Medium-and-large-sized capacitive touch panel film pasting device

A capacitive touch and film device technology, applied in layered products, lamination auxiliary operations, lamination, etc., can solve the problems of easily scratched film body, broken touch film, incomplete bubble scraping, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

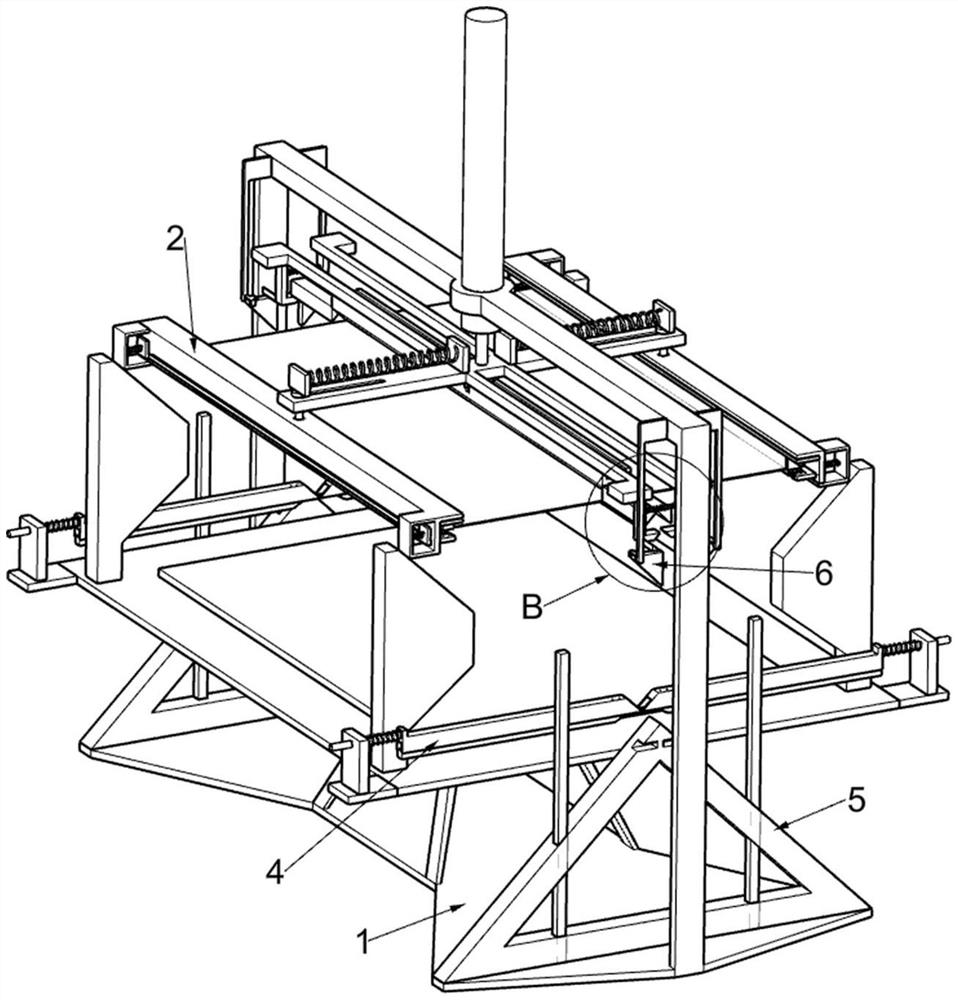

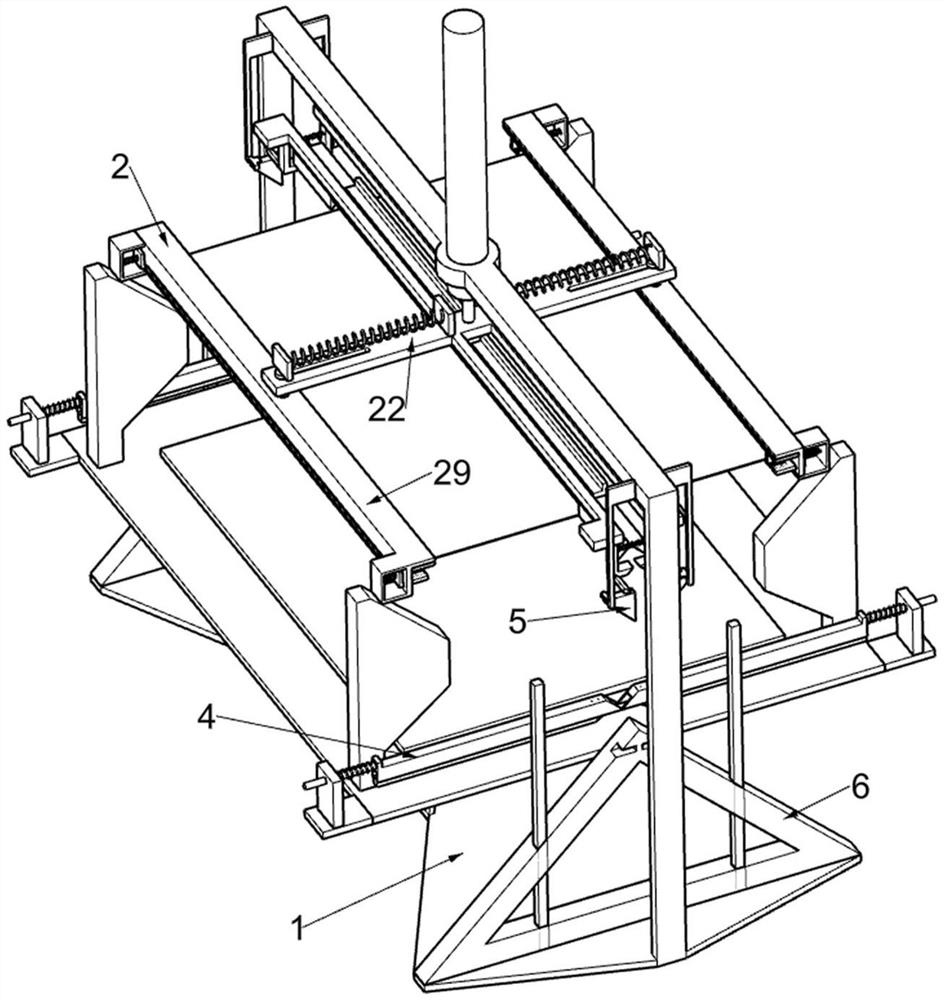

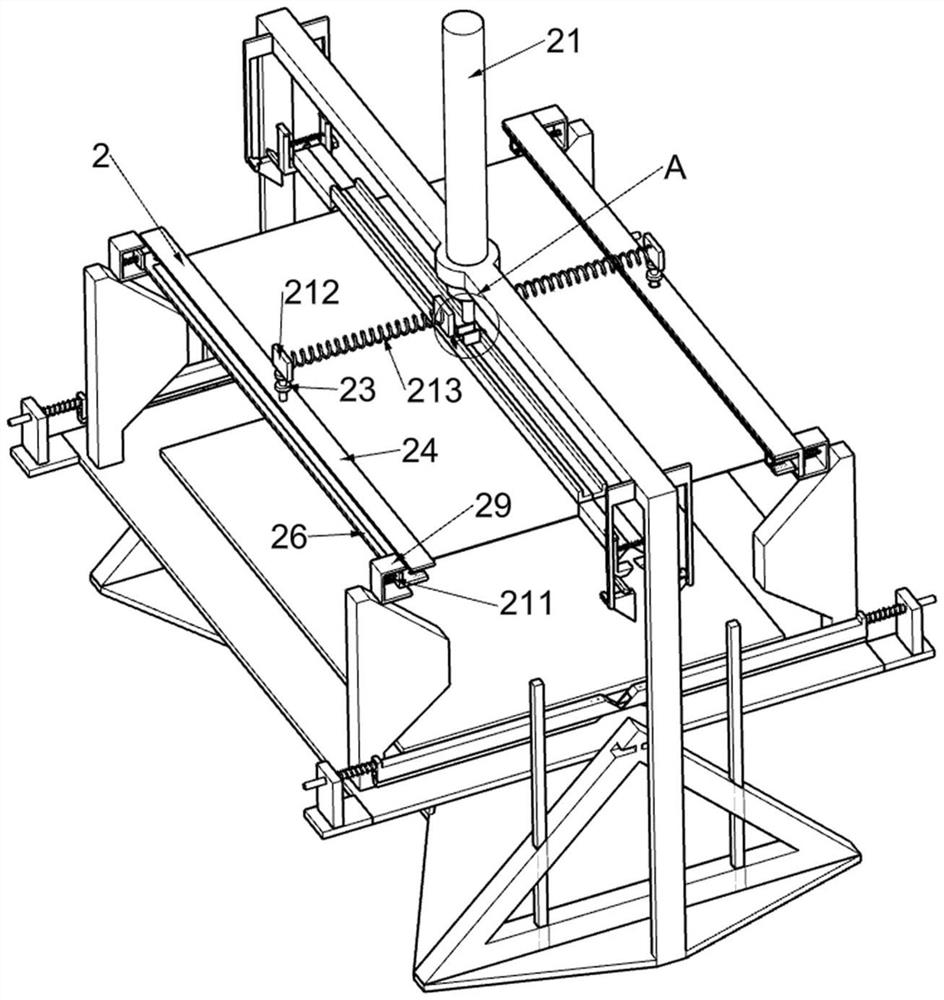

[0025] Embodiment: a kind of film sticking device of medium and large capacitive touch panel, such as Figure 1-9 As shown, it includes a supporting chassis 1, a lifting mechanism 2, a clamping mechanism 3, an air bubble scraping mechanism 4, a pushing mechanism 5 and a reset mechanism 6. The supporting chassis 1 is provided with a lifting mechanism 2, and the lifting mechanism 2 is provided with The clamping mechanism 3, the clamping mechanism 3 is used to fix the support scraper 41 and the bubble scraping mechanism 4 on the support chassis 1, and the bubble scraping mechanism 4 is used between the touch film and the medium and large capacitive touch panel The air bubbles are fully scraped off, the pushing mechanism 5 is slidably connected to the lifting mechanism 2, and the reset mechanism 6 is arranged on the supporting chassis 1.

[0026] The lifting mechanism 2 includes an electric push rod 21, a cross 22, a first slide bar 23, a first clamping plate 24, a first wedge blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com