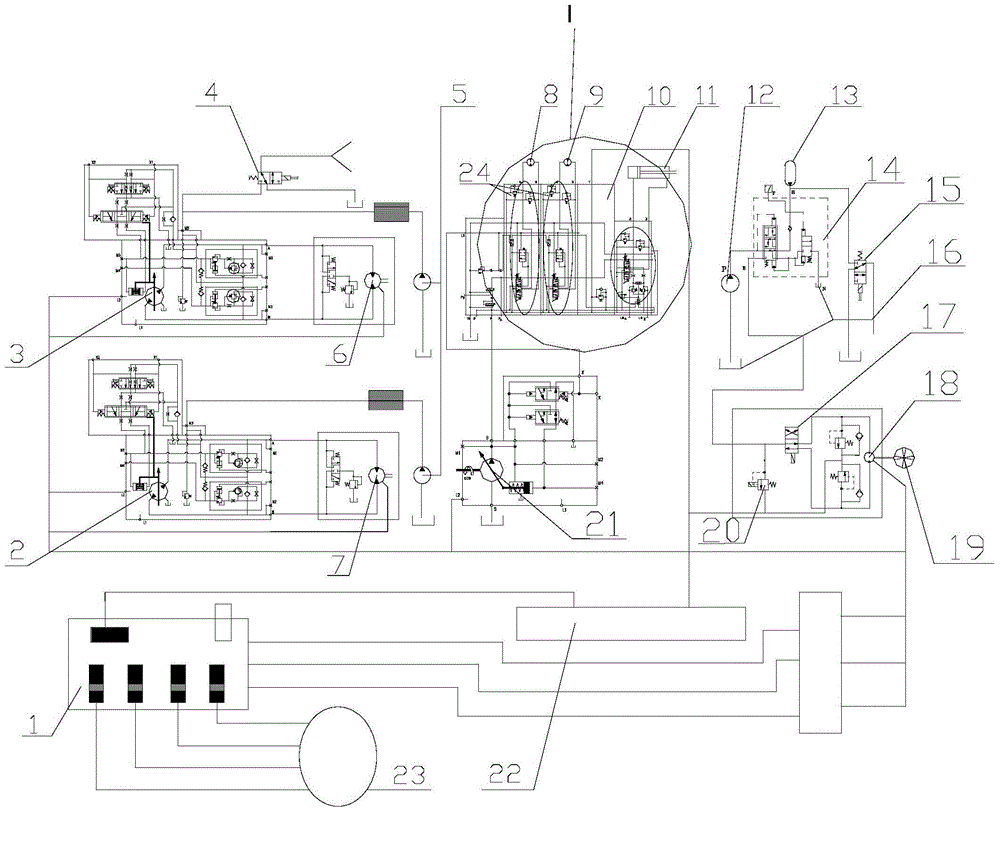

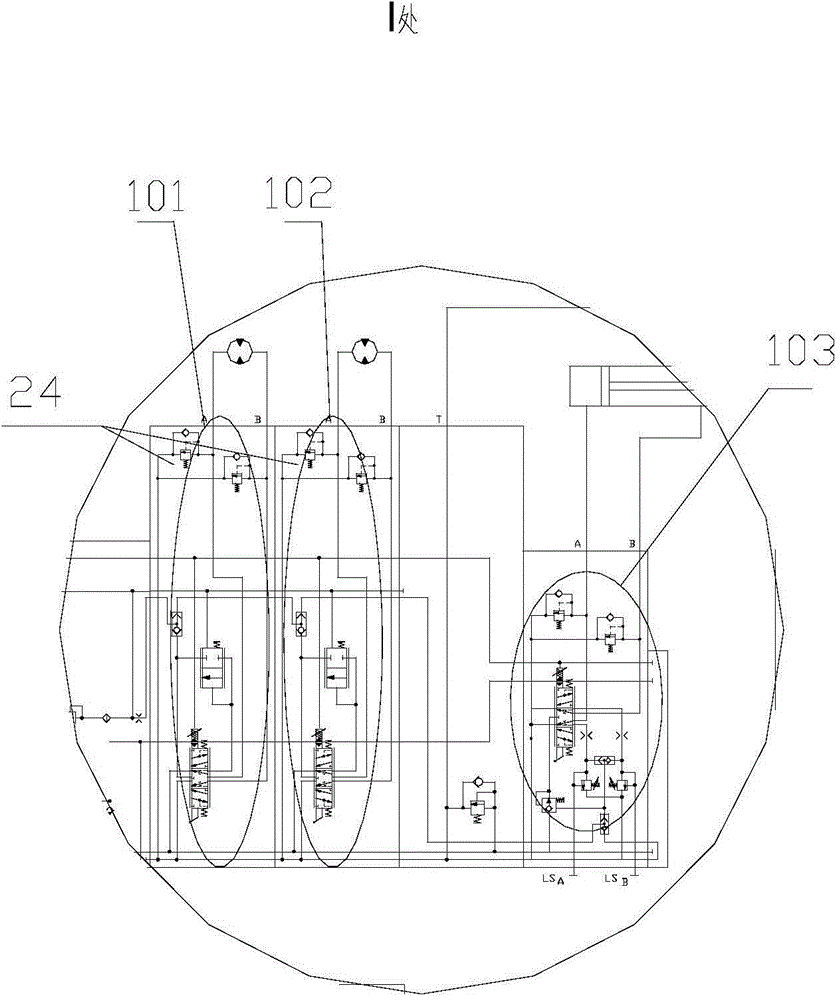

[0037] The present invention as Figure 1-3 As shown, the pipelayer includes a wireless communication module and an electro-hydraulic control system,

[0038] a plurality of said pipelayers communicate through said wireless communication module;

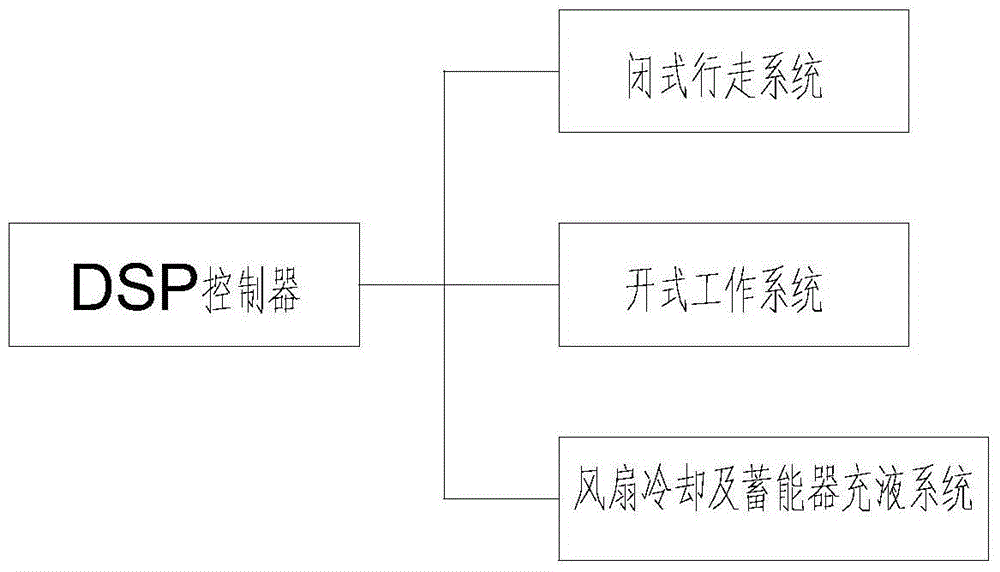

[0039] The electro-hydraulic control system includes a DSP controller, a closed walking system, an open working system, a cooling fan and an accumulator filling system;

[0040] The closed walking system includes a left walking closed pump 2, a left walking closed motor 7, a right walking closed pump 3, a right walking closed motor 6, and the left walking closed pump 2 and the left walking closed motor 7 connected, the right-traveling closed pump 3 is connected with the right-traveling closed-type motor 6, and the DSP controller controls the left-traveling closed-type pump 2 and the right-traveling closed-type pump 3 respectively;

[0041] The open working system includes a variable working pump 21, an electric proportional multi-w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com