Sliding rail assembly and bracket device thereof

A technology of bracket device and slide rail assembly, which is applied in the field of brackets and can solve problems such as inability to play the foolproof function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

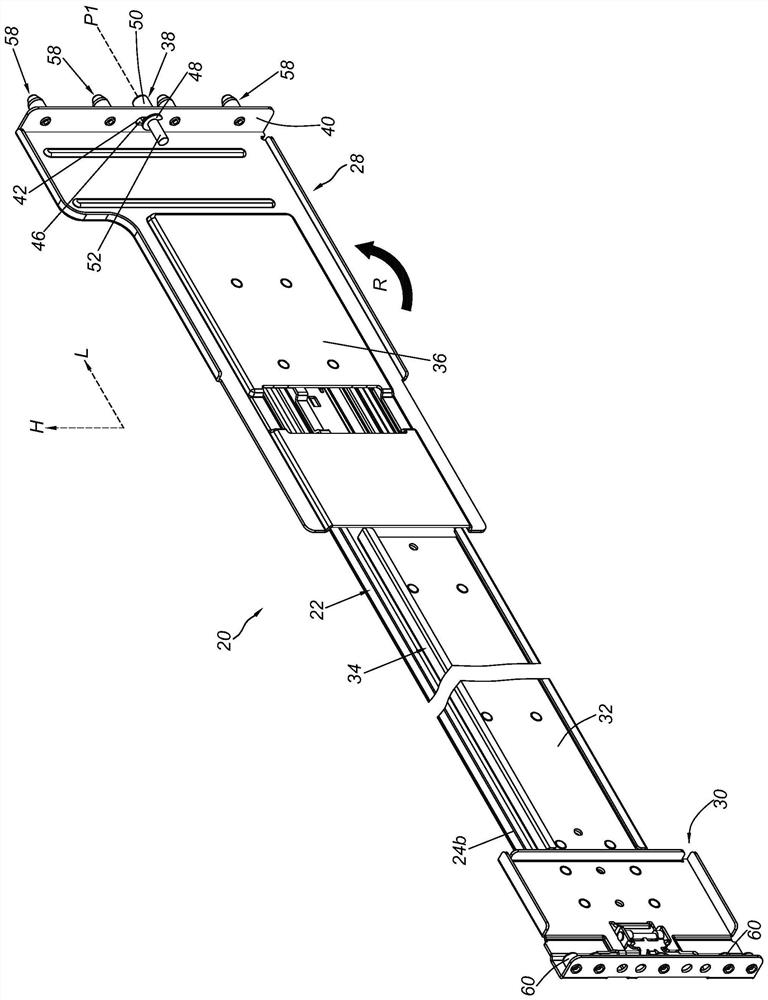

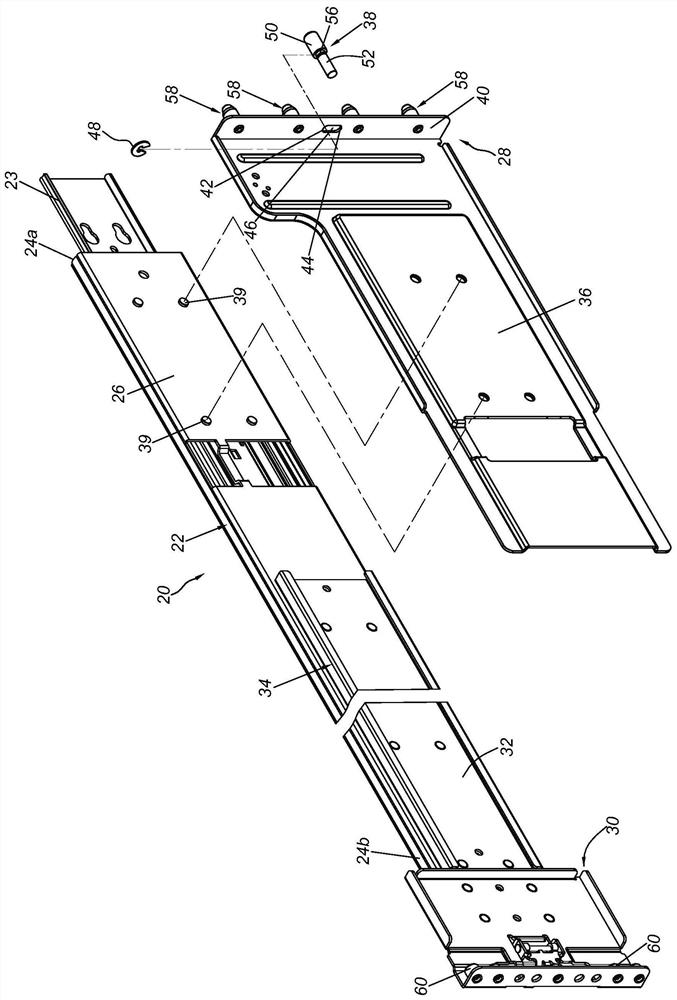

[0037] Such as figure 1 and figure 2 As shown, a sliding rail assembly 20 according to the embodiment of the present invention includes a rail 22 , preferably, at least one movable rail 23 telescopically connected to the rail 22 so as to be longitudinally displaceable relative to the rail 22 . The rail 22 has a first end portion 24a, a second end portion 24b and a longitudinal body 26 located between the first end portion 24a and the second end portion 24b. Wherein, a first bracket device 28 is arranged adjacent to the first end portion 24a, and a second bracket device 30 is arranged adjacent to the second end portion 24b.

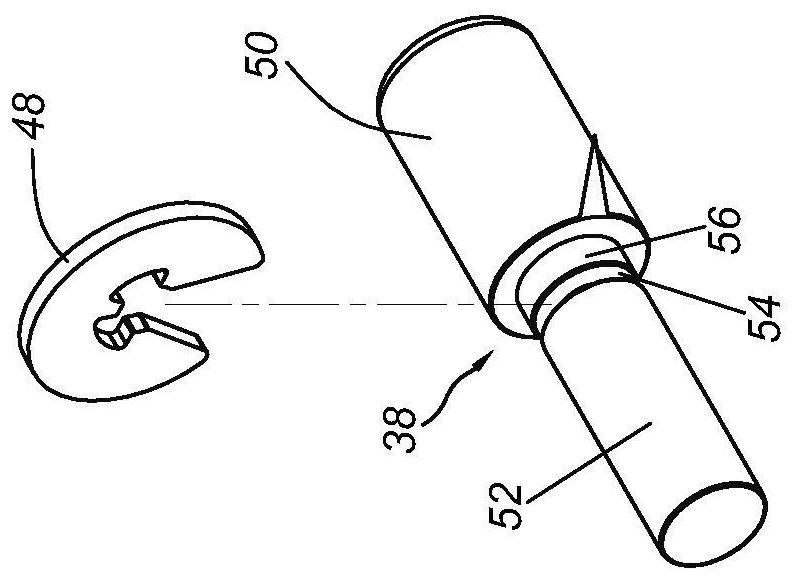

[0038] Preferably, the rail 22 is configured with a reinforcing member 34 to facilitate the structural strength of the rail 22 , and the second bracket device 30 is connected to the rail 22 adjacent to the reinforcing member 34 . On the other hand, the first bracket device 28 is connected to the rail 22 . The first bracket device 28 includes a longitu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com