A spinal rod system

A nail-rod and spine technology, which is applied in the field of fixation devices in spinal repairs, can solve the problems of destroying the micro-movement of the rod body, weak rigidity, and operation failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The spinal rod system of the present invention will be further described in detail through specific embodiments below.

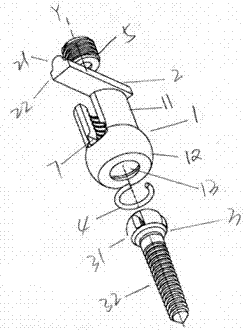

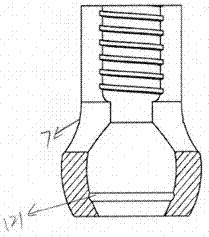

[0030] according to figure 1 . The spinal screw rod system shown in 2 includes a receiving part 1, the upper part of the receiving part 1 is two longitudinally parallel straight arm structures 11, the inner surfaces of the two straight arms 11 are arc surfaces, the proximal end has a threaded structure 111, and the upper outer surface Being a cylindrical structure, a channel is defined between the two parallel arms, which channel defines a longitudinal axis Y. The lower part has an outwardly protruding enlarged structure 12. The enlarged structure 12 can be a symmetrical arc-shaped structure, an asymmetric arc-shaped structure, or an outwardly convex straight column or cone-shaped structure, as long as it can ensure that it can accommodate The accommodating space of the screw head of the elastic structure does not deviate from the spirit of the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com