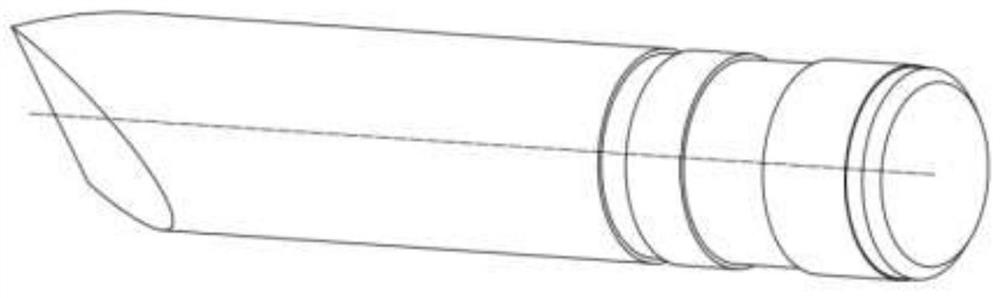

Preparation method of soldering bit with long service life and low cost

A low-cost, soldering iron tip technology, applied in the field of ferrous metal alloys, can solve problems such as high production cost of soldering iron tips, troubles in the development of soldering iron tips, and impact on the quality of soldering iron tips, and achieve long service life, low cost, and stable quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

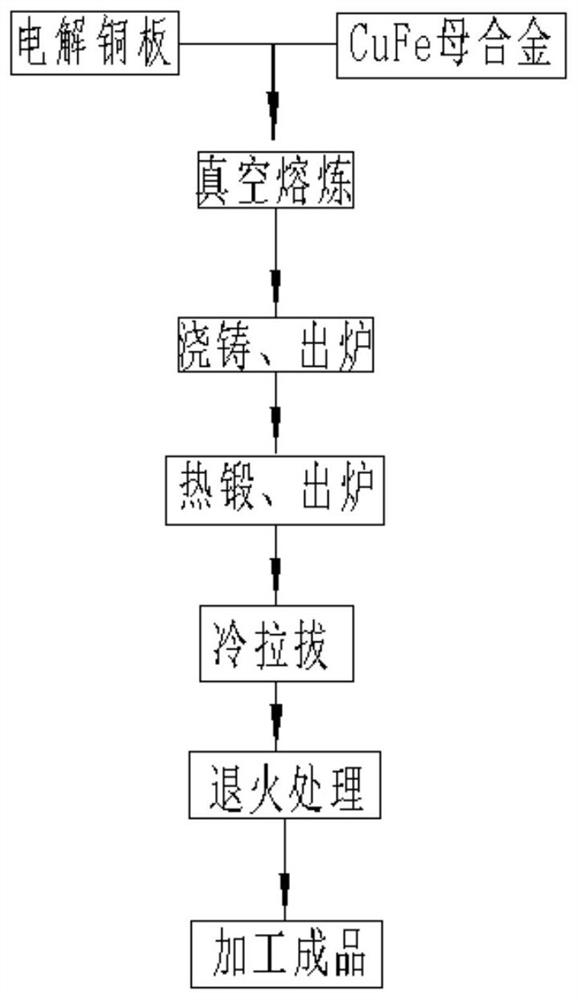

[0025] A method for preparing a long-life, low-cost soldering iron tip: comprising the following steps:

[0026] S1: Ingredients: prepare the raw material CuFe master alloy, the mass ratio of Cu and Fe in the CuFe master alloy is 1:1, the size of the electrolytic copper plate is 0.2m*0.1m*0.05m, and the size of the CuFe master alloy is 0.1m*0.1 m*0.02m, control the mass percentage of Fe element in the raw material at 50%, too large metal volume is not conducive to controlling the content of Fe in the ingredients, and too small metal volume is easy to oxidize the metal;

[0027] S2: Vacuum smelting: Put the raw materials prepared in S1 into a vacuum induction furnace, and vacuumize the vacuum induction furnace. When the vacuum degree in the vacuum induction furnace reaches р=4Pa, start heating and adjust the vacuum The power of the induction furnace is 20KW, continue heating for 10 minutes, then increase the power of the vacuum induction furnace to 40KW, continue heating for 10...

Embodiment 2

[0033] A method for preparing a long-life, low-cost soldering iron tip: comprising the following steps:

[0034] S1: Ingredients: Prepare the raw material electrolytic copper plate and CuFe master alloy. The mass ratio of Cu and Fe in the CuFe master alloy is 1:1. During the batching, the mass percentage of Fe element in the raw material is controlled at 40%, and the electrolytic copper plate The size is 0.2m*0.1m*0.05m, and the CuFe master alloy size is 0.1m*0.1m*0.02m. Too large a metal volume is not conducive to controlling the content of Fe in the ingredients, and too small a metal volume is easy to oxidize the metal;

[0035]S2: Vacuum smelting: Put the raw materials prepared in S1 into a vacuum induction furnace, and vacuumize the vacuum induction furnace. When the vacuum degree in the vacuum induction furnace reaches р=3Pa, start heating and adjust the vacuum The power of the induction furnace is 25KW, continue heating for 8 minutes, then increase the power of the vacuu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com