Cable terminal pressing mechanism

A technology for crimping terminals and cables, which is applied in the field of secondary wire complete processing, which can solve the problems of increasing production management difficulty and production cost, occupying space and personnel, and low price, and achieves stable and reliable linkage effect, reduces labor intensity, The effect of fewer parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

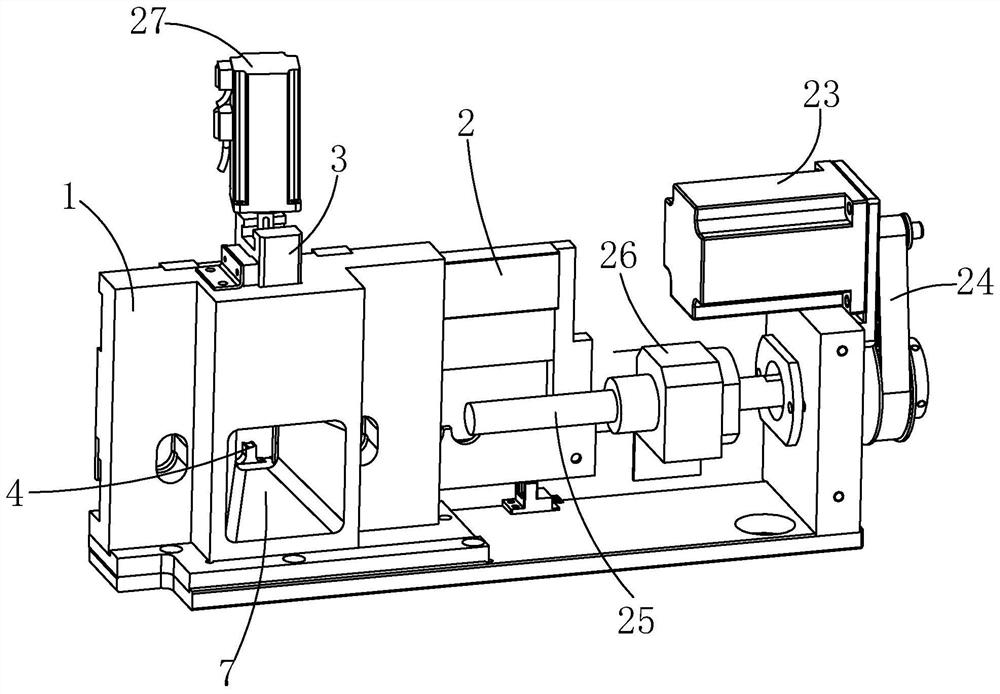

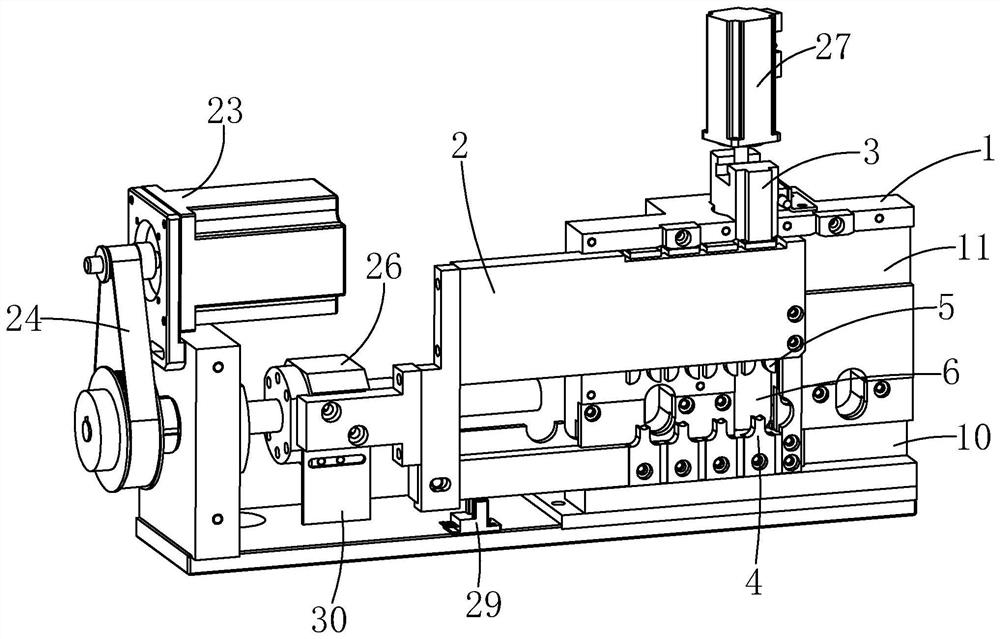

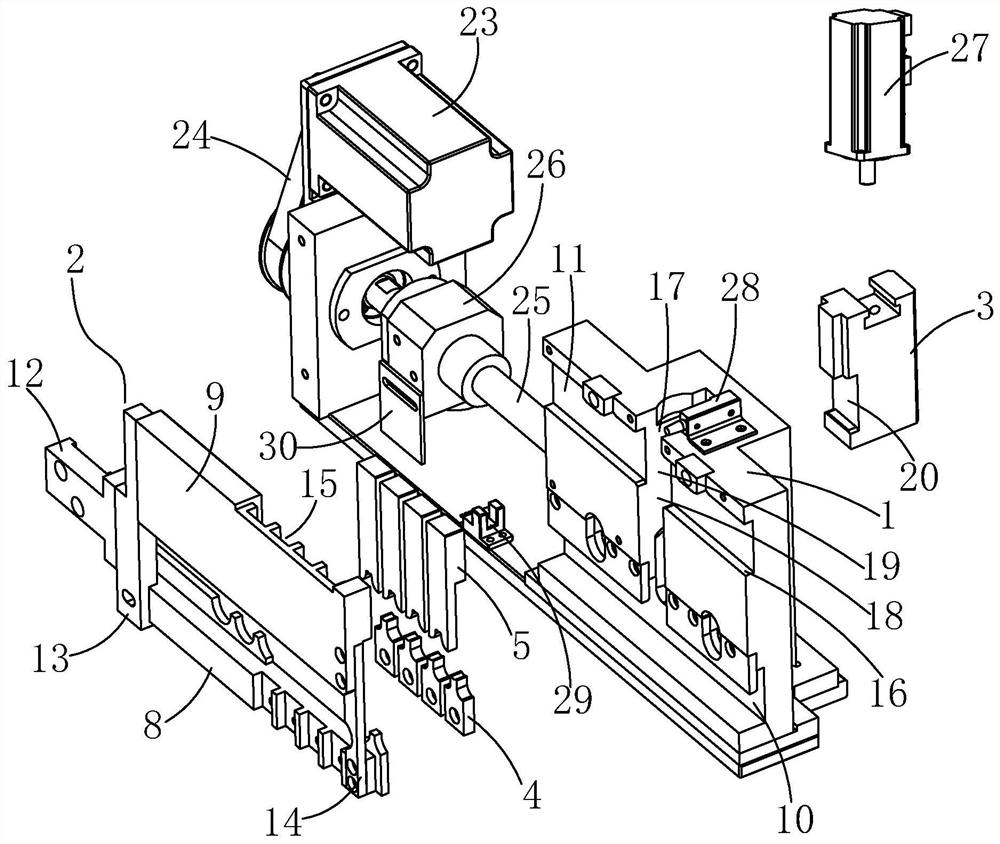

[0037] refer to Figure 1 to Figure 9 , a cable crimping terminal mechanism, including a fixed frame 1, a movable frame 2 movably arranged in the fixed frame 1, a first driving device acting on the movable frame 2, several cutter assemblies arranged on the movable frame 2, A drive block 3 that is movably arranged on the fixed frame 1 and used to drive the cutter assembly, and a second drive device that acts on the drive block 3;

[0038] The cutter assembly includes several sets of one-to-one corresponding lower knife assemblies 4 and upper knife assemblies 5, a storage gap 6 is provided between the lower knife assemblies 4 and upper knife assemblies 5, and the drive block 3 can It is connected with the transmission of the upper knife assembly 5;

[0039] The fixed frame 1 is provided with several sockets 7, and the sockets 7 are ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com