Large porcelain bottle carrying and cleaning equipment

A technology for cleaning equipment and porcelain bottles, applied in the directions of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of slow work efficiency, easy damage to large porcelain bottles, high labor costs, and achieve the effect of pulling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

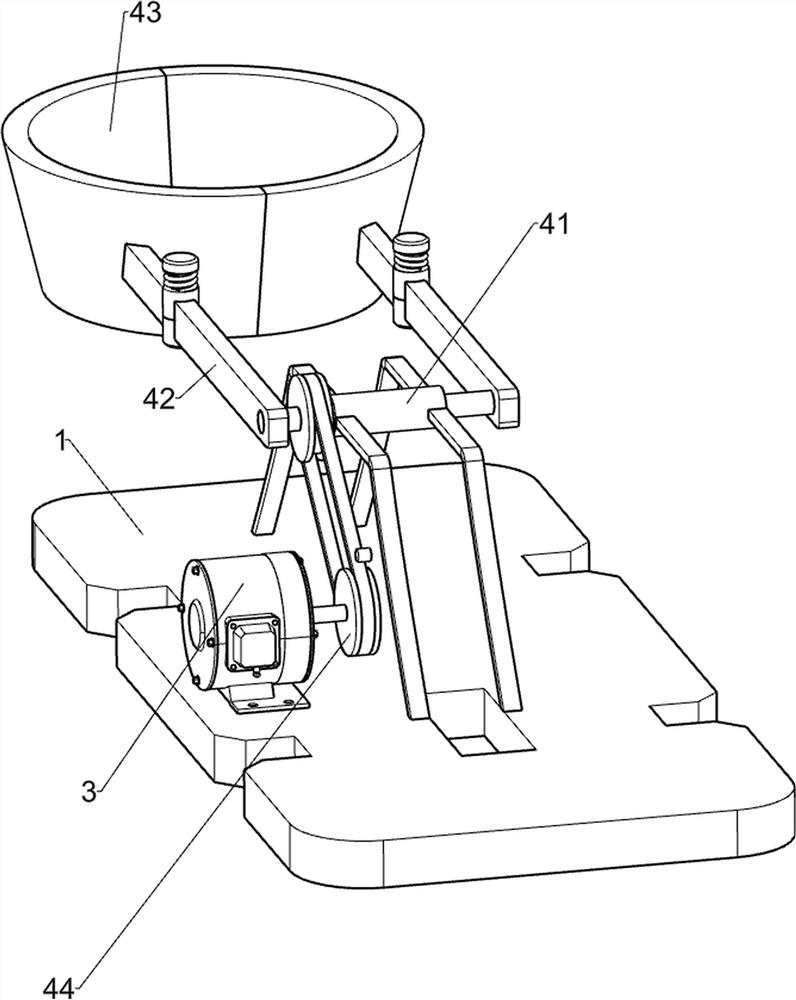

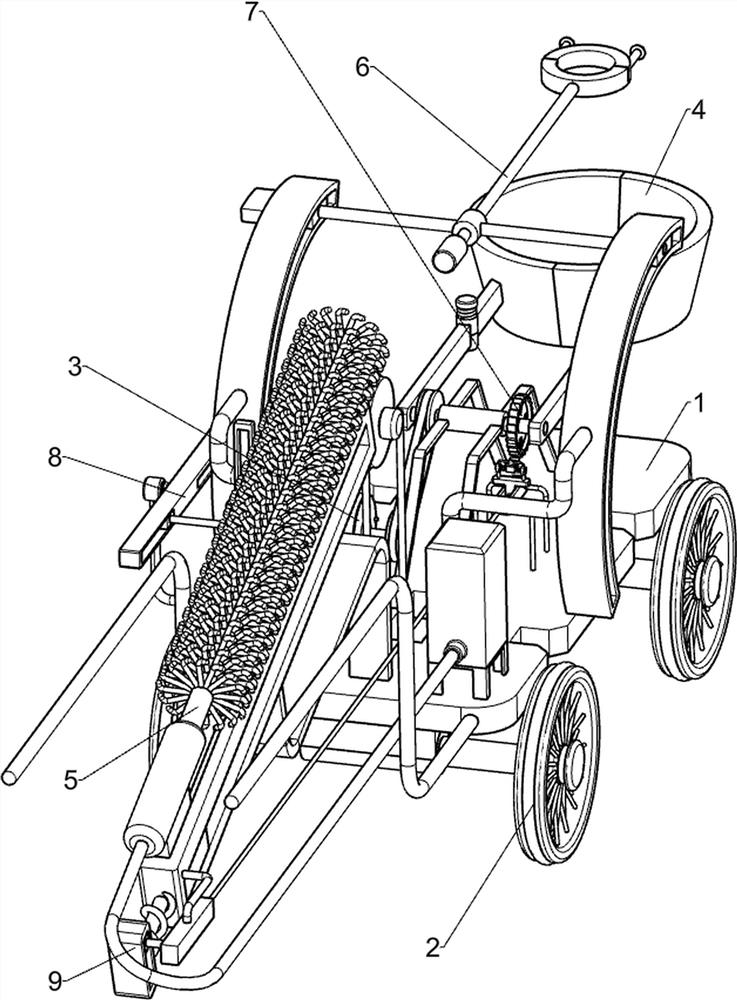

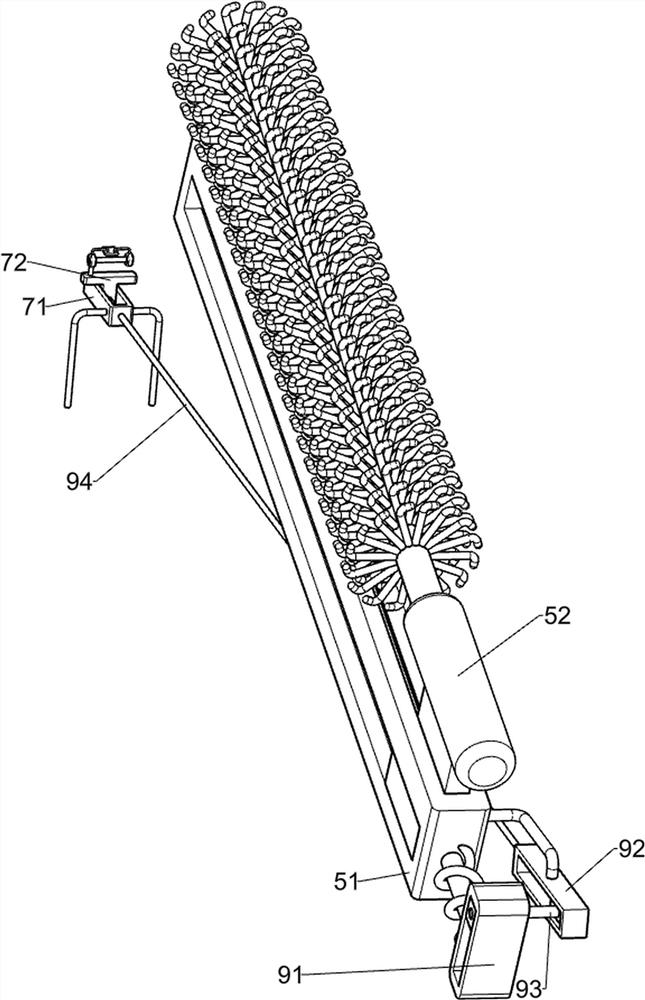

[0060] A large porcelain bottle handling and cleaning equipment, such as figure 1 As shown, it includes base plate 1, moving assembly 2, motor 3, clamping and lifting mechanism 4 and cleaning mechanism 5. The lower part of base plate 1 is provided with moving assembly 2. A clamping and lifting mechanism 4 is provided in the middle, and a cleaning mechanism 5 is provided on the front side of the bottom plate 1 .

[0061] When people want to clean large porcelain bottles, they can use this large porcelain bottle handling and cleaning equipment. First, the user pushes the device, and the moving component 2 drives the device to move to the vicinity of the large porcelain bottle, and then places the large porcelain bottle on the clamping and lifting In the mechanism 4, the motor 3 is started, and the output shaft of the motor 3 drives the cleaning mechanism 5 to operate to clean the large porcelain bottle to realize the cleaning effect of transportation.

Embodiment 2

[0063] On the basis of Example 1, such as figure 2 and image 3As shown, the clamping and lifting mechanism 4 includes a first rotating sleeve 41, a lifting rod 42, a clamping assembly 43 and a transmission assembly 44. The upper and middle part of the bottom plate 1 is rotatably provided with a first rotating sleeve 41. The first rotating sleeve 41 has two left and right sides. Lifting rods 42 are provided on both sides, a clamping assembly 43 is arranged between the rear sides of the two lifting rods 42 , and a transmission assembly 44 is connected between the output shaft of the motor 3 and the first rotating sleeve 41 .

[0064] The user places the large porcelain bottle in the clamping assembly 43, the clamping assembly 43 clamps the large porcelain bottle, starts the motor 3, and the output shaft of the motor 3 drives the transmission assembly 44 to rotate, thereby driving the first rotating sleeve 41 to rotate, thereby driving the lifting The rod 42 moves upward, and ...

Embodiment 3

[0068] On the basis of Example 2, as Figure 4-Figure 7 As shown, it also includes a fixed guide mechanism 6, and a fixed guide mechanism 6 is provided on the front side of the bottom plate 1. The fixed guide mechanism 6 includes a second guide sleeve 61, a guide block assembly 62 and a fixed assembly 63. The front side of the bottom plate 1 is left and right. Both parts are provided with second guide sleeves 61 , a guide block assembly 62 is slidably disposed between the upper portions of the rear sides of the two second guide sleeves 61 , and a fixed assembly 63 is disposed in the middle of the guide block assembly 62 .

[0069] After the large porcelain bottle is placed in the clamping assembly 43, the fixing assembly 63 fixes the upper part of the large porcelain bottle. When the guide block assembly 62 moves downward, the fixing assembly 63 is driven to move downward, and the large porcelain bottle is further driven to move downward to achieve With the guiding effect, whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com