Flat Panel Phased Array Antenna

A phased array antenna and flat panel technology, which is applied to antennas, antenna arrays, antenna components, etc., can solve the problems of increased pressing times, high processing costs, and difficult processing, and achieves reduced antenna area and low processing costs , The effect of small processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

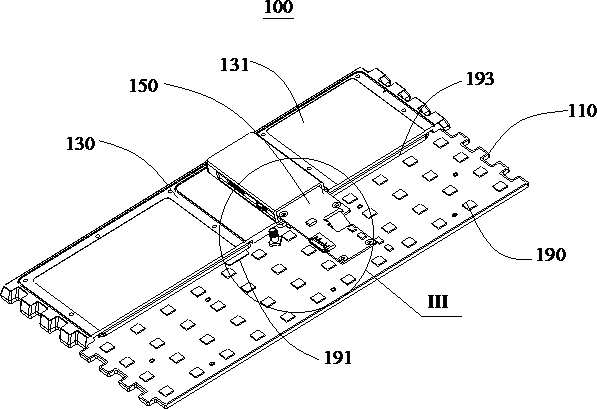

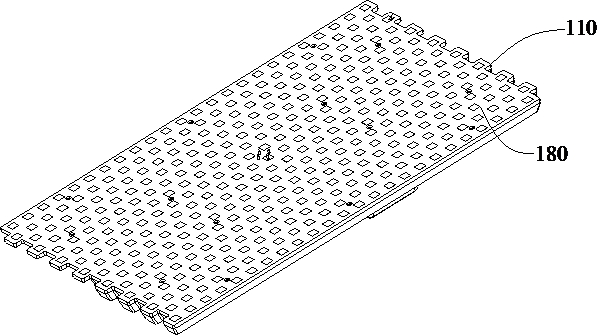

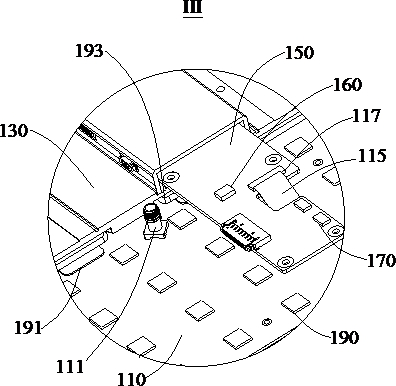

[0034]Please refer toFigure 1 to Figure 4The embodiment of the present invention provides a flat-panel phased array antenna 100, which can realize arbitrary splicing and large-array array, and has a small size, low processing difficulty, low processing cost, and convenient disassembly, maintenance or replacement.

[0035]The flat-panel phased array antenna 100 provided in this embodiment includes a microwave board 110, a structural member 130, a digital circuit board 150, a control unit 160, a power supply unit 170, and multiple antenna radiation units 180. The multiple antenna radiation units 180 are arranged in the microwave On one side surface of the board 110, the structural member 130 is mounted on the other side surface of the microwave board 110, the digital circuit board 150 is mounted on the structural member 130 and is electrically connected to the microwave board 110, and the control unit 160 and the power supply unit 170 are both arranged on On the digital circuit board 150...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com