Confluence control device of hydraulic crane

A technology for hydraulic cranes and control devices, which is applied to fluid pressure actuation devices, mechanical equipment, transportation and packaging, etc., can solve problems such as crane confluence and impact, and achieve the effects of good fretting performance and enhanced operability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing.

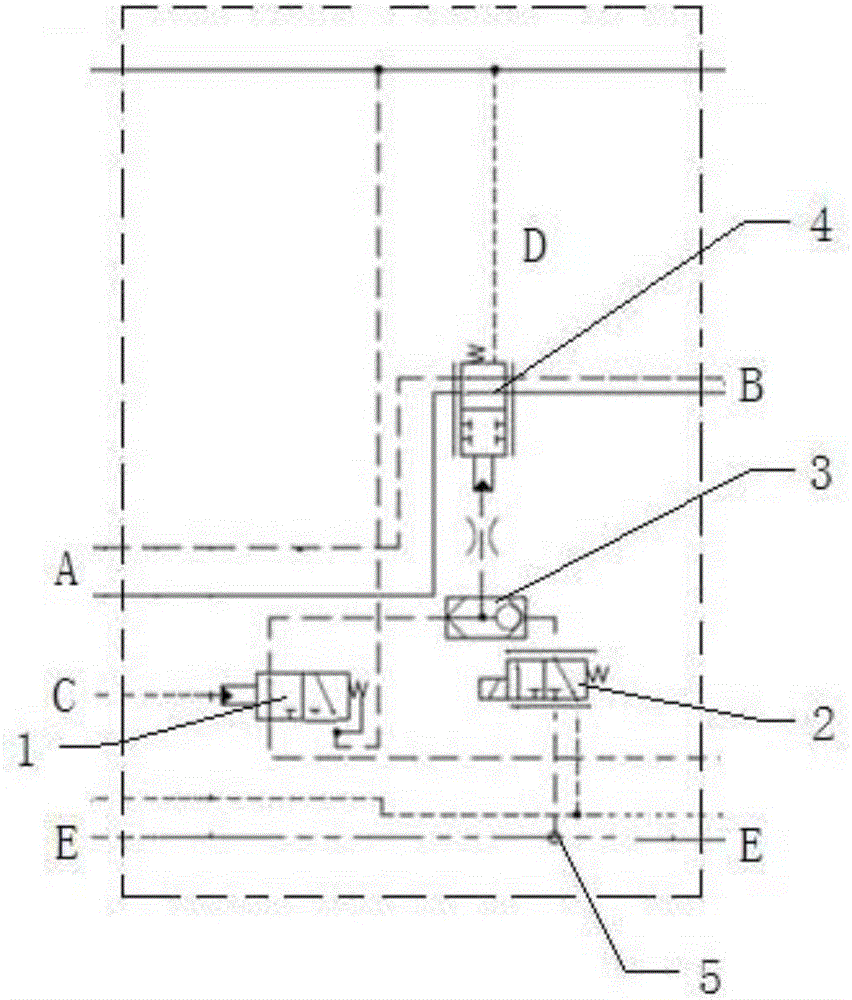

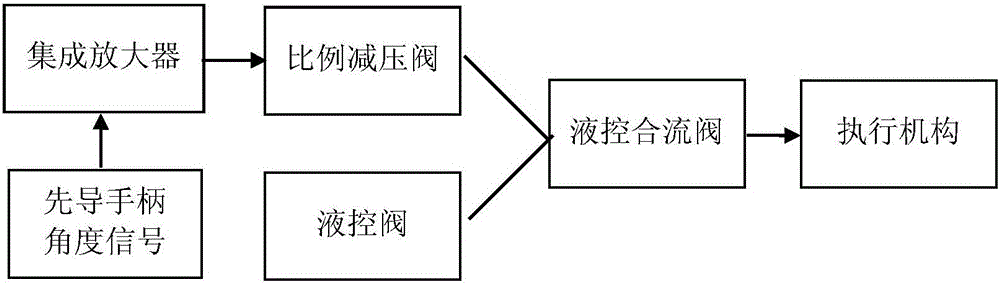

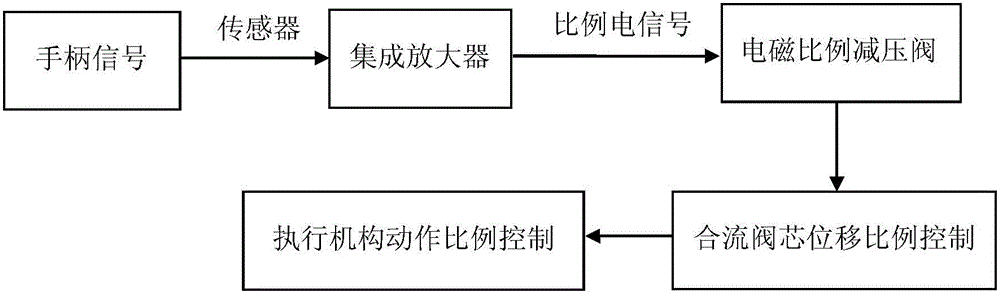

[0014] Such as Figure 1 to Figure 3 As shown, a hydraulic crane confluence control device, the hydraulic crane confluence control device adopts two methods of pilot hydraulic control and proportional solenoid valve pilot control, to accurately control the on-off and size of the confluence on both sides, the confluence device on and off depends on For the hydraulic control pilot oil circuit and the electric proportional control pilot oil circuit, the pressure of the pilot oil circuit is higher, the size of the joint flow on the left and right sides depends on the continuous change of the deflection angle of the pilot handle or the pressure on both sides of the system; , pressure and flow requirements, choose to merge from left to right or from right to left, and reduce the impact of confluence when the crane moves and control the flow of the confluence valve by controlling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com