A rotary buffer valve

A technology of rotary buffer and valve body, which is used in fluid pressure actuating devices, servo motor components, mechanical equipment, etc., can solve the problems of increased manufacturing and design costs, cumbersome inventory management, and no rotation of the mechanism, and achieves a compact structure. Wide application, smooth stop effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following is a specific embodiment of the present invention, and the present invention will be further described in conjunction with the accompanying drawings.

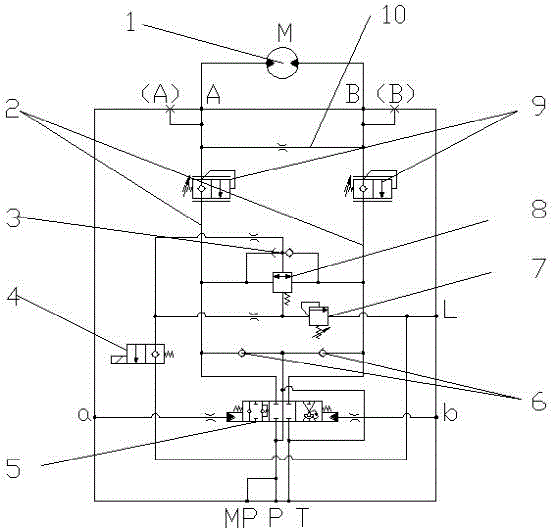

[0020] Such as figure 1 As shown, a rotary buffer valve has two main oil passages 2 in the valve body, and the valve body is also opened with pilot control oil port a, pilot control oil port b, oil inlet P, oil return port T, drain Oil port L and oil port A and oil port B connected to the oil inlet and outlet of the rotary motor; three-position six-way hydraulic control reversing valve 5, main overflow valve 8 and free-slip solenoid valve 4 are mainly installed in the valve body; three-position six-way The valve stem of the hydraulic control reversing valve 5 is provided with an oil return orifice to improve system stability. The left position of the three-position six-way hydraulic control reversing valve 5 is connected to the left and right channels, and the middle channel is disconnected. The left and r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com