Preparation method of vacuum coating pill carrier

A technology of vacuum coating and carrier, applied in vacuum evaporation coating, manufacturing tools, sputtering coating, etc., can solve the problems of uneven steel wire, unstable product quality, low efficiency, etc. Rust, labor saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

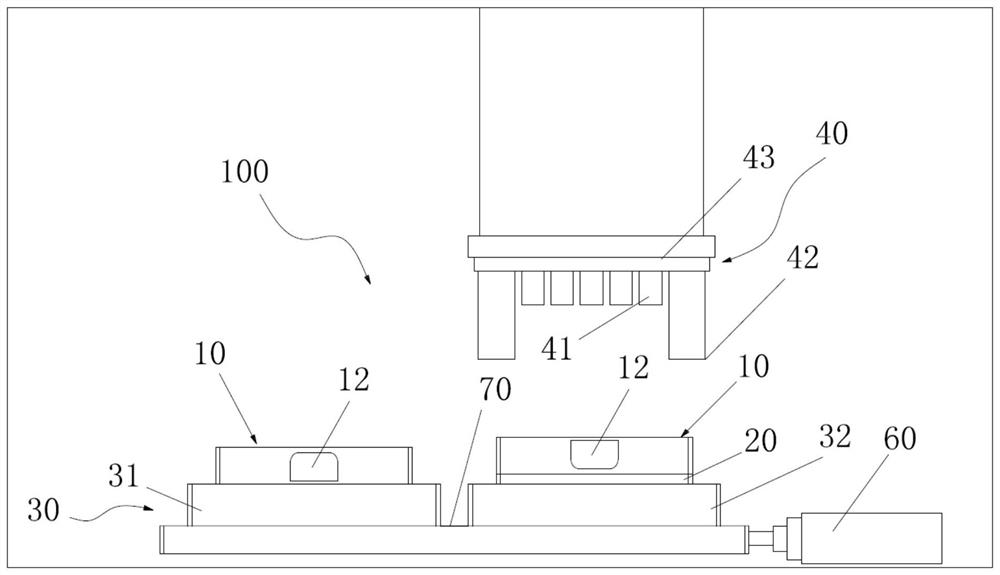

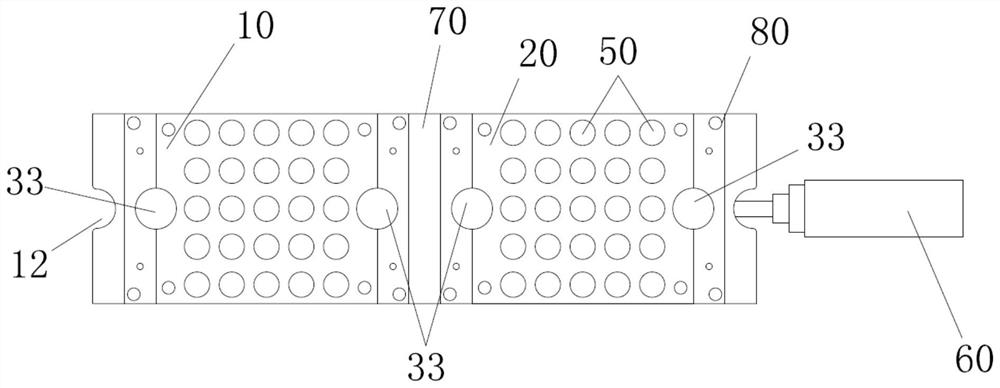

Image

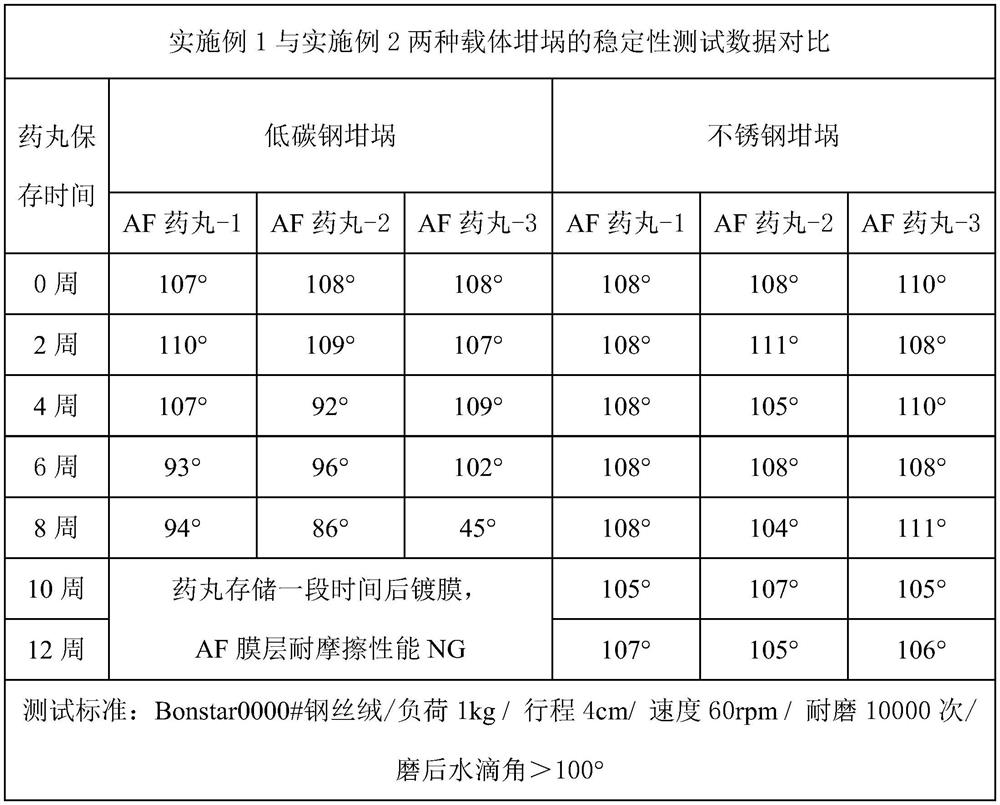

Examples

preparation example Construction

[0031] The preparation method of the vacuum-coated pill carrier of the present invention mainly includes the preparation of stainless steel microfilament felt and punching the inner core.

[0032] Stainless steel microfilament mat preparation. First select stainless steel microwires with a diameter of 20-40 microns, and use a fiber stretcher to cut the stainless steel microwires to a suitable length as the substrate. As an embodiment of the present invention, it can be cut to 50cm or other sizes to adapt to the desired Factors such as the size of the pressing die and the sintering furnace are determined. Then, the stainless steel microwires are uniformly and non-woven paved on the forming net, and 8-10 layers are paved to obtain the superimposed layer of the stainless steel microwires. A high-temperature-resistant isolation layer is placed on the superimposed layer, and 8-10 layers of microfilament superimposed layers are continued to be non-woven on the isolated layer. Accor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap