Battery cabin body with inner cabin and outer cabin

A battery compartment and inner compartment technology, applied in battery pack components, circuits, electrical components, etc., can solve problems such as abnormal use, environmental pollution, damage to batteries, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

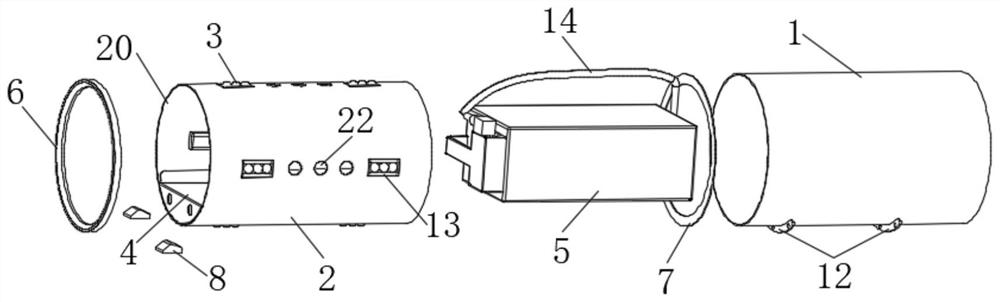

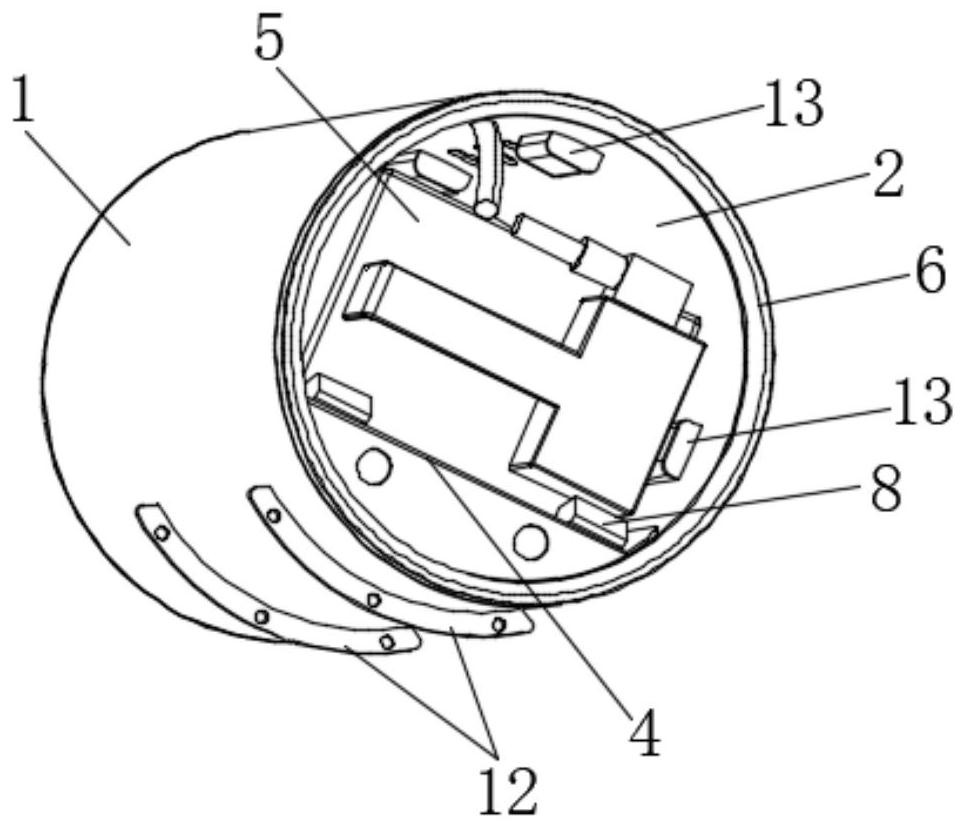

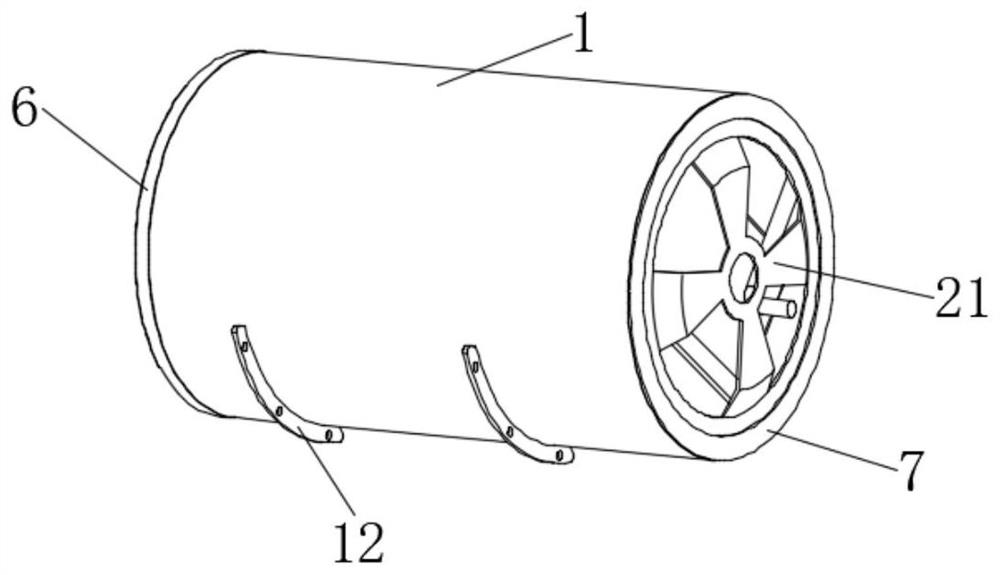

[0029] A battery compartment with inner and outer compartments, such as Figure 1~3 shown, including:

[0030] An outer cabin body 1 and an inner cabin body 2 arranged inside the outer cabin body 1;

[0031] The side wall of the inner cabin body 2 is provided with a plurality of balls 3 slidingly abutting against the outer cabin body 1, and the outer cabin body 1 is used to rotate circumferentially along the side wall of the inner cabin body 2;

[0032] A support platform 4 is provided inside the inner cabin body 2 , and the support platform 4 is used for placing the battery module 5 .

[0033] When the battery module 5 and the support platform 4 are placed inside the inner cabin body 2, the support platform 4 can increase the weight of the inner cabin body 2, so that the center of gravity of the inner cabin body 2 is not easy to shift, thereby effectively increasing the weight of the inner cabin body. 2, the stability of the center of gravity of the outer cabin body 1 and t...

Embodiment 2

[0048] The difference between this embodiment and Embodiment 1 is that in order to improve the heat dissipation efficiency of the inner cabin body 2, the top plate 42 is provided with air holes communicating with the first cavity 9 and the second cavity 10 at the same time, and a plurality of air holes are evenly distributed on the top plate 42 , and the plurality of air holes correspond to the plurality of through holes 22 provided on the upper side wall and the lower side wall of the inner cabin body 2, wherein both the air holes and the through holes 22 have good ventilation and heat dissipation performance, thereby effectively improving the performance of the battery module 5. The heat dissipation efficiency when charging inside the inner cabin body 2 improves the service life of the battery cabin body.

[0049] Other structures of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

Embodiment 3

[0051] The difference between this embodiment and Embodiment 1 is that in order to know the information of the battery module 5, the outer wall of the outer cabin body 1 is provided with a data storage chip, and the data information in the data storage chip and the information of the battery module 5 inside the battery cabin body Correspondingly, by storing and outputting information of different battery modules 5 through the data storage chip, information tracking of different battery modules 5 can be realized, thereby improving the management and control efficiency of the battery compartment for different battery modules 5 .

[0052] Other structures of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

[0053] Obviously, the present invention puts the battery into the inner compartment of the battery compartment, no matter how many angles the outer compartment rotates, the inner compartment and the battery module can always be kept at a ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com