A Calculation Method of Actual Mining Thickness in Underground Coal Gasification

A technology of underground gasification and calculation method, which is applied in the direction of applying stable tension/pressure to test the strength of materials, instruments, measuring devices, etc., can solve problems such as the underground gasification of coal that has not been calculated yet, and improve the development height of overlying fissures and surface movement and deformation prediction accuracy, reduce redundancy waste, and improve the effect of recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

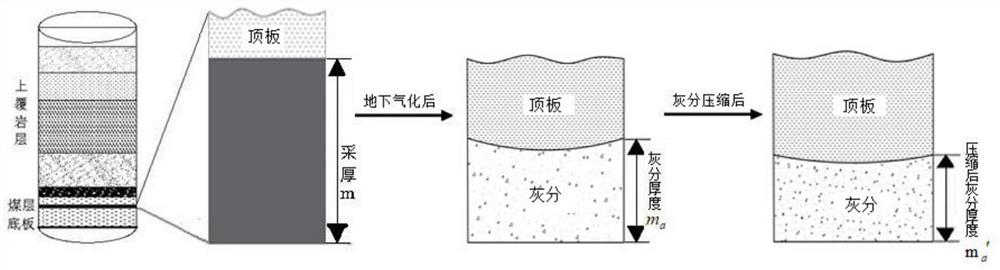

[0025] Step 1: For the underground coal gasification area, collect relevant data such as the geological mining conditions of the research area and the physical, chemical and mechanical properties of the coal, and understand the underground coal gasification process and the product types after gasification;

[0026] Step 2: According to the collected data, determine the thickness of the coal seam to be 3m, and determine the average ash content of the coal to be 30% according to the properties and composition of the coal seam, then the ash content thickness of the coal can be calculated m a for:

[0027] m a =0.9m;

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com