Rough rolling pass system for flexible rolling of H-shaped steel and rolling method

A rough rolling pass, flexible rolling technology, applied in metal rolling, metal rolling, metal rolling stands, etc., can solve the problems of frequent roll changes and high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

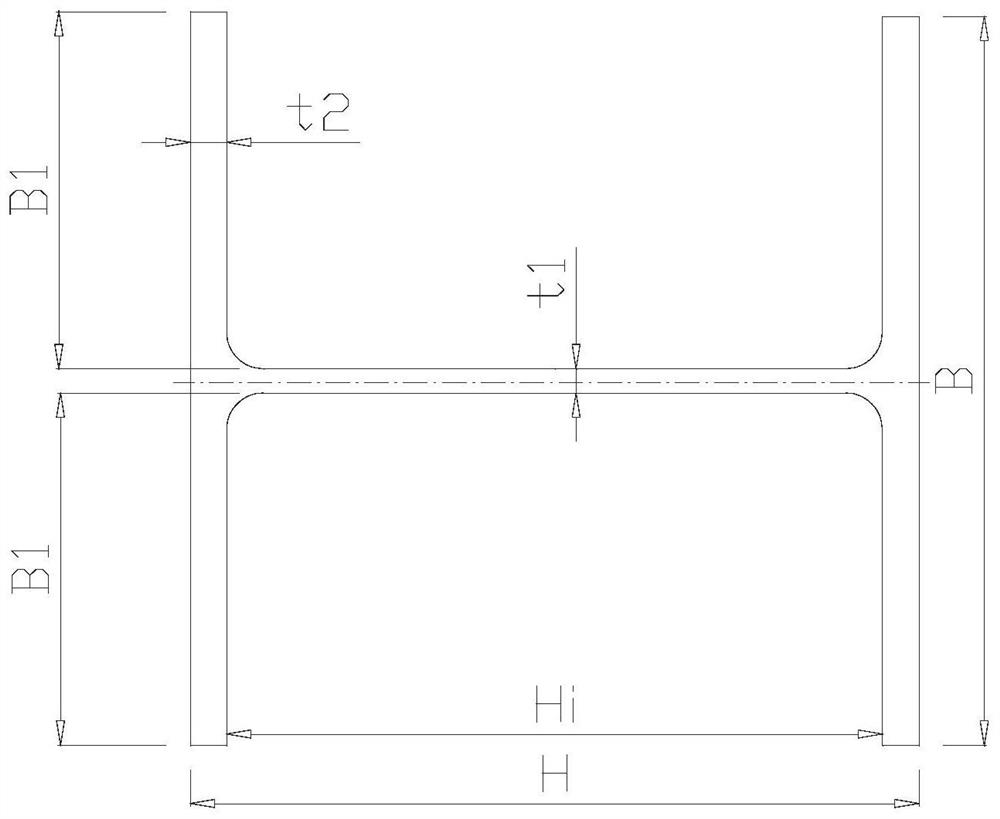

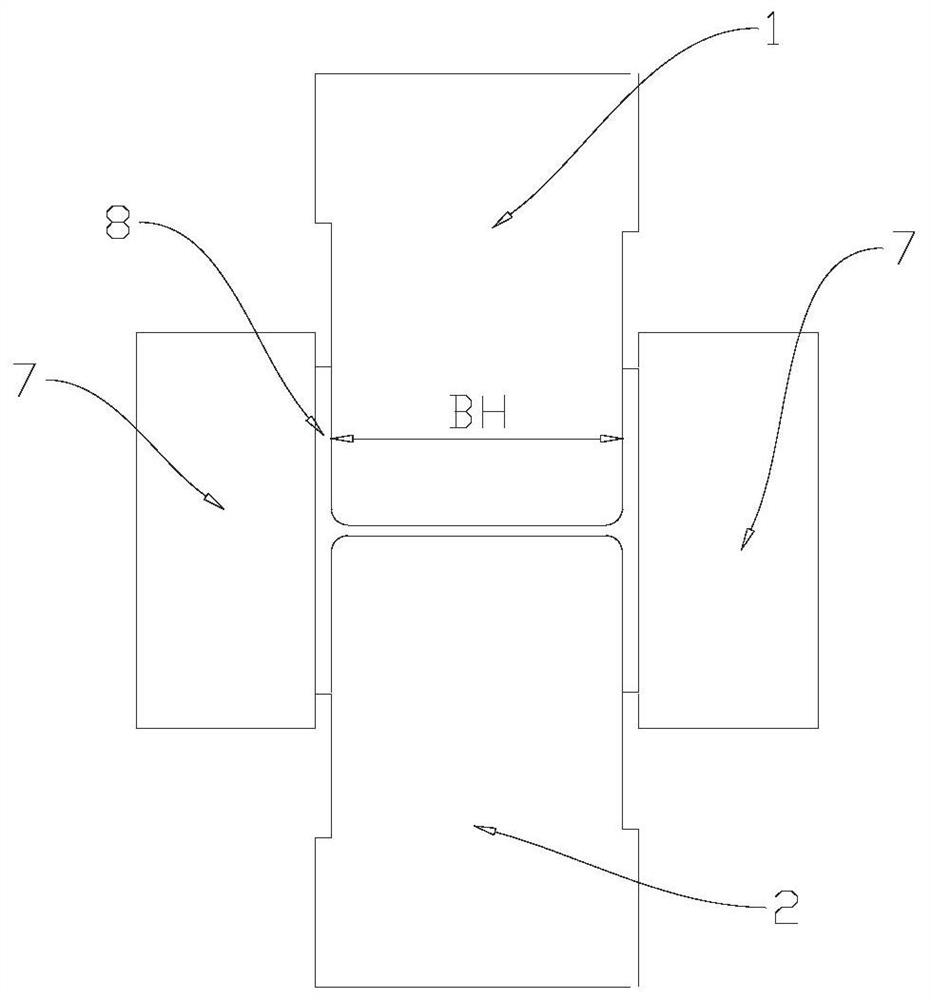

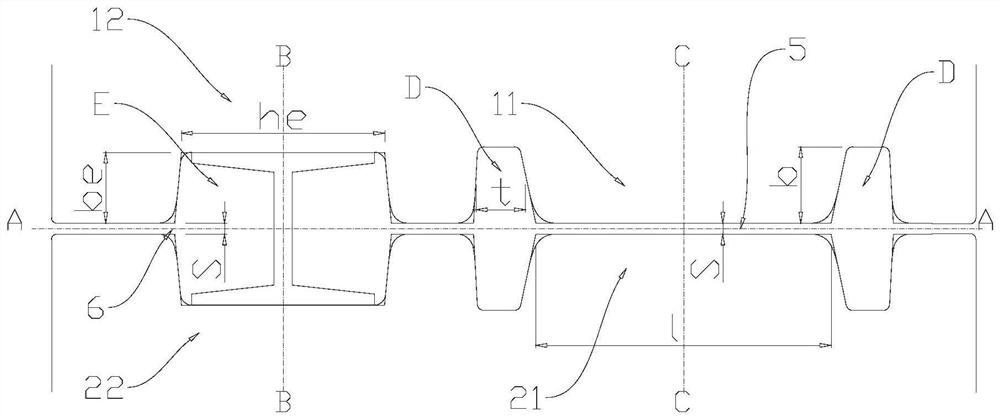

[0053] Two-roll mills are used for rough rolling, universal rolling mills and edgers are used for finishing mills, special-shaped billets are used for steel billets, and the models of H-beams are H300×300, H390×300, and H440×300. The pass system provided by the present invention is composed of a flat rolling pass D and a vertical rolling pass E. The rolling groove depth b of the flat rolling pass is 138mm; the height of the inner side of the web of the flat rolling pass is l=397; The rolling groove width t=97mm, the groove bottom width he=320mm of the vertical rolling pass; the rolling groove depth of the vertical rolling pass is 120mm.

[0054] The rolling method of the H-shaped steel based on the above-mentioned rough rolling mill pass system may further comprise the steps:

[0055] 1) Heating: Put the profiled blank into a heating furnace for heating, the heating temperature is controlled at 1250°C to 1280°C, the heating time is 2 to 4 hours, and then it is taken out of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com