Cast aluminum dummy shaft

A dummy shaft, cast aluminum technology, applied in the manufacture of stator/rotor body and other directions, can solve the problems of high equipment investment cost, waste of water resources, insufficient tightening effect, etc., and achieve good stacking uniformity of shaft holes and save water resources. , good tightening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

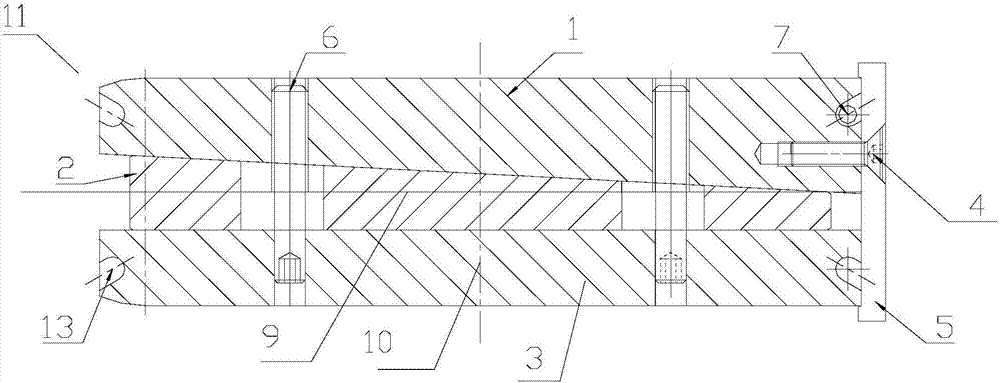

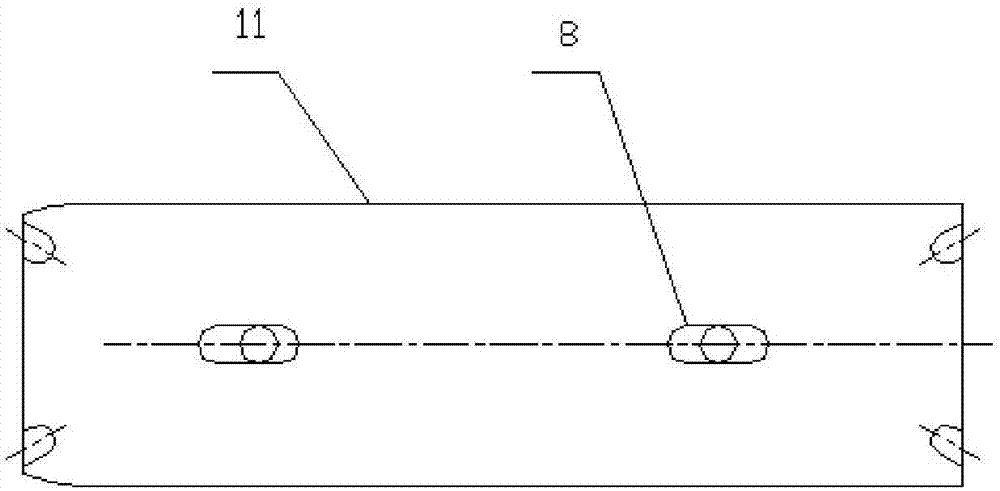

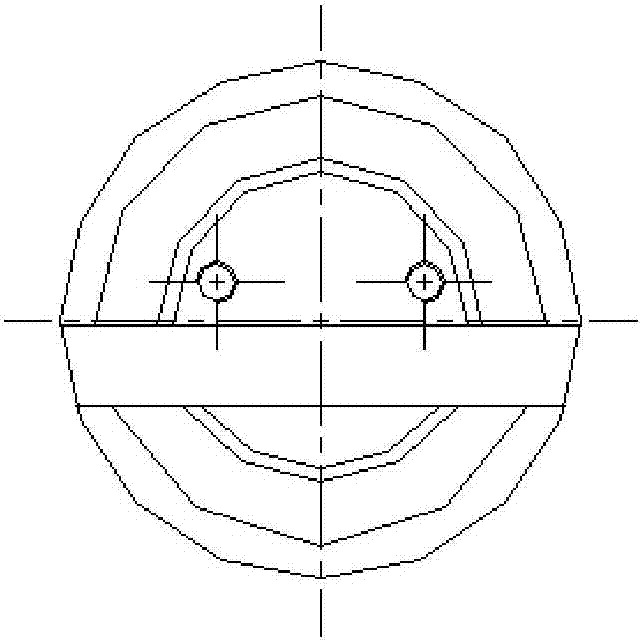

[0025] A cast aluminum dummy shaft includes: dummy shaft fixed block 1, middle block 2, dummy shaft movable block 3, fixing bolt 4, cover plate 5, positioning pin 6, extension spring 7, keyway 8, first datum 9, second Datum 10, dummy shaft body 11, relief hole 12 and tension spring groove 13. The vertical section of the dummy shaft fixed block 1 is a conical surface, and the longitudinal section of the middle block 2 is a conical surface. The same ends of the dummy shaft fixed block 1, the middle block 2, and the dummy shaft movable block 3 are in contact with the cover plate 5, and the dummy shaft is fixed. The block 1 is connected with the cover plate 5 with the fixing bolt 4, and the dummy shaft body 11 abuts against the cover plate 5 with the first datum 9 to set the relief hole 12 downward, the outer circular end surface of the dummy shaft fixed block 1 and the dummy shaft movable block 3 On the first datum 9 and the second datum 10, two symmetrical tension spring grooves...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com