Motor driven hydraulic system for crane luffing mechanism and its working method

A technology of luffing mechanism and hydraulic system, which is applied in the field of boom hydraulic cylinder luffing mechanism and hydraulic cylinder driving lifting mechanism, which can solve the environmental protection trend that does not conform to energy saving and emission reduction, large diesel engine volume, large emission pollution, etc. problem, to achieve the effect of large speed regulation rigidity, small size and simple circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

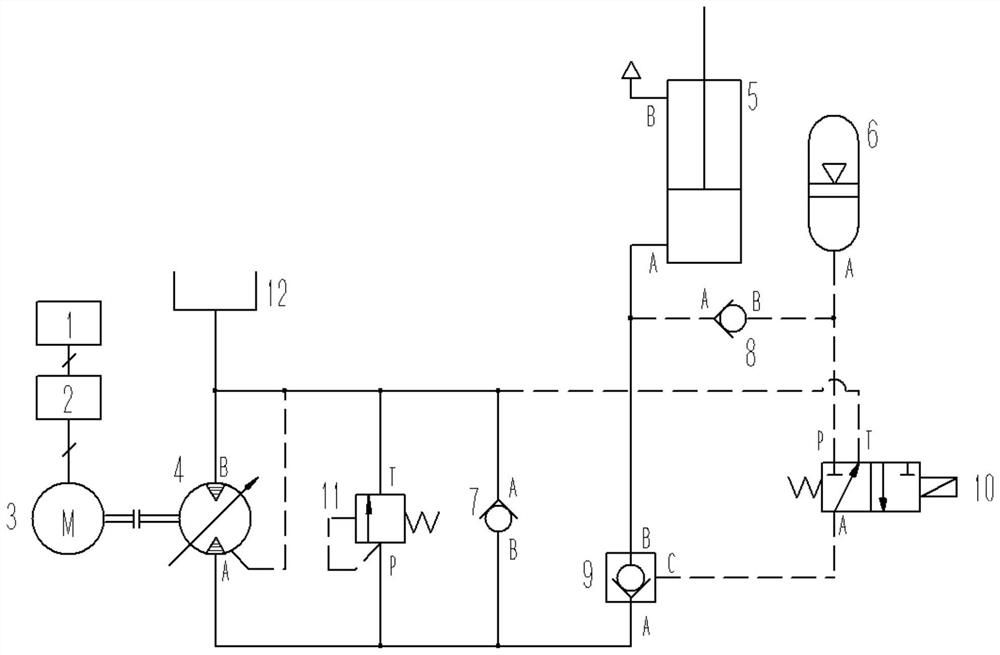

[0021] The specific implementation manners of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

[0022] Luffing stop action working condition: the motor 3 is stopped, the electromagnetic reversing valve 10 is powered off, the hydraulic control check valve 9 is reversely closed, the oil in the rodless chamber of the hydraulic cylinder 5 is sealed, the piston rod is kept at a fixed position, and the luffing Institutions do not act. The weight of the arm rod and the lifting object acts on the oil in the rodless chamber through the piston rod to generate pressure, and the pressure oil enters the accumulator 6 through the second check valve 8, and is filled with oil until the pressure in the accumulator 6 is equal to the pressure in the rodless chamber. Similarly, when the pressure in the rodless cavity is lower than the pressure in the accumulator 6, the second check valve 8 is closed in reverse, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com