High-altitude tightening device for Dyneema rope

A high-voltage, main-body technology, applied in the direction of overhead lines/cable equipment, etc., can solve problems such as difficult control, safety and reliability judged only by experience, inconvenient transition, etc., and achieve tightening speed that is easy to adjust, easy to maintain and Good effect of upgrade and fretting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

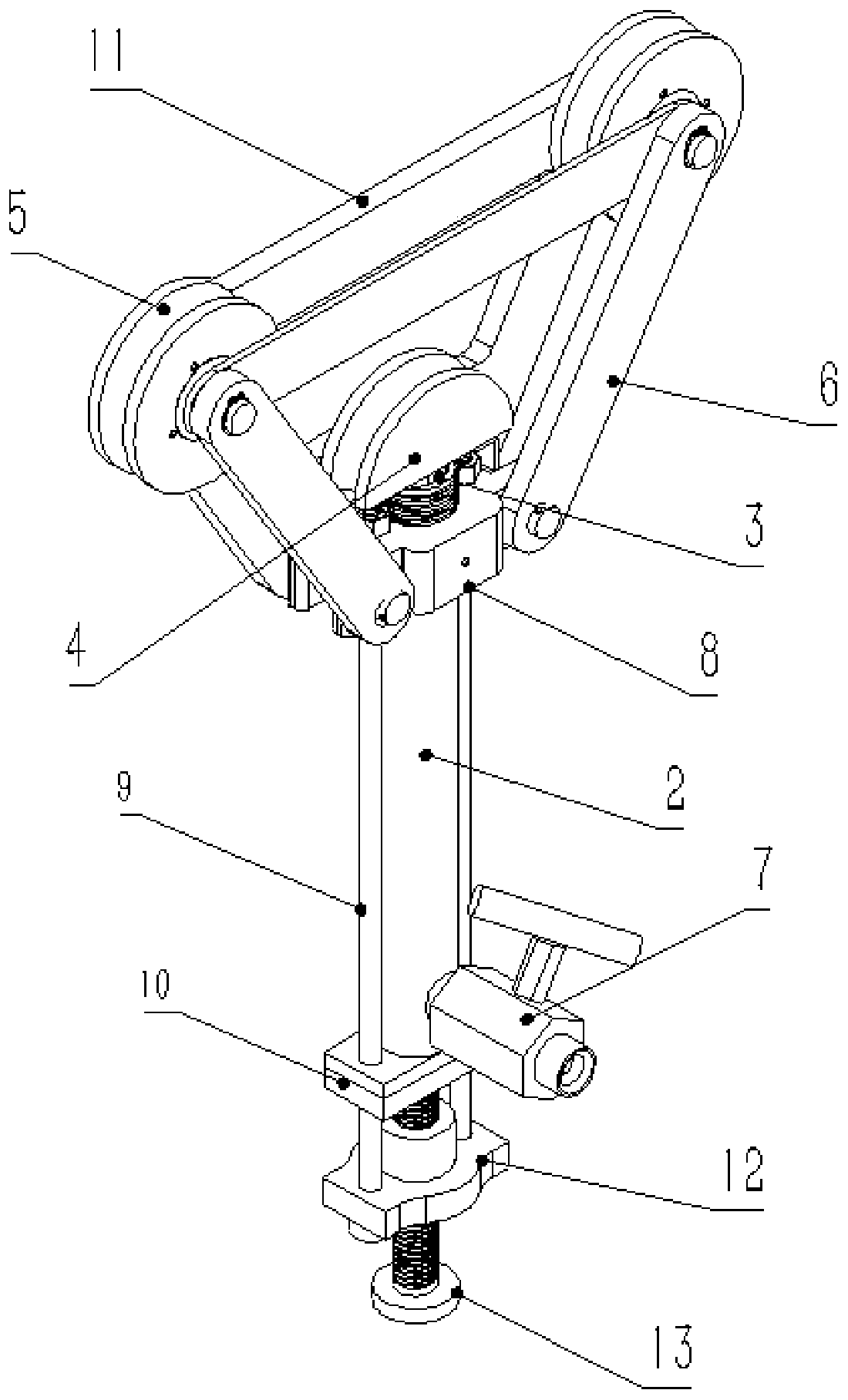

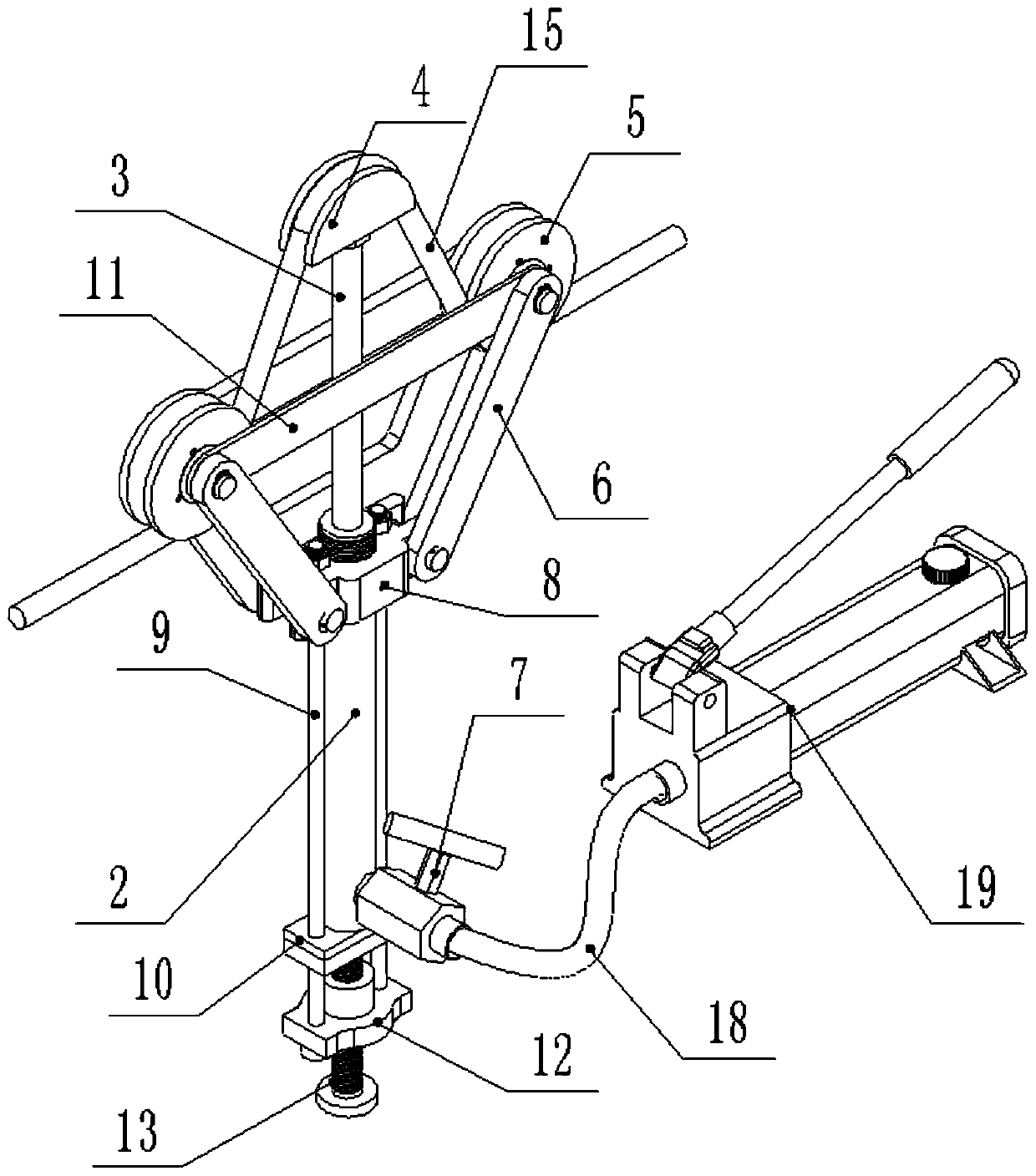

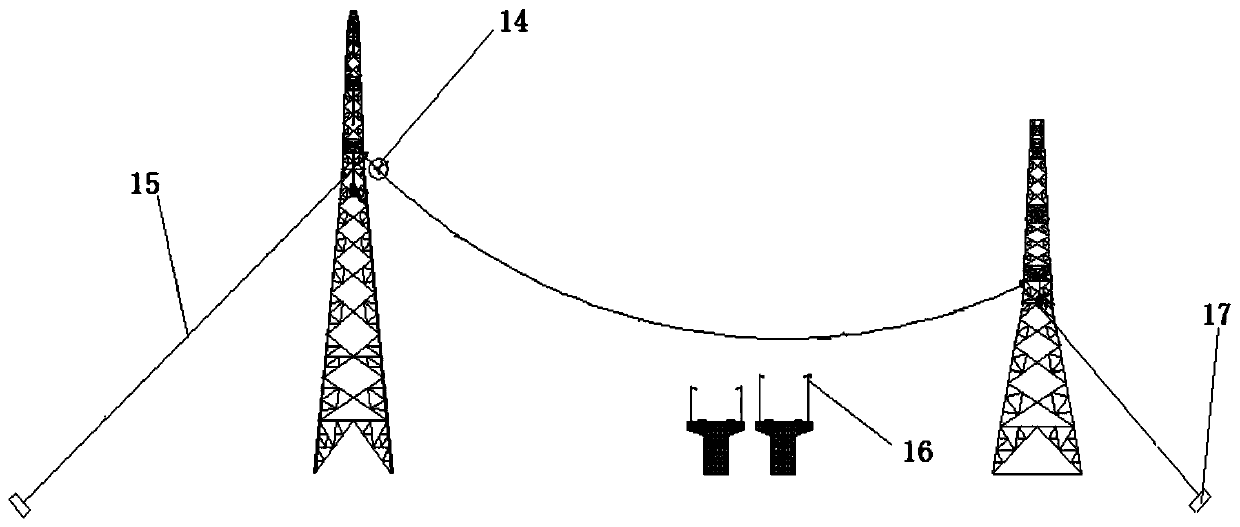

[0022] Such as figure 1 As shown, the Dyneema rope high-altitude tightening device includes a main body support frame, two sets of rollers 5 are respectively connected to both sides of the main body support frame, and the rollers 5 are detachably connected to the main body support frame. The telescoping end of the mechanism is connected with a propulsion wheel 4, and the propulsion wheel 4 moves up and down between two groups of rollers 5.

[0023] The telescoping mechanism is preferably a high-pressure oil cylinder 2, which provides power for the device. The top end of the piston rod 3 of the high-pressure oil cylinder 2 is connected with the propulsion wheel 4; the small-volume high-pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com