Loading and unloading switching valve for lorry-mounted crane

A technology for truck-mounted cranes and switching valves, applied in mechanical equipment, fluid pressure actuators, servo motors, etc., can solve the problems of no hydraulic interlock, misoperation, high cost, etc., to avoid high-pressure shock and operate fretting Good, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

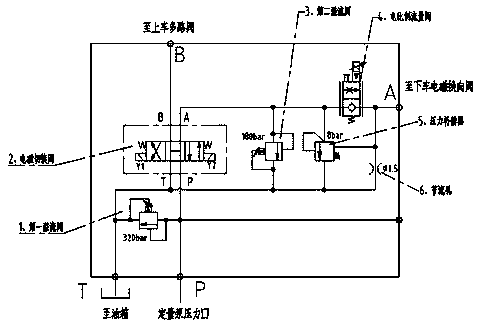

[0024] The switching valve for getting on and off the truck, including the first relief valve, electromagnetic switching valve, second relief valve, electric proportional flow valve, pressure compensator and orifice;

[0025] The first overflow valve is arranged between the quantitative pump pressure port pipeline and the oil tank pipeline;

[0026] The quantitative pump pressure port pipeline is connected to the electromagnetic switching valve through the P port, and the fuel tank pipeline is connected to the electromagnetic valve through the T port;

[0027] The electromagnetic switching valve is connected to the boarding multi-way valve through port B, and the solenoid valve is connected to the outrigger control system through port A.

[0028] the lower outrigger control system includes a second relief valve for low pressure limiting of outrigger system pressure;

[0029] The outrigger control system also includes an electric proportional flow valve, a pressure compensator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com