Load-sensitive multiway valve with micromotion valve element

A load-sensitive, micro-valve technology, applied in the field of multi-way valves, can solve the problems of increasing the difficulty of valve core processing, large system pressure loss, high energy consumption, etc., to improve energy utilization, reduce system pressure loss, structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

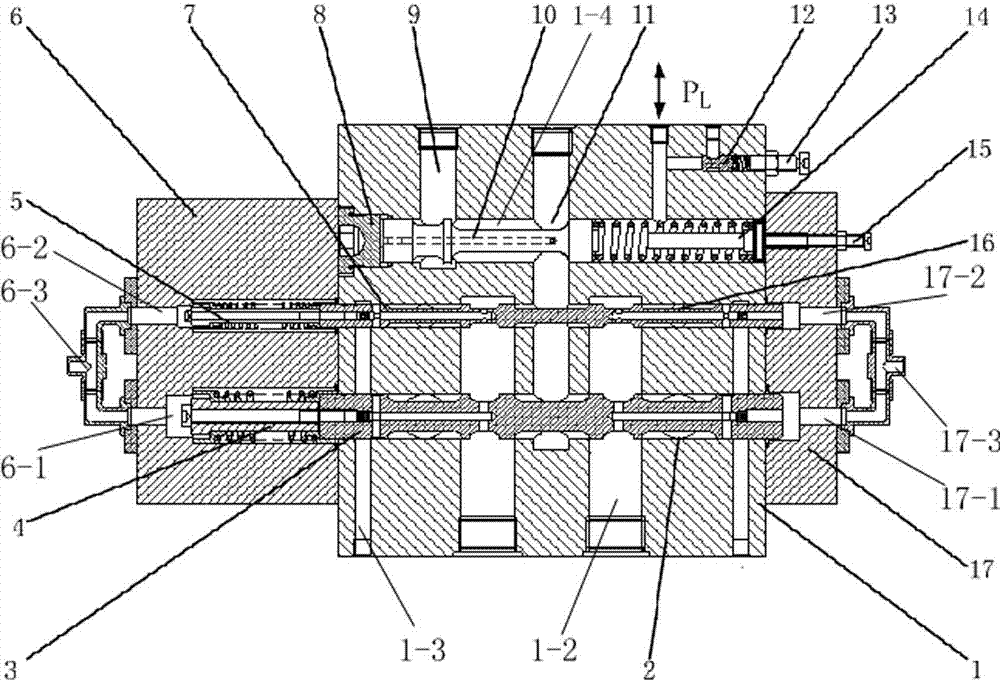

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

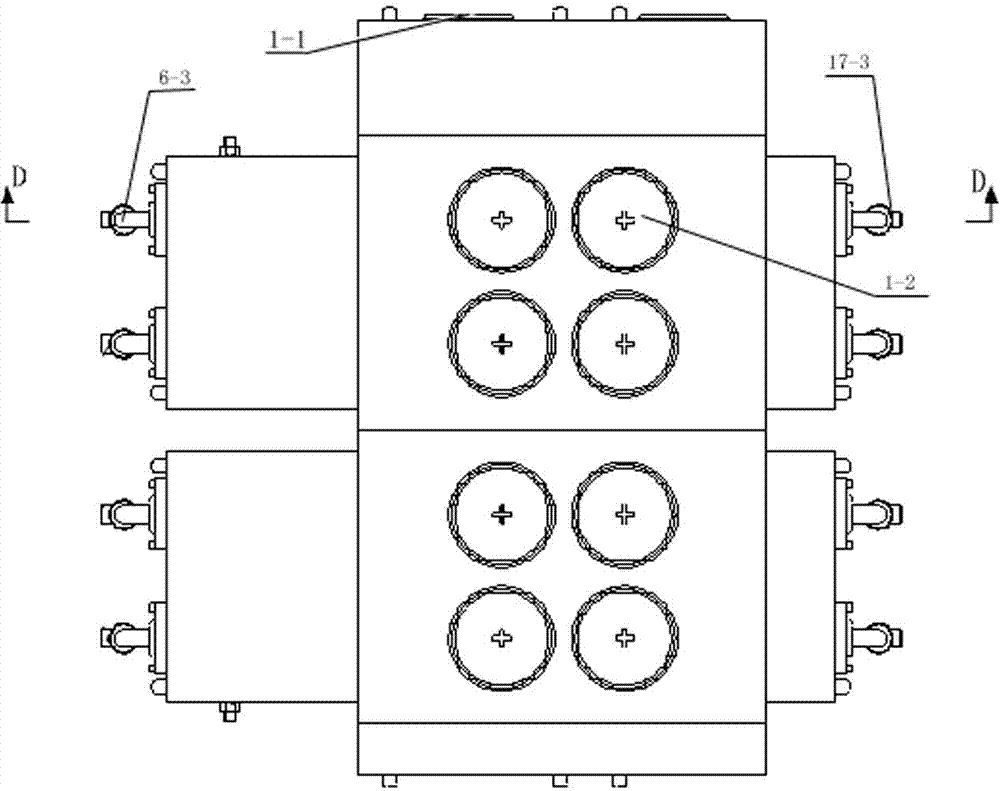

[0017] Such as figure 1 , 2 As shown, the present invention comprises two valve bodies 1, a bottom plate and a top plate, and the valve body 1 is provided with an oil inlet hole and two groups of valve plates, and the oil inlet hole is a through hole, and the two valve bodies 1, the bottom plate and the The top plate is connected by screws, the two valve bodies 1 are located between the bottom plate and the top plate, and the oil inlet holes of the two valve bodies 1 are connected; the bottom plate and the top plate are sealed with the valve body 1, and the two valve bodies 1 are sealed. The base plate and the top plate are installed on the surface where the oil inlets of the oil inlet holes 1-7 of the two valve bodies 1 are located. An oil inlet hole is arranged on the top plate corresponding to the oil inlet hole of the valve body 1 . Both ends of the valve body 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com