Drilling fluid backflow system for offshore drilling without marine riser

A drilling fluid and riser technology, used in wellbore/well components, earthmoving, wellbore flushing, etc., can solve problems affecting wellbore stability, limitation of pumping capacity, and inability to pump drilling fluid back to the drillship And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

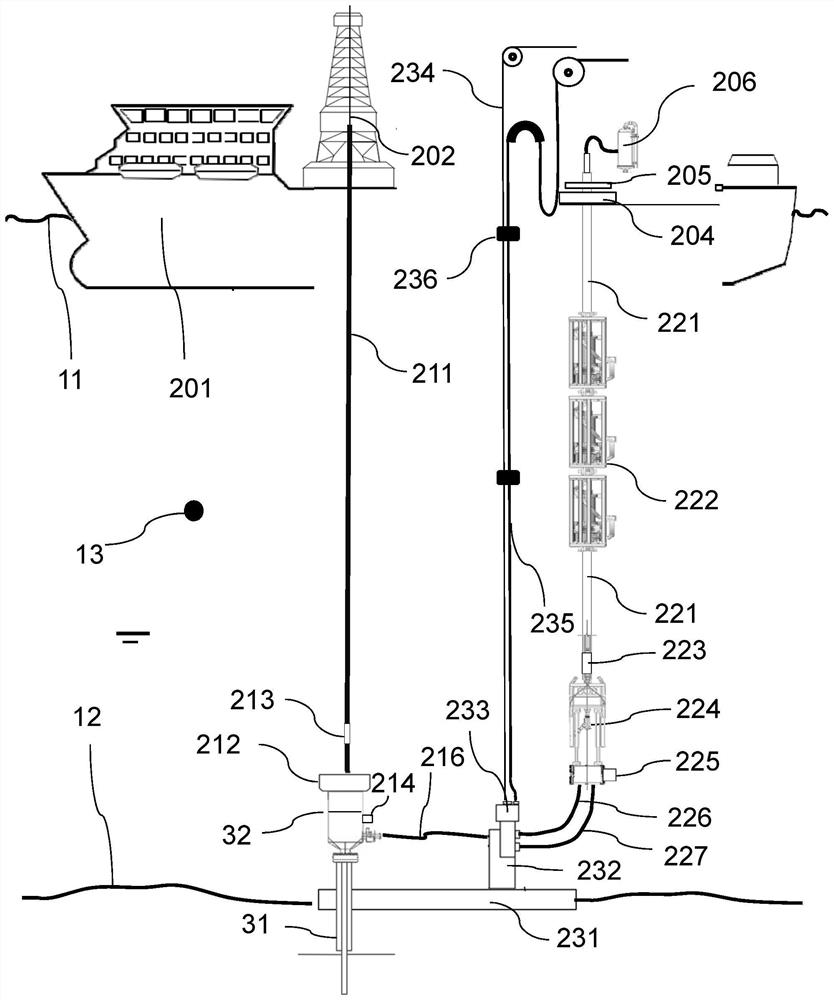

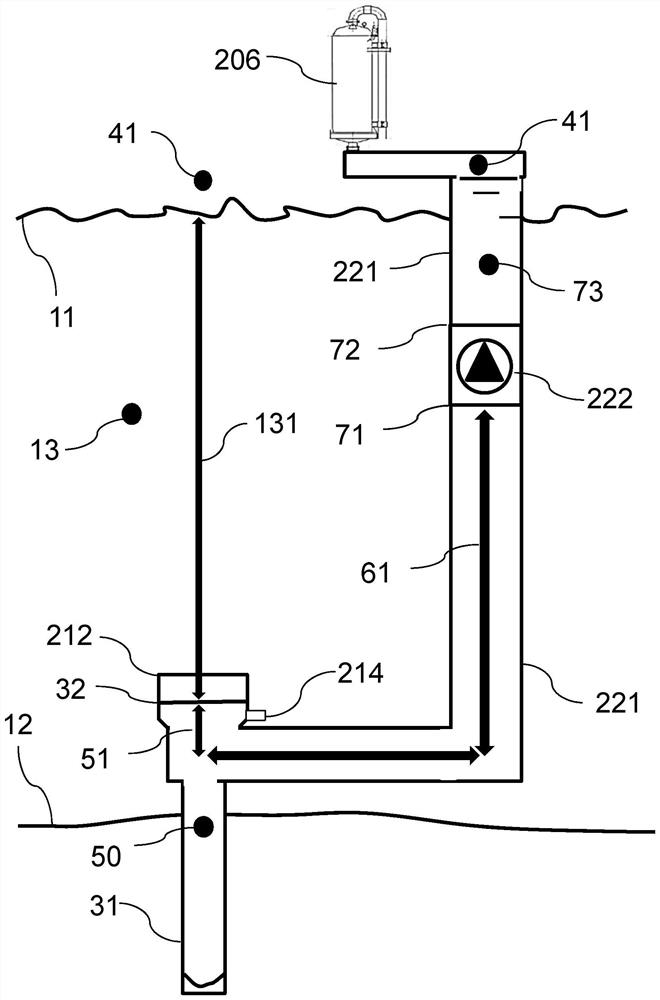

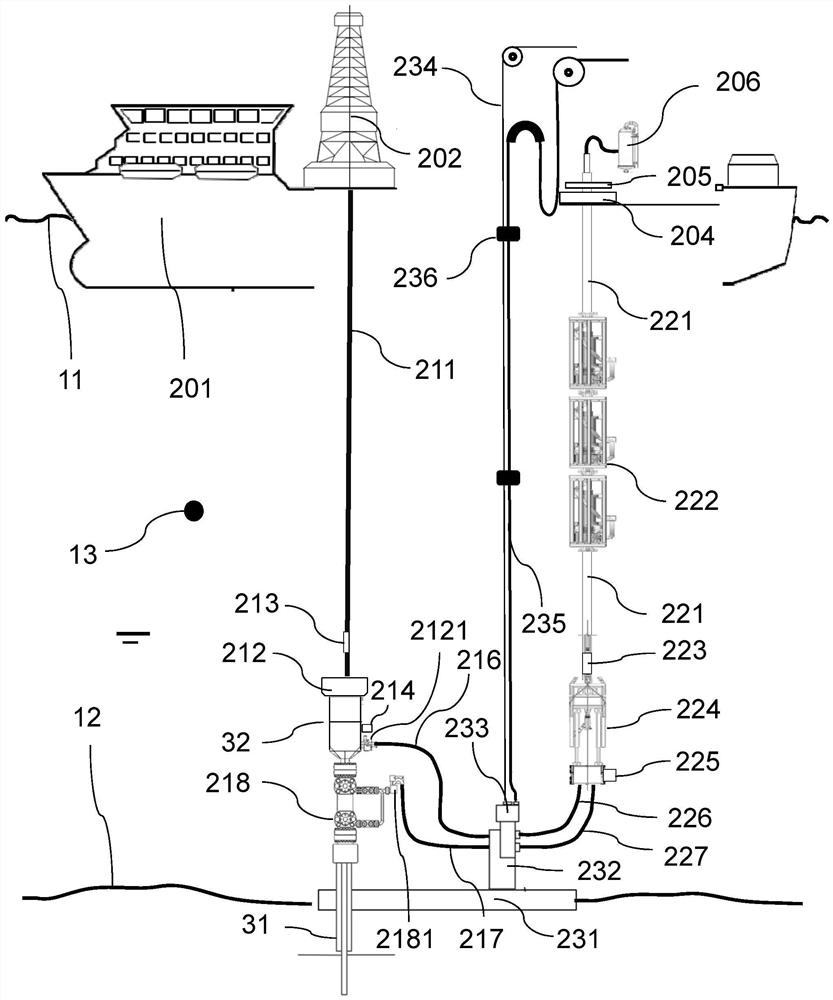

[0071] The present disclosure provides an offshore riserless drilling fluid return system for offshore drilling operations that can return drilling fluid from a wellbore to a drilling platform without using a conventional offshore platform riser. The offshore riserless drilling drilling fluid return system described in this disclosure is not limited by the size of the drilling ship or the water depth capability when performing drilling operations, so relatively small floating drilling platforms (such as drilling ships or other Offshore drilling equipment), greatly improving the economic benefits. The drilling fluid return system for offshore riserless drilling of the present disclosure can be applied to deepwater drilling or ultra-deepwater drilling of underwater substrates or sedimentary formations.

[0072] The drilling fluid return system for offshore riser-free drilling provided by the present disclosure includes: a drilling fluid volume control unit, an open water drillin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com