Roughness detection tool

A technology for detecting tooling and roughness, which is applied to measurement devices, instruments, etc., can solve the problems of small measurement range, small measurement data, difficulty in ensuring measurement accuracy, poor measurement accuracy, etc., to achieve convenient adjustment and operation, and reliable measurement stability. Good performance and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

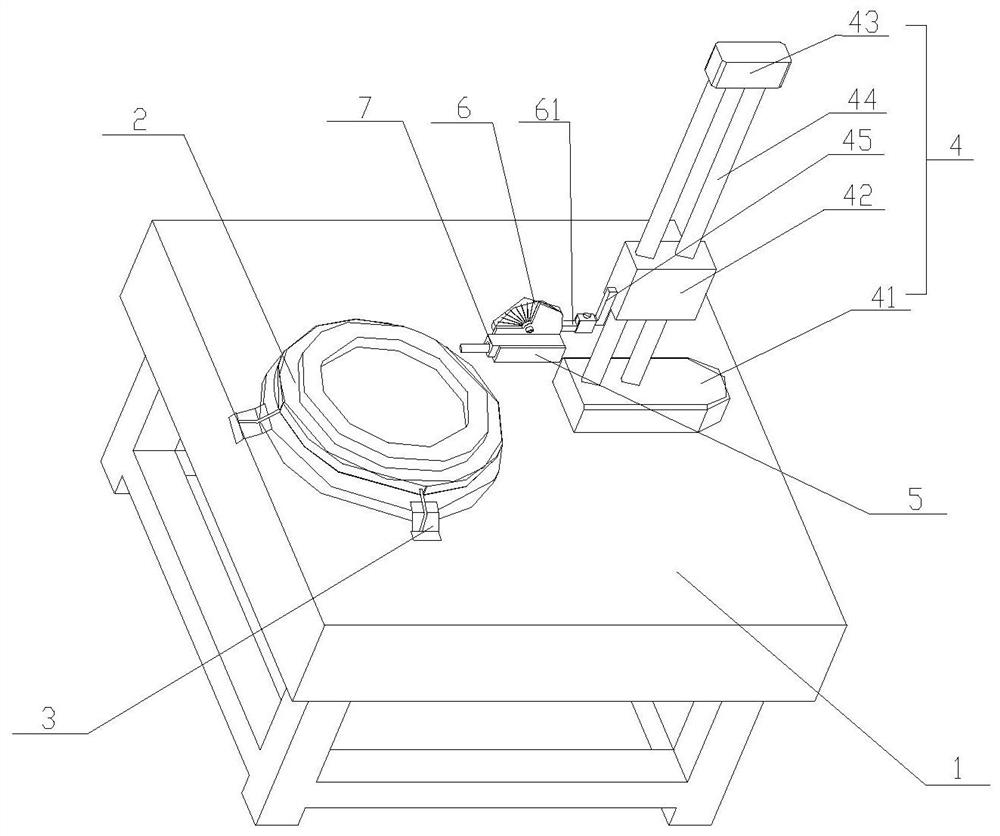

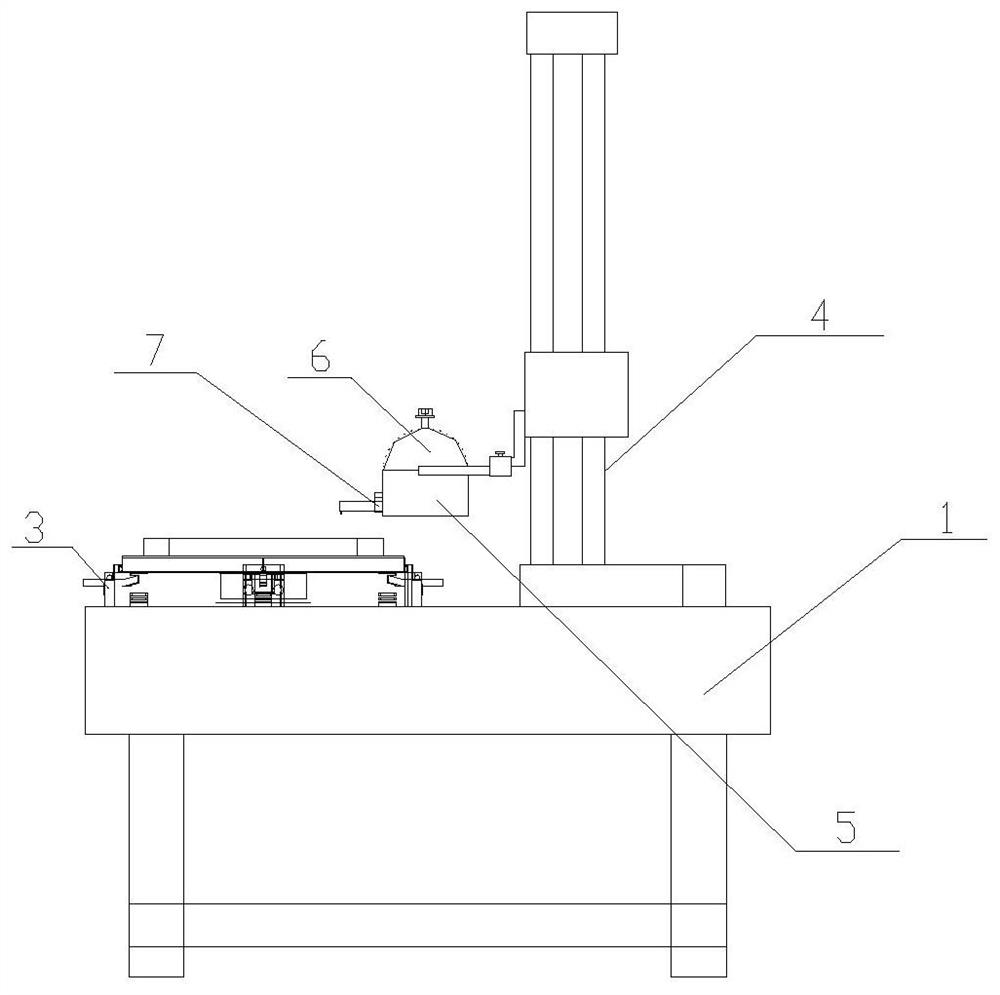

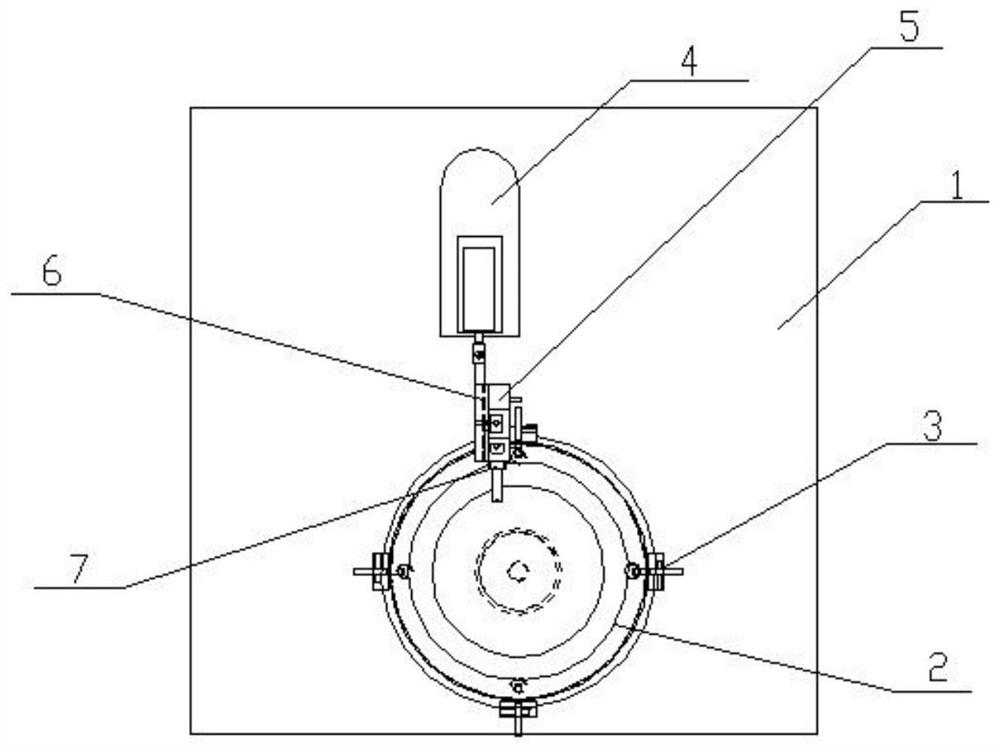

[0028] Embodiment 1 refers to Figure 1 to Figure 6 , this embodiment provides a roughness detection tool, including a frame 1, a locking device 3, a roughness detection device, a turntable 2 installed on the frame 1, and a lifting platform 4, and the lifting platform 4 includes a lower support seat 41 , the upper support seat 43, the guide rail 44 is installed between the lower support seat 41 and the upper support seat 43, the lifting seat 42 that can move up and down is installed on the guide rail 44, and the side wall of the turntable 2 is provided with some arc-shaped draw grooves 21, locking The device 3 includes a bracket and a card tube installed on the bracket. A spring 31 with a spring ball head 32 at the end is installed inside the card tube. The spring ball head 32 can be snapped into the corresponding arc shape after the turntable 2 rotates at a corresponding angle. In the slot 21, the roughness detection device includes a dial 6, a measuring table 5 and a roughne...

Embodiment 2

[0035] Embodiment 2, except that an electric push rod is installed on the lower support base 41, and the push rod end of the electric push rod is connected with the bottom surface of the lifting seat 42, all the other structures are the same as in Embodiment 1.

Embodiment 3

[0036] Embodiment 3, except that the turntable driving device is installed on the frame 1, the turntable driving device includes a servo motor, the output end of the servo motor is connected with the bottom surface of the lower turntable, and the servo motor can control the rotation of the turntable to keep at 90° each time, the rest of the structure Same as Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com