Automatic cleaning system for electrical cabinet cleaning

A technology for automatic cleaning and electrical cabinets, applied in the direction of using liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve the inconvenience of manual cleaning of electrical cabinets, etc., to save costs, reduce failure rates, and ensure stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

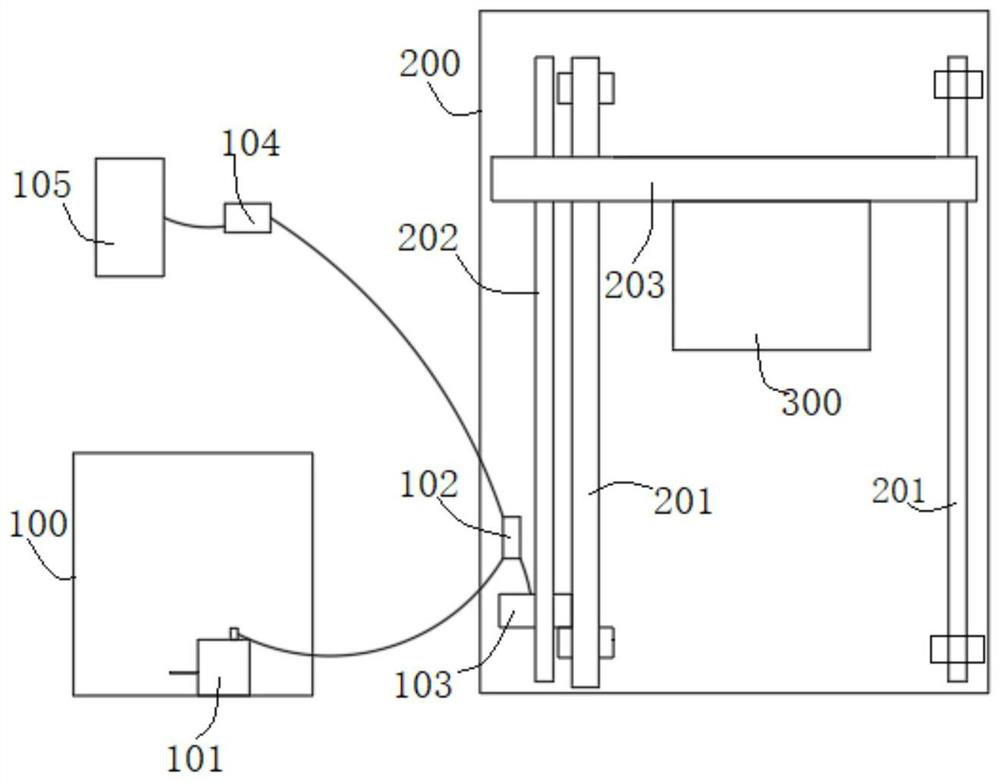

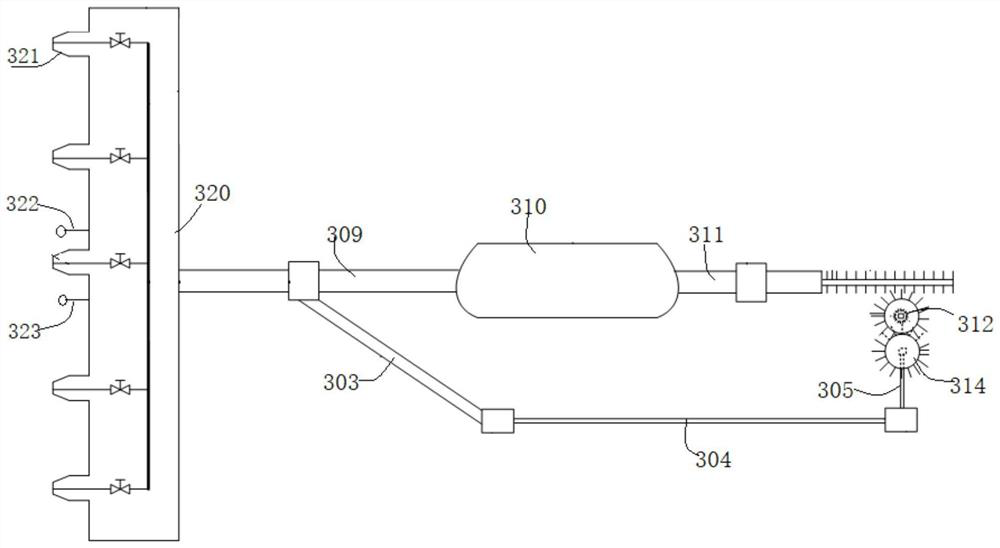

[0035] Such as Figure 1-Figure 4 As shown, an automatic cleaning system for cleaning electrical cabinets in this embodiment includes a cleaning unit 200. The cleaning unit 200 includes transmission belts 201 distributed on both sides along the height direction of the electrical cabinet and used for transmission. The transmission belts 201 on both sides are arranged There is a crossbeam 203, which can be fastened by screws between the concrete crossbeam 203 and the transmission belt 201; the crossbeam 203 is provided with multiple groups of shower heads 320, and each group of nozzle holders 320 is provided with at least one nozzle 321, and the transmission belt 201 is used to drive the crossbeam 203 and The nozzles 321 rise and fall along the height direction; each group of nozzle holders 320 is also equipped with a temperature sensor 322 and a density sensor 323, which are specifically temperature sensors and density sensors for air detection, and are used to detect the intern...

Embodiment 2

[0049] An automatic cleaning system for cleaning electrical cabinets in this embodiment is basically the same as in Embodiment 1. Further, an infrared thermal imager is also provided on the beam 203 for subsequent inspections. In actual use, step S3 follows After the first cleaning of the quality of the cleaning solution that fits the information, an infrared thermal imager is used to inspect the electrical cabinet again, and the temperature and density information of the grid area that is still heating is detected again, and its temperature rise is compared with the initial Compared with the temperature rise, if the error is less than 3%, the cleaning is up to standard; if the error is still greater than 3%, continue to clean according to the quality of the cleaning solution that is not less than the fitting, and if the grid area still cannot meet the standard after 3 inspections, record The location information judges the failure of the grid area, which is used for confirmati...

Embodiment 3

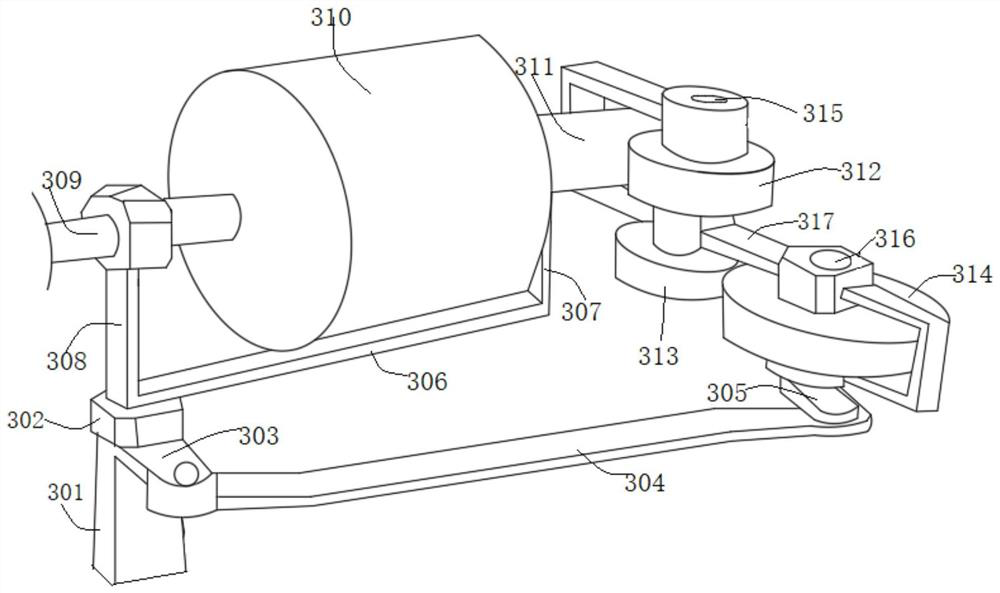

[0051] An automatic cleaning system for cleaning electrical cabinets in this embodiment is basically the same as in Embodiment 2. Furthermore, in this embodiment, the beam 203 is also provided with a nozzle adjustment unit for adjusting the spray angle of each group of nozzle holders 320 300, so that during spray cleaning, the spray angle can be flexibly adjusted to achieve a better spray effect. Specifically, the nozzle adjustment unit 300 can be driven by a motor, and the output shaft end of the motor is connected to the nozzle frame 320. By controlling the motor The angle of the nozzle holder 320 can be reversed by forward and reverse rotation, so as to realize the change of the angle of spray cleaning and meet the needs of actual use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com