Explosive bolt automatic mounting equipment

A technology of explosive bolts and automatic installation, which is applied to metal processing equipment, metal processing, manufacturing tools, etc., can solve problems such as low work efficiency, high labor costs, and difficult construction, so as to improve construction efficiency, reduce construction costs, and improve The effect of installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

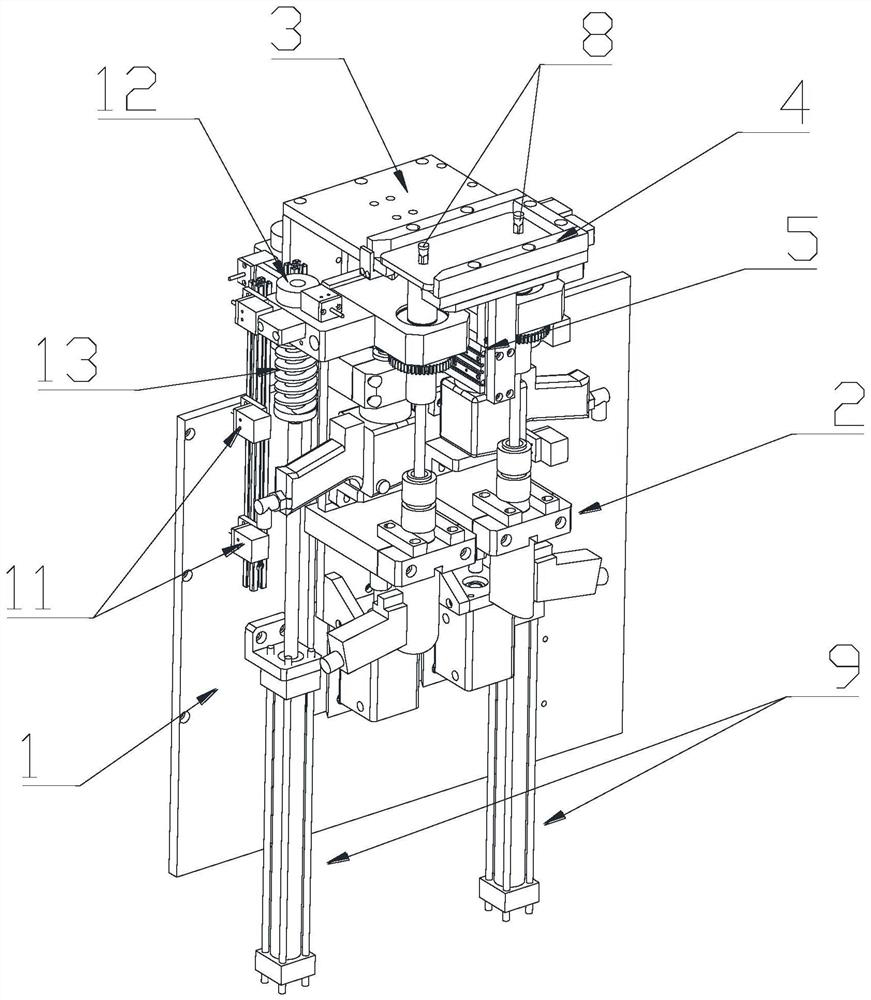

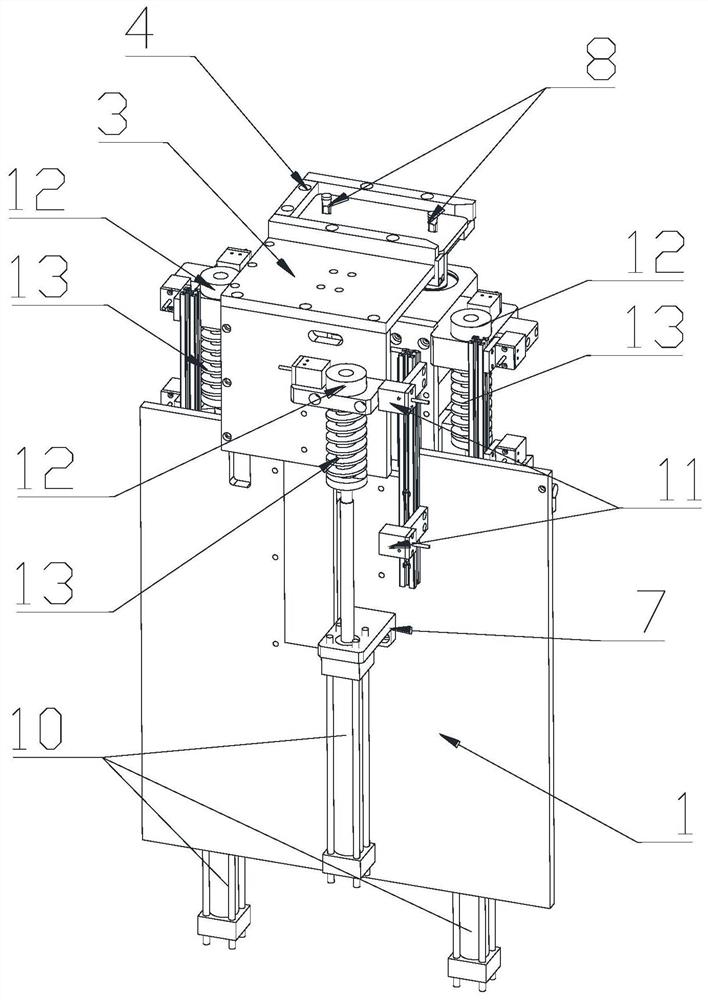

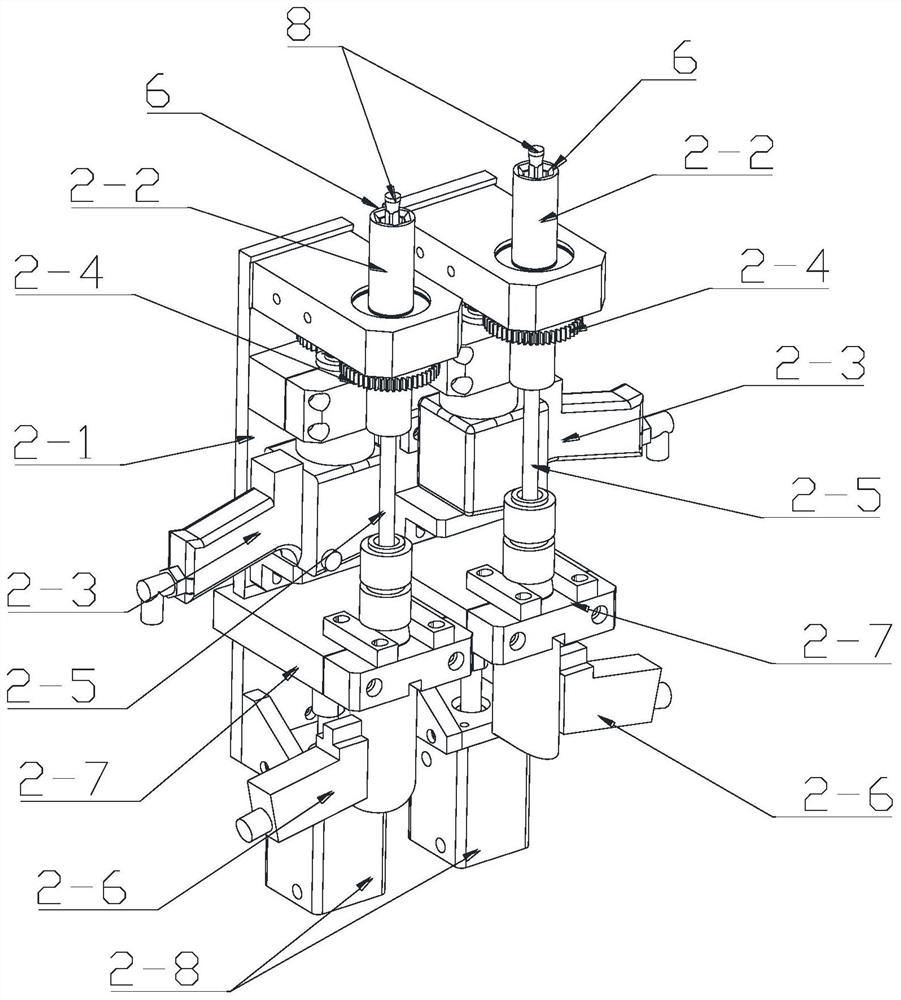

[0024] see Figure 1-Figure 7 , the automatic installation equipment for fasteners applying the automatic installation equipment for explosive bolts of the present invention includes a frame 1, a fastener lifting module arranged on the frame 1 for driving the fasteners to move linearly to the position to be installed, and The automatic installation device 2 for explosive bolts of the present invention for installing the fasteners on the bolt holes, wherein the fasteners are equipped with explosive bolts 8, and the explosive bolts 8 are sleeved on the fasteners On, the lower end of the explosive bolt 8 is provided with a nut.

[0025] The fastener lifting module includes a connecting frame 3, a positioning seat 4 arranged on the connecting frame 3, and a lifting drive mechanism 7 for driving the positioning seat 4 to perform linear motion, wherein, the positioning seat 4 is provided below There is a clamping mechanism 5 for clamping an explosive bolt 8 in a fastener located on...

Embodiment 2

[0049] The difference between this embodiment and Embodiment 1 is that the frame 1 is a hand-held bracket, so that the automatic bolt installation device can be similar to a hand-held electric drill, so that the automatic bolt installation device of the present invention can be operated Hand-held by personnel, compared with traditional wind guns, the automatic bolt installation device of the present invention can drive the explosive bolts 8 into the corresponding installation positions respectively, and then lock the explosive bolts 8 at the installation positions , the whole action is done in one go, and there is no need to replace equipment halfway, which greatly improves work efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com