Isolating switch contact finger pressure sensor, tester and method

A pressure sensor, isolating switch technology, applied in force/torque/work measuring instruments, instruments, measuring devices, etc., can solve problems such as poor operation, easy to fall off, measurement error, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Such as figure 1 as shown,

[0021] Such as figure 1 As shown, the present disclosure provides a contact finger pressure sensor of an isolating switch, including: a pressure sensor, a positioning structure connected to the pressure sensor; the positioning structure includes an elastic member and a clamping member, one end of the elastic member is connected to the housing, The other end is connected with the contact finger of the isolating switch to be tested; one end of the clamp is connected with the housing, and the other end is connected with the contact finger of the isolating switch to be tested.

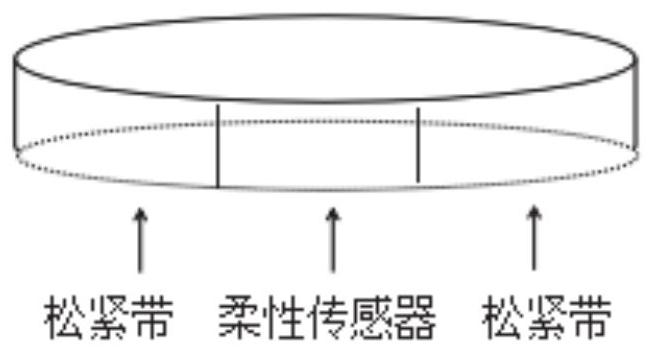

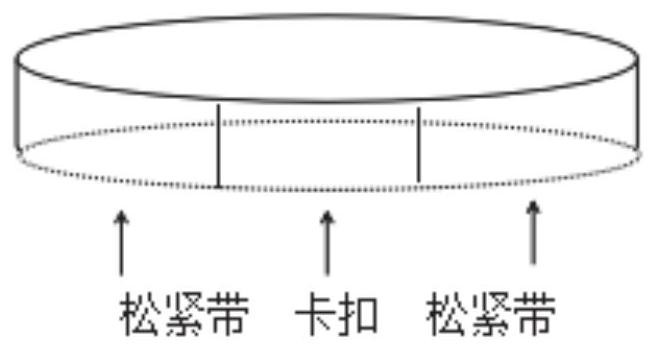

[0022] Further, the elastic member includes several elastic bands, including at least two circumferential elastic bands and multiple radial elastic bands; the two circumferential elastic bands are respectively the first circumferential elastic band and the second circumferential elastic band, and the first circumferential elastic band The elastic band is installed on o...

Embodiment 2

[0028] The present disclosure also provides a disconnector finger pressure tester, which uses the disconnector finger pressure sensor as described in the above-mentioned embodiments to perform a pressure test.

[0029] The pressure tester includes a display screen, which can display pressure distribution through the display screen and print test results through the printer.

Embodiment 3

[0031] A method for using a contact finger pressure sensor of an isolating switch, comprising:

[0032] The pressure sensor is connected with the contact finger of the isolating switch to be tested through the elastic part of the positioning structure, and is in the center state;

[0033] The position of the pressure sensor and the isolating switch to be tested is fixed by the clip of the positioning structure, so that the position of the detection process remains unchanged; it is fixed on the contact surface to be tested by the buckle and the elastic band, and the shape of the dynamic and static contact rod of the isolating switch is different during the test. , The angle of the contact surface is different, this sensor structure can prevent the sensor from falling off. To prevent artificial placement at the moment when the contact rod is closed, the center of the sensor is not necessarily at the center of the contact surface, causing measurement errors.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com