Auxiliary equipment for material distribution of precast slab and processing technology thereof

A technology of auxiliary equipment and prefabricated slabs, which is applied in the direction of auxiliary forming equipment, manufacturing tools, ceramic forming machines, etc., can solve the problems affecting the superimposition effect of prefabricated slabs and cast-in-place concrete layers and the strength of laminated floors, so as to achieve easy adjustment, The effect of easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

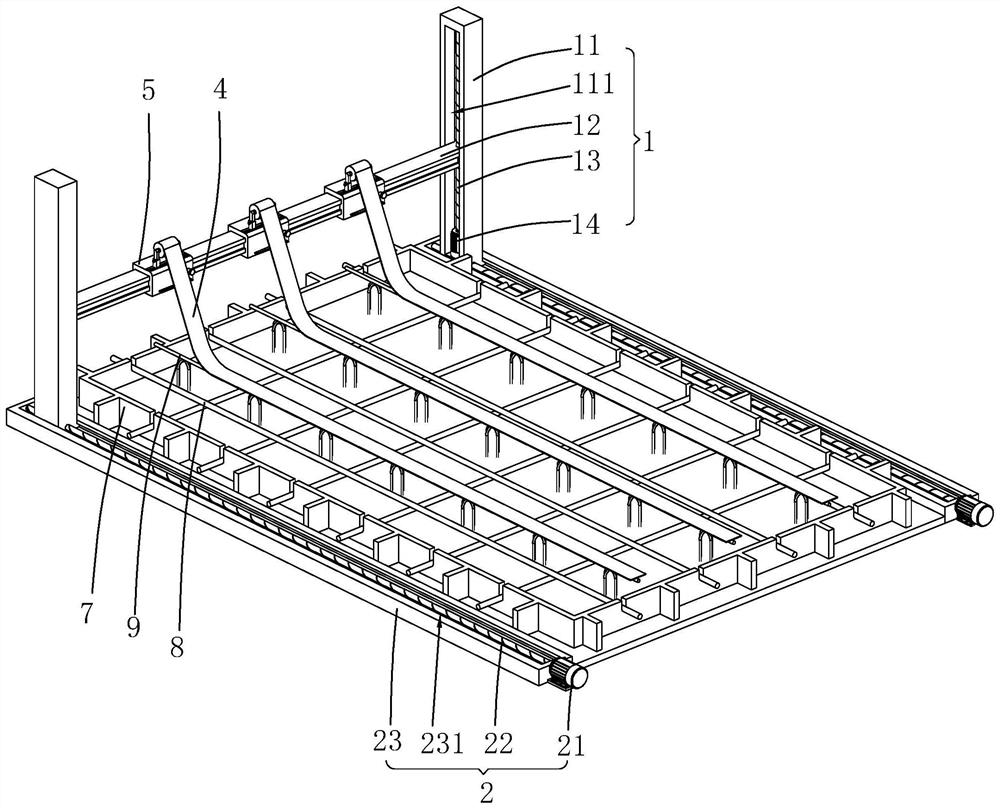

[0039]The following is attached Figure 1-2 The application is described in further detail.

[0040] When processing the bottom slab of prefabricated laminated slabs, first assemble the mold 7 on the workbench, and set up criss-cross and vertical embedded steel bars 8 on the mold 7, as well as truss steel bars 9 connected by steel bar seats. The embedded steel bars 8 are located in the mold 7 inside, the distance between the truss reinforcement 9 and the workbench is greater than the height of the mold 7 . After the mold 7 is assembled and the embedded steel bar 8 and the truss steel bar 9 are installed, concrete needs to be poured into the mold 7 .

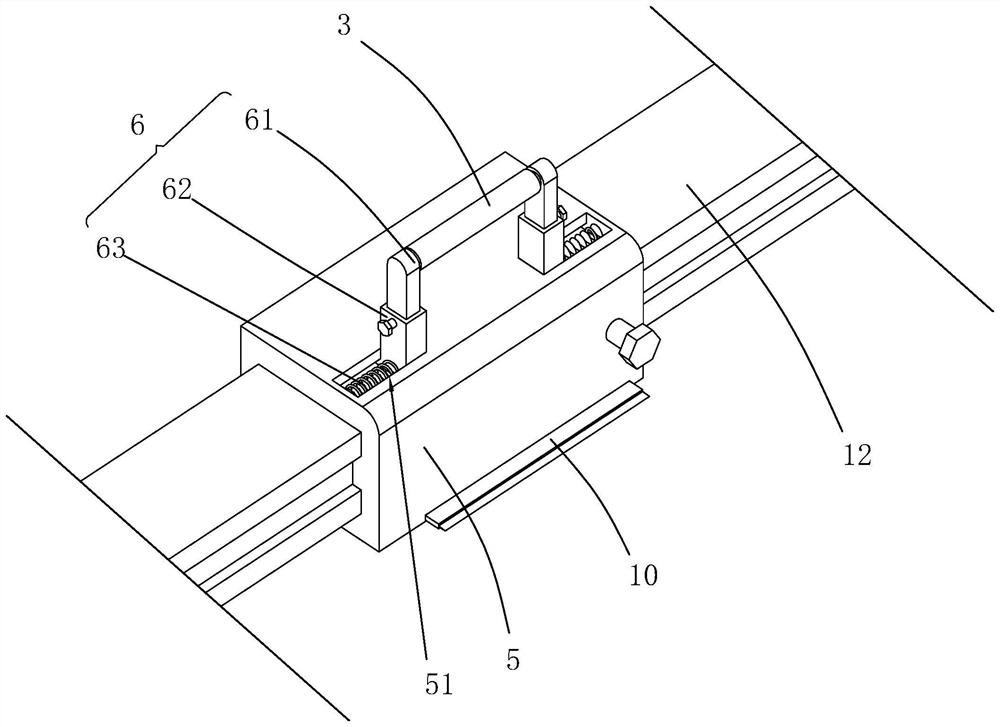

[0041] The embodiment of the present application discloses an auxiliary device for distributing prefabricated slabs, which is used after the truss reinforcement 9 is installed and before the concrete is poured. refer to figure 1 , Auxiliary equipment for prefabricated panel distribution includes a driving mechanism 2 , a suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com