Production process for dry-type transformer

A dry-type transformer and production process technology, applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve the problems of lower quality of iron core products, oxidation and rust on the surface of silicon steel sheets, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

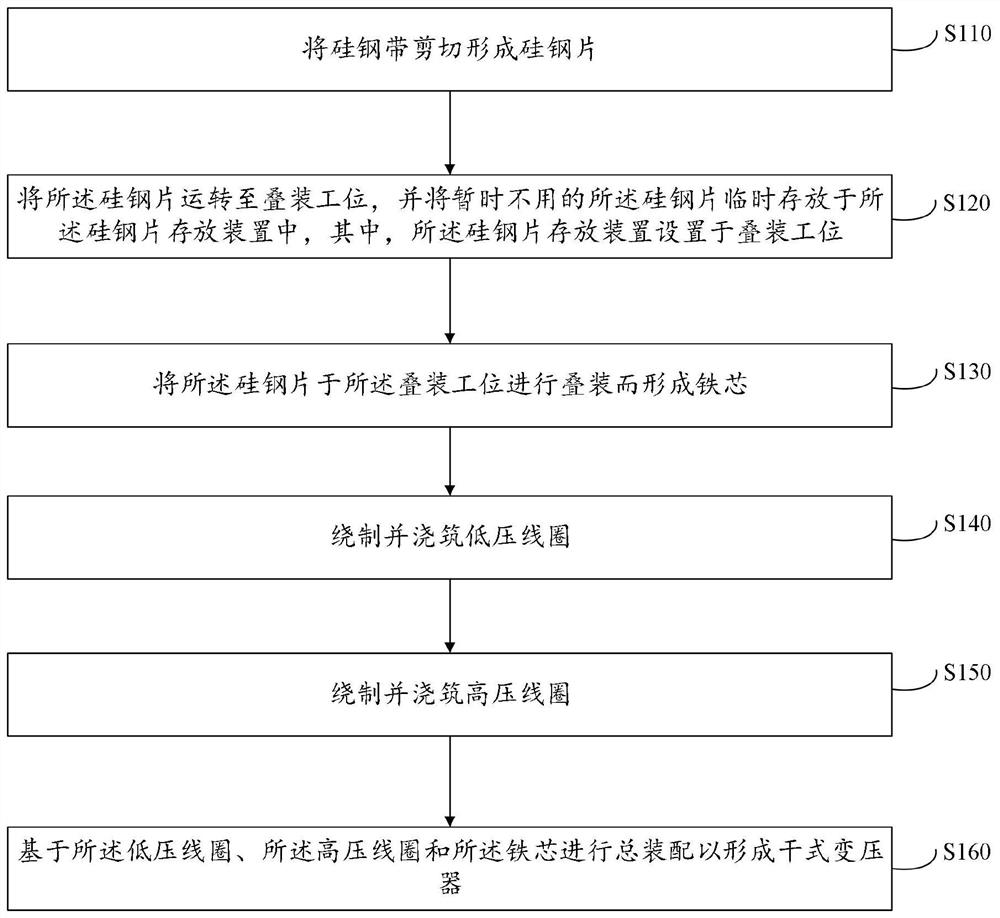

[0069] The invention proposes a dry-type transformer production process method.

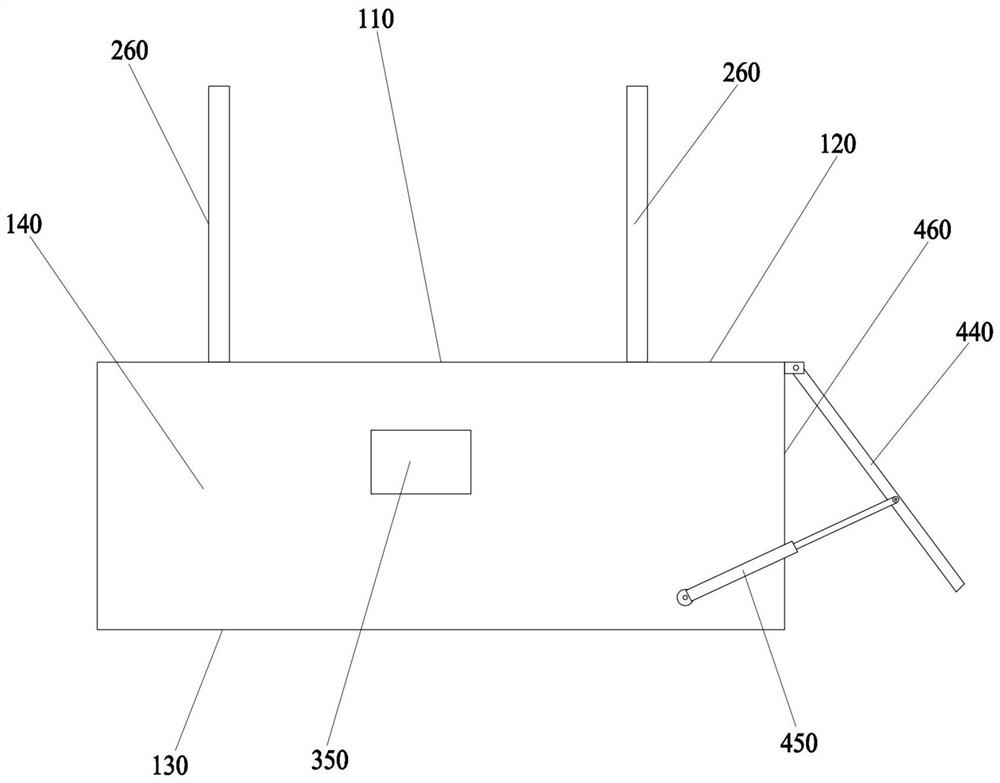

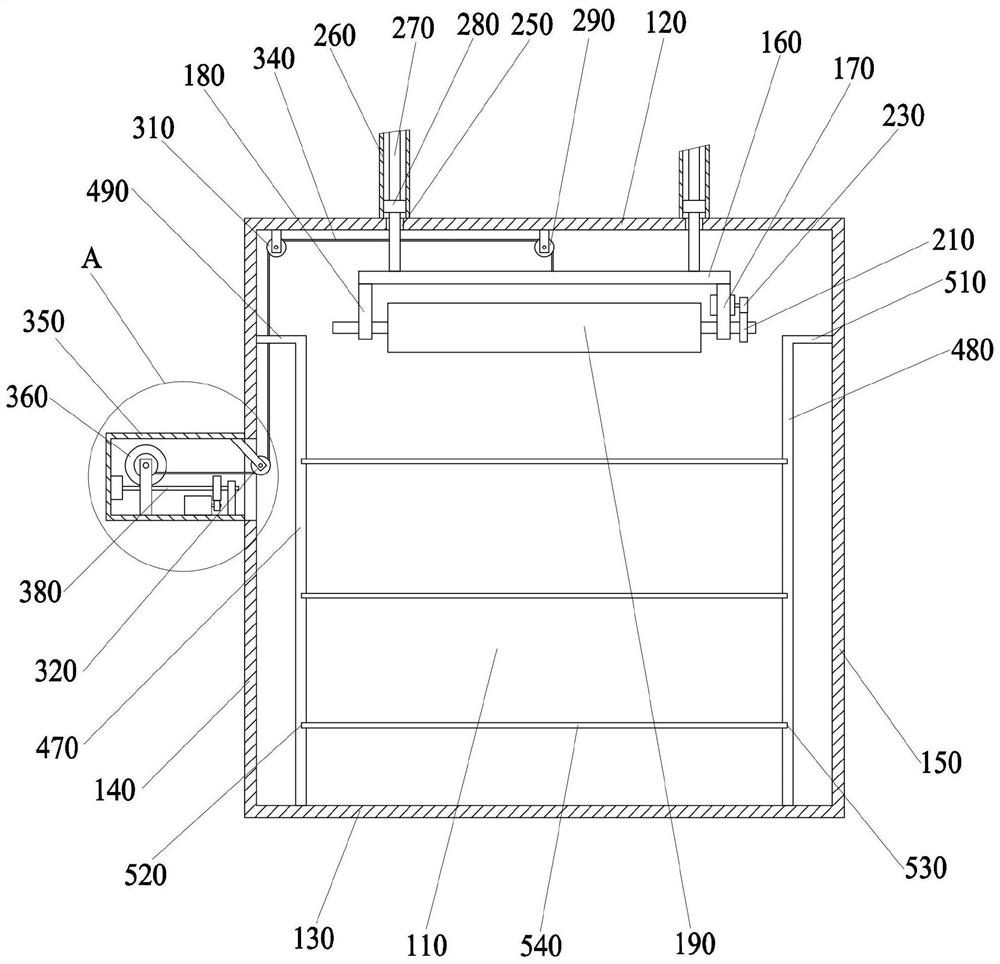

[0070] as attached figure 1 As shown, in the first embodiment of a dry-type transformer production process proposed by the present invention, the dry-type transformer production process is applied to a silicon steel sheet storage device; the silicon steel sheet storage device includes a storage box 110, a sealed door 440, an air pump (not shown), a first solenoid valve (not shown), a vacuum pump (not shown), a second solenoid valve (not shown) and a hydraulic cylinder 450; the storage box 110 is opened for putting in Or take out the inlet 460 of the silicon steel sheet; the sealing door 440 can seal the cover on the inlet 460, specifically, the sealing door 440 is hinged on the upper end of the inlet 460, and the base of the hydraulic c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap