Three-dimensional magnetic flux leakage imaging detector in multi-section combined pipeline

A combination and detector technology, which is applied in the direction of instruments, measuring devices, and measuring distances, can solve the problems of detectors not working properly, slow propulsion speed, and small flow, so as to avoid equipment malfunctioning, improve battery life, The effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

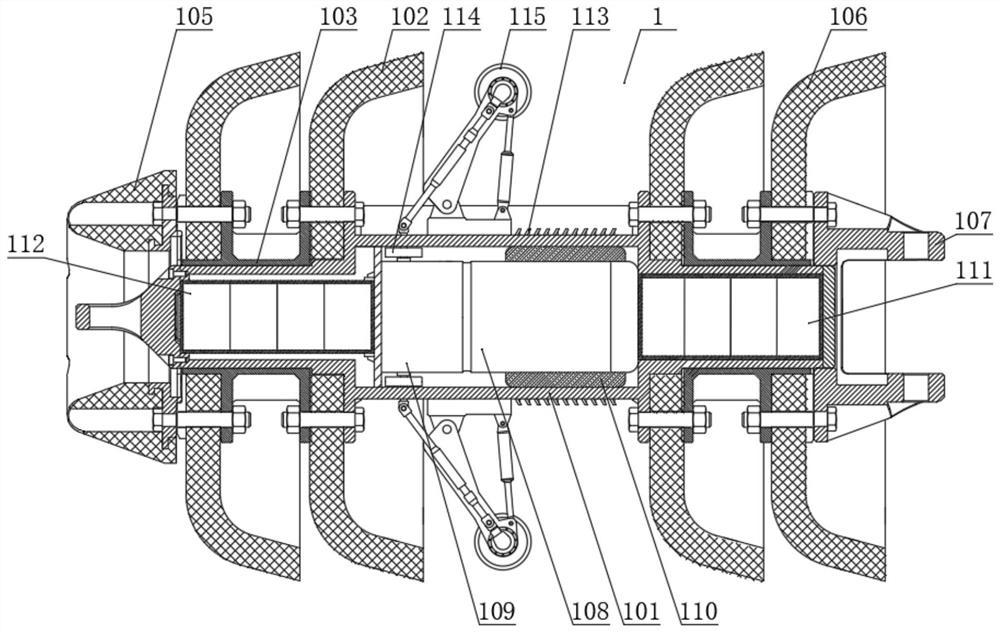

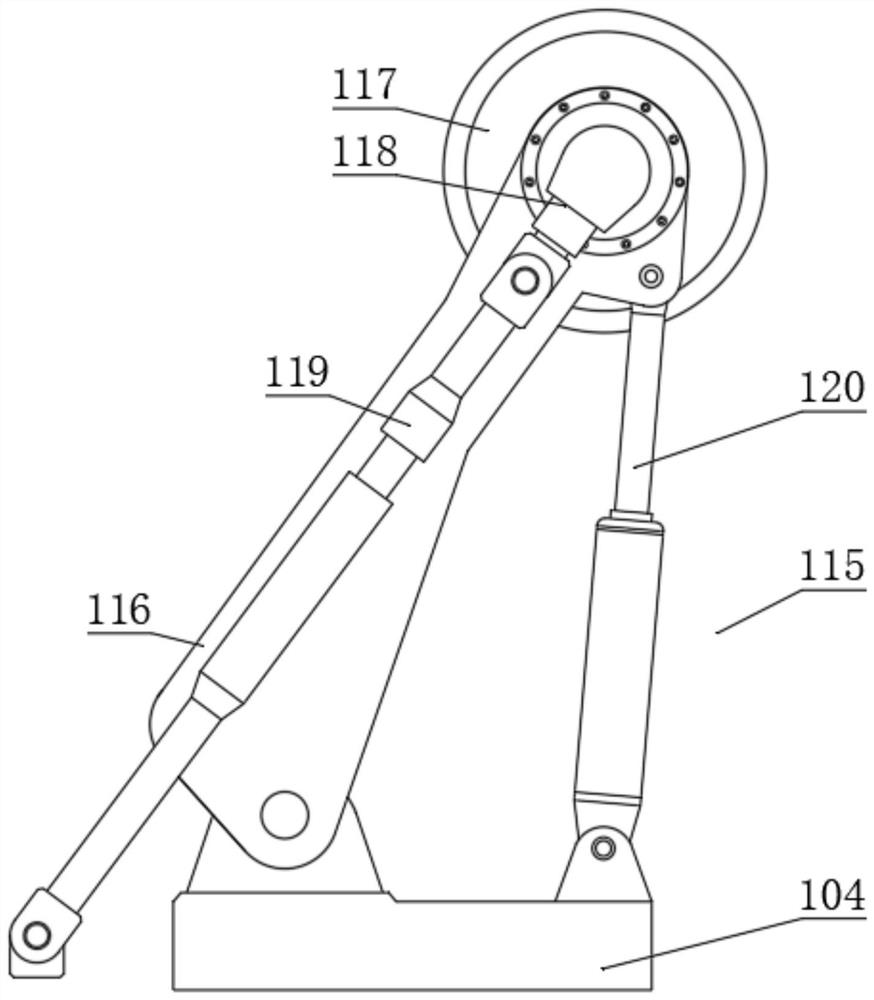

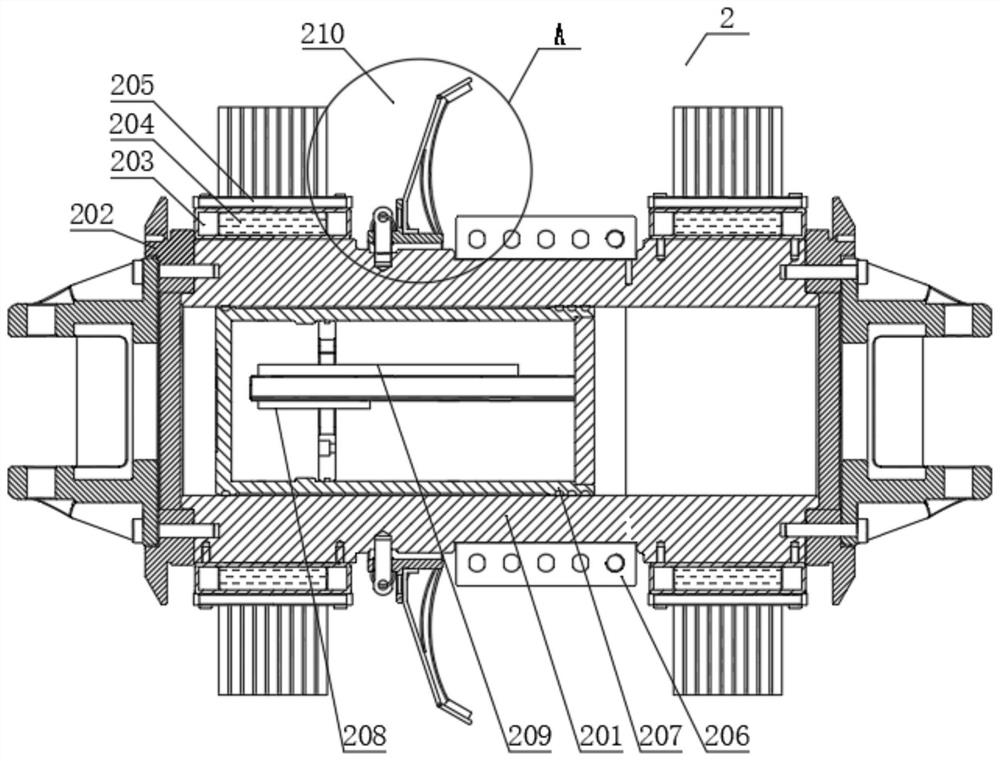

[0031] The multi-section combined three-dimensional magnetic flux leakage imaging detector in the pipeline includes a drive section assembly 1, a detection section assembly 2, an IO / DO detection section assembly 3, and a mileage wheel assembly 4, which are sequentially connected along the advancing direction of the detector. The second end of 1 and the second end of the detection section assembly 2 are hinged with a coupling assembly 5, such as Figure 8 As shown, the coupling assembly 5 includes a coupling rod 501 and two coupling housings 502, a first pin hole 503 is opened on the top of one end of the coupling housing 502, and a first pin hole 503 is opened on the side of the other end of the coupling housing 502. There is a second pin hole 504, the first pin hole 503 and the second pin hole 504 are perpendicular to each other, the second pin holes 504 of the two coupling seats 502 are all pierced with a pin shaft and connected to the connecting shaft through the pin shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com