Civil aircraft product ground tester pressure system calibration method

A pressure system and calibration method technology, applied in the field of measurement, can solve the problems of pressure sensor signal line damage, low work efficiency, inconsistent calibration state and use state, etc., and achieve the effect of solving the inconsistent calibration state and working state and efficient calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

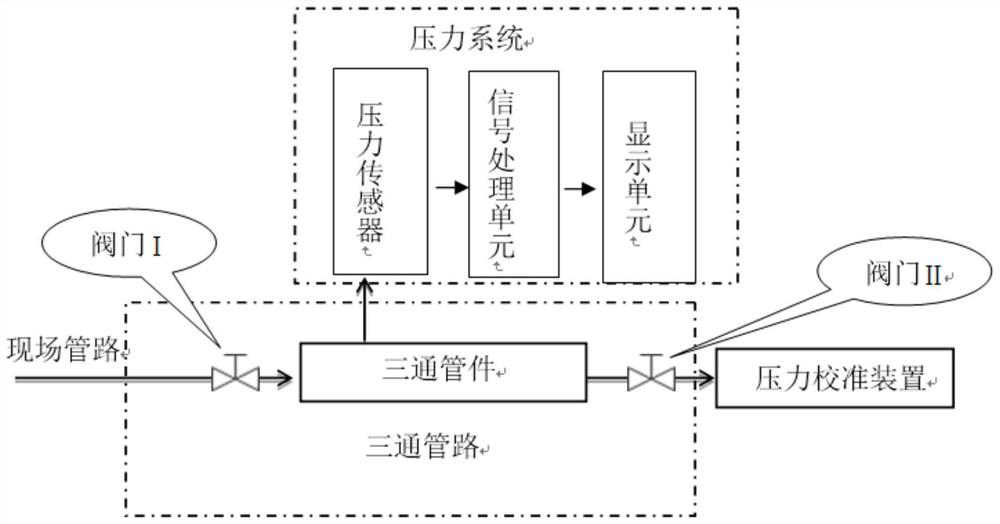

[0019] When the civil aircraft product ground tester has a three-way pipeline and does not have the conditions for autonomous operation, the calibration method of the present invention is used, taking a set of pressure systems with a measurement range of (0-1000) kPa and an accuracy of ±0.5% FS as an example.

[0020] 1. If figure 1 As shown, connect the pressure output port of the pressure calibration device to valve II and ensure a reliable seal.

[0021] 2. Adjust the valve to the calibration state (close valve I, open valve II).

[0022] 3. Pressurize to the upper limit of the pressure system (1000kPa) by the pressure calibration device, keep it for 1min, and observe the tightness of the whole system.

[0023] 4. Stable pressurization by the pressure calibration device to each calibration point (0kPa, 200kPa, 400kPa, 600kPa, 800kPa, 1000kPa) to the upper limit of the range, and then reverse calibration until the pressure drops to the lower limit of the range

[0024] 5. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com