A kind of rice shelling equipment for food factory

A factory and rice technology, applied in the field of rice shelling equipment used in food factories, can solve the problems of poor shelling effect, waste, rice crushing, etc., and achieve the effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

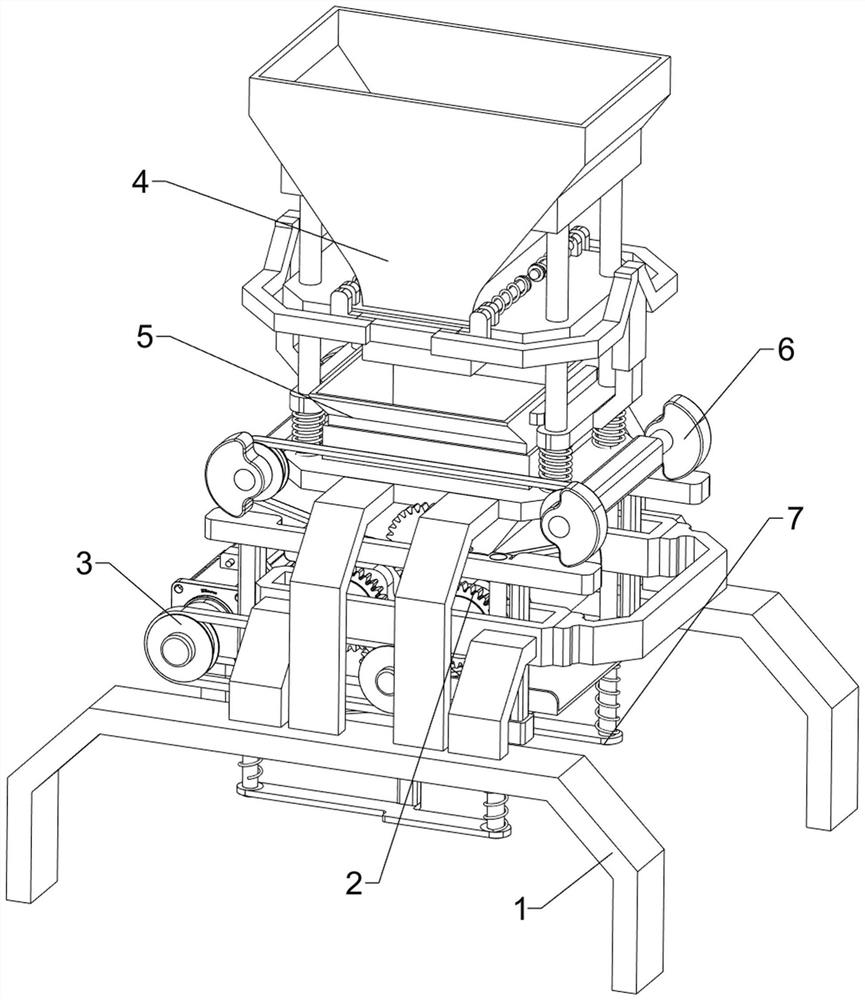

[0051] A rice shelling equipment for food factories, such as figure 1 As shown, it includes a base 1 , a grinding mechanism 2 and a driving mechanism 3 . The top of the base 1 is provided with a grinding mechanism 2 , and a driving mechanism 3 is connected between the grinding mechanism 2 and the base 1 .

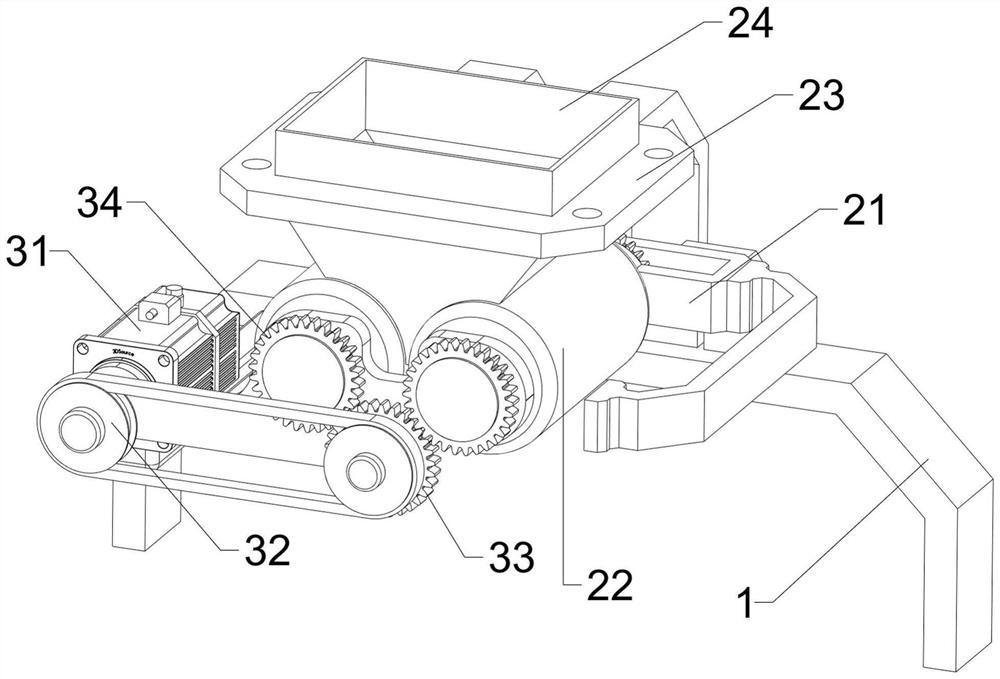

[0052] like figure 2 As shown, the grinding mechanism 2 includes a first mounting frame 21, a roller 22, a second mounting frame 23 and a funnel 24, the top of the base 1 is provided with a first mounting frame 21, and the first mounting frame 21 is provided with a left-right symmetrical rotating The roller 22, the top rear side of the first mounting frame 21 is provided with a second mounting frame 23, and the second mounting frame 23 is provided with a funnel 24.

[0053] like figure 2 As shown, the drive mechanism 3 includes a motor 31, a first transmission assembly 32, a first gear 33 and a second gear 34, a motor 31 is provided on the left side of the top of the ba...

Embodiment 2

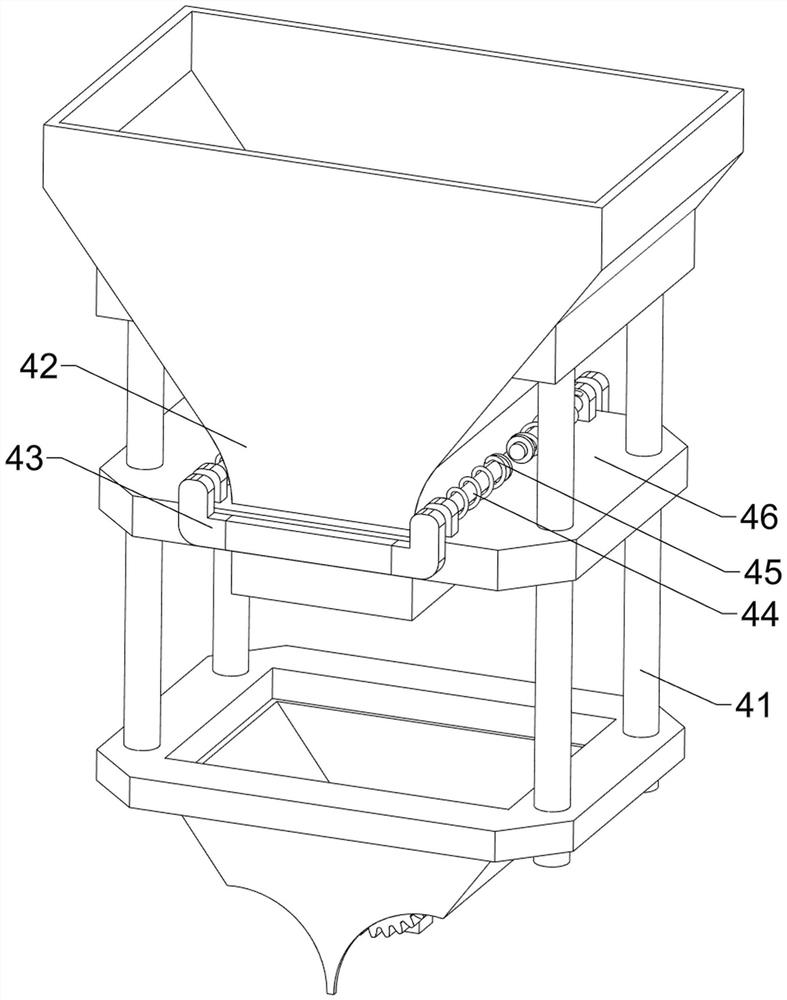

[0056] On the basis of Example 1, as image 3 As shown, it also includes a storage mechanism 4. The storage mechanism 4 includes a mounting column 41, a storage bin 42, a first baffle 43, a first guide rod 44, a first spring 45 and a fixed plate 46. The top of the funnel 24 The left and right sides are symmetrically provided with mounting posts 41 in the front and rear. A storage bin 42 is connected between the tops of the mounting posts 41, and a fixed plate 46 is connected between the upper sides of the mounting posts 41. The storage bin 42 passes through the fixed plate 46, and the fixed plate The left and right sides of the top of the 46 are provided with first guide rods 44 in a front and rear symmetrical sliding type. A first spring 45 is connected.

[0057] When the rice is shelled, the staff can also pour the unshelled rice into the storage bin 42. When there is no rice in the funnel 24, the first baffles 43 on the front and rear sides can be pulled to move to the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com