Bucket-descending-preventing protection device of mixer

A protection device and mixer technology, which is applied to mixer accessories, mixers, transportation and packaging, etc., can solve problems such as increased operational complexity, deformation that cannot be withdrawn, and damage to the mixing tank, so as to increase the convenience of operation, the appearance of the machine and equipment, Simple and clear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

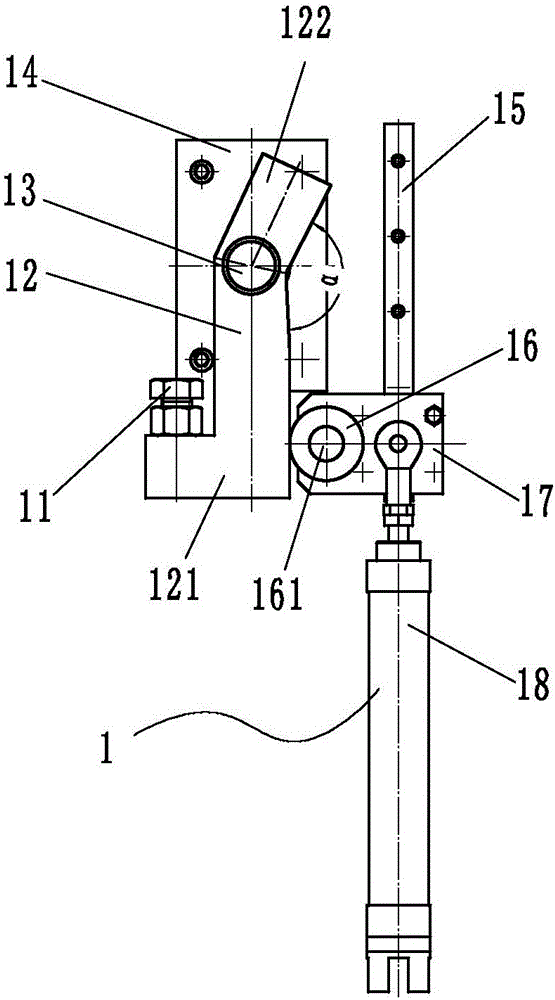

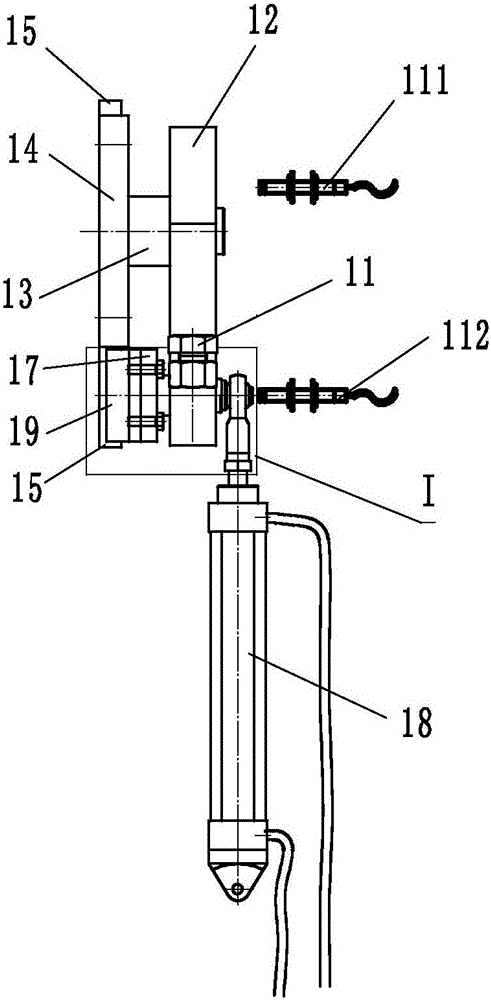

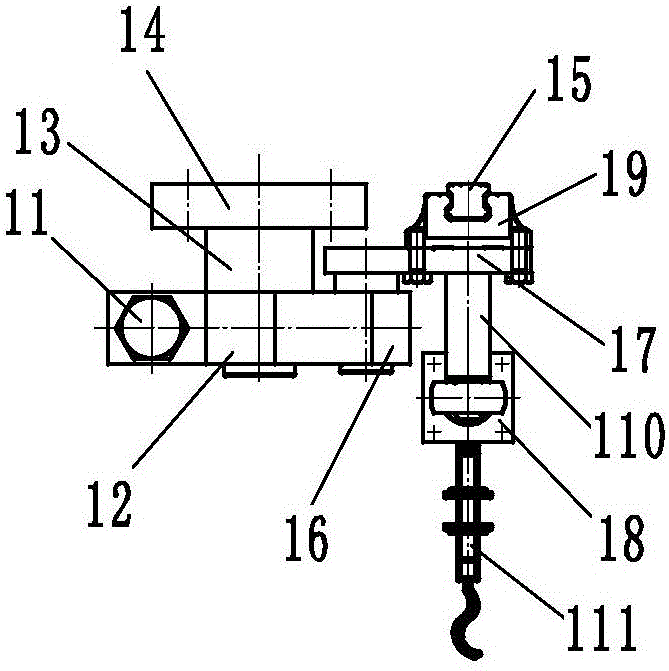

[0026] Embodiment 1: A kind of anti-dripping protection device for mixer, such as Figure 1-Figure 7 Shown, comprise L-shaped turret 12, turret support 14, linear guide rail 15, push ring 16, slide block 19, slide block mount 17 and driving device 18, described driving device 18 is hydraulic oil cylinder, described The L-shaped turret 12 is made of an L-shaped plate 121 and a push plate 122 connected to the top of the L-shaped plate. The angle α between the push plate 122 and the longitudinal plate of the L-shaped plate 121 is 100 to 160 degrees, preferably 150 degrees. , the L-shaped turret 12 is installed on the turret support 14 through the pin shaft I13, and under the action of the push ring, the "L-shaped turret" can rotate to realize two working states of locking and loosening; the slider 19 is sleeved on the linear guide rail 15 and connected with the slide block mount 17, the push ring 16 is installed on the slide block mount 17 through the rotating shaft 161, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com