Combined multi-way reversing valve for coal mine full hydraulic tunnel drilling rig

A multi-way reversing valve and tunnel drilling rig technology, applied in the field of hydraulic valves, can solve problems such as difficult centralized control, messy hydraulic oil pipes, and affecting the reliability of the main engine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

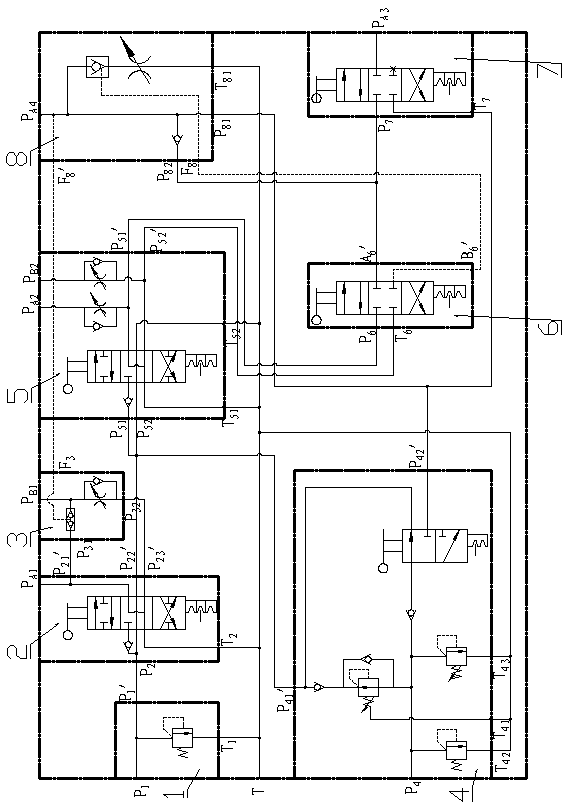

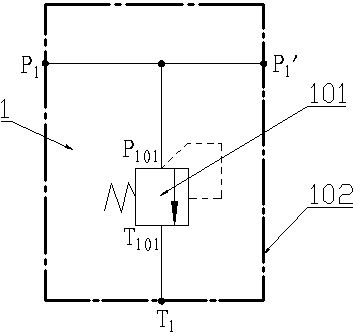

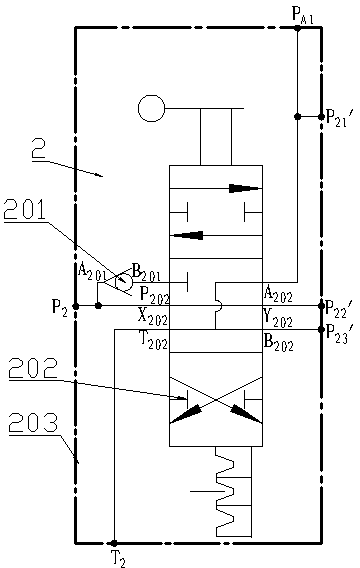

[0026] Such as figure 1 As shown, the combined multi-way reversing valve for coal mine full hydraulic tunnel drilling rig consists of oil inlet valve body 1, motor direction control valve body 2, motor speed control valve body 3, auxiliary control valve body 4, oil cylinder direction and speed control valve Body 5, hydraulic chuck control valve body 6, gripper control valve body 7, and hydraulic chuck oil return valve body 8 are connected in sequence; among them, the oil outlet P of oil inlet valve body 1 1 ' and the oil inlet P of the motor direction control valve body 2 2 Connected, the first oil outlet P of the motor direction control valve body 2 21 ' and the first oil inlet P of the motor speed control valve body 3 31 Connected, the second oil outlet P of the motor direction control valve body 2 22 ' and the direction of the oil cylinder, the first oil inlet P of the speed control valve body 5 51 , the second oil inlet P 52 Connected sequentially, the third oil out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com