Connector and connector system

一种连接器、导体连接的技术,应用在连接、固定连接、导电连接等方向,能够解决难以处理电线导体直径减小端子布置间距减小等问题,达到避免高度的增加、避免增加的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Embodiments of the present invention will now be described in detail with reference to the accompanying drawings. In the drawings, corresponding constituent elements are denoted by the same reference numerals.

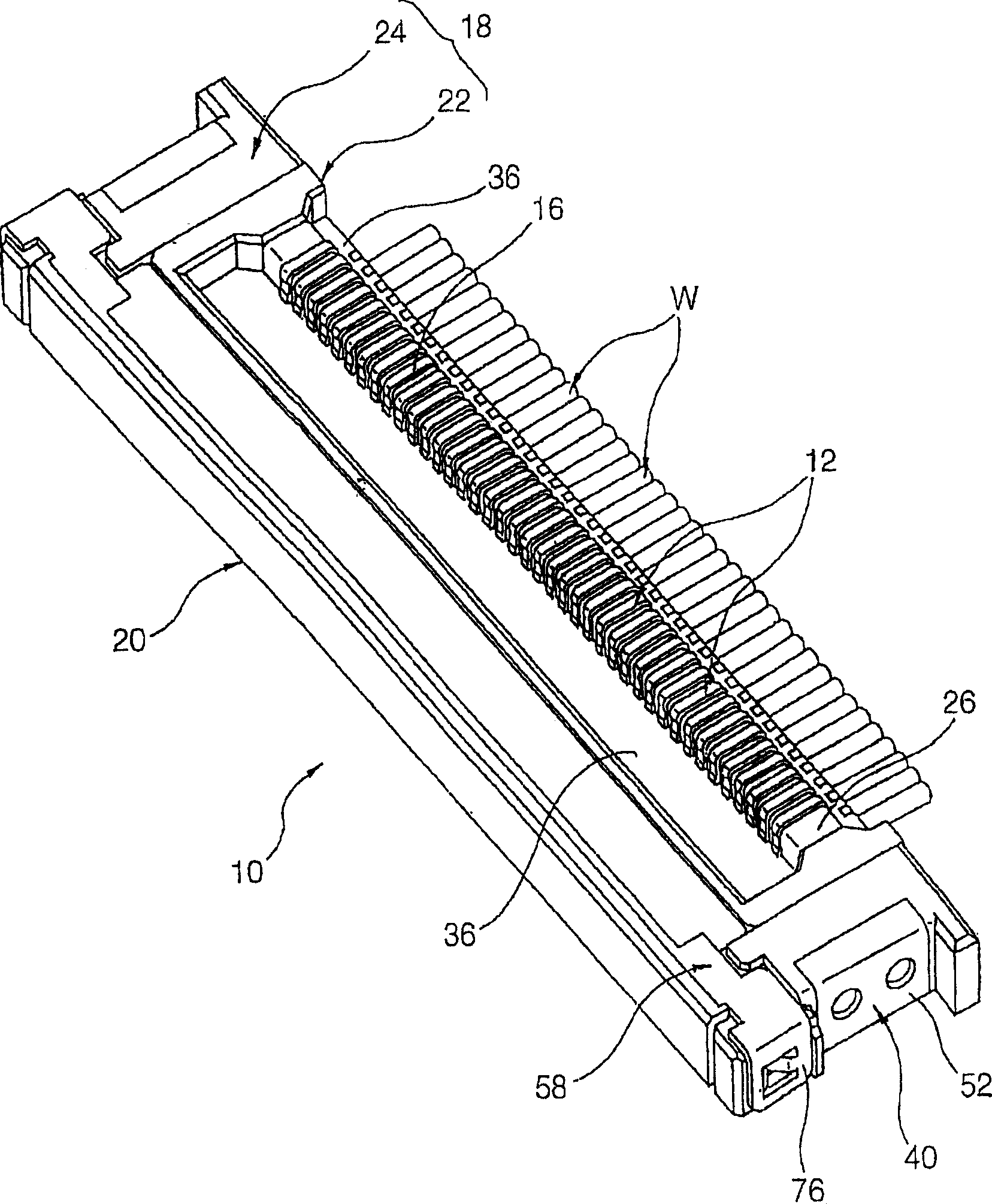

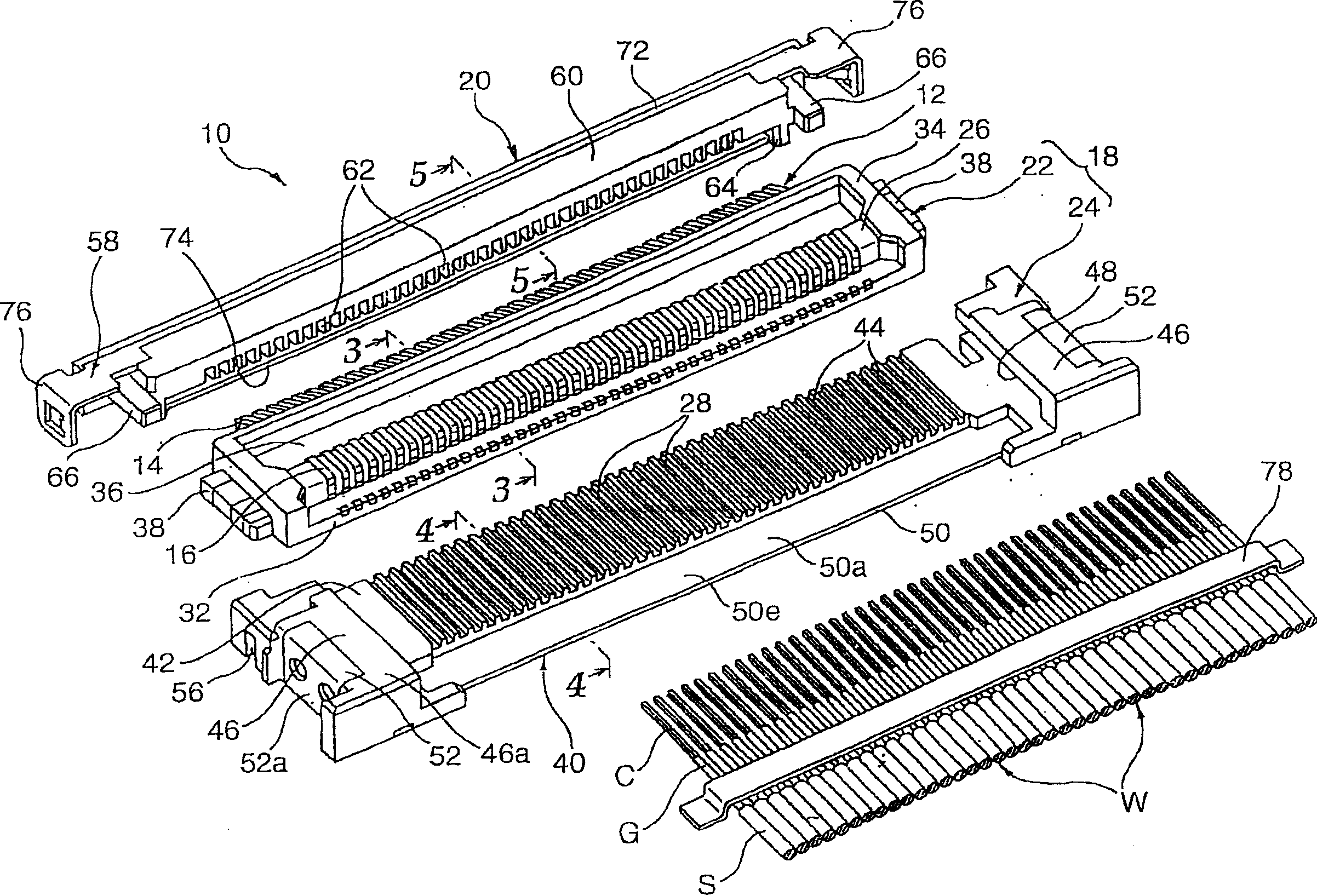

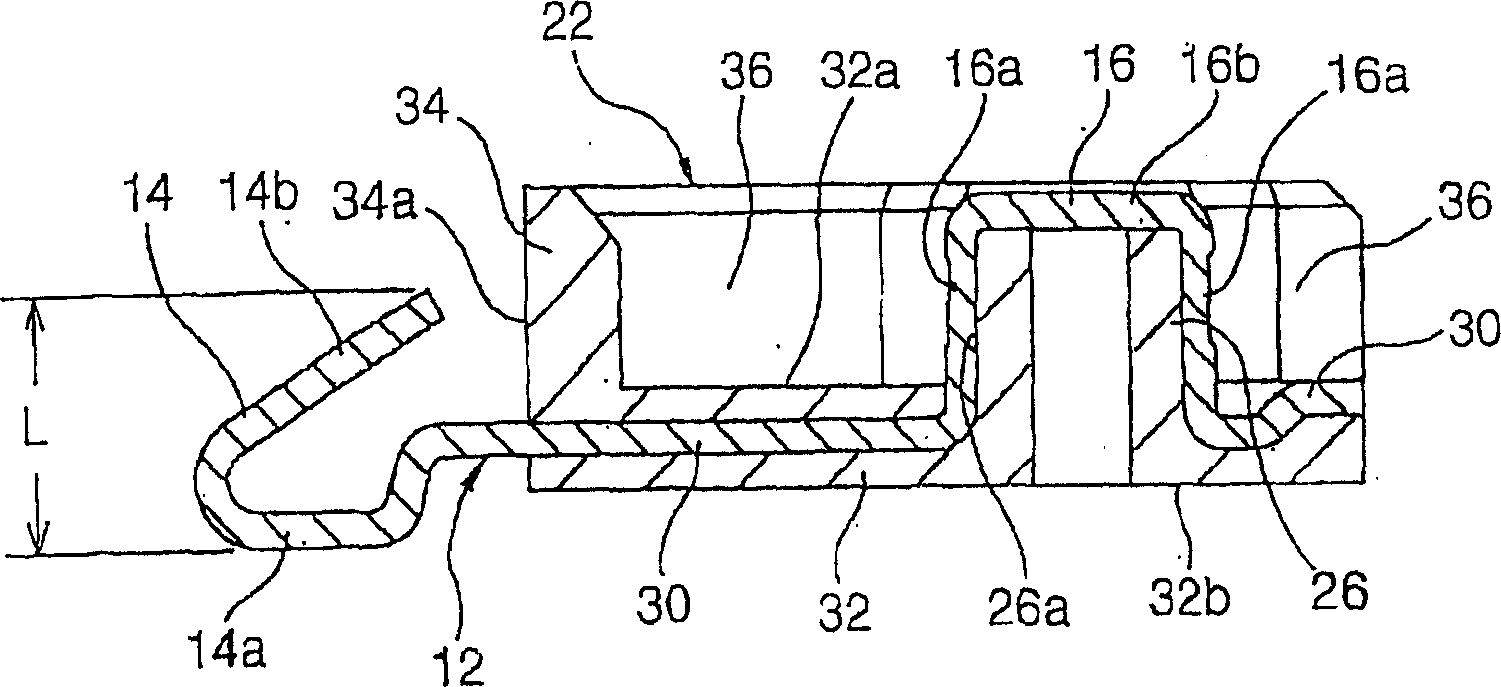

[0055] figure 1 is a perspective view showing a state when the connector 10 according to an embodiment of the present invention is assembled, figure 2 To show a perspective view of the connector 10 in an exploded state, and Figures 3 to 5 is a sectional view showing main constituent elements of the connector 10 . The connector 10 has a conductor butt type (abut type) wire connection structure in which the conductor C exposed by removing the wire sheath S at one end of the wire W by a required distance and the abutted terminal element 12 The conductor connection portions 14 are connected. The connector 10 can advantageously be used to connect a multi-conductor flat coaxial cable to a circuit board. In this case, another connector (referred to as a correspo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com