Patents

Literature

63results about How to "Connection will not affect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

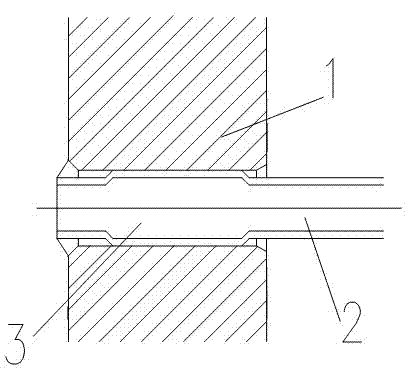

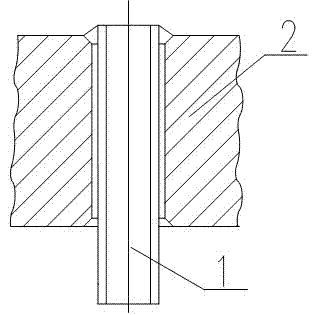

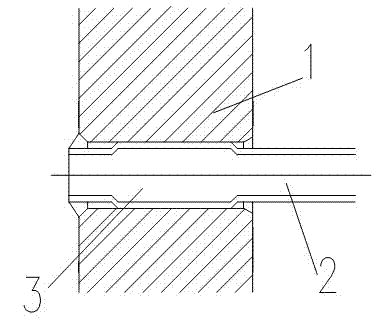

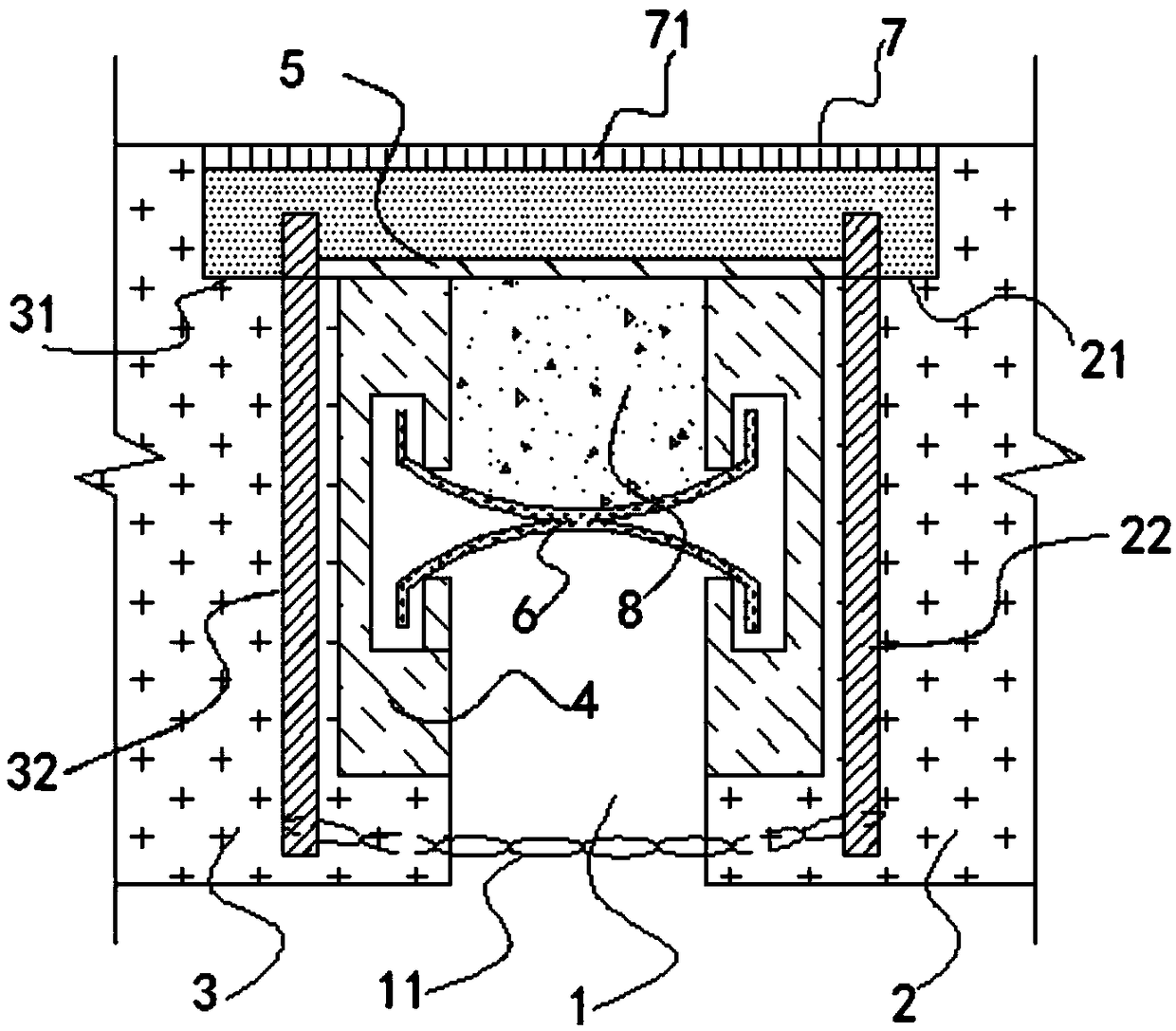

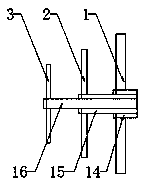

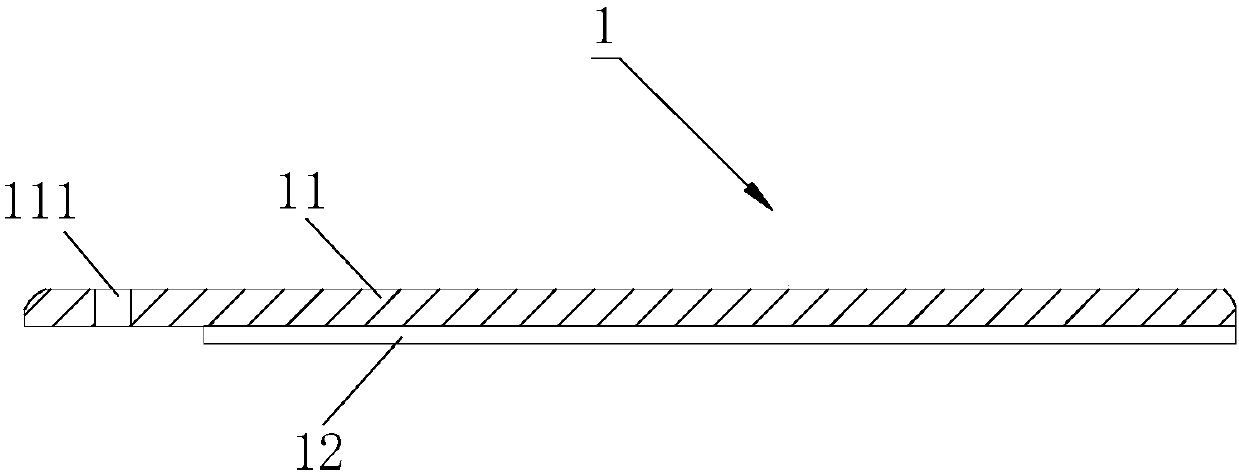

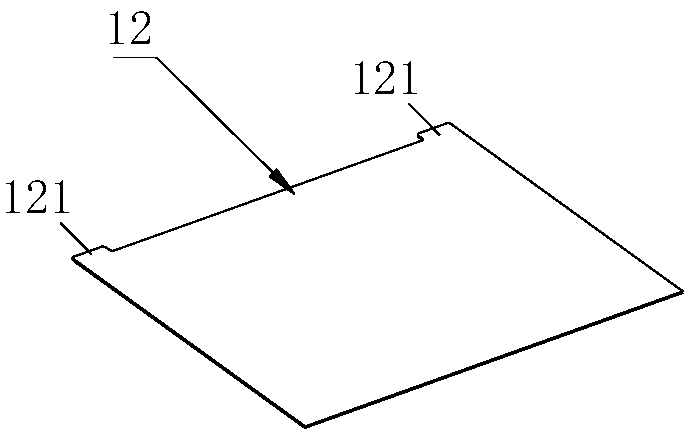

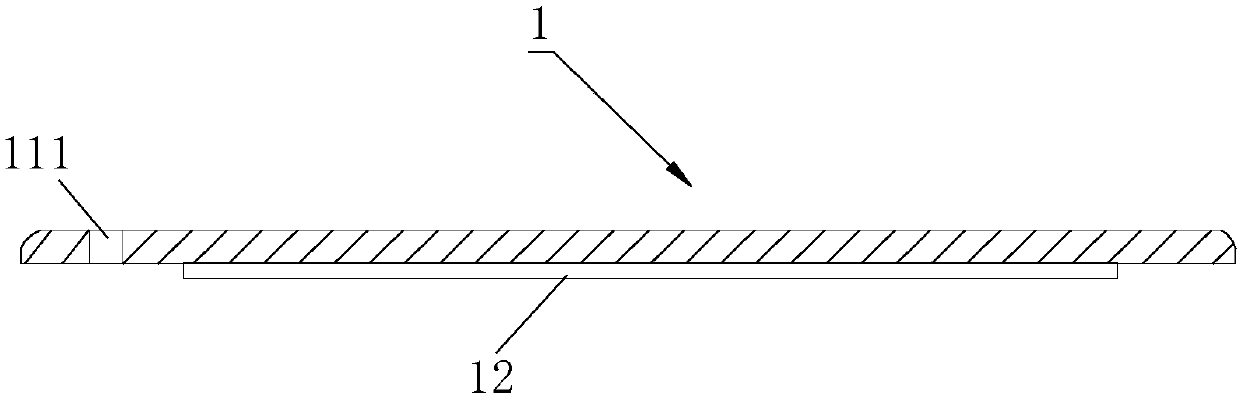

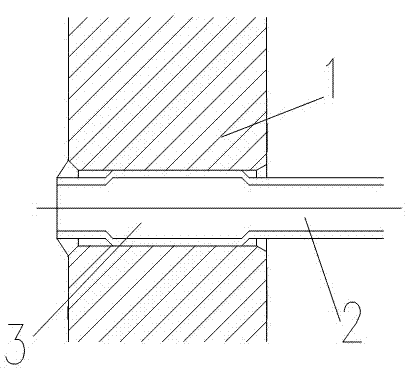

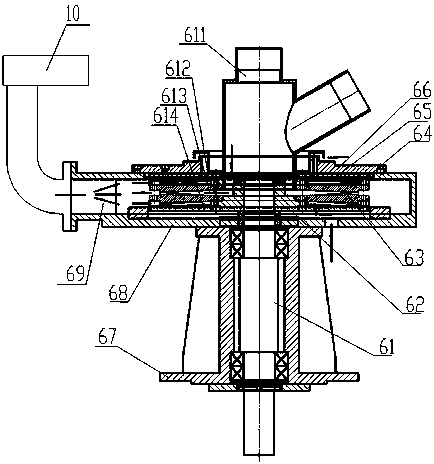

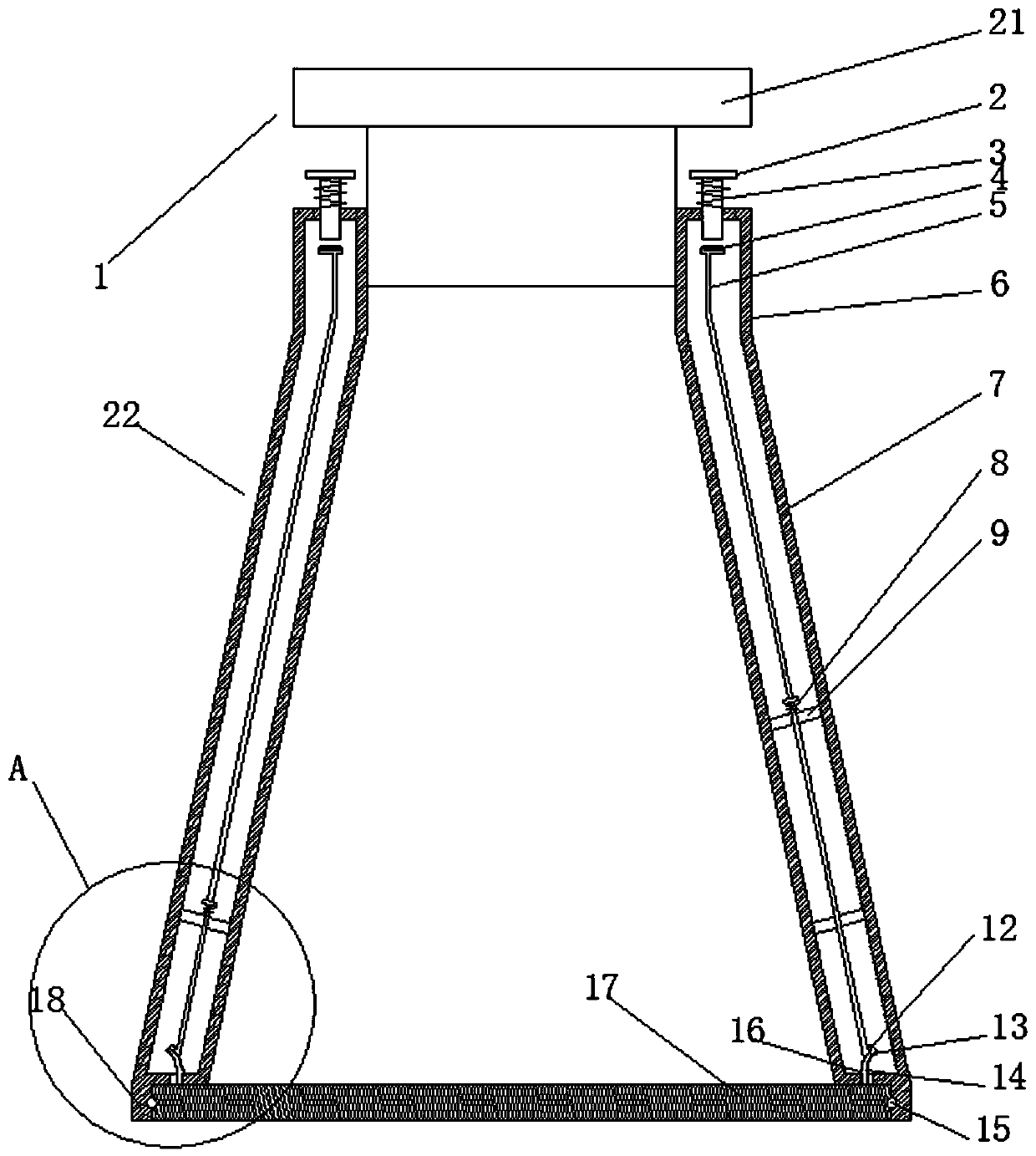

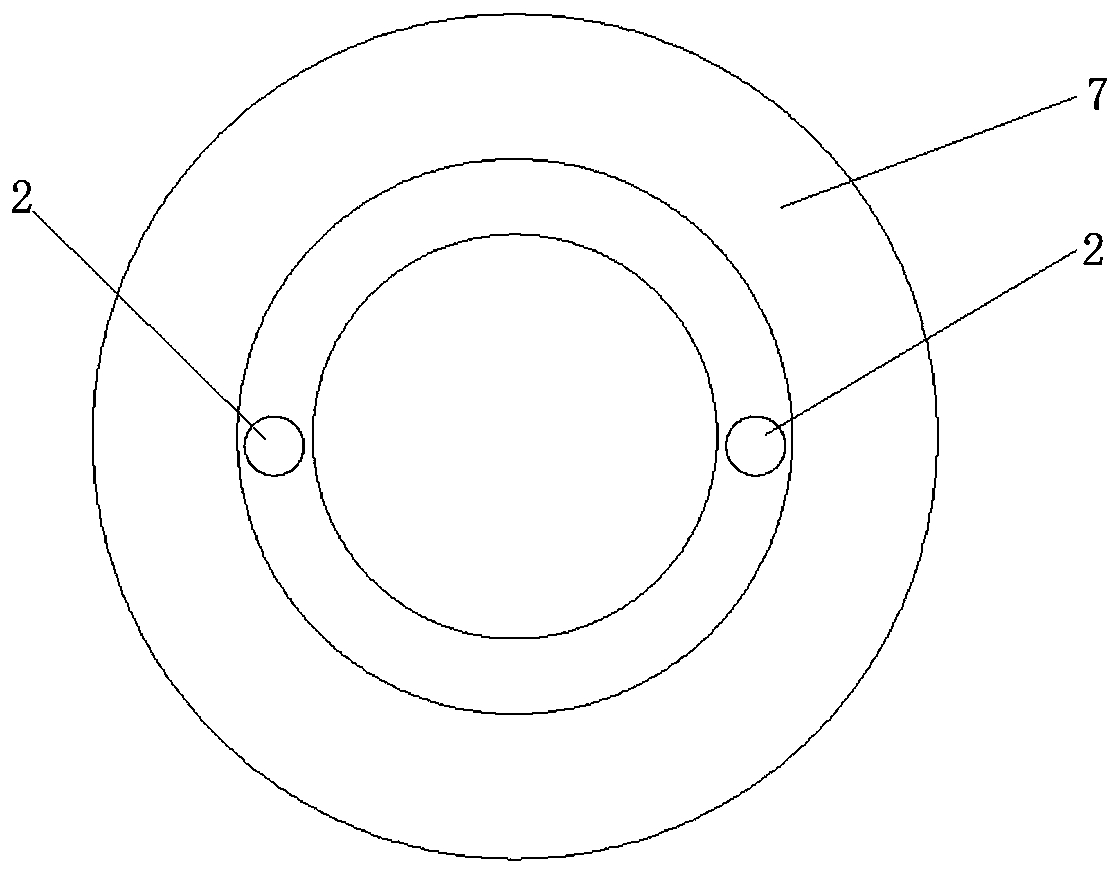

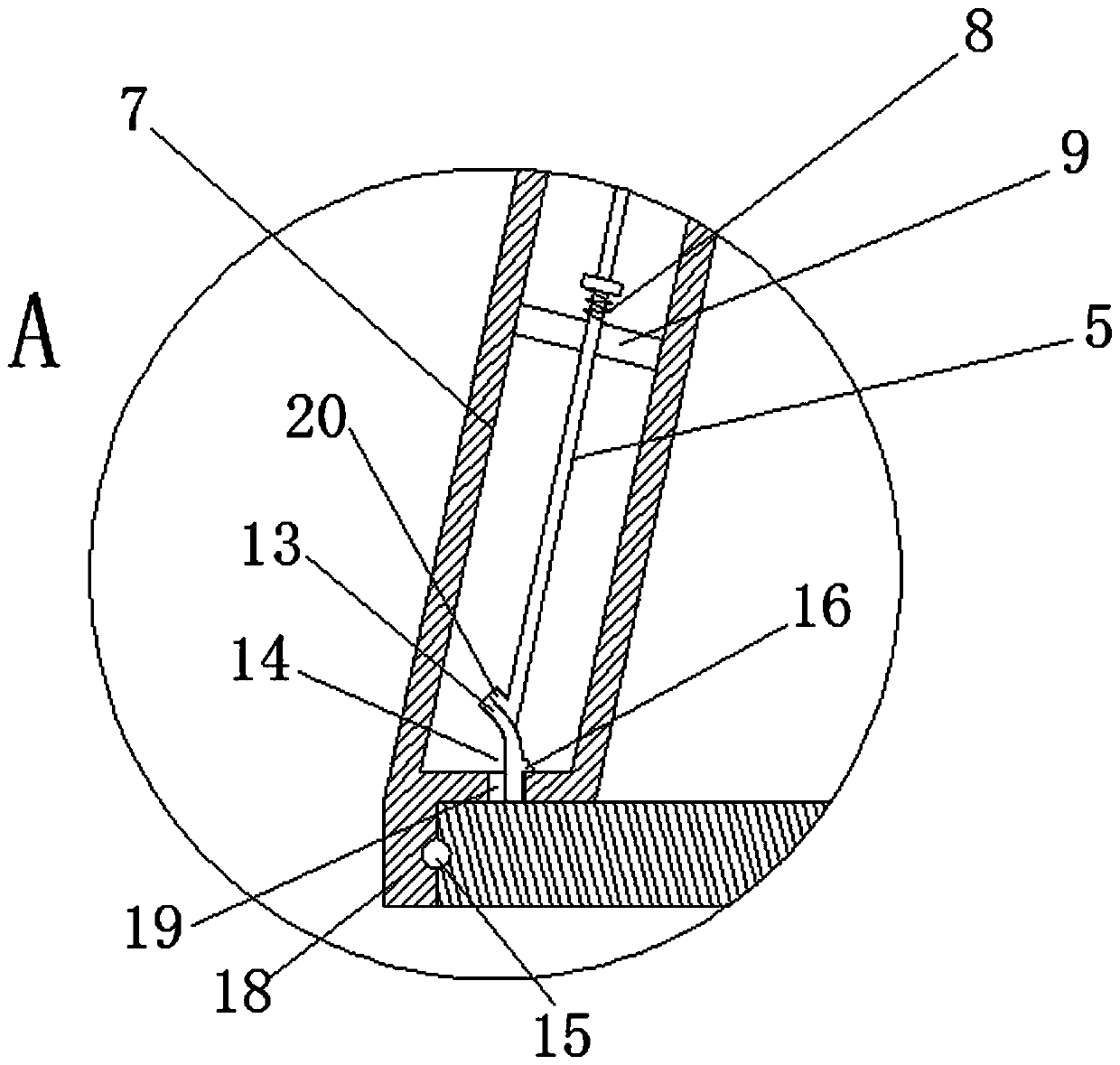

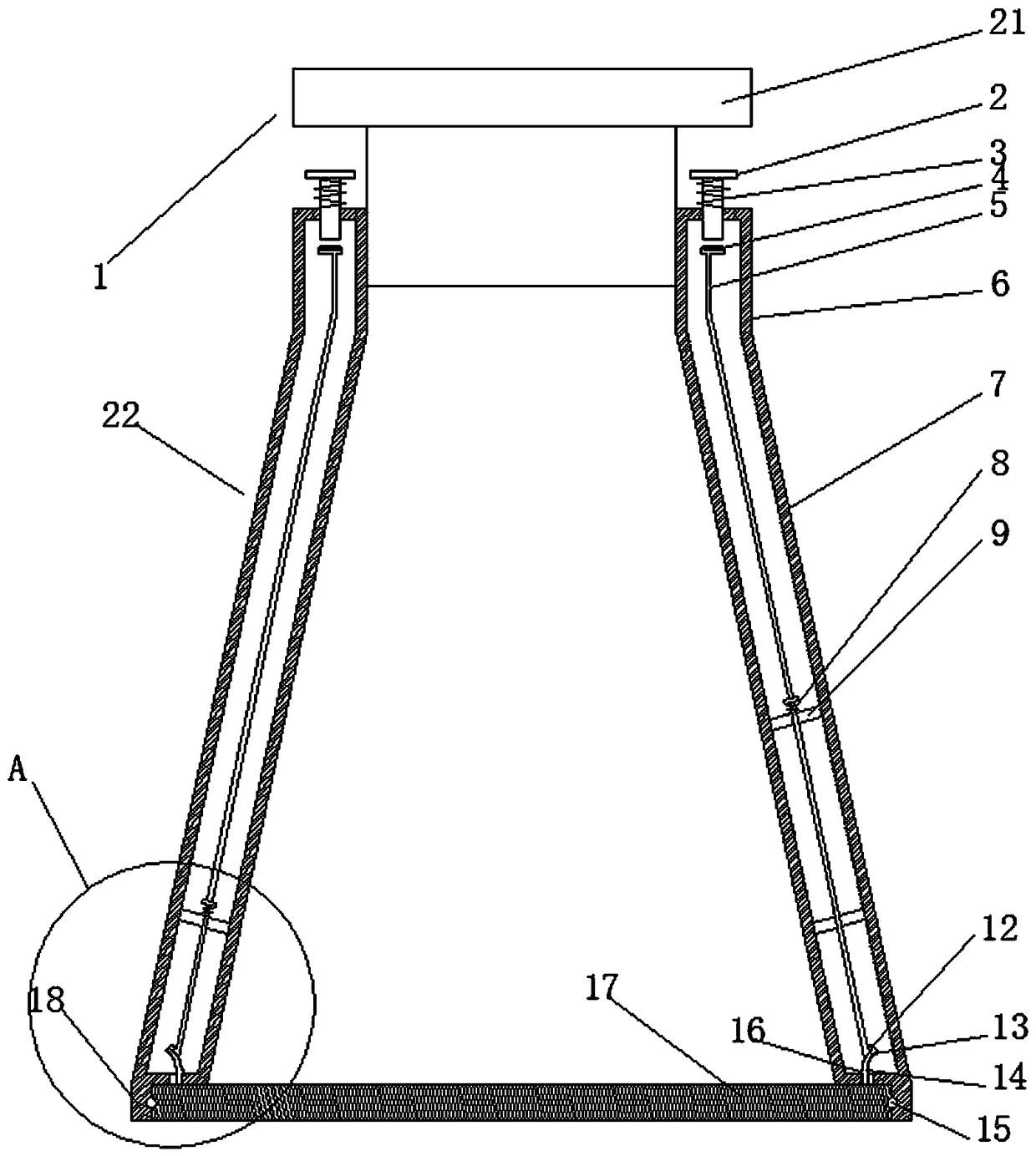

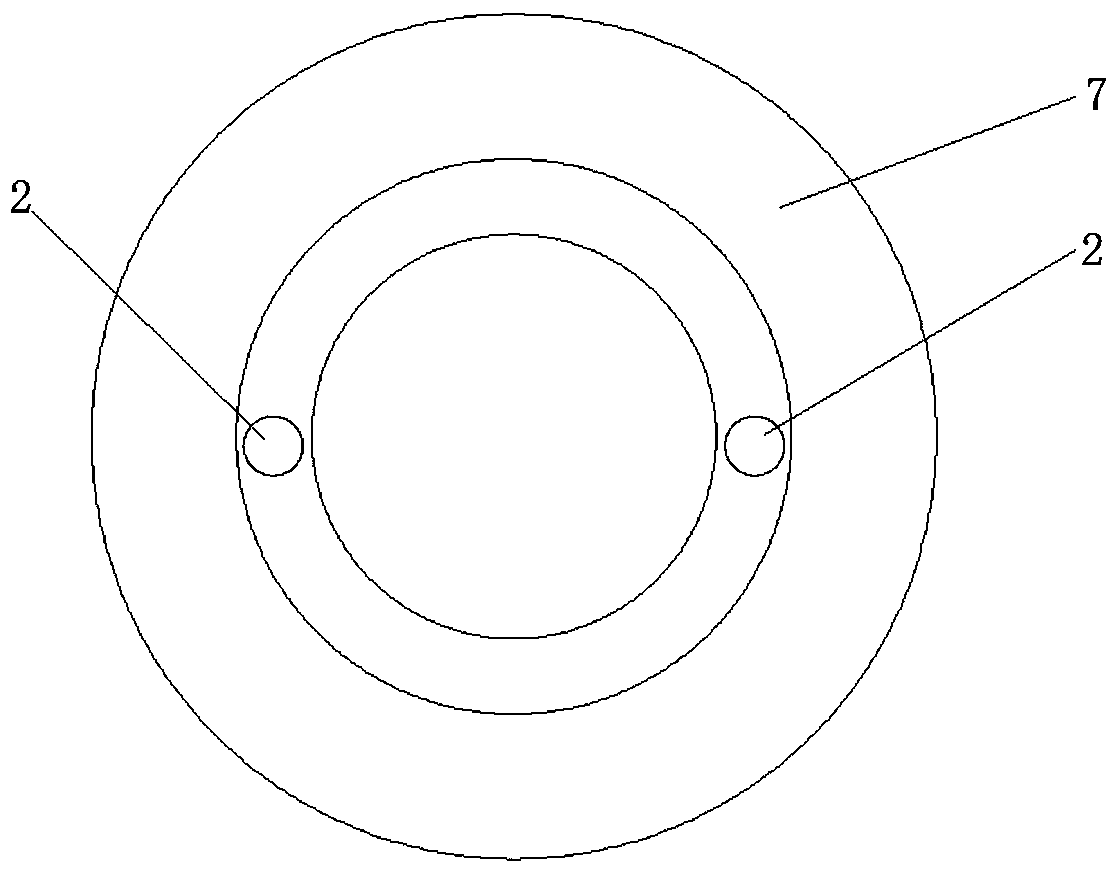

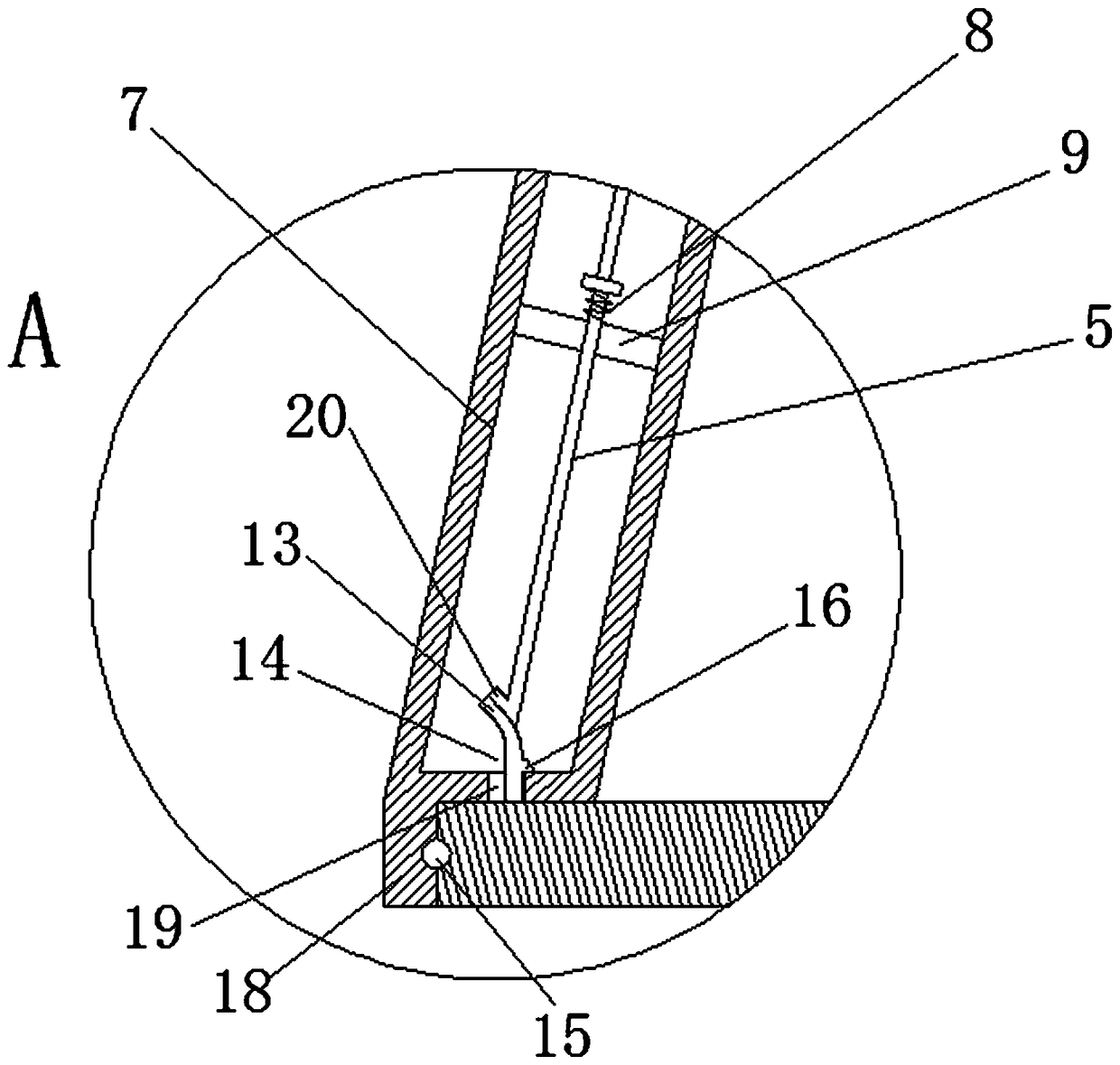

Connection structure and connection method of heat exchange tube and tube plate

ActiveCN102305572ASolve the problem that the sealing requirements cannot be metConnection will not affectHeat exchanger casingsMetal working apparatusEngineeringMaterial hardness

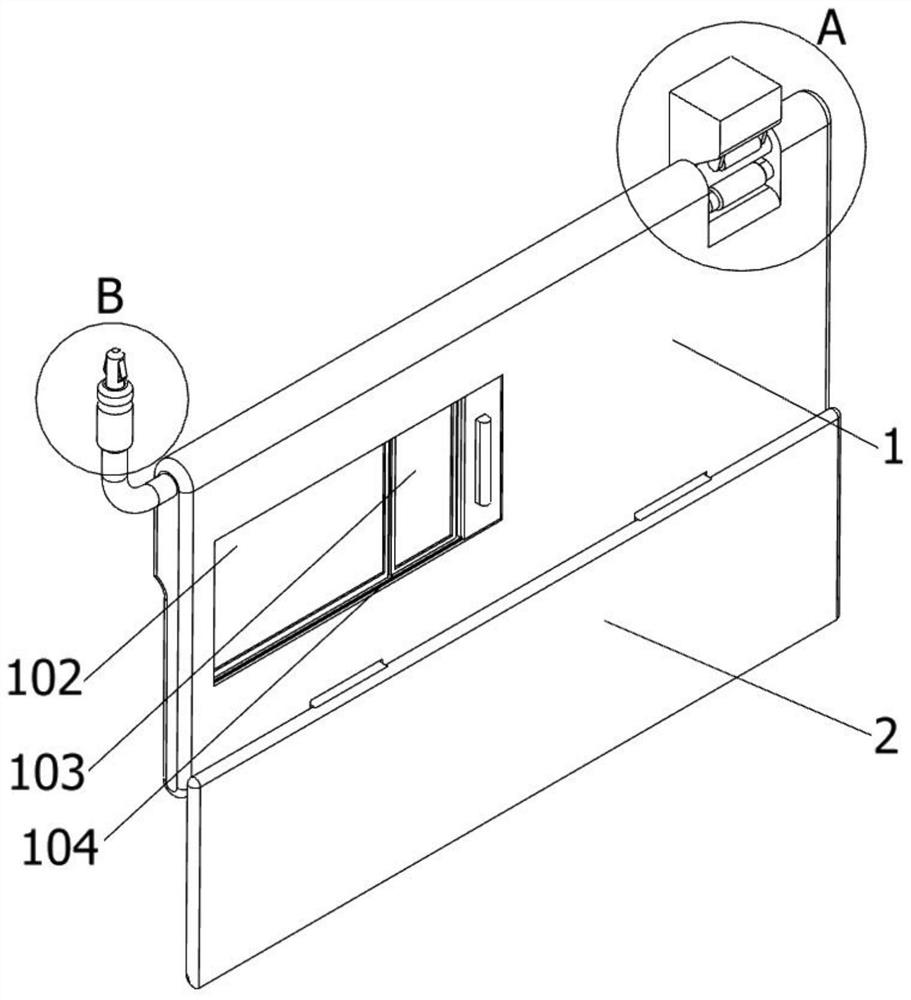

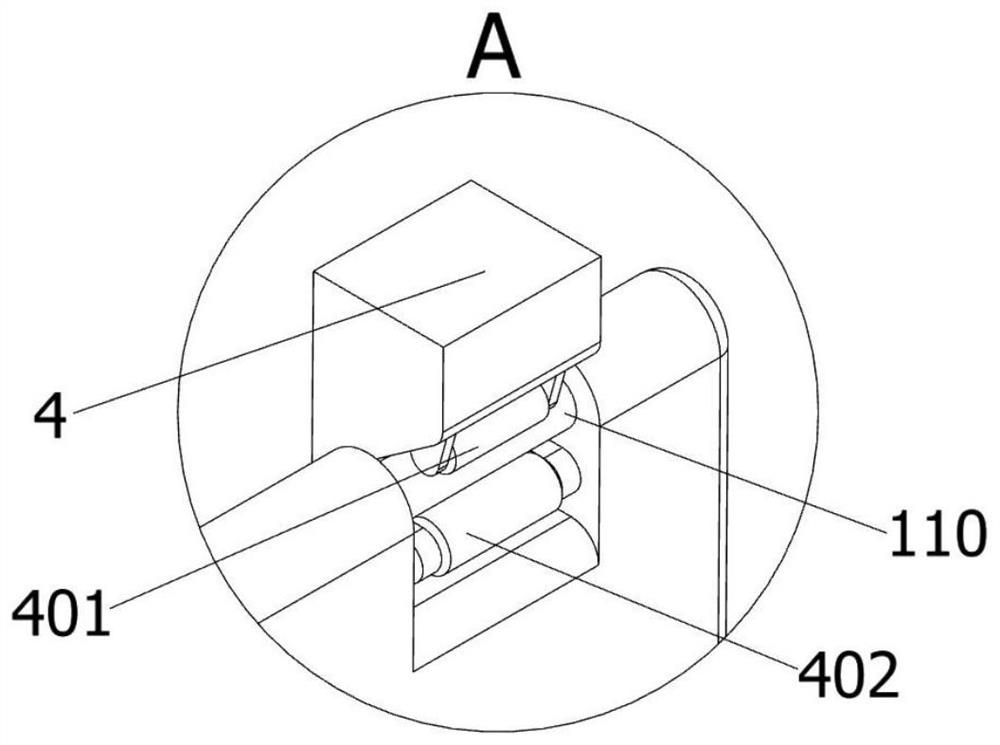

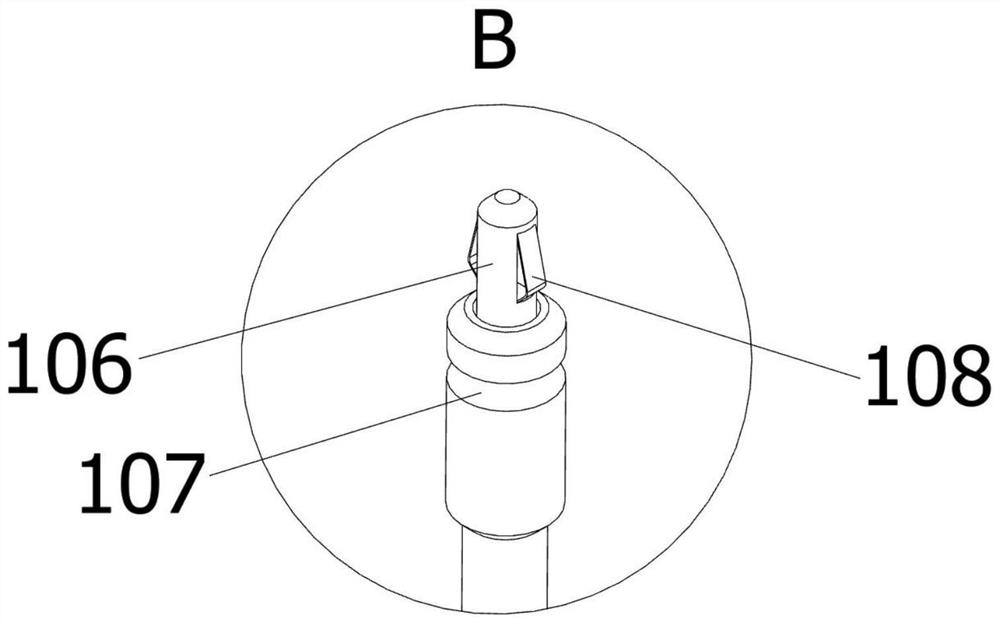

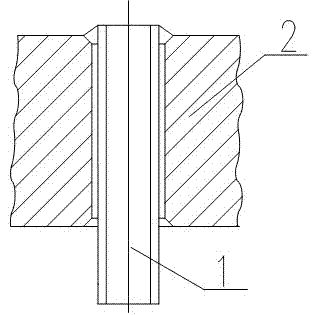

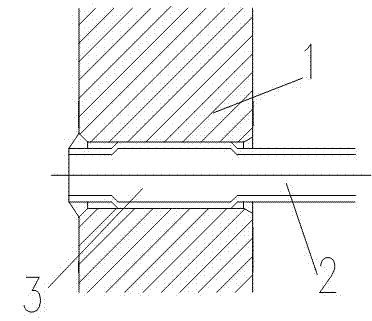

The invention discloses a connection structure of a heat exchange tube and a tube plate. The connection structure comprises the tube plate and the heat exchange tube. The connection structure is characterized in that: a section of annular sealing groove and a section of internal thread are formed on an inner wall of a heat exchange tube hole in the tube plate; a distance between the internal thread and a heat exchange tube orifice (namely an end face of the tube plate) is smaller than the distance between the annular sealing groove and the heat exchange tube orifice; an O-shaped sealing ring is sleeved on the inner section of the heat exchange tube hole of the heat exchange tube; and the O-shaped sealing ring is placed in the annular sealing groove and in fit with the annular sealing groove and the heat exchange tube. The connection structure also comprises a threaded plug, wherein threads which are in fit with the internal thread of the tube hole in the tube plate are formed on an outer wall of the threaded plug; a hollow hole is formed inside the threaded plug; the inner wall of the hole is in fit with the outer wall of the heat exchange tube; a shrinkage step is arranged in thehole; a clearance is reserved between the step and the heat exchange tube orifice; and the material hardness of the threaded plug is lower than that of the tube plate. In the situation that the heat expansion amount of the heat exchange tube cannot influence the connection of the tube plate and the heat exchange tube, the connection structure has excellent sealing performance.

Owner:SICHUAN BLUSR MACHINERY

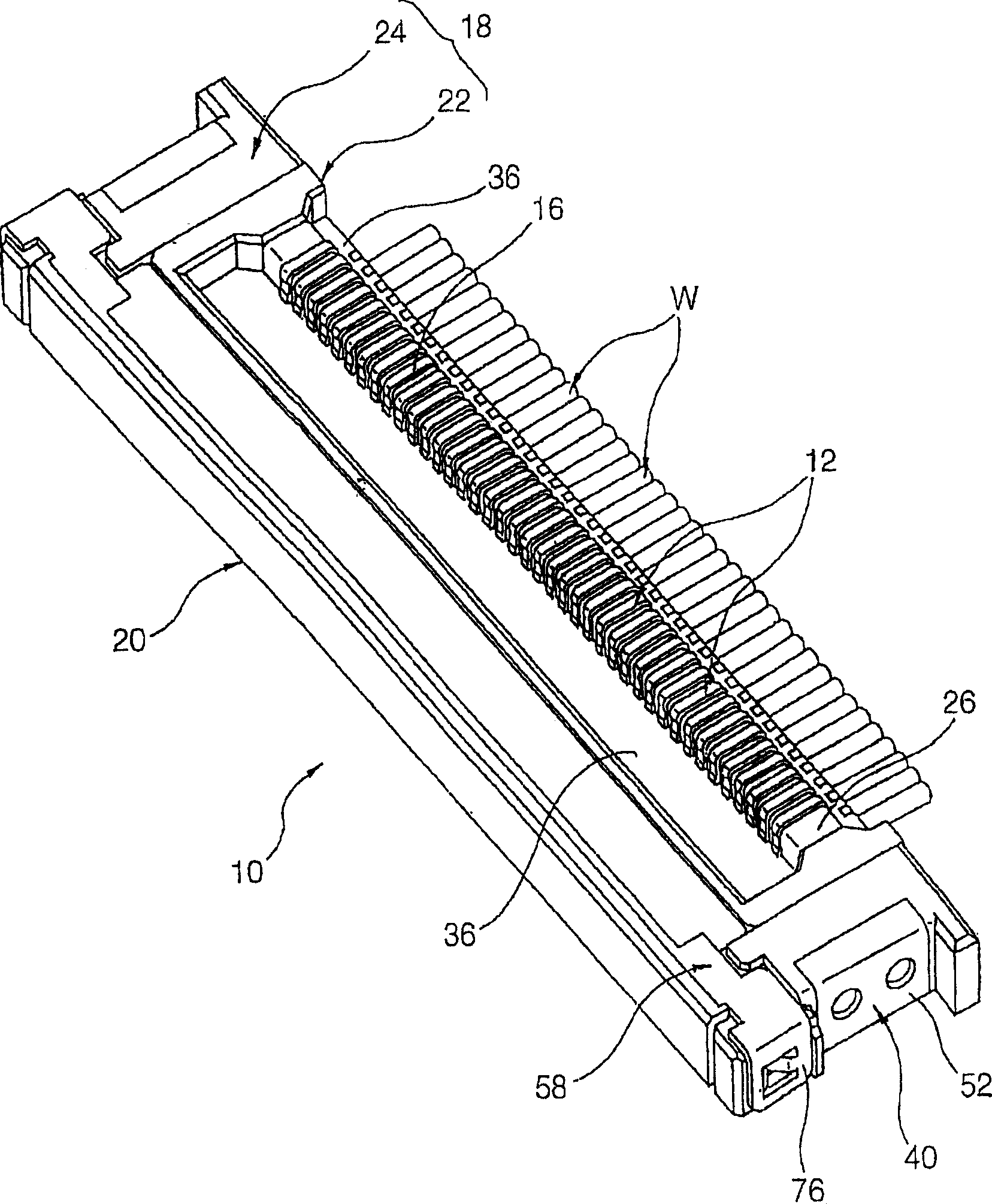

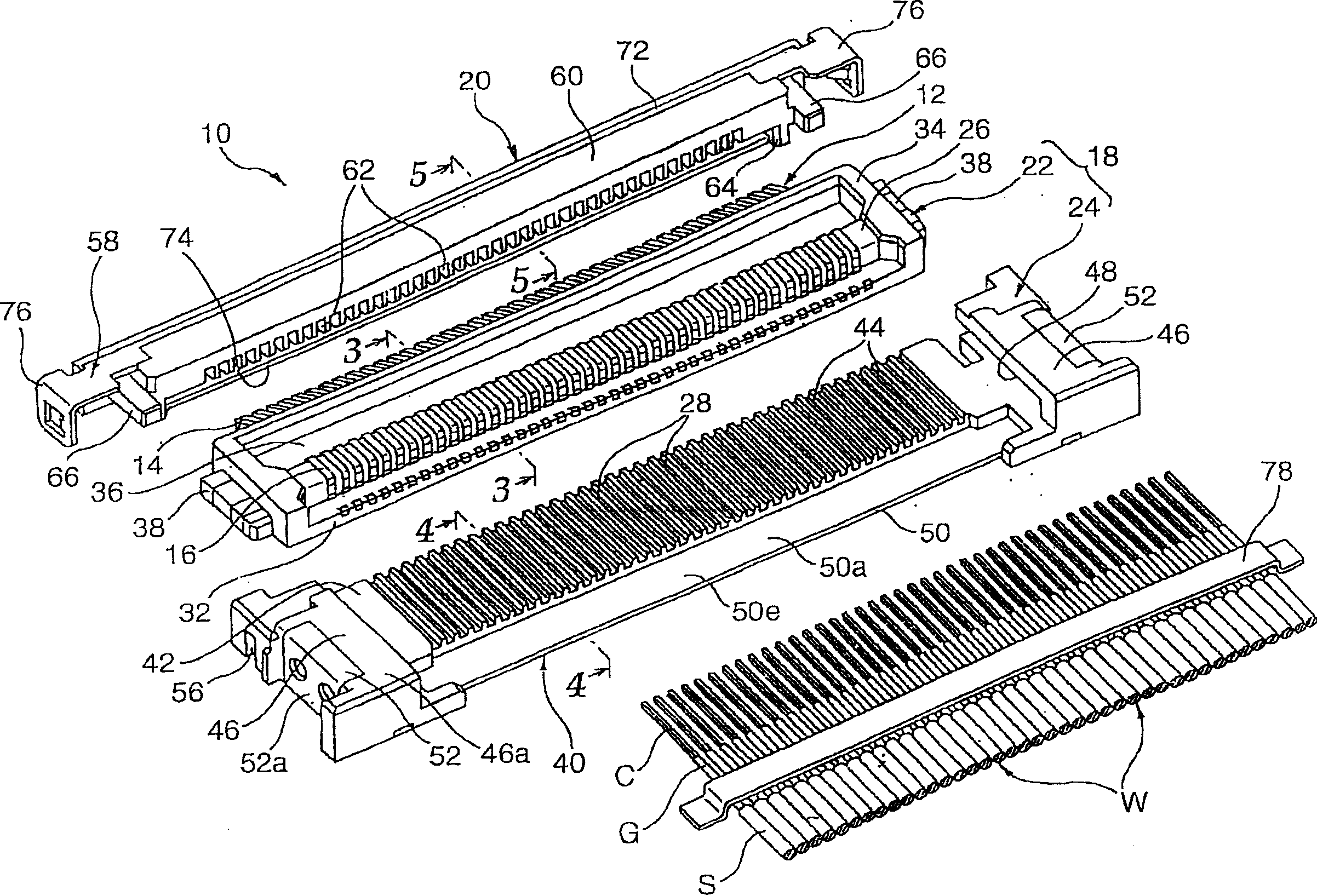

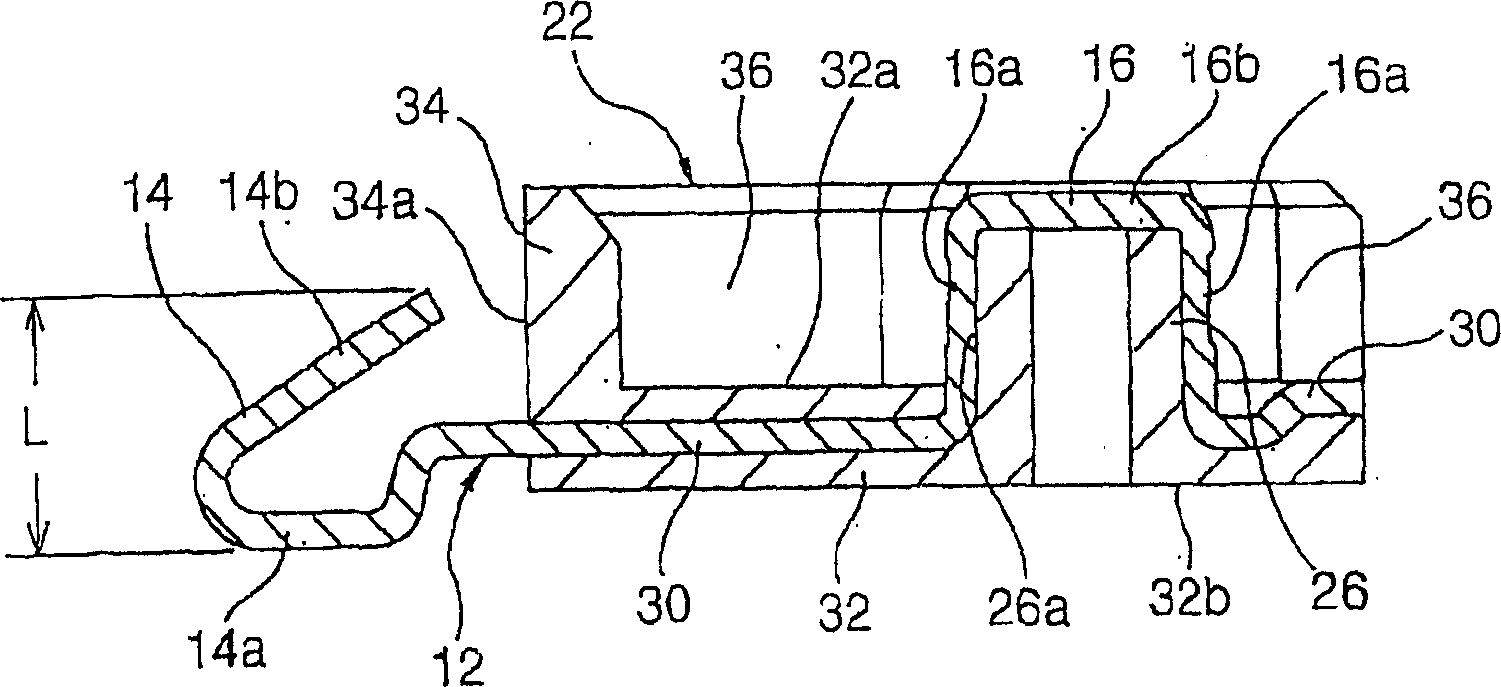

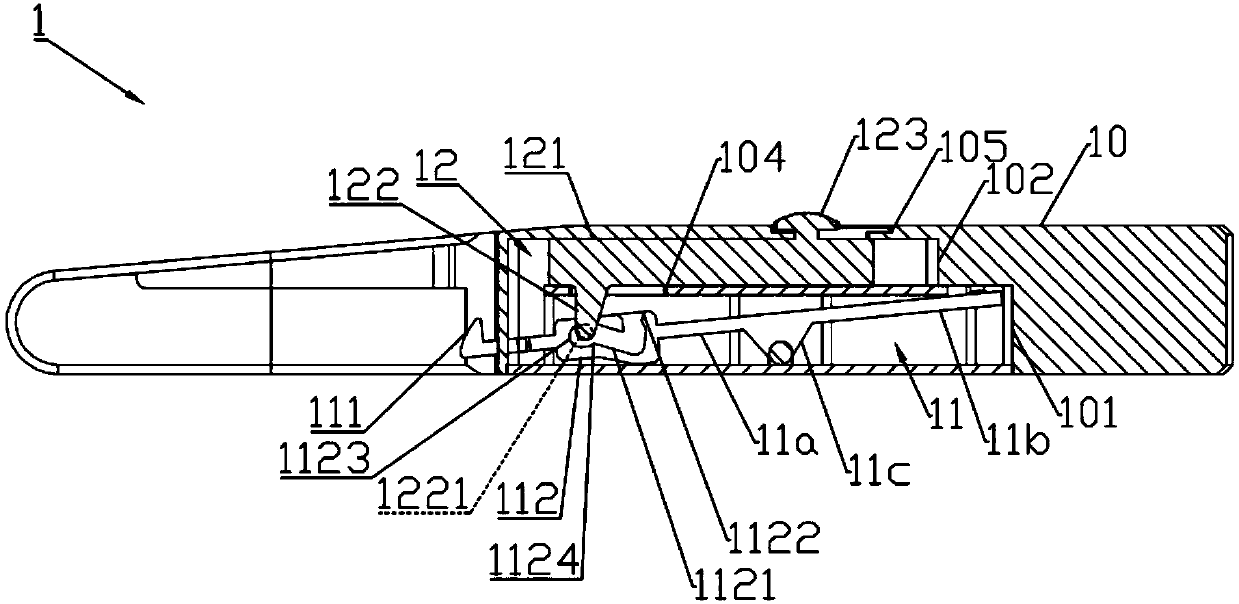

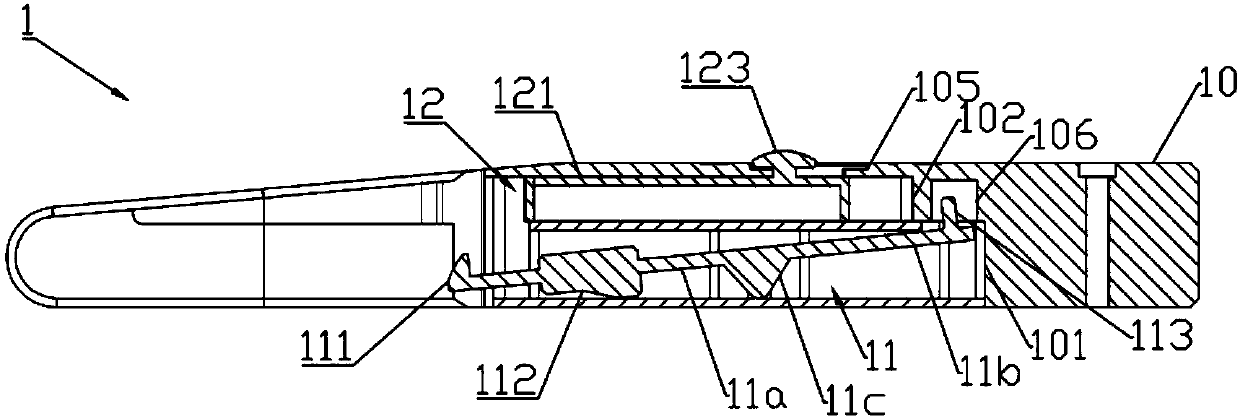

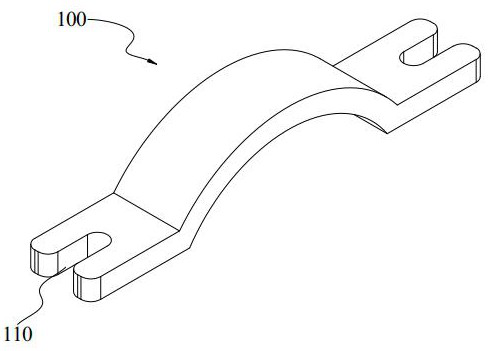

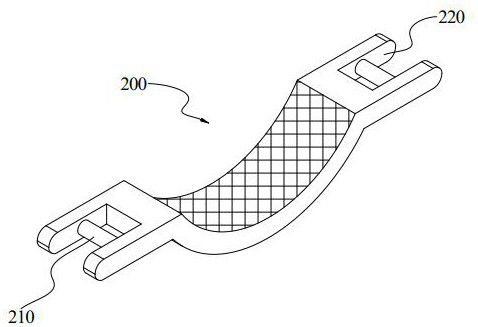

Connector and connector system

InactiveCN1871747AIncrease heightConnection will not affectElectrically conductive connectionsTwo-part coupling devicesElectrical conductorAbutment

In a connector having a wire connection structure of a conductor abutting type, it is an object to decrease the external size of the connector as much as possible without impairing the stability and reliability in a connection between a terminal element and a conductor. A connector (10) is provided with a terminal element (12) including a conductor-connecting section (14) connectable to a conductor (C) of an electric wire (W) and a contact section (16) capable of coming into conductive contact with a corresponding terminal element of a counterpart connector, an electrically insulating body (18) for supporting the terminal element (12) while exposing the conductor-connecting section (14) and the contact section (16), and an abutting member (20) assembled with the body (18) and bringing the wire conductor (C) into abutment with the conductor-connecting section (16) of the terminal element (12) under pressure. The body (18) includes a fitting portion (26) capable of fitting with a counterpart connector while positioning the contact section (16) of the terminal element (12) with respect to the corresponding terminal element. The conductor-connecting section (14) and the contact section (16) of the terminal element (12) are arranged to be aligned with each other in a direction generally orthogonal to a connector fitting direction defined by the fitting portion (26). The connector fitting direction is generally perpendicular to a wire extending direction on the body (18).

Owner:3M INNOVATIVE PROPERTIES CO

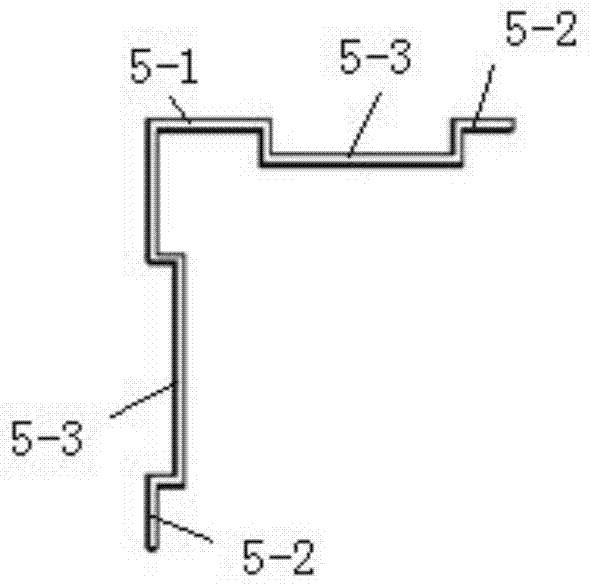

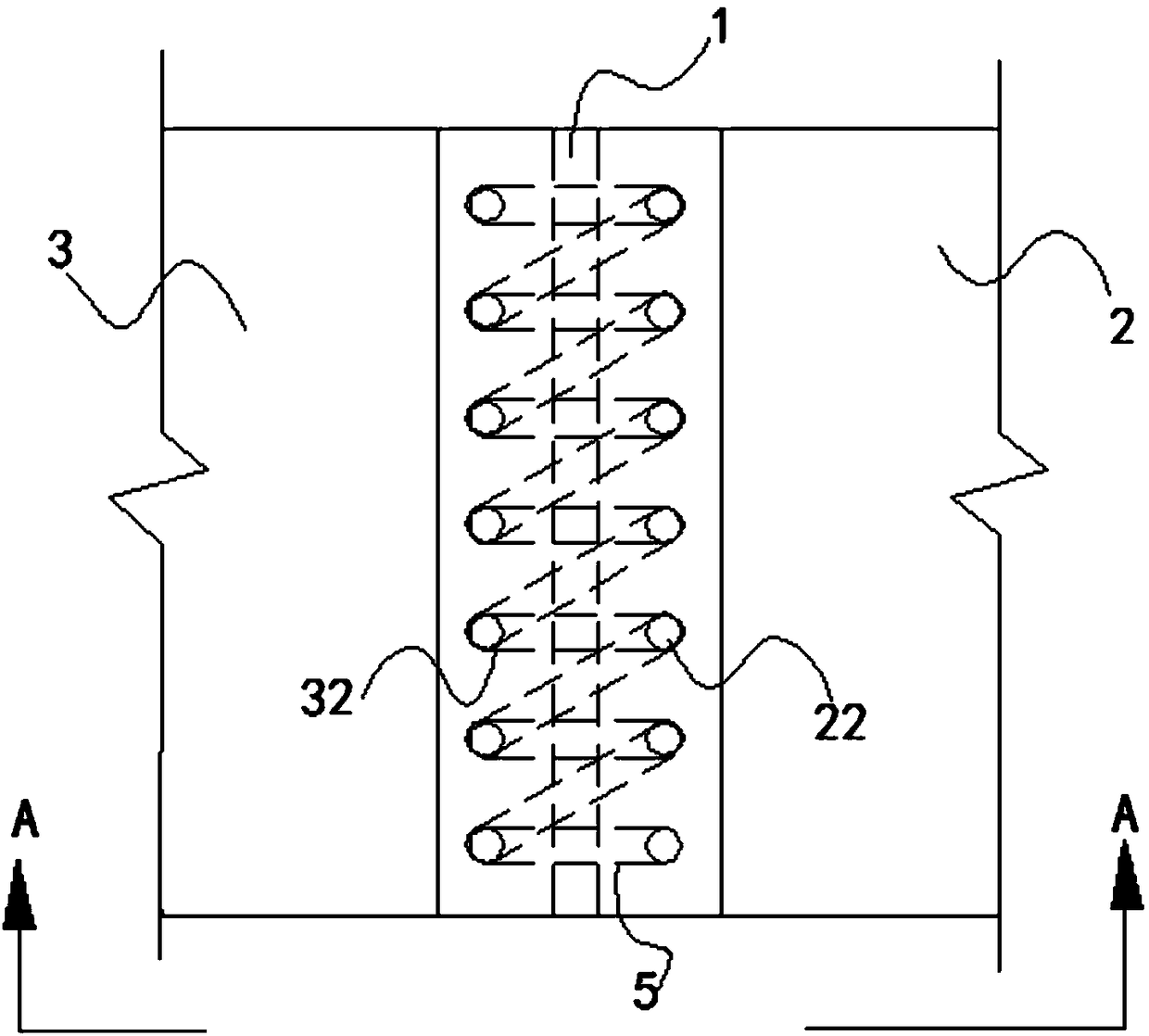

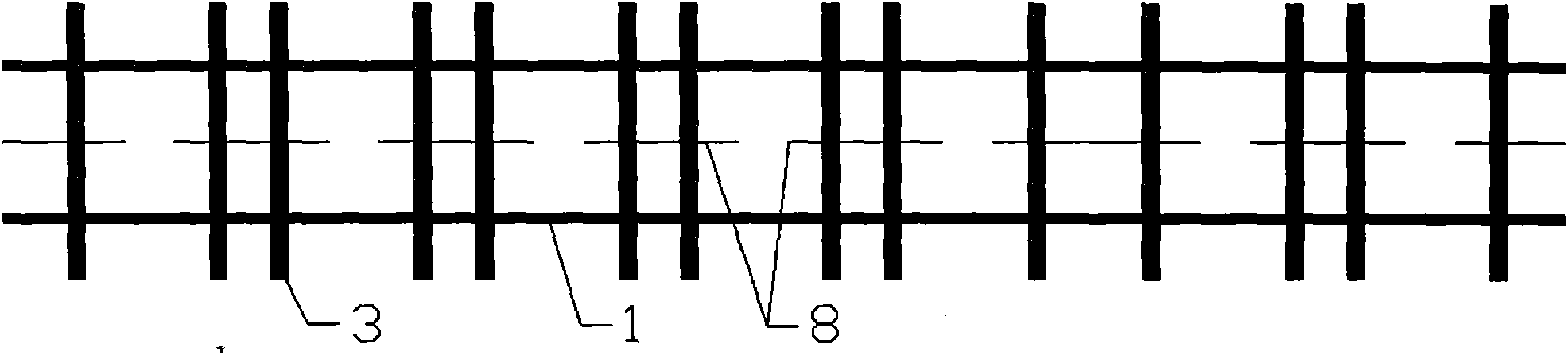

Concrete filled steel tube specially shaped column suitable for industrial production

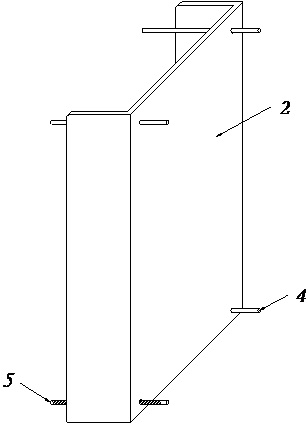

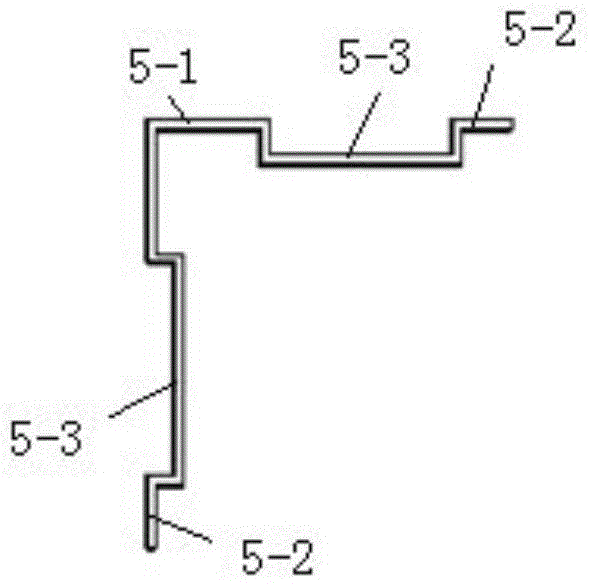

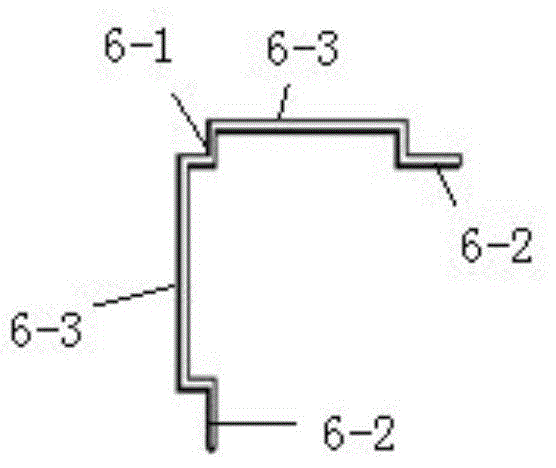

The invention relates to a concrete filled steel tube specially shaped column suitable for industrial production, which is a cross specially shaped column. The column comprises steel plates, long through bolts and concrete; the steel plates comprise four interior angle steel plates (6) and four U-steel plates (8); the interior angle steel plates (6) comprise corner parts (6-1), two end parts (6-2) and two side parts (6-3); the four interior angle steel plates (6) and the U-steel plates (8) are matched with each other in dimensions; the U-steel plates (8) and the end parts of the adjacent interior angle steel plates (6) are welded and connected respectively to form a cross specially shaped column body; the center and four end part sections of the cross specially shaped column are all square; the side parts of the corresponding interior angle steel plates (6) are consistent in dimensions, are provided with bolt holes, and are fixed and connected by virtue of the long through bolts; concrete is poured in the cross specially shaped column. The concrete filled steel tube specially shaped column disclosed by the invention is suitable for industrial batch production, and quick splicing in a construction site is realized.

Owner:TIANJIN UNIV

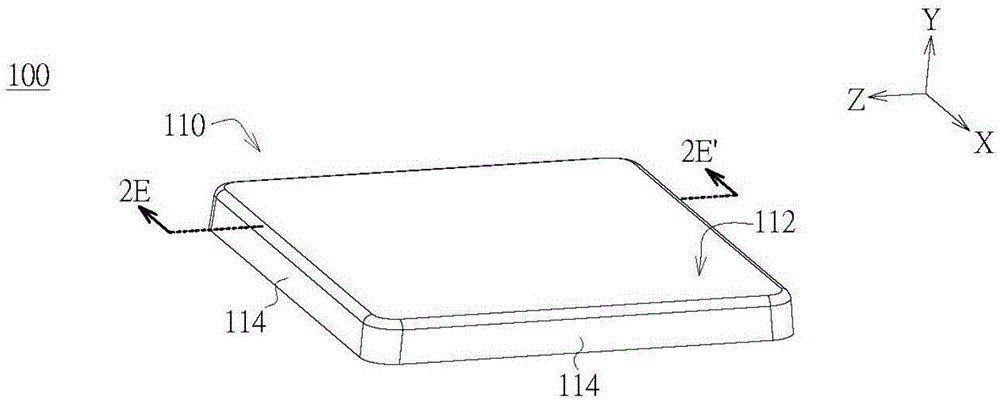

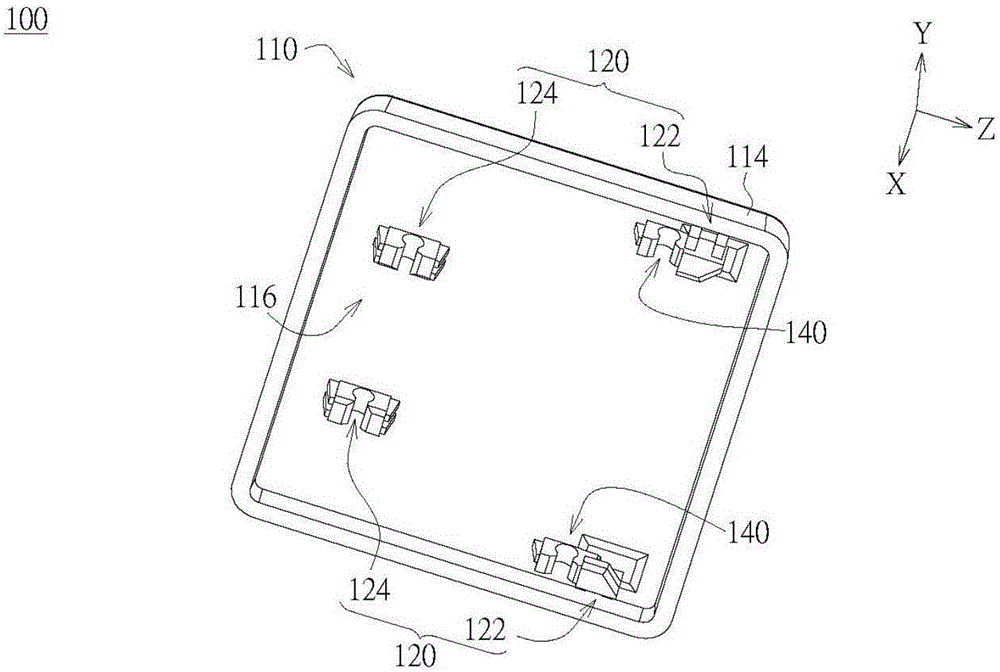

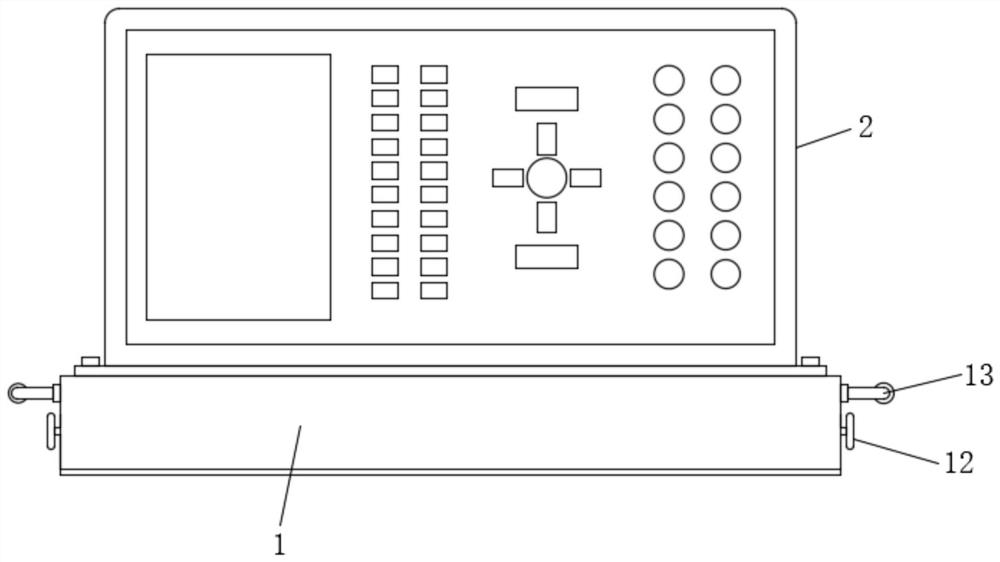

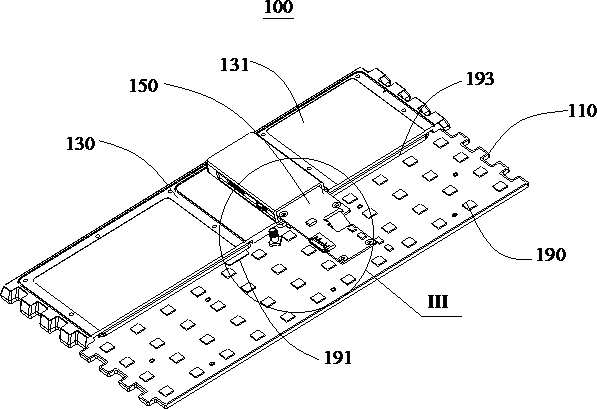

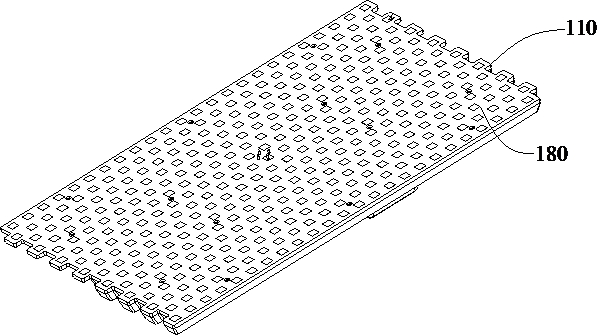

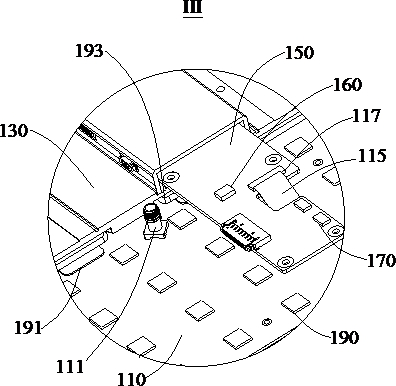

Key cap and key structure using the key cap

ActiveCN105070563AExtended service lifeEasy to makeOperation facilitationElectric switchesElectrical and Electronics engineeringEngineering

The invention discloses a key cap and a key structure using the key cap. The key cap comprises a key cap body, a support connecting structure and a tool connecting structure. The key cap body comprises a top face, a bottom face and a plurality of skirt structures. The top face is opposed to the bottom face which is located among the skirt structures. The support connecting structure is arranged on the bottom face and used for connecting a key cap supporting structure. The tool connecting structure is arranged on the bottom face and used for connecting a tool so as to make the tool bear a key cap. The tool connecting structure and the support connecting structure are connected in an adjacent way. When the key cap is arranged on the tool for processing, influence on the support connecting structure can be prevented. Meanwhile, the key cap can be arranged on a keyboard in a more stable way. The service lifetime of the keyboard can be prolonged.

Owner:DARFON ELECTRONICS (SUZHOU) CO LTD +1

Bridge expansion joint structure

InactiveCN108149564AMeet the needs of expansion and deformationStable structureBridge structural detailsBridge materialsFilling materialsExpansion joint

The invention discloses a bridge expansion joint structure includes a bridge main body and an expansion joint, the expansion joint divides the bridge main body into a first bridge main body and a second bridge main body, and a first support step is formed at the first bridge main body; the first support step is provided with a first fixing column, a second support step is formed at the second bridge main body, the second support step is provided with a second fixing column, and the side surfaces of the first and second support steps are separately and fixedly connected with C-shaped steel plates; an expansion joint connecting piece is arranged between the first bridge main body and the second bridge main body; the expansion joint connecting piece includes an upper support body and a lowersupport body which are both provided with reinforcing ribs; the upper of the expansion joint is provided with a cover plate; and elastic filling materials are filled between the expansion joint and the expansion joint connecting piece. According to the bridge expansion joint structure, the demand of expansion and deformation of a road can be met, the structure is steady, the bearing capacity is better, and the smoothness and the better comfort are achieved in the driving process; and the installation, the check and the maintenance are simple and convenient at the same time.

Owner:湖南鸿路建设工程有限公司

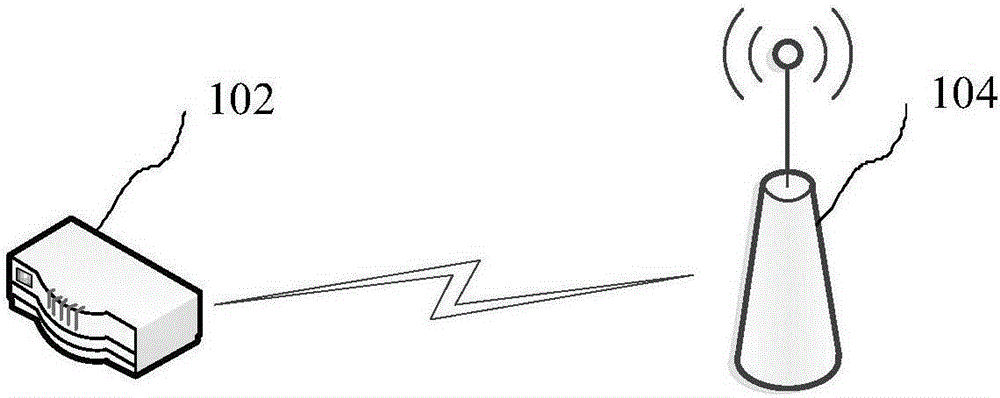

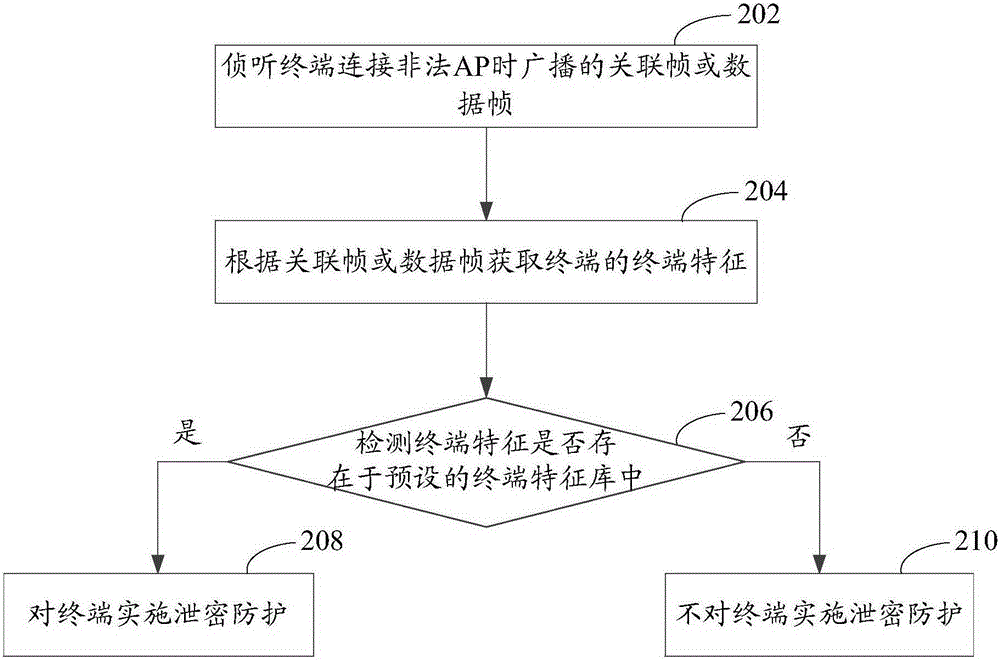

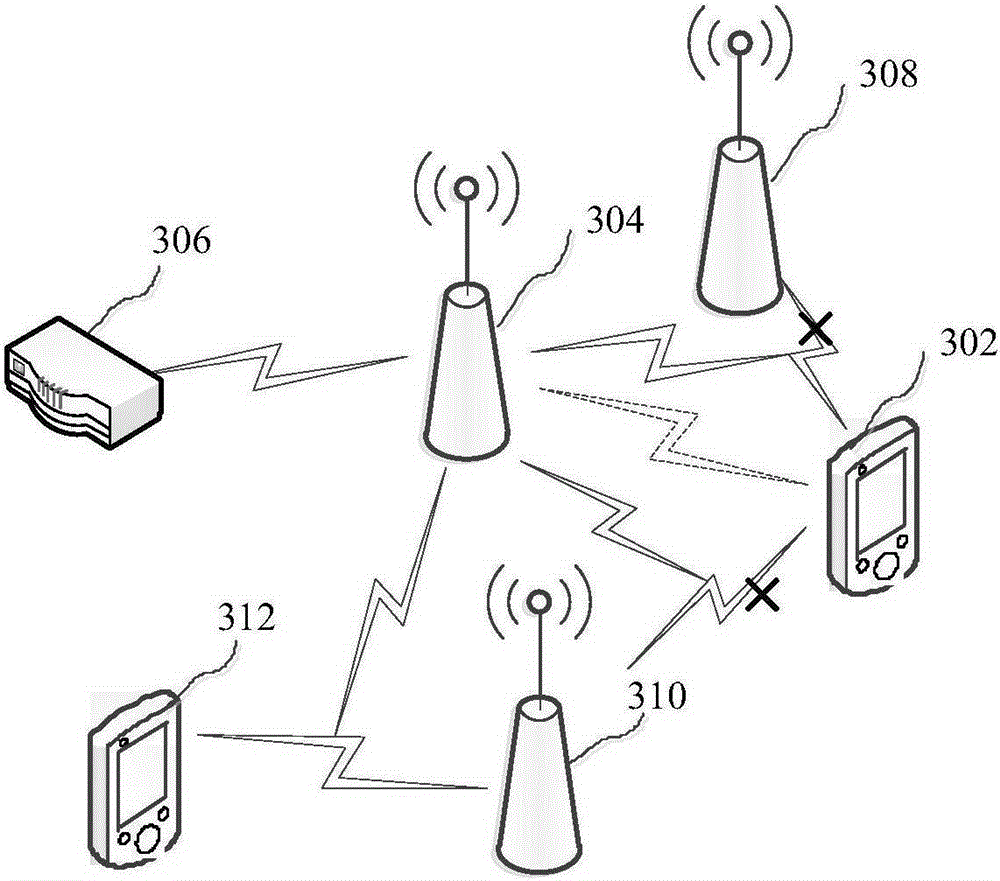

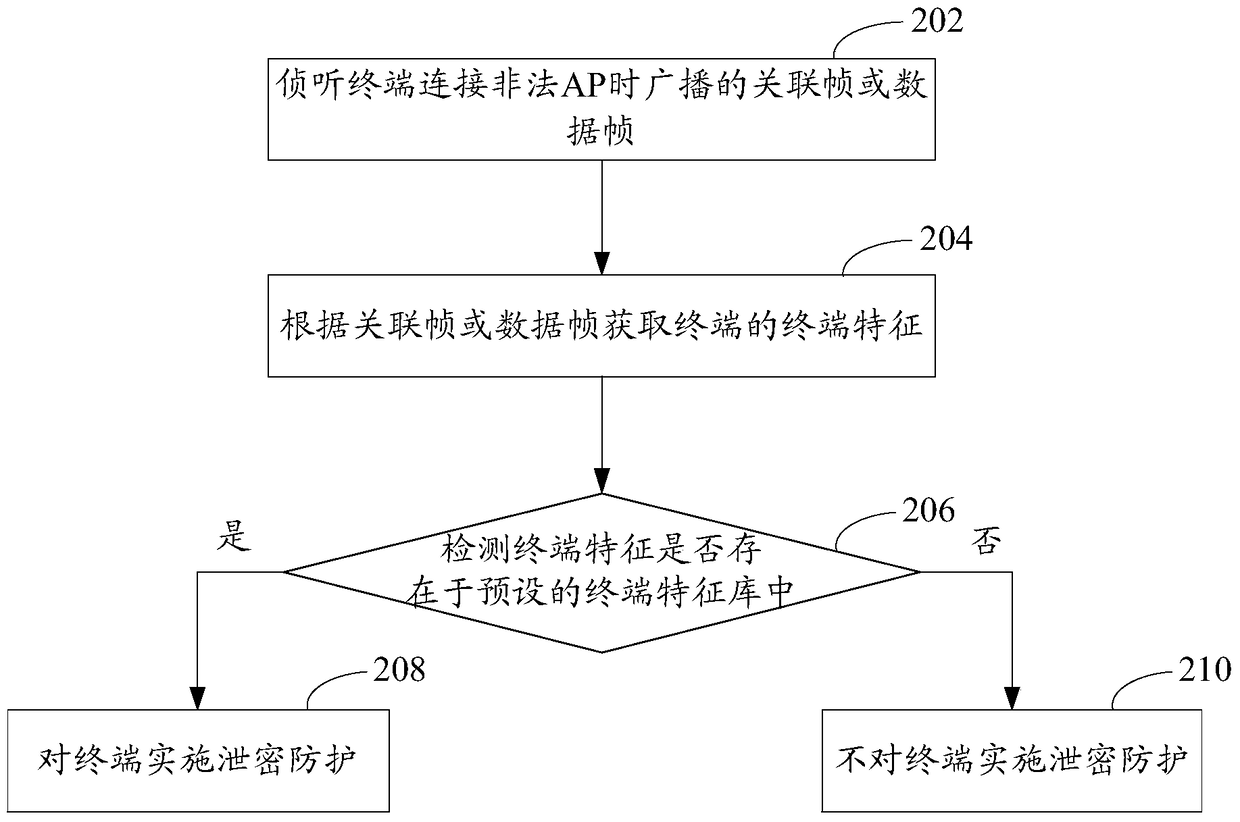

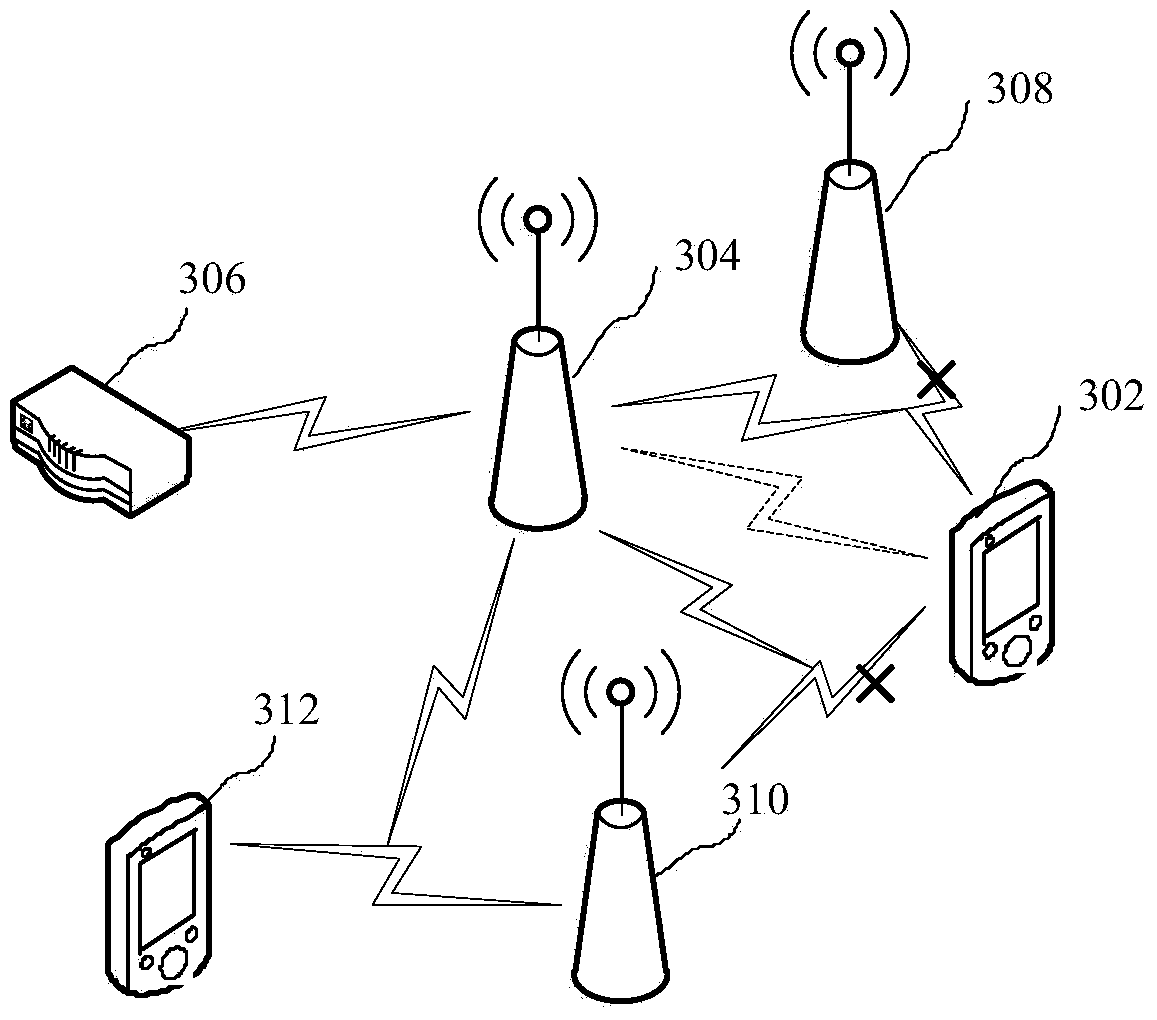

Confidence leakage protection method and device

The invention discloses a confidence leakage protection method, comprising steps of broadcasting related frame or data frames when a monitoring terminal is connected to an illegal AP, obtaining terminal characteristics of the terminal according to the related frame and the data frame, detecting whether the terminal characteristics exist in a preset terminal characteristic database, if yes, performing the leakage protection on the terminal. In leakage protection method, because the terminal characteristic database stores terminal characteristics of the terminal which is connected to the legal AP, so that the confidence leakage protection can be only applied on the terminal of the terminal characteristic database, and the confidence leakage protection is not performed on the terminal which is not in he terminal characteristic database without affecting the illegal connection with the AP by the terminal which is not in the terminal characteristic database. The invention does not affect the connection with the AP by the terminals of the other enterprise, and reduces the misjudgment.

Owner:SHENZHEN SUNDRAY NETWORK SCI TECH

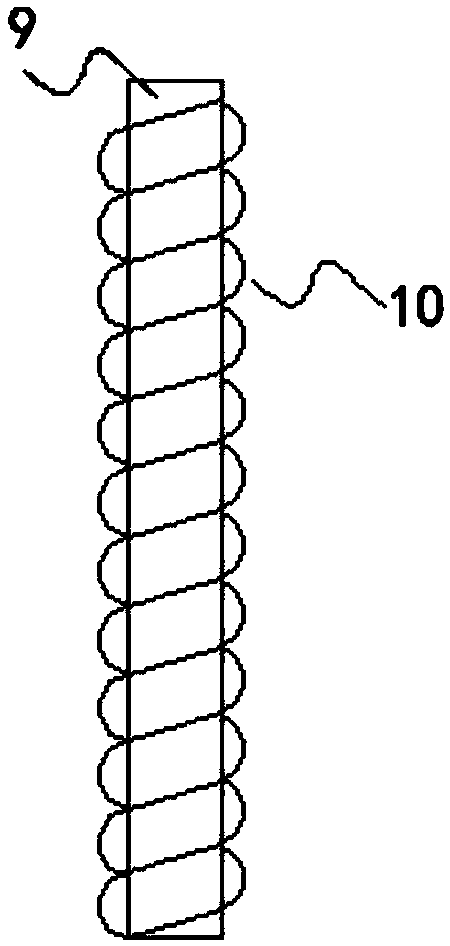

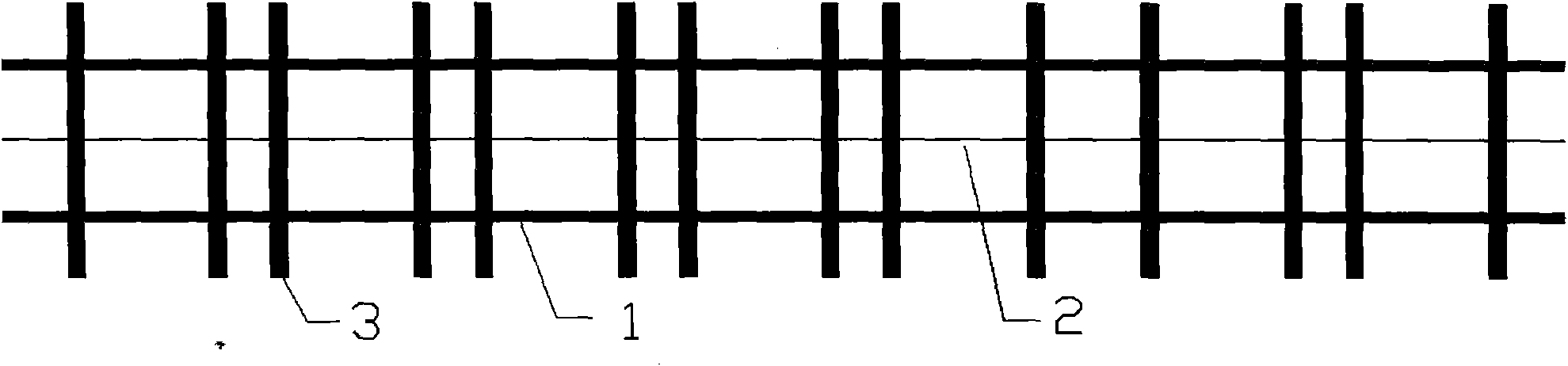

Method for manufacturing lamp belt and lamp belt

InactiveCN101825243AGuaranteed stabilityDoes not affect the connectionElectric circuit arrangementsElectric lightingLight sourcePower cord

The embodiment of the invention discloses a method for manufacturing a lamp belt and the lamp belt, wherein the lamp belt comprises at least two first leads and at least one lamp string, wherein the first leads are used as main power lines, the lamp string is electrically connected with the first leads through a second electric conductor, the lamp string comprises a plurality of connecting lines,and the lamp string also comprises a light source or a first electric conductor welded between the connecting lines. By adopting the method, the manufacturing flow of the lamp belt can be simplified.The lamp belt provided by the invention has simple structure and good stability.

Owner:刘昌贵

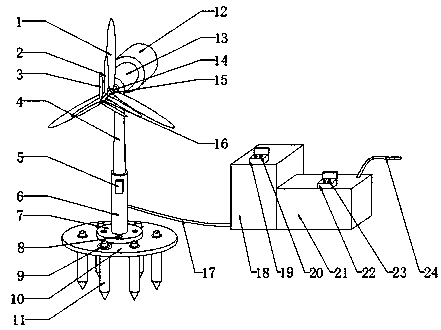

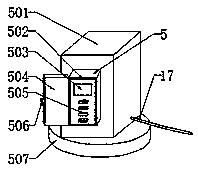

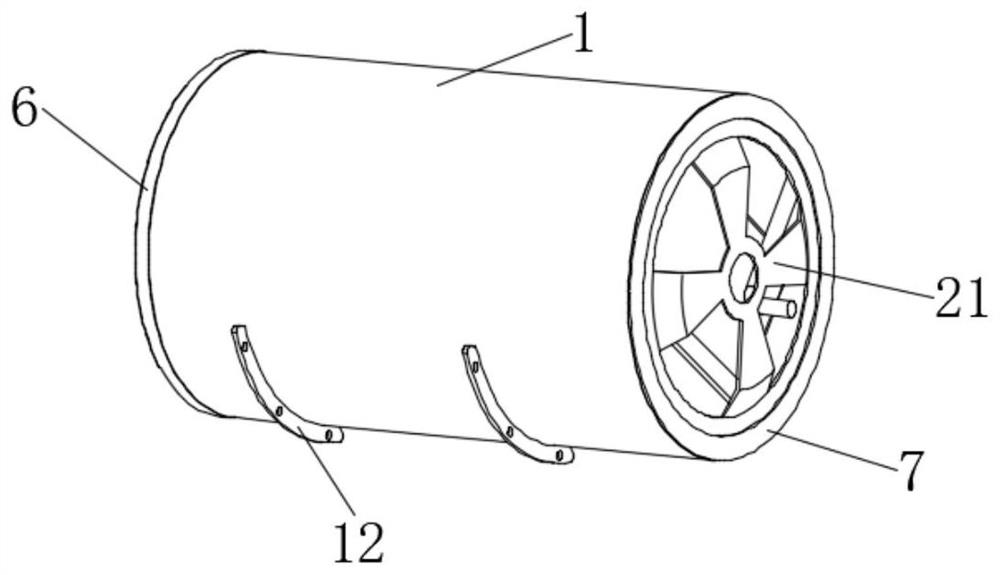

New-energy high-efficient wind power electric generation method

InactiveCN109306936AImprove stabilityAvoid leaningWind motor controlWind motor supports/mountsNew energyEngineering

The invention discloses a new-energy high-efficient wind power electric generation method. The device for implementing the new-energy high-efficient wind power electric generation method comprises a vertical rod, wherein an expansion fixed pile inner core is arranged in the expansion fixed pile; an expansion fixed pile outer layer is arranged on the surface of the expansion fixed pile inner core;a supporting rod is arranged at the top of the vertical rod; an electric generator connecting cylinder is arranged at the top of the supporting rod; an electric generator is arranged on one side of the electric generator connecting cylinder; a first wind blade shaft, a second wind blade shaft and a third wind blade shaft are arranged in the electric generator connecting cylinder; a first wind blade is arranged at one end of the first wind blade shaft; a second wind blade is arranged at one end of the second wind blade shaft; and a third wind blade is arranged at one end of the third wind bladeshaft. According to the new-energy high-efficient wind power electric generation device disclosed by the invention, the expansion fixed pile, the first wind blade, the first wind blade shaft, the second wind blade, the second wind blade shaft, the third wind blade and the third wind blade shaft are arranged.

Owner:太仓新宏电子科技有限公司

Automobile sun shield

InactiveCN111619321AEasy to replaceEasy to separateAntiglare equipmentSun visorsEngineeringStructural engineering

Owner:HUBEI SHUANGOU AUTOMOTIVE TRIM

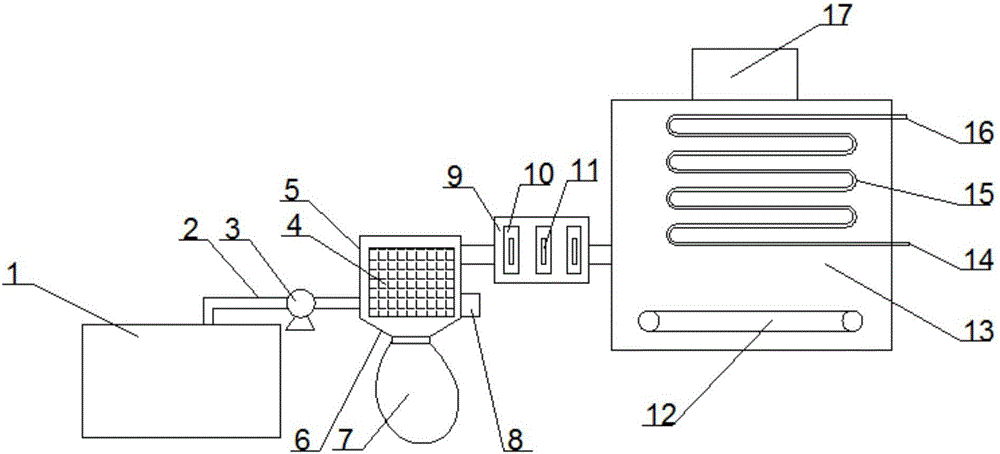

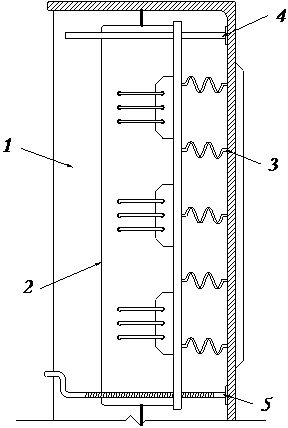

Ceramic kiln exhaust gas residual heat recovery apparatus

InactiveCN106247809AEfficient removalReduce foulingEnergy industryIncreasing energy efficiencyFlue gasEngineering

The invention discloses a ceramic kiln exhaust gas residual heat recovery apparatus, which comprises a boiler body, a flue gas pipe is arranged at the upper end of the boiler body, a draft fan is arranged on the flue gas pipe, and the flue gas pipe is connected with the left side of an electrostatic precipitator; dust collecting electrodes are arranged in the electrostatic precipitator, a flue-dust retainer is arranged at the lower end of the electrostatic precipitator, and a detachable dust collecting bag is arranged at the lower end of the flue-dust retainer; the upper right end of the electrostatic precipitator communicates with an exhaust pipe, and a vibrator is arranged at the lower right end of the electrostatic precipitator; the electrostatic precipitator is connected with the left bottom of a green body drying box through the exhaust pipe, and an adsorption box is arranged on the exhaust pipe. The ceramic kiln exhaust gas residual heat recovery apparatus is convenient to use, decreases the frequency of shutdown for dust removal, reduces the maintenance cost, has a good dust removal and purification effect, and increases the efficiency of dust removal; the ceramic kiln exhaust gas residual heat recovery apparatus can purify harmful gas in exhaust gas, so the environment is protected; moreover, by using exhaust gas to dry ceramic green bodies and heat cold water, the ceramic kiln exhaust gas residual heat recovery apparatus can reduce resource waste and cost.

Owner:XUZHOU CITY JIAWANG DISTRICT LUOZI AGRI TECH CO LTD

Touch screen of electronic device and electronic device

ActiveCN107704141AReduce areaLow costInput/output processes for data processingElectrical and Electronics engineeringElectronic equipment

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Structure for enhancing connection stability

InactiveCN105972006ARealize detachable connectionFirmly connectedSecuring devicesBlind holeEngineering

The invention discloses a structure for enhancing connection stability. The structure comprises a body and an auxiliary body. One end of the body is provided with an insertion groove which is formed in the height direction of the body. The other end of the body is provided with a blind hole which is formed in the width direction of the body. The auxiliary body connected to the body is arranged at one side of the blind hole. The two ends of the auxiliary body are each provided with a detachable guide block and a locking device used for fastening the auxiliary body and the guide block. Each locking device comprises a first groove, a second groove, a first column, a second column and a locking piece. The first grooves are formed in the guide blocks. The second grooves are formed in the auxiliary body. The first columns are arranged in the first grooves, and the second columns are arranged in the second grooves. A first clamping hook and a second clamping hook are arranged at the two ends of each locking piece correspondingly. The first clamping hooks hook the first columns, and the second clamping hooks clamp the second columns. The structure for enhancing the connection stability has high connection stability, selection according to requirements can be available, and real-time locking can be conducted; and the structure can be used flexibly and conveniently and is worthy of popularization.

Owner:陈昊书

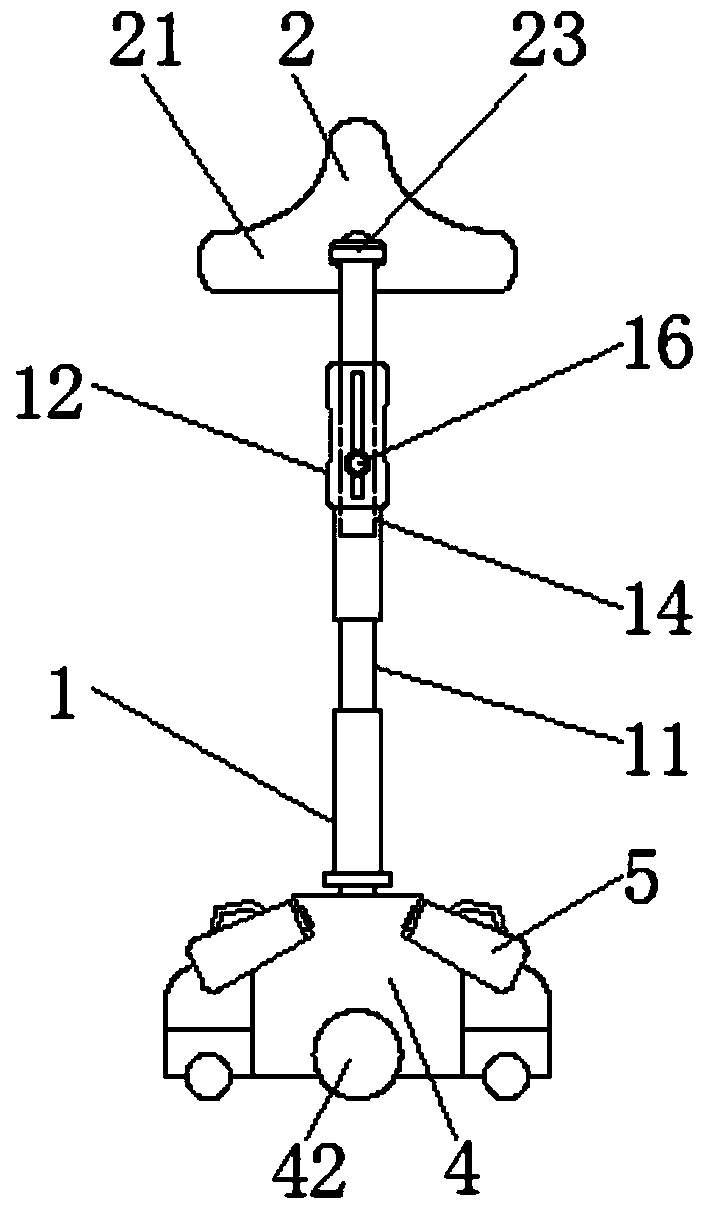

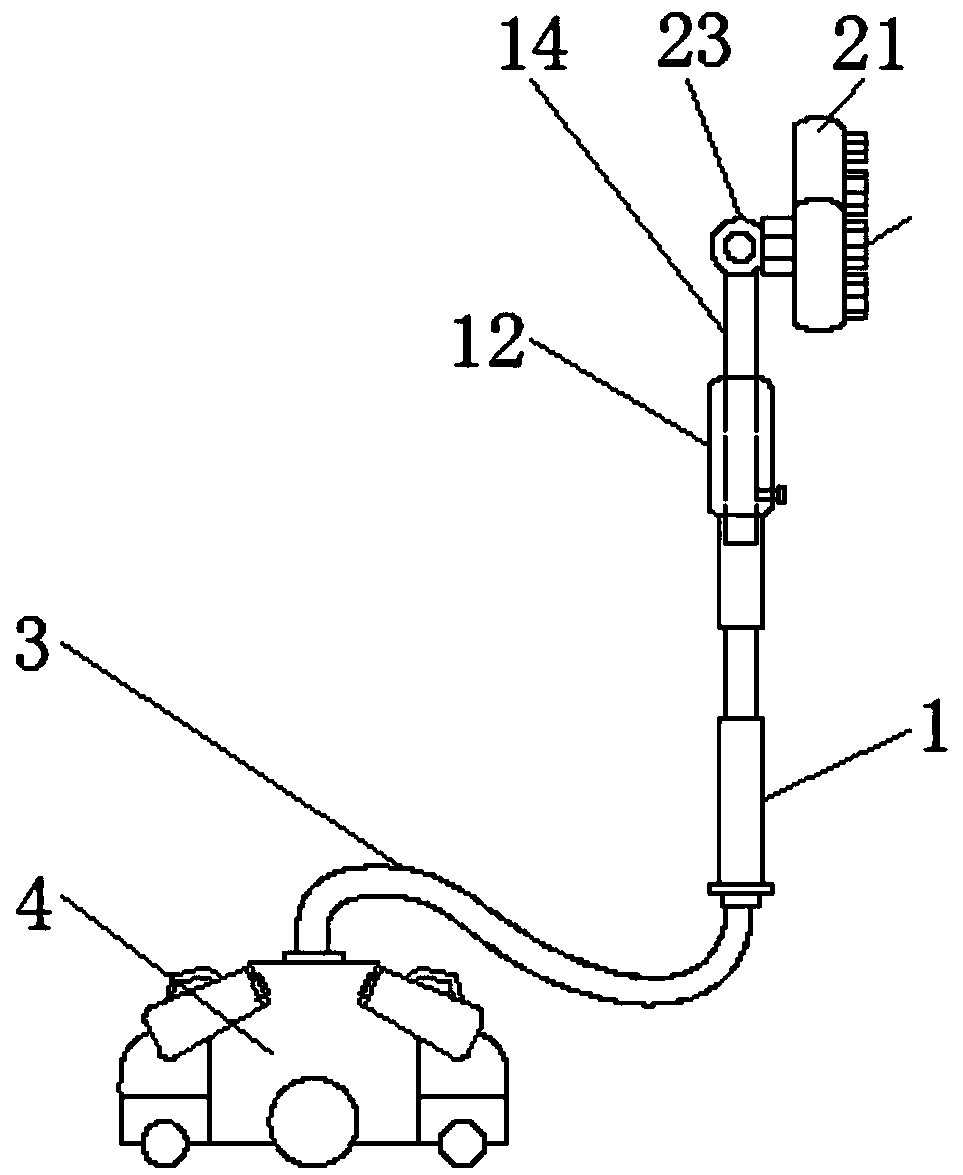

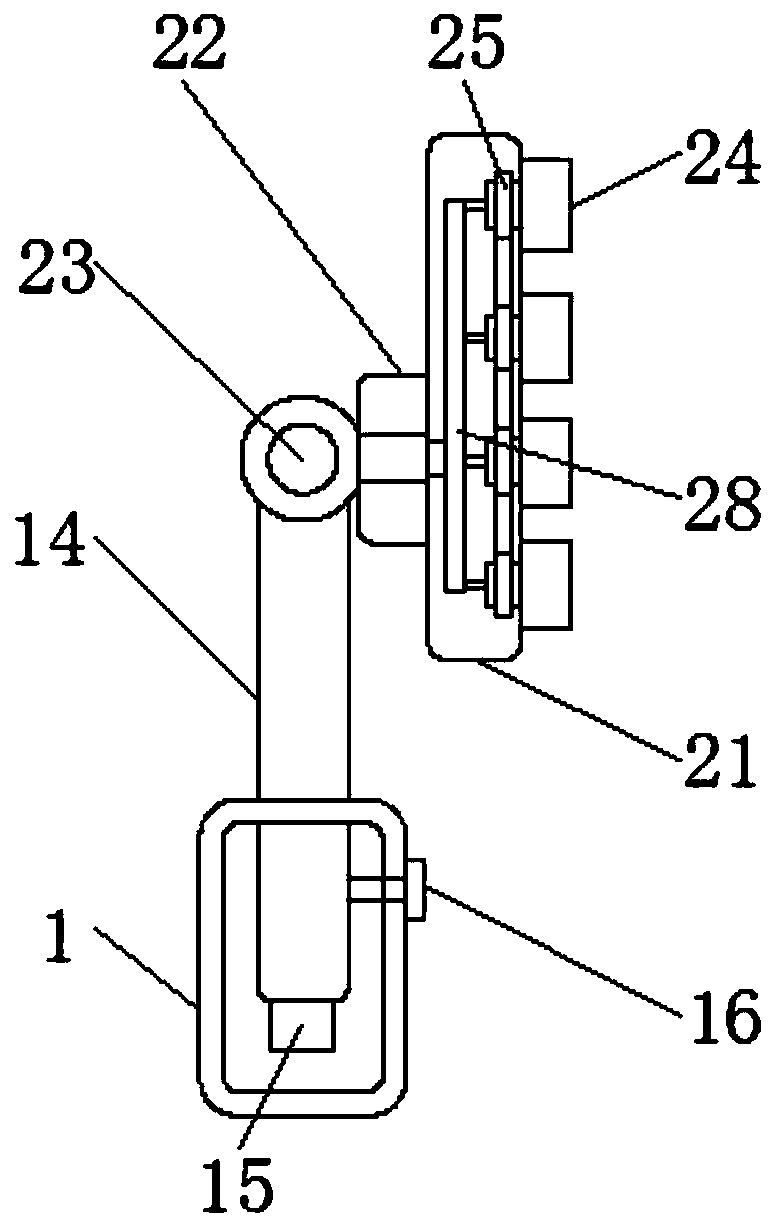

A sofa maintenance device for maintenance of office equipment

InactiveCN109199235AReduce physical exertionAvoid swingingCarpet cleanersFloor cleanersGear driveGear wheel

A sofa maintenance device for maintenance of office equipment includes an extension mechanism, a cleaning structure, a hose, a loading mechanism, a storage and a winding mechanism, and is characterized in that one end of the extension mechanism is installed with a cleaning structure, the other end of the extension mechanism is fixed with the hose, the loading mechanism is installed at one end of the hose, a storage device is fixed on one side wall of the loading mechanism, the winding mechanism is installed in the middle of the loading mechanism; the winding mechanism is wound with a hose; thedevice is provided with an atomizer capable of humidifying the brush head, the atomizer converts the cleaning liquid in the reservoir into water vapor, The hose is introduced into the brush head, andthe servo motor is used to drive the belt to rotate, and the gear drives the brush head to rotate under the action of the belt, so that the sofa can be scrubbed and cleaned to a certain extent, and the atomized liquid does not soak the sofa, dampens the sofa, and is convenient for the sofa to be ventilated and dried.

Owner:ZHONGXIANGBOQIAN INFORMATION TECH CO LTD

Connection structure and connection method of heat exchange tube and tube plate

ActiveCN102305572BSolve the problem that the sealing requirements cannot be metConnection will not affectHeat exchanger casingsMetal working apparatusEngineeringThermal expansion

Owner:SICHUAN BLUSR MACHINERY

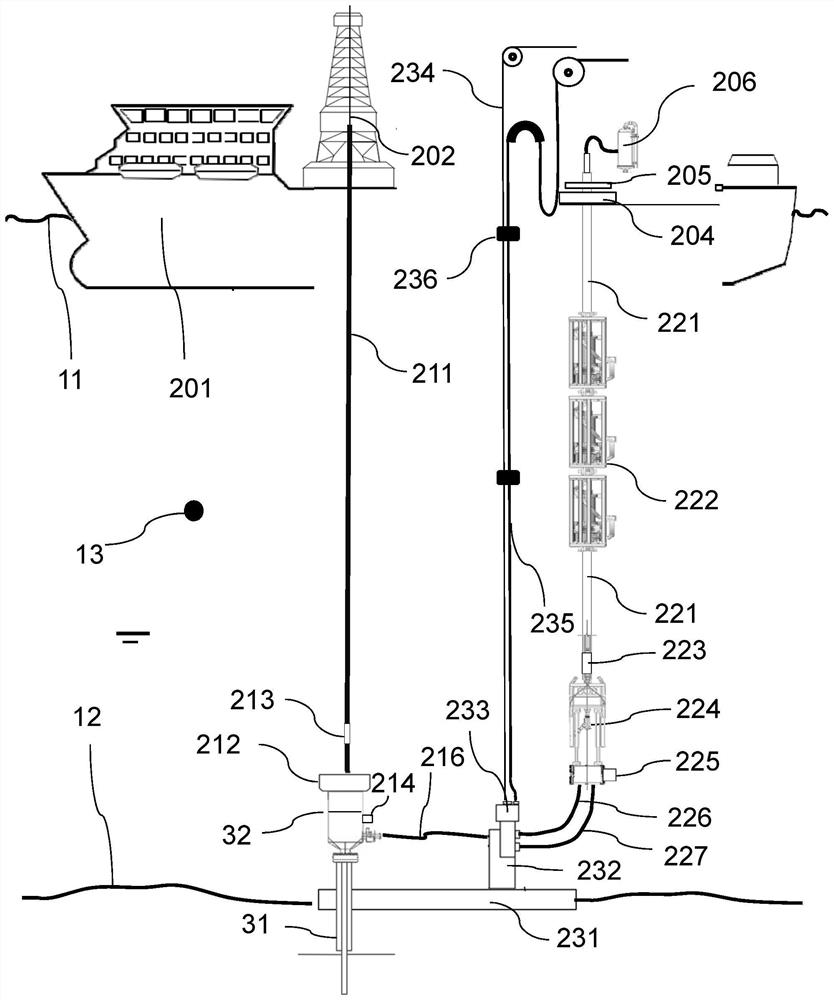

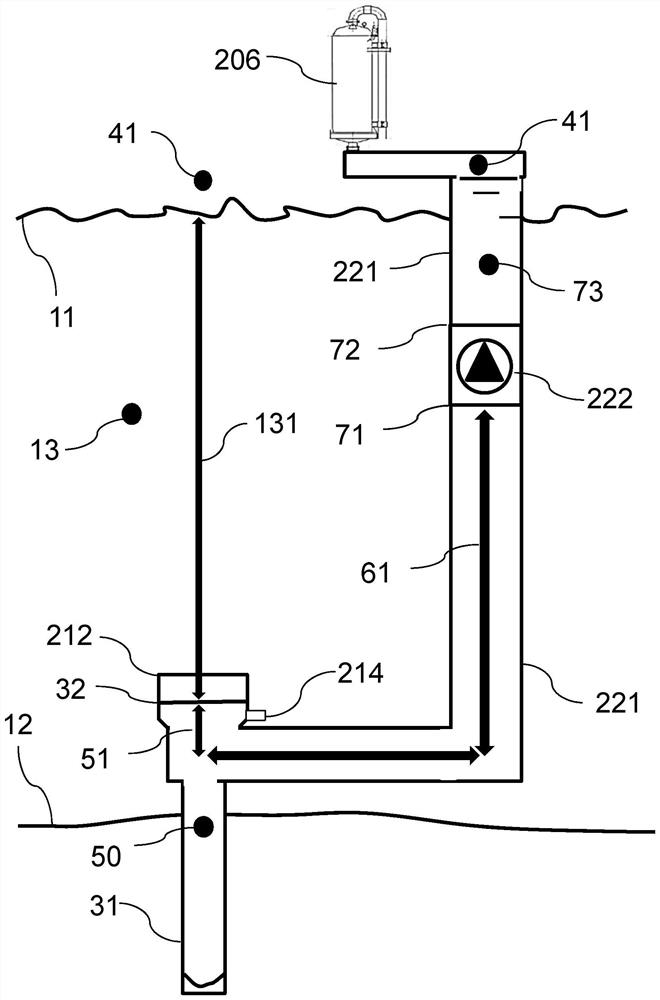

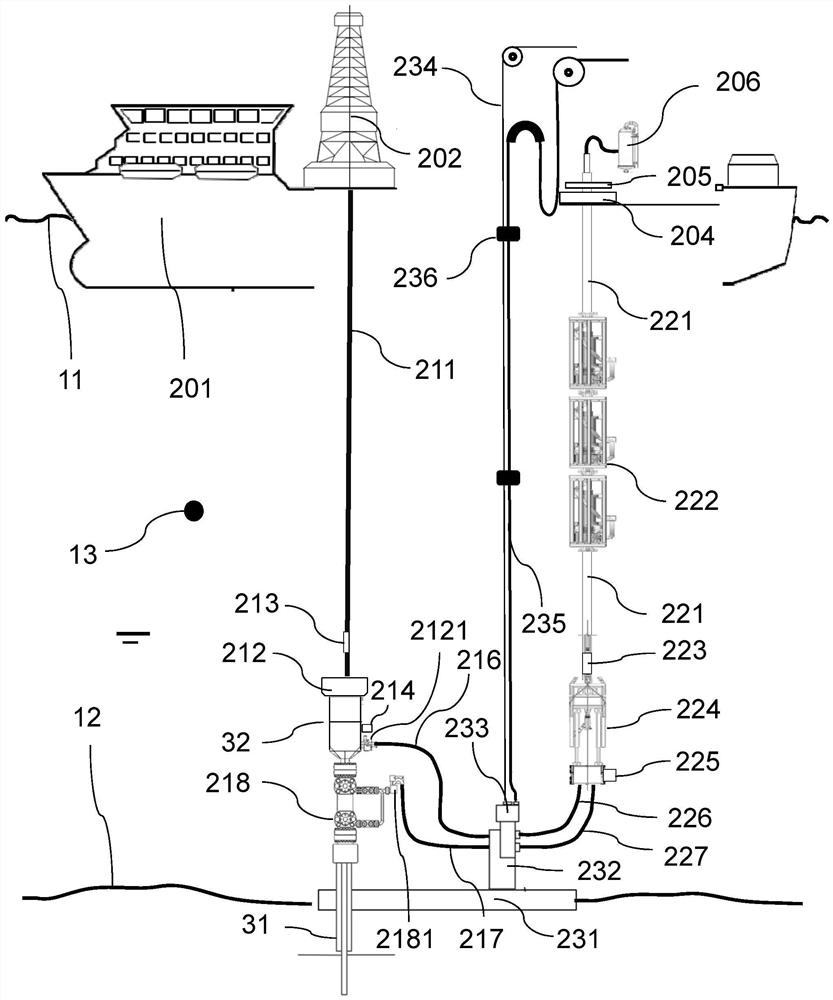

Drilling fluid backflow system for offshore drilling without marine riser

The invention provides a drilling fluid backflow system for offshore drilling without a marine riser. The drilling fluid backflow system comprises a drilling fluid volume control unit, an open water area drilling rod, a drilling fluid backflow pipeline, a drilling fluid backflow pump installed on the drilling fluid backflow pipeline and a drilling fluid processing device; the drilling fluid volume control unit is directly installed on a well head or above a blowout preventer without the marine riser, and the top of the drilling fluid volume control unit is open towards seawater; the drilling rod extends from a drilling platform through the volume control unit and performs a drilling operation passing through the interior of the volume control unit; the drilling fluid backflow pipeline is connected with the volume control unit through a hose, the drilling fluid backflow pump is sequentially installed on a pipe section in the backflow pipeline in the axial direction and used for pumping drilling fluid flowing into the backflow pipeline from the volume control unit to back to the drilling platform, and the drilling fluid is recycled after being treated by the drilling fluid processing device. The drilling fluid backflow system is not limited by the size and the water depth of a drilling ship, capable of effectively recovering the drilling fluid, and suitable for full-water-depth drilling operation.

Owner:派格水下技术(广州)有限公司

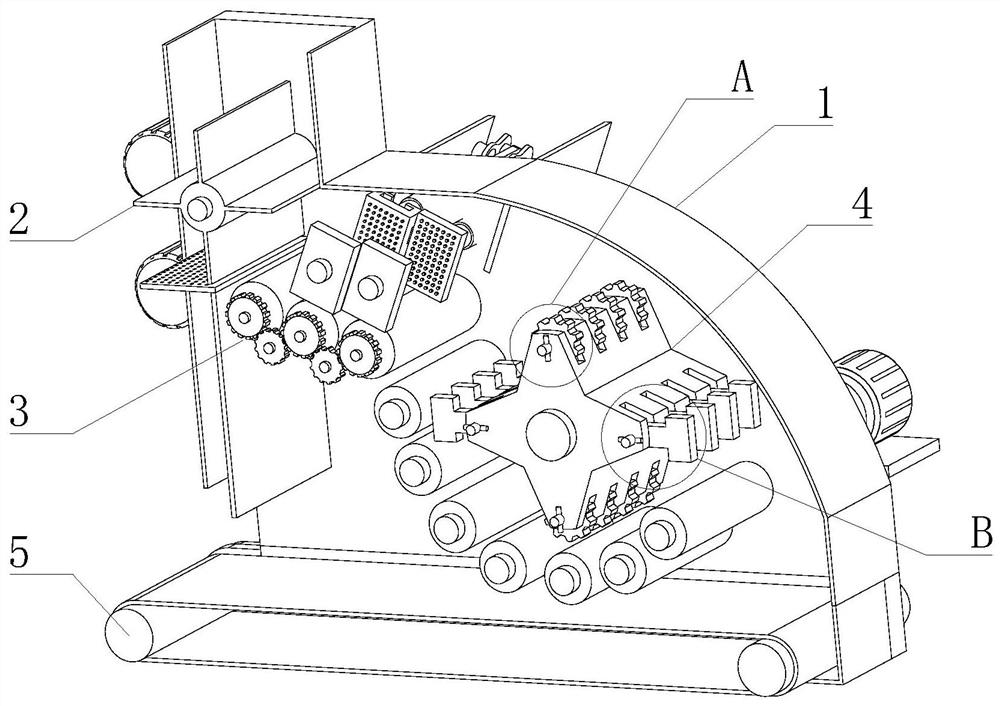

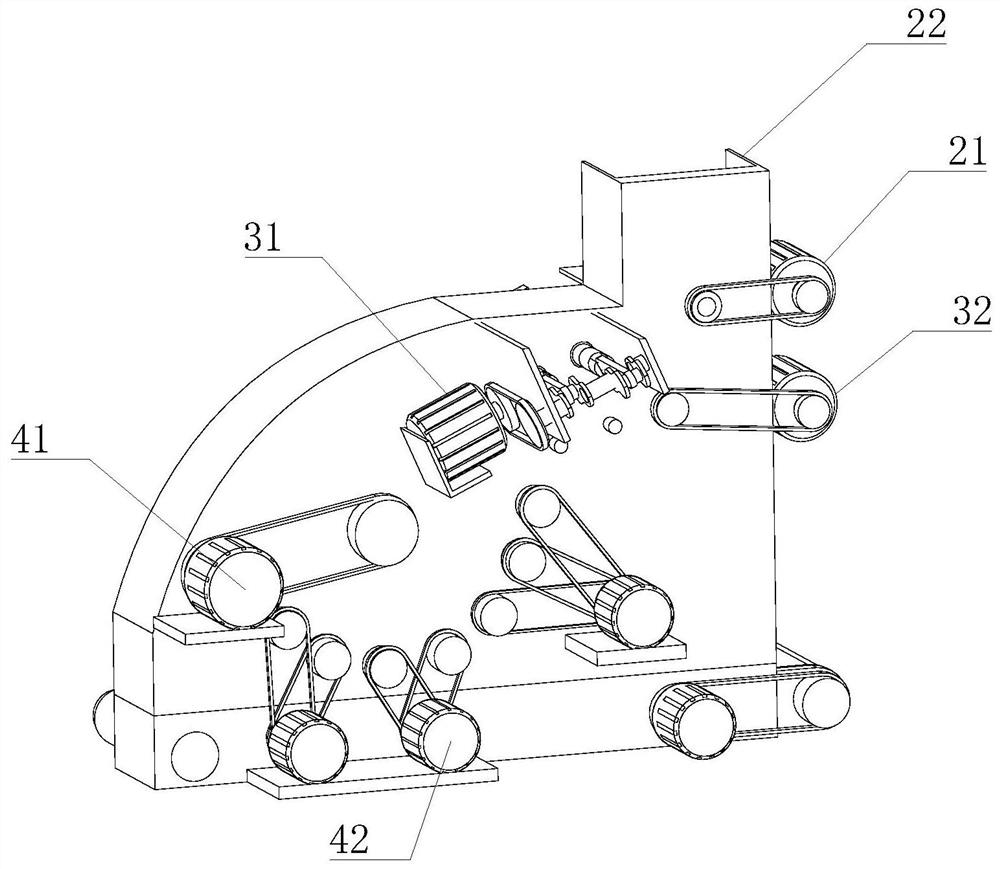

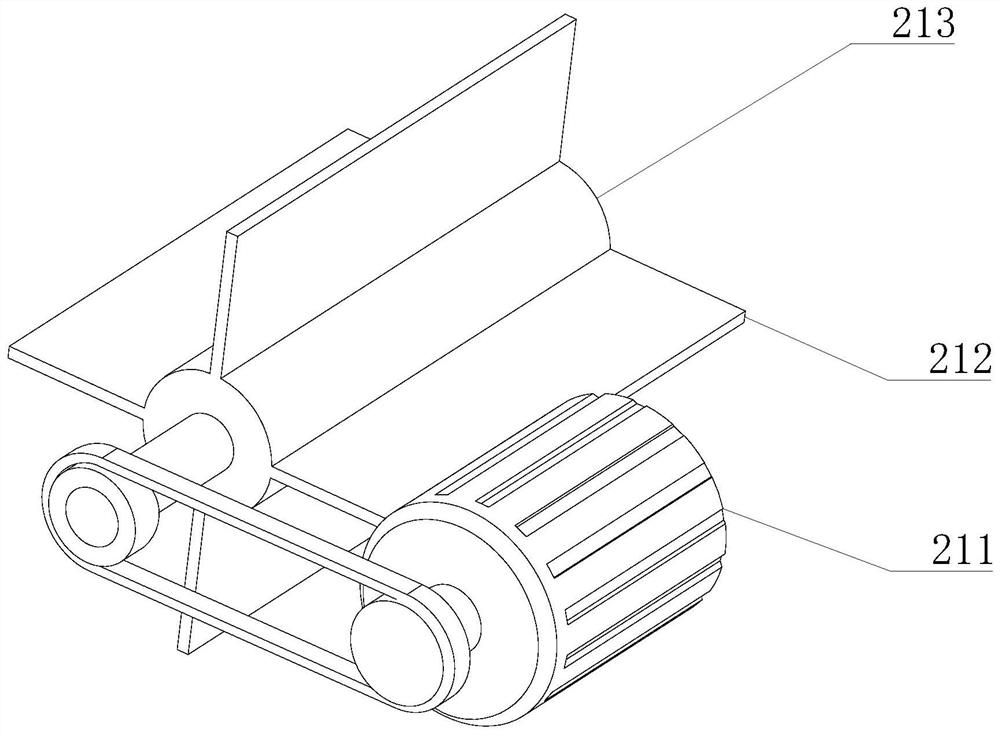

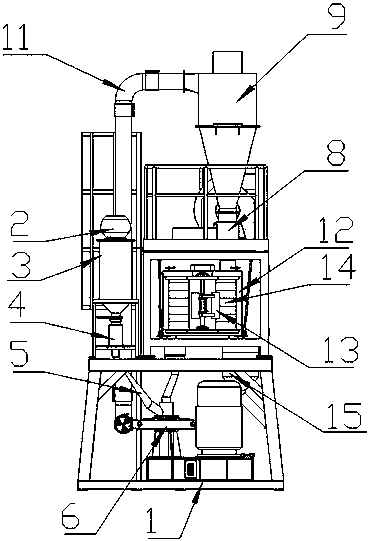

Screening and crushing all-in-one machine for coal mining

PendingCN113522502AWon't stayAbnormal operationMagnetic separationGrain treatmentsCoal briquetteMining engineering

The invention discloses a screening and crushing all-in-one machine for coal mining, and relates to the technical field of screening and crushing all-in-one machines. The screening and crushing all-in-one machine for coal mining comprises a case, an iron removal device is fixedly mounted at the left end in the case, and a first-stage screening and crushing device is fixedly mounted in the case and on the right side of the iron removal device; and a second-stage screening and crushing device is fixedly installed in the case and located on the right side of the first-stage screening and crushing device, and a conveying device is fixedly installed at the lower end in the case. The iron removal device is arranged to be a rotatable device, the iron removal area is increased, the iron removal efficiency is improved, and it is guaranteed that a large number of coal briquettes cannot stay on an iron removal plate when entering the device, so that the situation that the whole machine operates abnormally is avoided, a first-stage crushing device is additionally arranged before crushing of a crushing wheel, and extrusion and preliminary crushing are conducted between a movable crushing plate and a fixed crushing plate; and the size of the coal briquettes is reduced, so that the size of the coal briquettes before entering the crushing wheel is reduced, and abnormal shutdown of the whole machine due to clamping stop between the crushing wheel and a screening roller caused by overlarge size of the coal briquettes is avoided.

Owner:文振荣

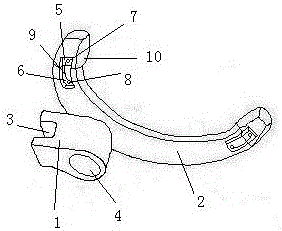

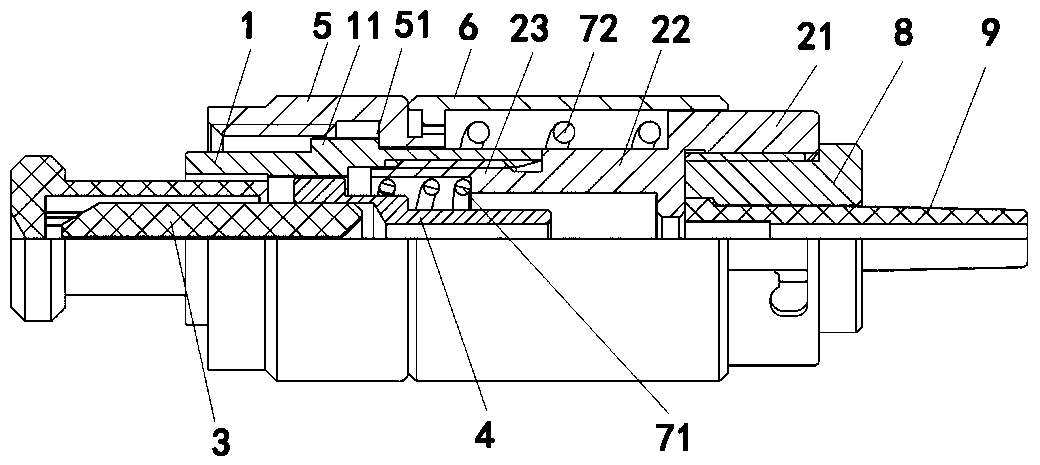

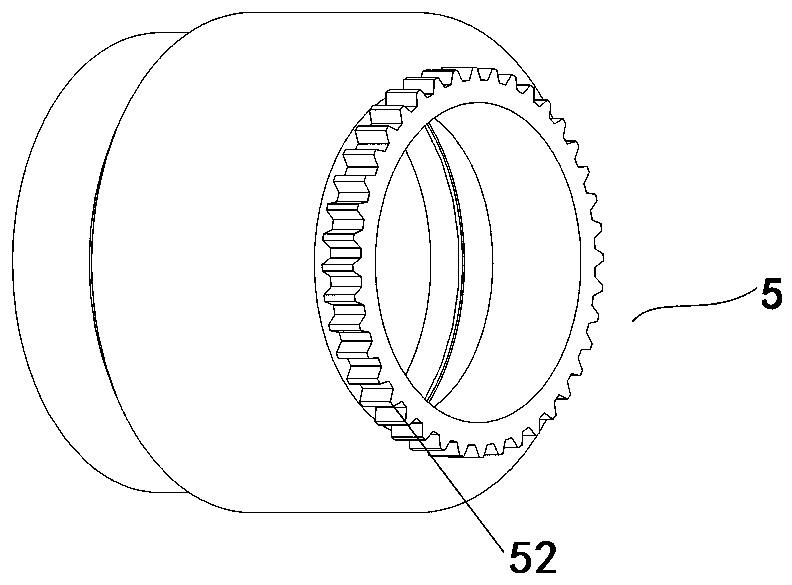

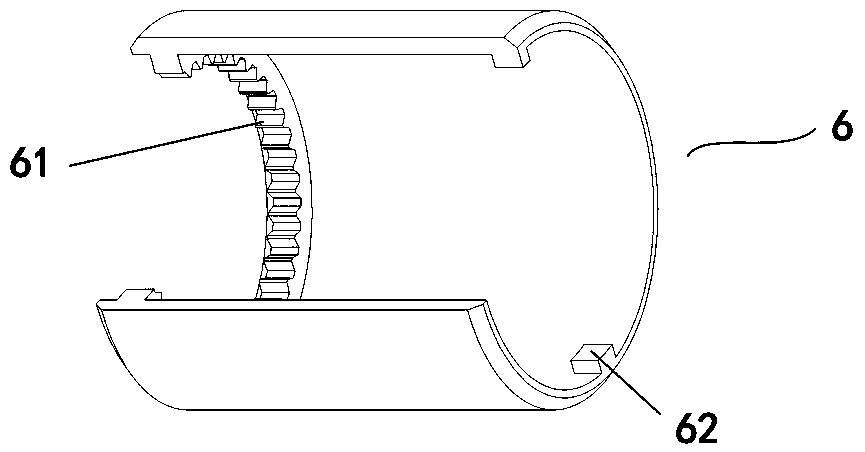

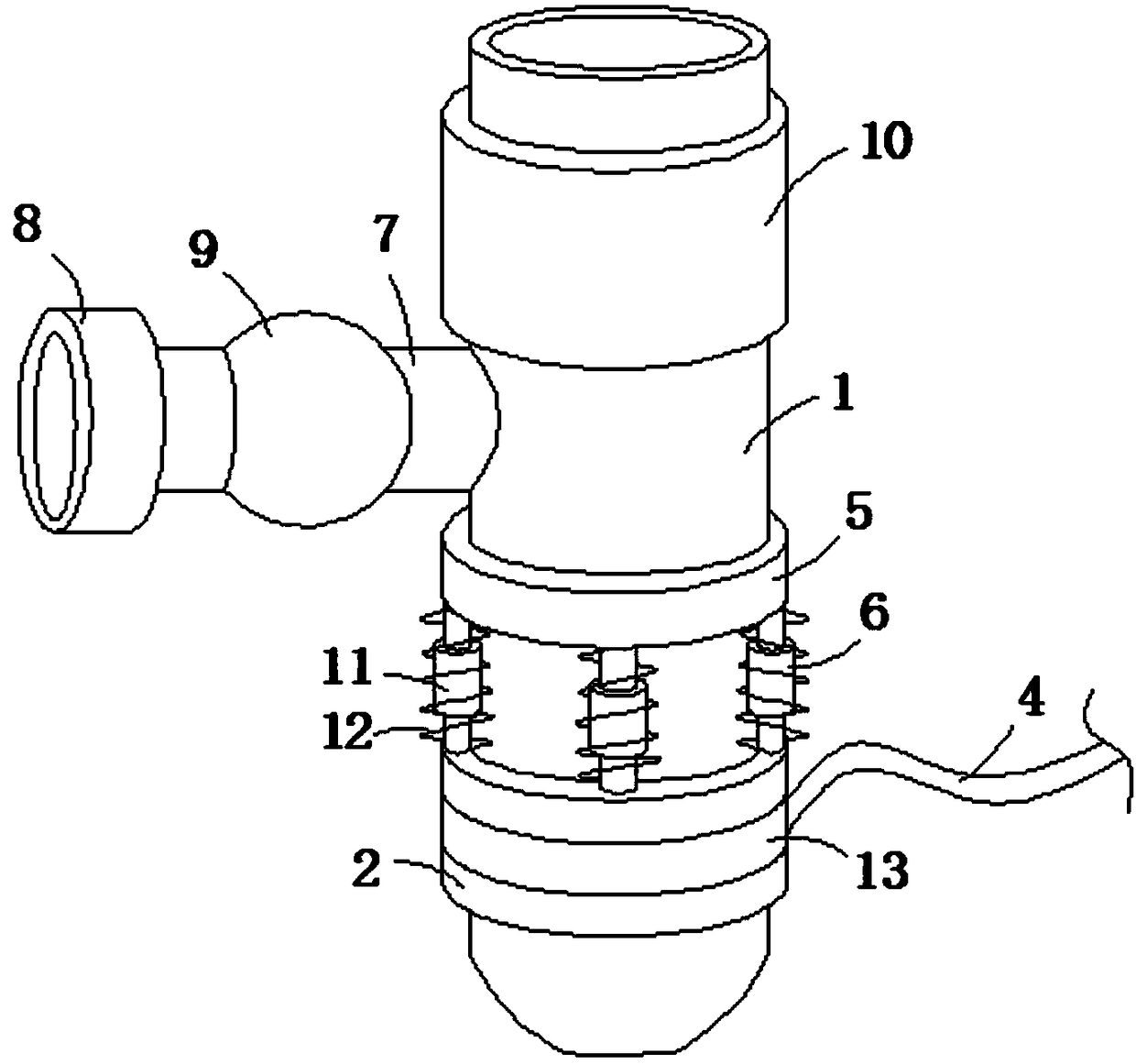

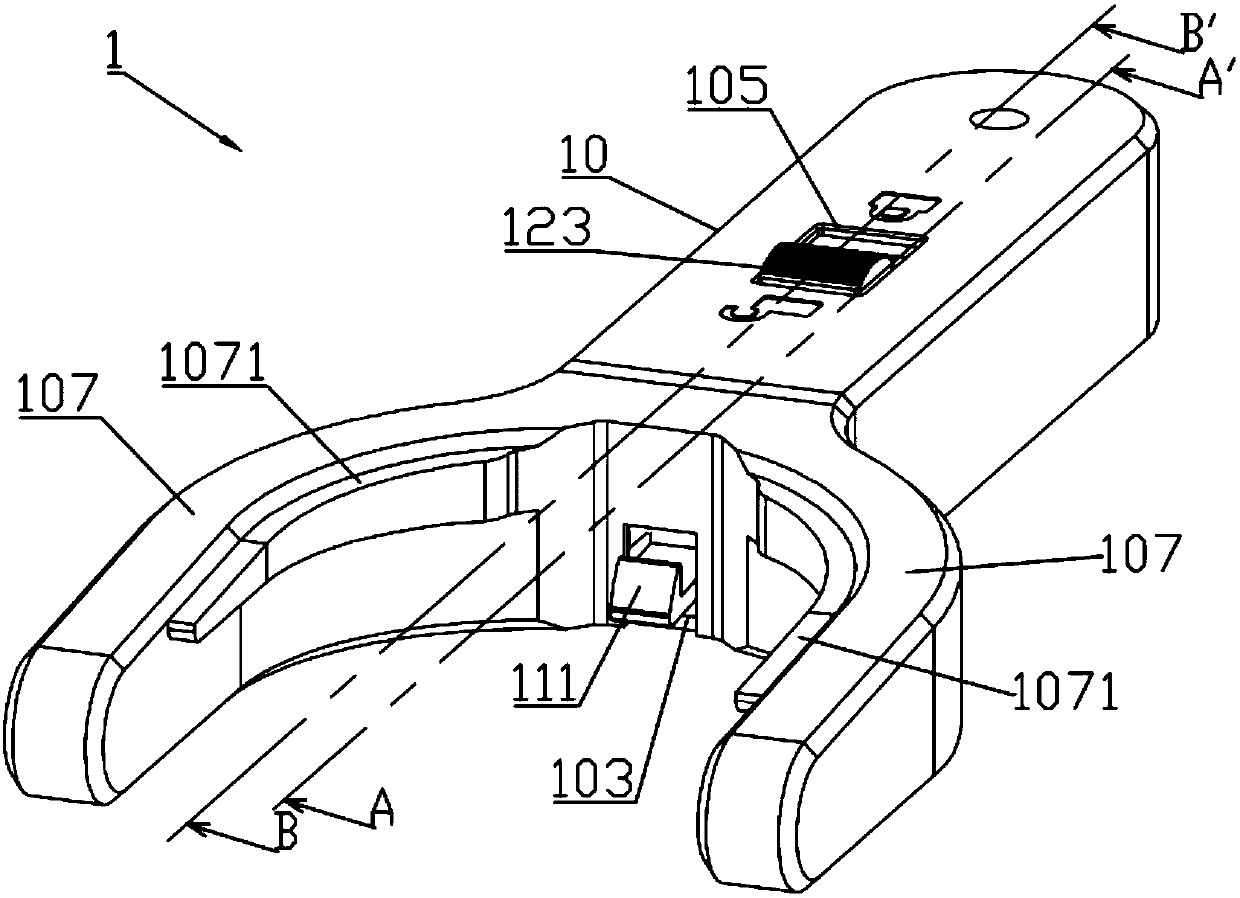

Anti-loosening optical-fiber connector plug shell body

ActiveCN110618501AHigh strengthImprove reliabilityCoupling light guidesEngineeringOptical fiber connector

The invention relates to an anti-loosening optical-fiber connector plug shell body and an anti-loosening optical-fiber connector plug. The anti-loosening optical-fiber connector plug shell body includes a front sleeve and a rear sleeve assembled together in a thread manner. A connection nut is arranged outside the front sleeve in a sleeving manner, and is used for thread connection with a socket.A locking shell body is assembled outside the rear sleeve in a sliding guiding manner. A connection nut rotation preventing structure is arranged between the connection nut and the locking shell body.The locking shell body has a locking position and an unlocking position in a moving stroke thereof. The locking shell body rotation preventing structure is arranged between the rear sleeve and the locking shell body. Springs are arranged between the rear sleeve and the locking shell body. Compared with arranging a notch at a thread section of the front sleeve to realize rotation preventing assembly of the locking shell body with the front sleeve and the rear sleeve, the embodiment of the invention arranges the locking shell body rotation preventing structure on the rear sleeve, cannot impactconnection of the front sleeve and the rear sleeve, and guarantees improvement of strength and reliability of the optical-fiber connector plug on the premise that an anti-loosening role can be played.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

Injection molding machine with convenient-to-clean discharge hole

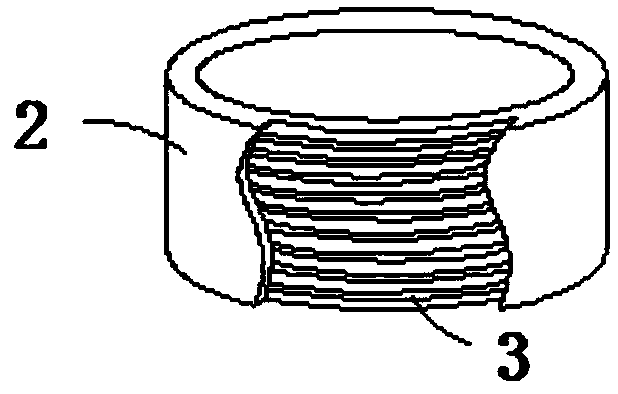

The invention discloses an injection molding machine with a convenient-to-clean discharge hole. The injection molding machine with the convenient-to-clean discharge hole comprises an injection moldingmachine discharge hole, wherein an annular heat-conducting block sleeves on the injection molding machine discharge hole; an electric heating wire is arranged in an annular cavity; a wire is fixedlyconnected to one end of the electric heating wire; one end, far away from the electric heating wire, of the wire penetrates through the annular heat-conducting block so as to extend to the outer partand be electrically connected with an external power supply; an annular limiting block is arranged on the upper side of the annular heat-conducting block; the annular heat-conducting block is fixedlyconnected with the annular limiting block through multiple elastic limiting mechanisms; a flushing pipe is horizontally arranged on the upper side of the annular limiting block; one end of the flushing pipe is fixedly connected with the injection molding machine discharge hole; a water pipe connector is fixedly connected to the other end of the flushing pipe; a first one-way valve is fixedly connected onto the flushing pipe; and a second one-way valve is fixedly connected onto the injection molding machine discharge hole. The injection molding machine with the convenient-to-clean discharge hole provided by the invention is reasonable in structure, the blockage of the injection molding machine discharge hole is reduced, and meanwhile, the injection molding machine discharge hole can be conveniently cleaned.

Owner:芜湖中科智捷信息科技有限责任公司

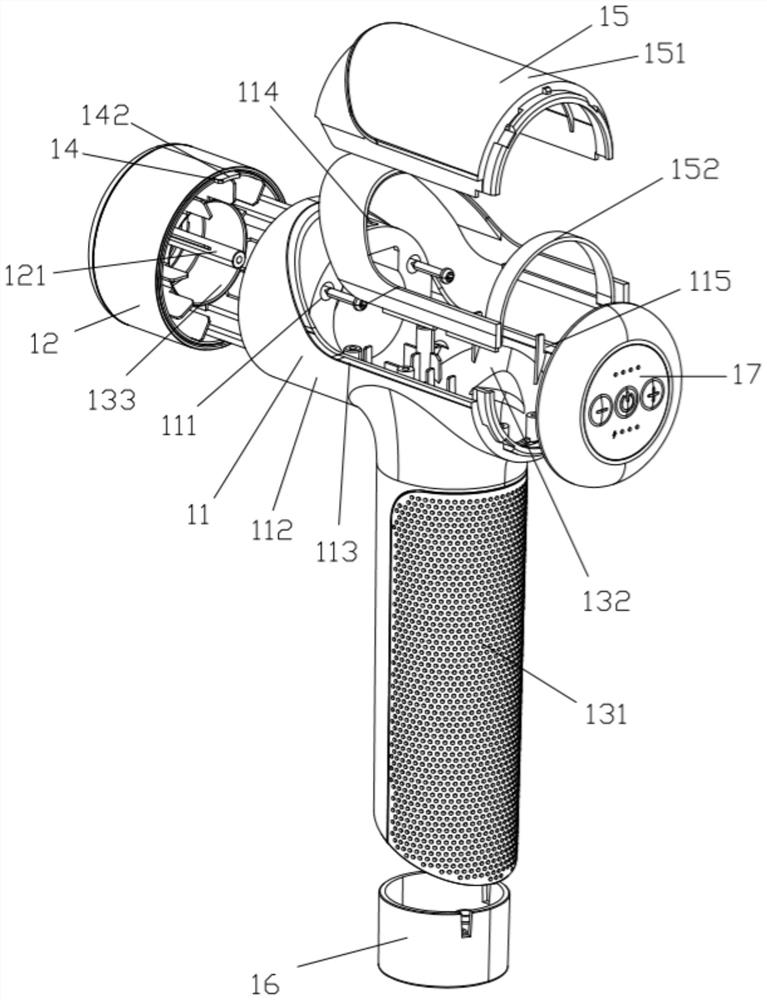

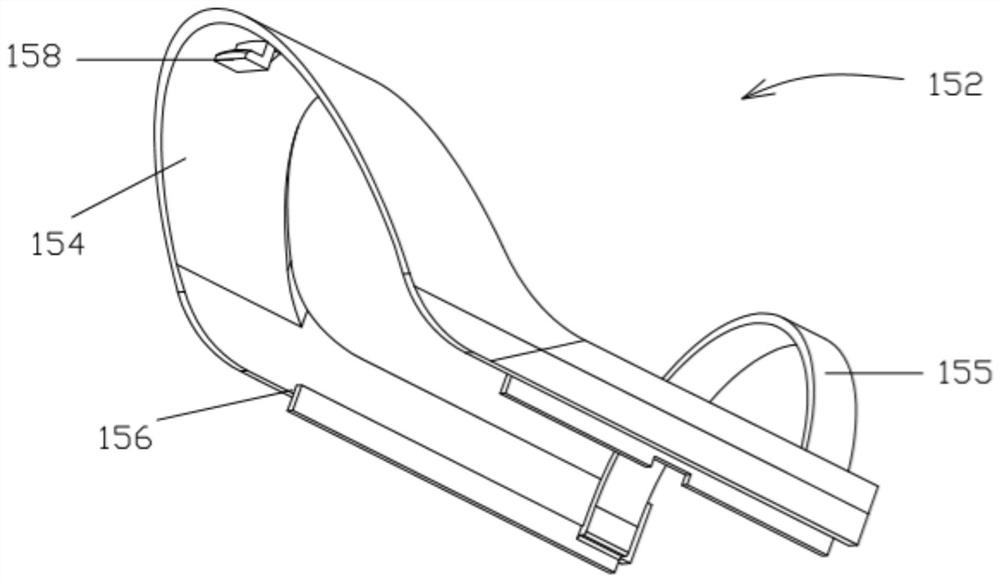

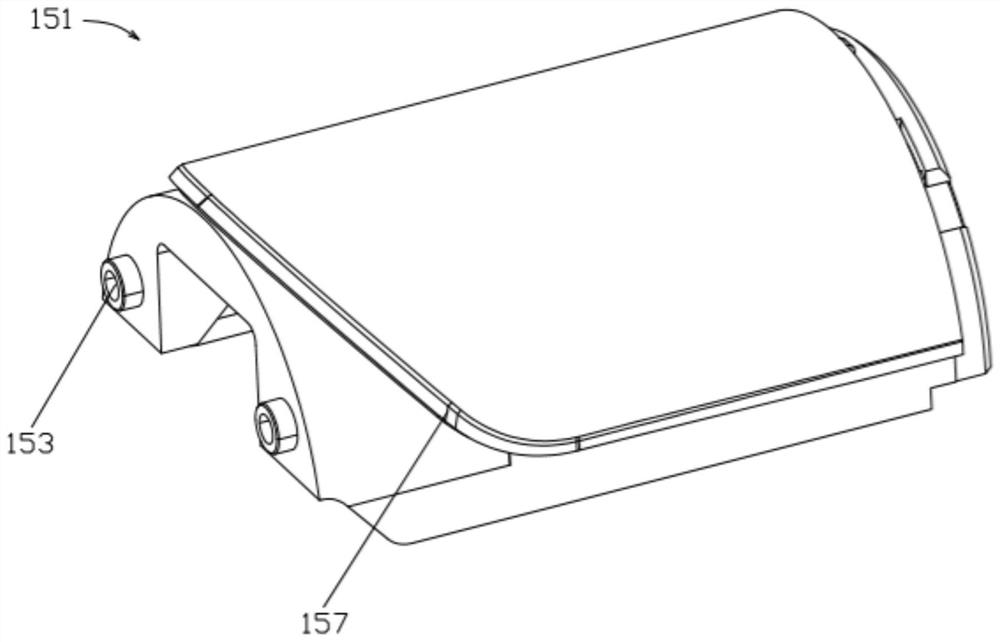

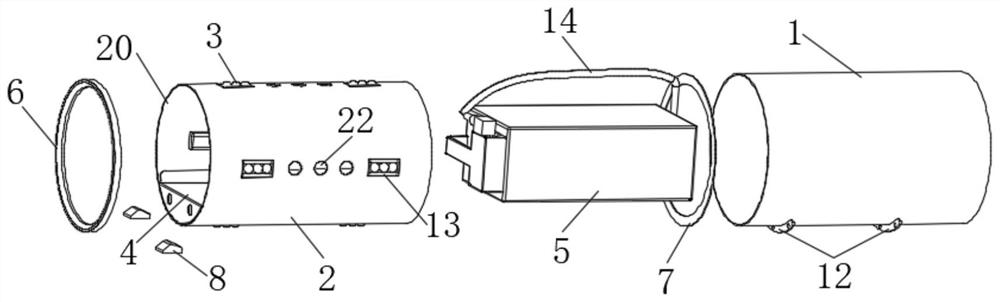

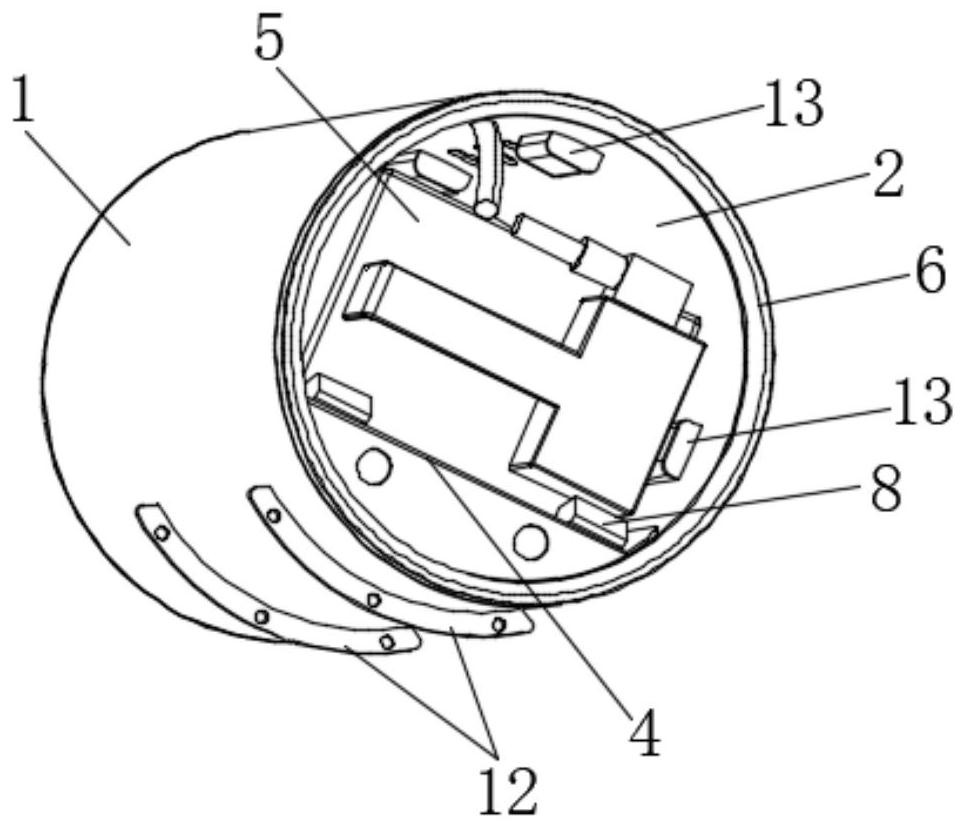

Fascia gun shell and fascia gun

PendingCN112022669AImprove convenienceConnection will not affectCasings/cabinets/drawers detailsVibration massageElectric machineryStructural engineering

The invention relates to a fascia gun shell and a fascia gun. The fascia gun shell comprises a first shell and a second shell, wherein the first shell is provided with a battery mounting part and a motor mounting part, and the second shell is detachably connected with the first shell and forms a transmission part mounting part together with the first shell in a surrounding manner. According to thetechnical scheme of the invention, By setting connection between the first shell and the second shell as detachable connection, when parts are damaged and the like, only the shell where the damaged parts are located needs to be detached to carry out disassembling of the related parts without influencing connection between the parts in the other shell and the shell, so that the disassembly and assembly convenience of the parts in the shell is improved.

Owner:永康骑客智能科技有限公司

High-precision four-wire type wire rod tester and testing method thereof

PendingCN112444757AEasy to installSafe and stable operationShort-circuit testingContinuity testingTester deviceStructural engineering

The invention relates to the technical field of wire rod testers, discloses a high-precision four-wire type wire rod tester and a testing method thereof, and solves the problems that a wire rod testerlacks fixing measures and is easy to fall off to be damaged in the use process, and meanwhile, a detector can be damaged by mistakenly pulling a wire in the use process. The tester comprises a base,a tester body is mounted at the top of the base, moving grooves are formed in one side of the top of the base at equal intervals, a buffer mechanism is mounted in each moving groove, a vertical blockis mounted at the top of each buffer mechanism, and a connecting wire fixing mechanism is mounted at the top of each vertical block. The high-precision four-wire type wire rod tester is provided withan effective fixing mechanism, so that the tester can be firmly mounted in use, and meanwhile, the wire rod tester is provided with a mechanism for fixing a wire, so that the wire rod tester can be guaranteed to be safely and stably operated and used; therefore, the high-precision four-wire type wire rod tester can meet the use requirements of people.

Owner:吉安县众兴电子科技有限公司

Fixing device for membrane type oxygenator

ActiveCN110898271AWon't interfere with readingConnection will not affectDialysis systemsMedicineNormal blood volume

The invention discloses a fixing device for a membrane type oxygenator. The fixing device comprises a shell, a snapping buckle member and a driving member, wherein the shell has a first accommodatingspace, a second accommodating space located above the first accommodating space and a gap, the snapping buckle member is arranged in the first accommodating space, one end of the snapping buckle member has a snap hook bulging from the gap, and the driving member is arranged in the second accommodating space and is connected with a guide groove of the snapping buckle member through a guide hole. The fixing device disclosed by the invention can be operated by a single hand, can be rapidly mounted on the membrane type oxygenator or demounted from the membrane type oxygenator and can be arranged at a joint of a blood reservoir and a connecting rack without hindering connection between draft tubes and the blood reservoir / oxygenator and reading of blood volume graduations of the blood reservoir.

Owner:DONGGUAN KEWEI MEDICAL INSTR

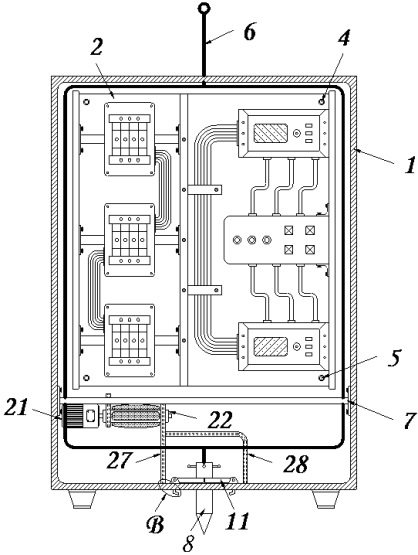

Low-voltage power distribution cabinet with grounding structure

InactiveCN114204424AEfficient guidanceGuaranteed tightnessEarthing arrangementsSubstation/switching arrangement casingsEngineeringStructural engineering

The invention discloses a low-voltage power distribution cabinet with a grounding structure, and the cabinet is provided with a cabinet body, and the interior of the cabinet body is movably provided with a mounting plate. The grounding lead fixedly penetrates through the top of the cabinet body, and a partition plate is fixed in the cabinet body on the outer side of the grounding lead; a fixing rod and an adjusting rod are arranged at the corners of a mounting plate in a penetrating mode. A mounting hole is formed in the cabinet body on the outer side of the grounding pile, and a sealing baffle plate is hinged to the side of the supporting shaft; a fixing hole is formed in the side surface of the grounding pile; and the motor is installed on the inner wall of the cabinet body through bolts, and an output shaft of the motor is fixedly connected with a connecting roller. According to the low-voltage power distribution cabinet provided with the grounding structure, after the power distribution cabinet is impacted and vibrated, the stability of the grounding structure can still be kept, efficient guiding of thunder and lightning is achieved, the sealing performance of the connecting position of the grounding structure and the power distribution cabinet can be guaranteed, and erosion to the surface of the grounding structure is reduced.

Owner:朱磊

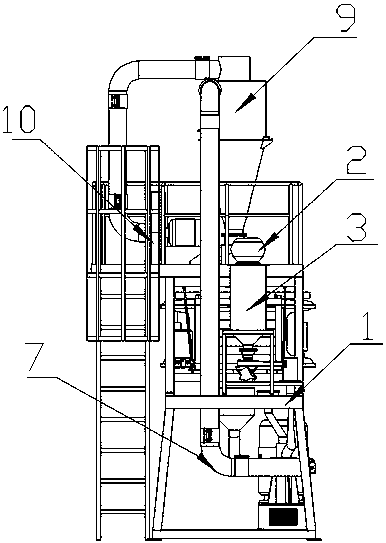

a mill

ActiveCN104941748BRealize all-round coolingImprove cooling effectGrain treatmentsRotational stabilityCyclone

The invention discloses a mill, which is composed of a frame, an automatic feeding machine, a particle material cylinder, a vibrating feeder, a feeding pipe, a mill, a fan, a material suction pipe, a cyclone separator, a combined shut-off fan, Composed of rotating frame, counterweight, separating screen and soft interface, the upper cover and the main shaft shell of the mill are respectively fixed on the upper and lower sides of the grinding disc shell, the main shaft is installed in the main shaft shell through the bearing, and the lower cutter head is installed on the movable There is a gap between the upper and lower cutter heads and the moving disk, the moving disk and the main shaft are fixed, the upper cutter head is fixed on the fixed seat, and there is a gap between the upper cutter head and the fixed seat, and the grinding disc shell is provided for cooling separately. On the outside of the upper cutter head, between the upper cutter head and the lower cutter head, on the upper air passage, the middle air passage, and the lower air passage outside the lower cutter head, the air outlet is connected to the fan, the fixing seat is connected to the upper cover, and the material inlet is connected to the fixing seat Connected, the present invention has the characteristics of adopting air cooling for the upper cutter head and the lower cutter head, stable rotation, high working efficiency, and automatic matching of eccentric loads.

Owner:烟台方大滚塑有限公司

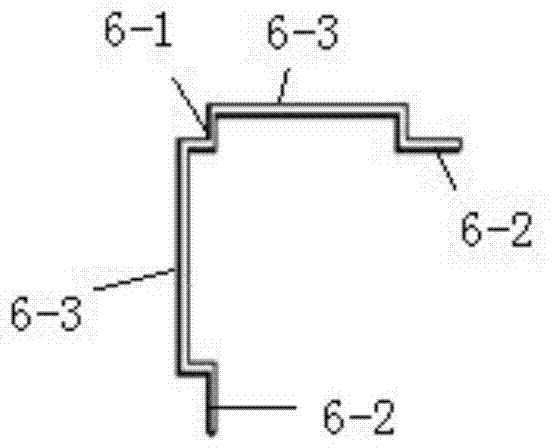

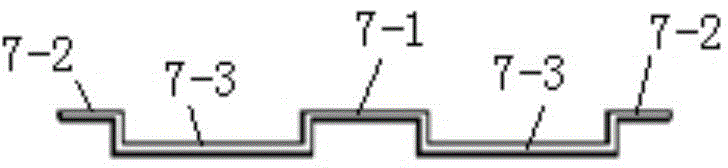

T-shaped concrete filled steel tube specially-shaped column applied to industrial production

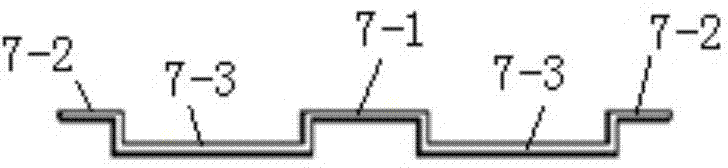

InactiveCN104947854AEasy to process and manufactureIncrease productivityStrutsPillarsSteel tubeSteel plates

The invention relates to a T-shaped concrete filled steel tube specially-shaped column applied to industrial production. The T-shaped concrete filled steel tube specially-shaped column comprises steel plates, through long bolts and concrete, and is characterized in that the steel plates comprise a side steel plate (7), two inner angle steel plates (6) and three edge slot steel plates (8), wherein the side steel plate (7) comprises a middle part (7-1), two end parts (7-2) and two side surface parts (7-3), the inner angle steel plates (6) comprise corner parts (6-1), two end parts (6-2) and two side surface parts (6-3); the side steel plate (7), the two inner angle steel plates (6) and the edge slot steel plates (8) are welded to form the T-shaped specially-shaped column, cross sections of the middle part and the three end parts of the T-shaped specially-shaped column are square, the corresponding side parts between the side steel plate (7) and the inner angle steel plates (6) as well as between the inner angle steel plates (6) are fixedly connected through the through long bolts, and concrete is poured into the T-shaped specially-shaped column. The T-shaped concrete filled steel tube specially-shaped column is applied to industrial batch production and can be rapidly spliced on construction site.

Owner:TIANJIN UNIV

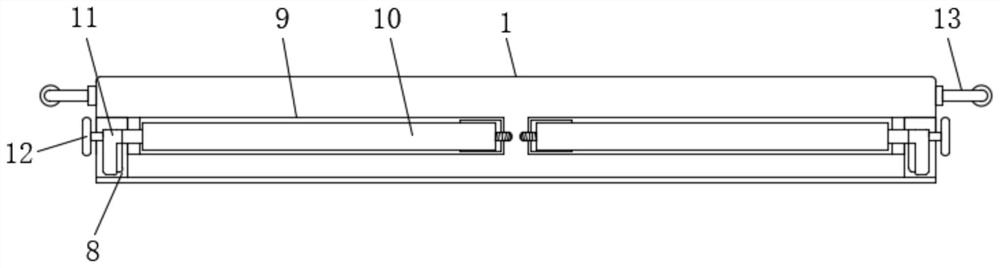

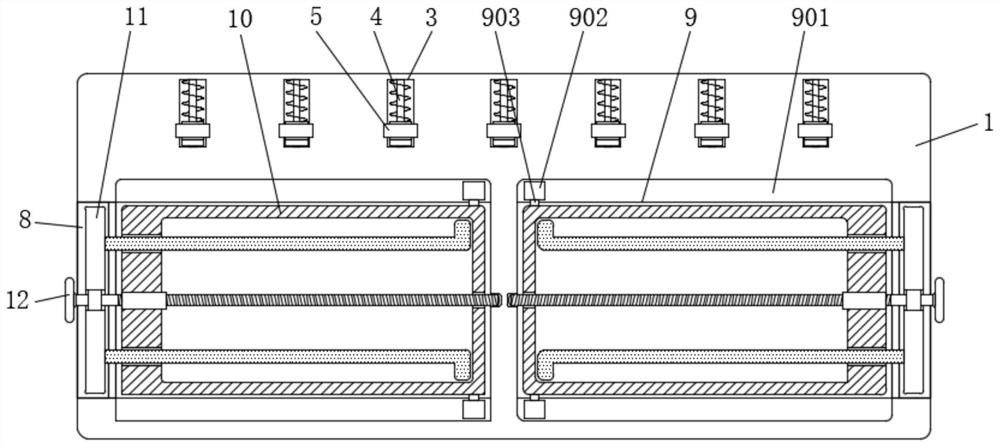

Battery cabin body with inner cabin and outer cabin

PendingCN112928375AConnection will not affectIncreased installation flexibilityCell component detailsElectrical batteryClassical mechanics

The invention belongs to the technical field of power supply equipment, and particularly relates to a battery cabin body with an inner cabin and an outer cabin. The battery cabin body comprises an outer cabin body and an inner cabin body arranged in the outer cabin body, wherein the side wall of the inner cabin body is provided with a plurality of balls slidably abutting against the outer cabin body, the outer cabin body is used for circumferentially rotating along the side wall of the inner cabin body, a supporting platform is arranged in the inner cabin body, and the supporting platform is used for placing a battery module. Due to the gravity factor of the inner cabin body, no matter how many angles the outer cabin body rotates, the inner cabin body and the battery can be always kept at the horizontal angle, and the battery cannot shake and move, so that the operation stability and safety of the battery cabin body are effectively improved.

Owner:DONGGUAN YANGTIAN ELECTRONICS TECH

Leakage protection method and device

ActiveCN105188062BConnection will not affectReduce misjudgmentSecurity arrangementComputer networkEmbedded system

The present invention relates to a secret leakage protection method, which includes listening to an associated frame or data frame broadcast when a terminal connects to an illegal AP; acquiring the terminal feature of the terminal according to the associated frame or data frame; detecting whether the terminal feature exists in the preset If it is in the preset terminal feature database, then implement leakage protection on the terminal. With this leak protection method, since the terminal feature database stores the terminal features of terminals capable of connecting to legitimate APs, the leak protection can only be implemented for terminals that exist in the terminal feature database, and for terminals that are not in the terminal signature database, the Leakage protection is not implemented, so that it will not affect the connection of terminals that are not in the terminal signature database to illegal APs, that is, it will not affect the connection of terminals of other enterprises to their APs, reducing misjudgment.

Owner:SHENZHEN SUNDRAY NETWORK SCI TECH

an ice cube

ActiveCN108387040BAchieve separationConnection will not affectLighting and heating apparatusIce productionRefrigerated temperatureMechanical engineering

Owner:凤阳县易天成模具有限公司

Flat Panel Phased Array Antenna

ActiveCN112103634BReduce processing difficultyReduce processing costsAntenna arraysRadiating elements structural formsMicrowaveControl cell

An embodiment of the present invention provides a flat-panel phased array antenna, which relates to the field of antenna technology. The flat-panel phased-array antenna includes a microwave board, a structural member, a digital circuit board, a control unit, a power supply unit, and multiple antenna radiation units. An antenna radiating unit is set on one side surface of the microwave board, the structural parts are mounted on the other side surface of the microwave board, the digital circuit board is installed on the structural parts and electrically connected with the microwave board, the control unit and the power supply unit are set on the digital On the circuit board, at least part of the digital circuit board is arranged opposite to the microwave board, and the projection of the digital circuit board on the microwave board is located in the microwave board. Compared with the prior art, the planar phased array antenna provided by the embodiment of the present invention can realize arbitrary splicing and large array formation, and has small size, low processing difficulty and low processing cost.

Owner:CHENGDU T-RAY TECH CO LTD

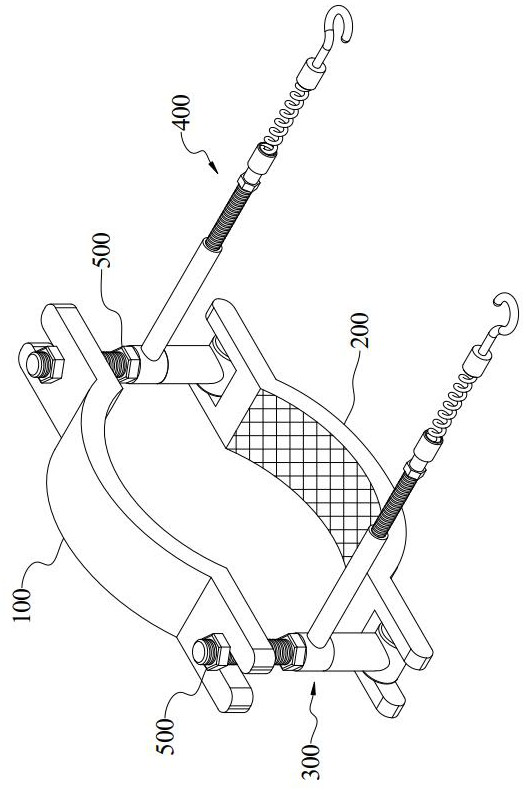

Connecting mechanism for natural gas sampling

ActiveCN112593933AEasy to operateImprove efficiencyDrilling rodsDrilling casingsThermodynamicsMechanical engineering

The invention provides a connecting mechanism for natural gas sampling, and the connecting mechanism for natural gas sampling is used for connecting a gas production pipeline with a sampling pipe. Theconnecting mechanism for natural gas sampling comprises an upper pipe clamp attached to the top of the gas production pipeline, a lower pipe clamp opposite to the upper pipe clamp and attached to thebottom of the gas production pipeline, bolts and connecting rods, one ends of the connecting rods are connected with the middles of the bolts, and the other ends of the connecting rods are connectedwith the sampling pipe; the two bolts and the two connecting rods are arranged symmetrically, one end of each bolt is rotatably connected with one end of the lower pipe clamp, and the other end of each bolt can be connected with one end of the upper pipe clamp in a clamped mode and locked on the upper pipe clamp through nuts. According to the connecting mechanism for natural gas sampling, the upper pipe clamp and the lower pipe clamp can be quickly connected to the gas production pipeline through the bolts rotationally connected with the lower pipe clamp, a connecting fulcrum is provided for butt joint of the sampling pipe and a sampling opening of the gas production pipeline, during disassembly, the upper pipe clamp and the lower pipe clamp can be disconnected by reversely rotating the bolts to be separated from the upper pipe clamp after the nuts are loosened, so that the upper pipe clamp and the lower pipe clamp can be quickly taken down, operation is convenient and simple, and efficiency is high.

Owner:CHINA NATURAL GAS GUANGYUAN CO LTD

Ice making device and bottom plate thereof

ActiveCN108397946AAchieve separationConnection will not affectLighting and heating apparatusIce productionEngineering

The invention relates to an ice making device and a bottom plate of the ice making device. The ice making device comprises an ice making barrel, the bottom plate and a barrel cover. The lower end of the ice making barrel is provided with a bottom plate installation barrel, the bottom plate installation barrel is provided with an installation barrel inner wall use for being in sealing fit with theperiphery of the bottom plate through a sealing ring, the bottom of the ice making barrel is provided with a hook through hole located on the inner side of the bottom plate installation barrel, the bottom plate is provided with an elastic hook used for penetrating into the ice making barrel through the hook through hole, the elastic hook is provided with a hook portion used for being in hooked fitwith the ice making barrel, the ice making barrel is provided with a push rod device which can move in the up-down direction for pushing the upper end of the elastic hook to enable the hook portion to be disengaged from the ice making barrel, a barrel cover is in threaded connection with the upper end of the ice making barrel, and the barrel cover is provided with a flanging pressing edge used for pressing the upper end of the push rod device. The problem that the ice making process is tedious due to the fact that freezing ice connection needs to be carried out in advance on the ice making barrel and the bottom plate in the prior art is solved.

Owner:泰州程顺制冷设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com