MOBILE ground WORKING MACHINE, COMPRISING A FUNCTIONAL DEVICE DECOUPLABLE PREFERABLY TOOL-FREE FROM THE MACHINE FRAME

A processing machine and mobile technology, applied in the direction of transportation and packaging, slitting machinery, conveyor objects, etc., can solve the problems of time-consuming and resource consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

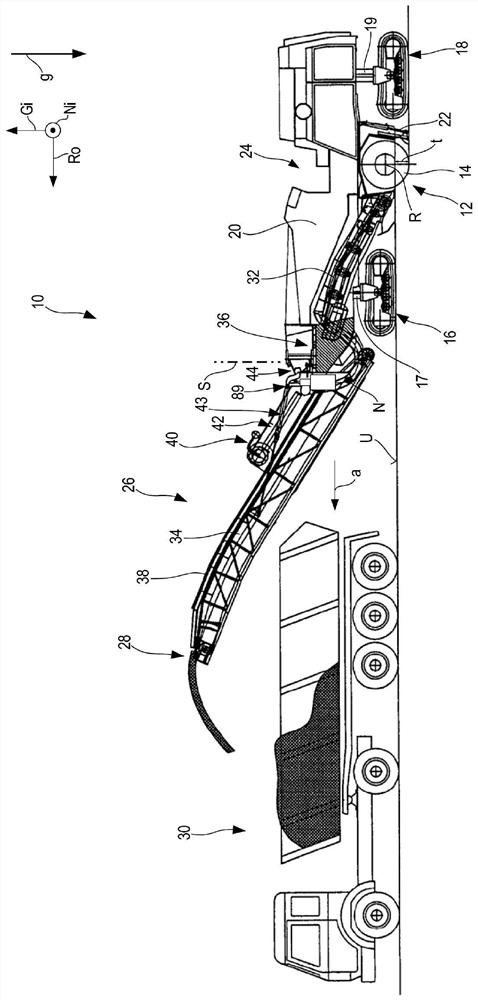

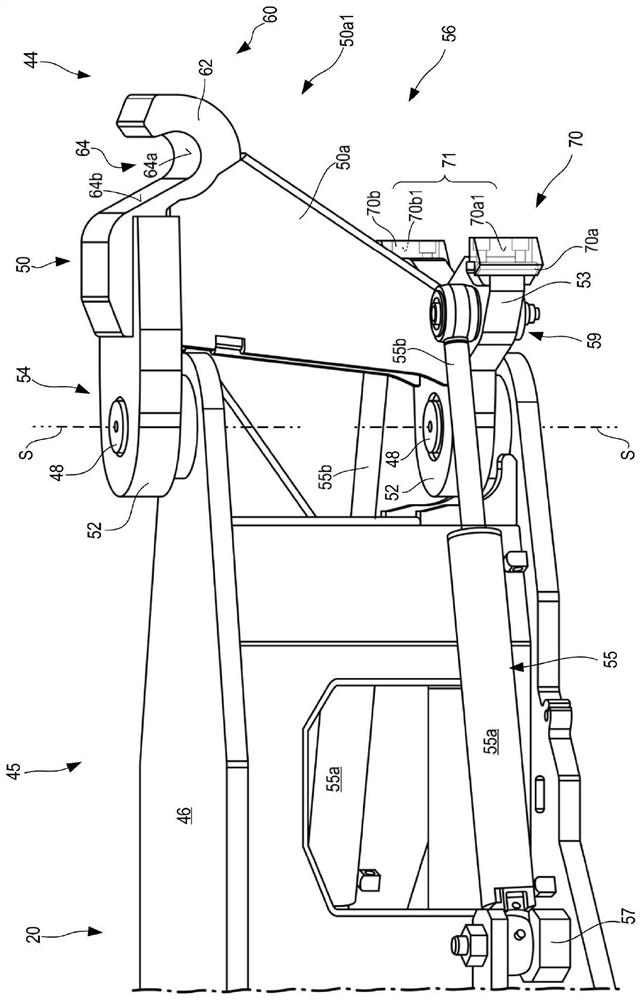

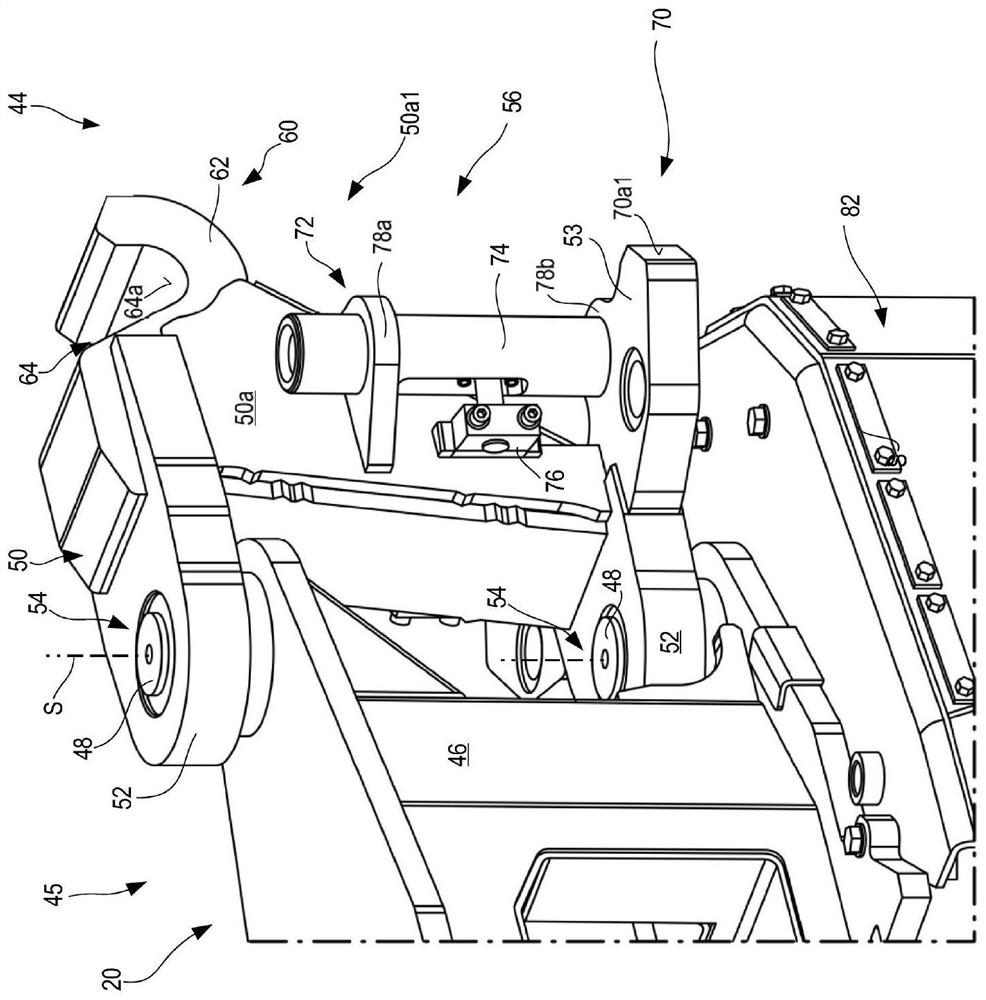

[0061] exist figure 1 In general, 10 denotes a floor working machine (hereinafter simply referred to as "machine") according to the invention. The machine 10 according to the invention is represented by way of example as a large-scale road milling machine, a working device 12 of the large-scale road-milling machine and a chassis 16 known per se, such as typically for large-scale road-milling machines, with milling rollers 14 arranged at the front and between the running gear 18 at the rear. The carriages 16 and 18 , which are each preferably driven by a hybrid motor not shown, are steerable and carry a frame 20 , which in turn carries the working device 12 . Machine 10 is thus a self-propelled vehicle.

[0062] exist Figure 1 to Figure 3 with Figure 5 to Figure 8 The arrow g marks the direction of gravity.

[0063] Can surround with figure 1 Orthogonal to the drawing plane of the machine 10, the axis of rotation R extending parallel to the pitch axis Ni of the machine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com