Automatic verticality regulating method for piling bar post and system thereof

A control system and technology of steel piles, which are applied in sheet pile walls, buildings, infrastructure engineering, etc., can solve the problems of difficulty in meeting millimeter-level requirements and large steps of screw elongation and shortening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

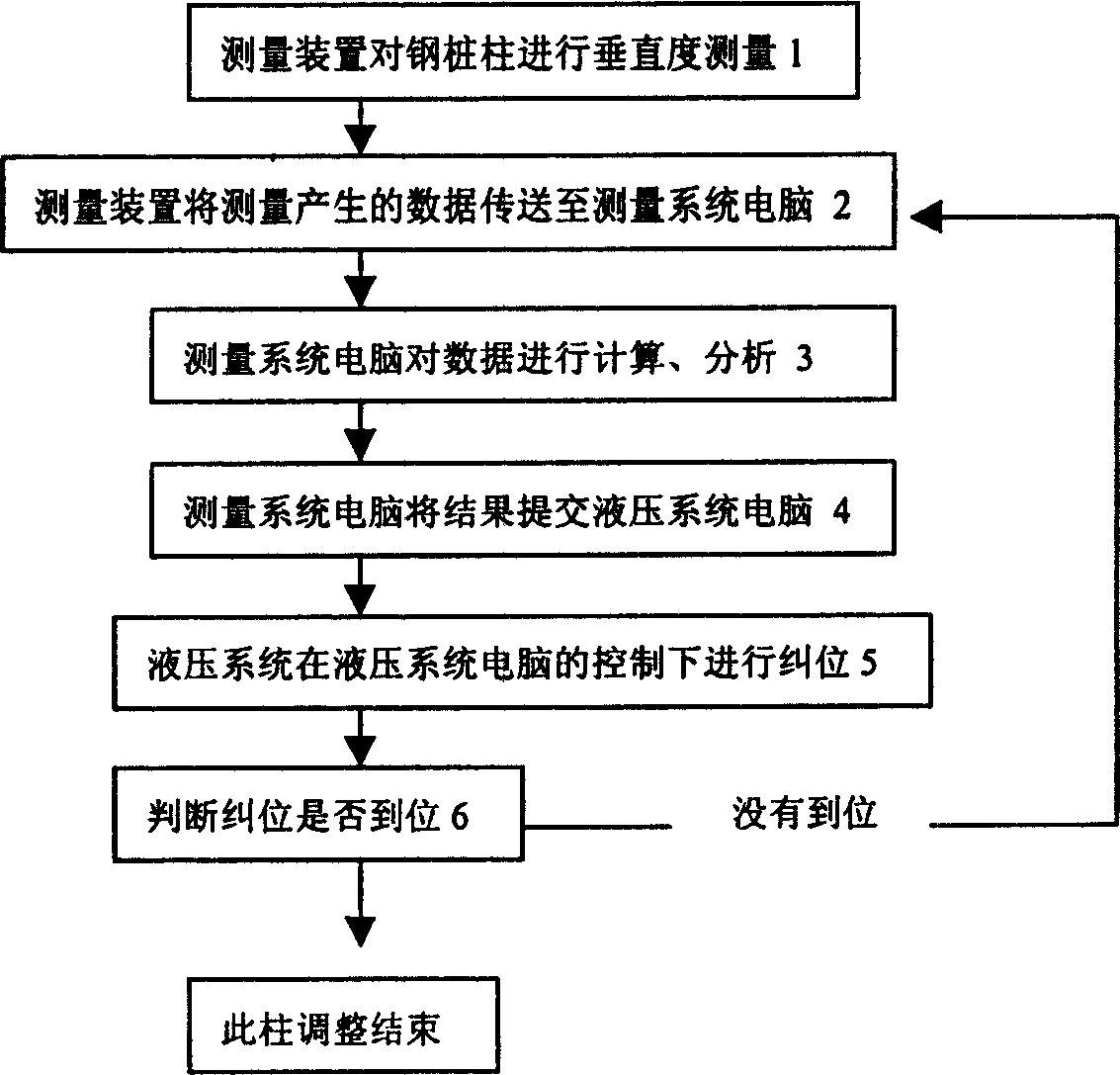

[0018] The steel pile automatic straightness control system of the present invention is used for measuring the verticality of the steel pile, and automatically adjusts according to the measured data, so as to realize precise straightening. It includes: measurement system, electrical control system and hydraulic drive system.

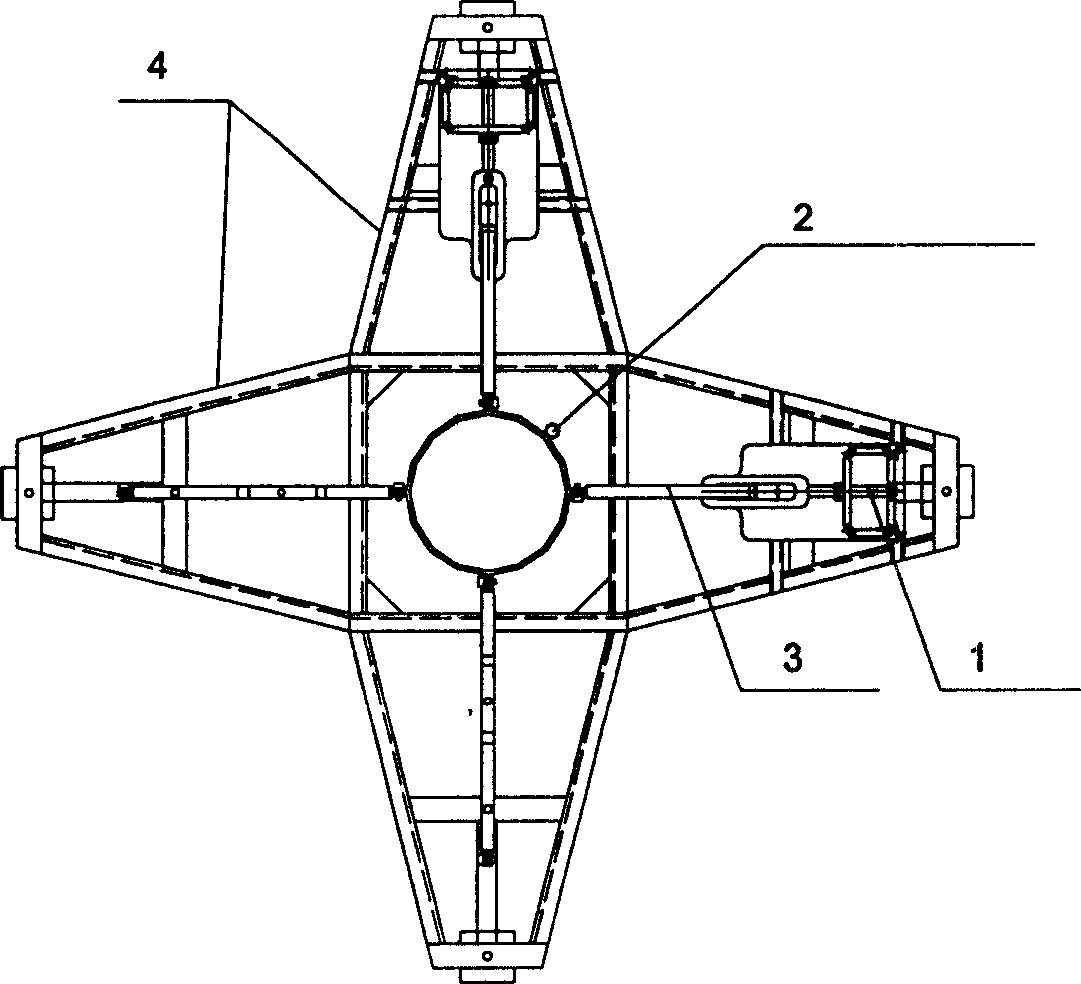

[0019] Such as figure 1 Shown: the measurement system includes a measurement device and a measurement system computer.

[0020] The measuring device is composed of an inclinometer tube 2 and an inclinometer, and is used to measure the verticality of the steel pile. The inclinometer tube is fixedly installed on the steel pile to be straightened.

[0021] The computer of the measurement system is connected with the inclinometer, and the data collected by the sensor of the inclinometer is transmitted to the computer of the measurement system, and the computer of the measurement system calculates the required adjustment amount and adjustment direction and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com