A tile screen printing machine mesh cleaning and adsorption equipment

A screen printing machine mesh and adsorption equipment technology, applied to printing machines, general parts of printing machinery, printing, etc., can solve problems such as harsh working environment, low safety factor, inaccurate timing of cleaning, etc., to reduce The effect of human labor intensity, improvement of cleaning effect, and good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

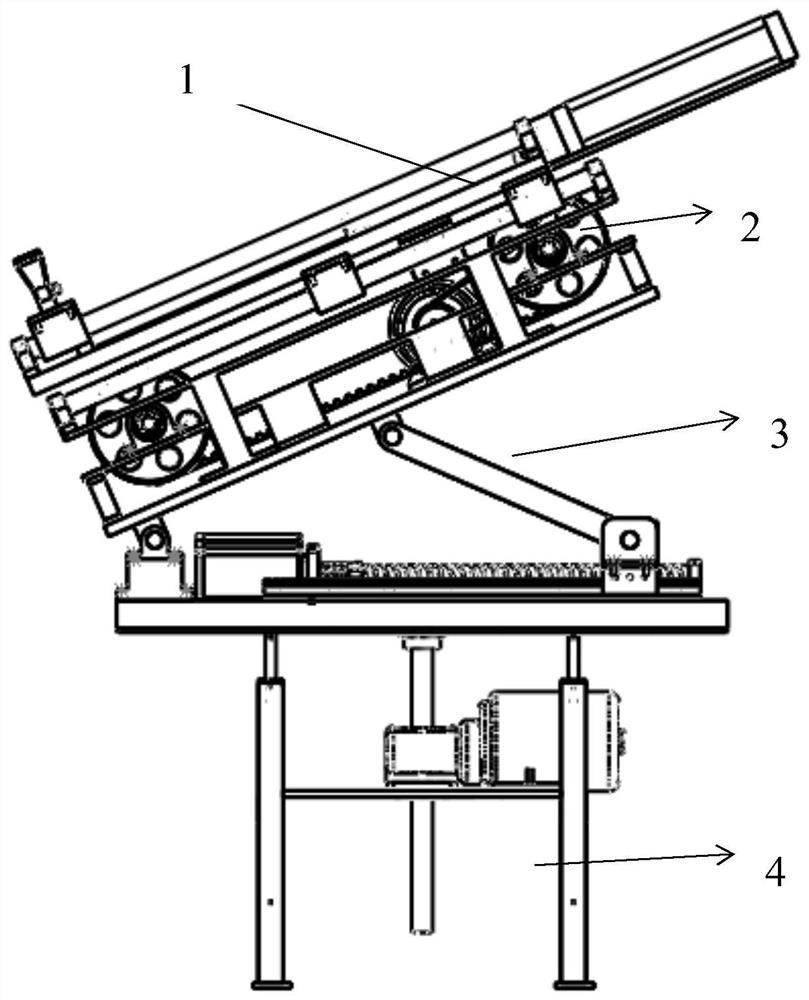

[0036] like Figure 1 to Figure 6 As shown, the present embodiment is a mesh cleaning and adsorption device for a ceramic tile screen printing machine, including:

[0037] A cleaning and adsorption device 1 for cleaning and vacuum adsorption cleaning of the screen printing screen;

[0038] A transmission device 2 for moving the cleaning adsorption device 1 along the length or width direction of the screen;

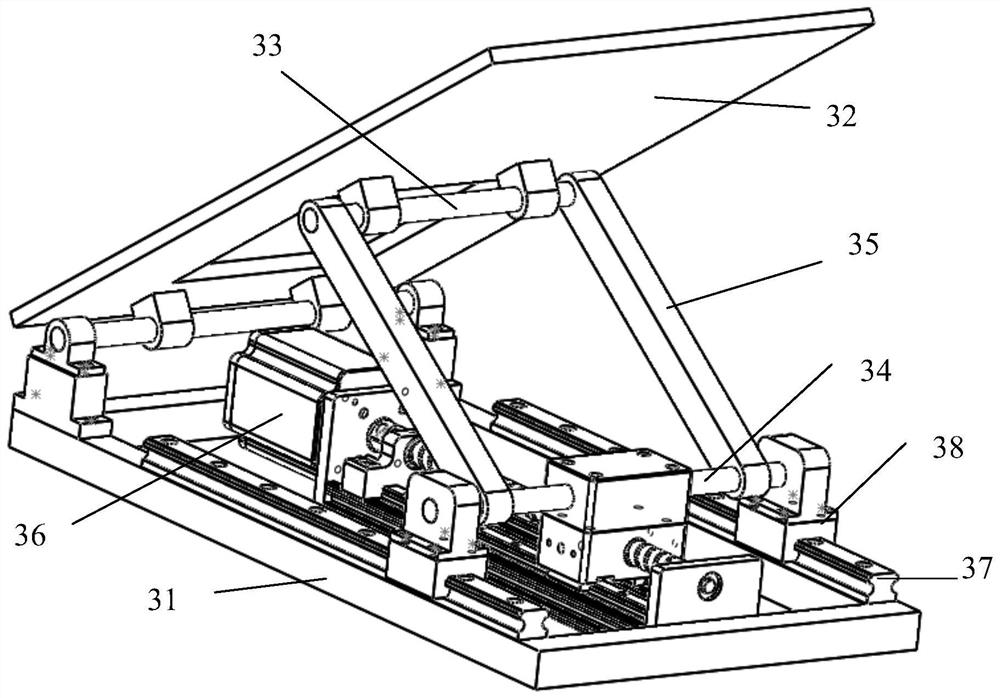

[0039] A rotary lifting device 3 for realizing rotary lifting;

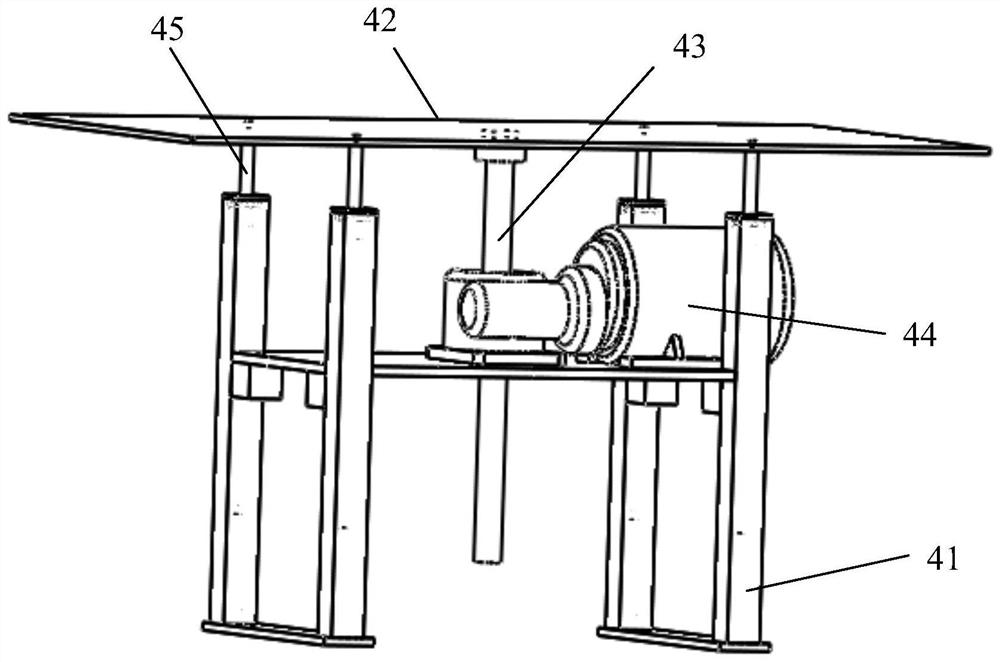

[0040] and a lifting device 4 for lifting and lowering;

[0041]The rotating lifting device 3 is arranged on the lifting device 4 to realize the lifting and lowering of the rotating lifting device 3; the transmission device 2 is arranged on the rotating lifting device 3 to realize the rotating and lifting of the transmission device 2; the cleaning adsorption device 1 is slidably arranged on the rotating lifting device 3, and connected with the transmission device 2, so that the cleaning and adsorption devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com