Metallic color anti-light projection imaging coating and preparation method thereof

A metal color and projection technology, applied in the field of optical imaging, can solve problems such as inability to have a good effect, insufficient brightness of the machine, and difficulty in achieving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This example is a metal-colored anti-light projection imaging coating, comprising film forming material, surfactant, colored pigment, inorganic pigment, high reflective pigment, diffuse reflective filler, melody reflective filler, and dispersion medium.

[0039] The film formation material, surfactant, colored pigment, inorganic pigment, high reflective pigment, diffuse reflective filler, mesh diffusion filler, and dispersion medium in the content of the metallic anti-light projection imaging coating are in turn weight. Comparison: 20-40: 5-10: 8-25: 0.1-0.9: 1-9: 5-15: 4-12: 10-35.

[0040] In this embodiment, the surfactant comprises a pH regulator, a wetting dispersant, a leveling agent, a defoamer, a preservative, a film forming aid, and a stream modifier. In a further technical solution, the pH adjusting agent, a wetting dispersant, a leveling agent, an antifoaming agent, a preservative, a film forming aid, and a rheological auxiliary agent are in the same amount of su...

Embodiment 2

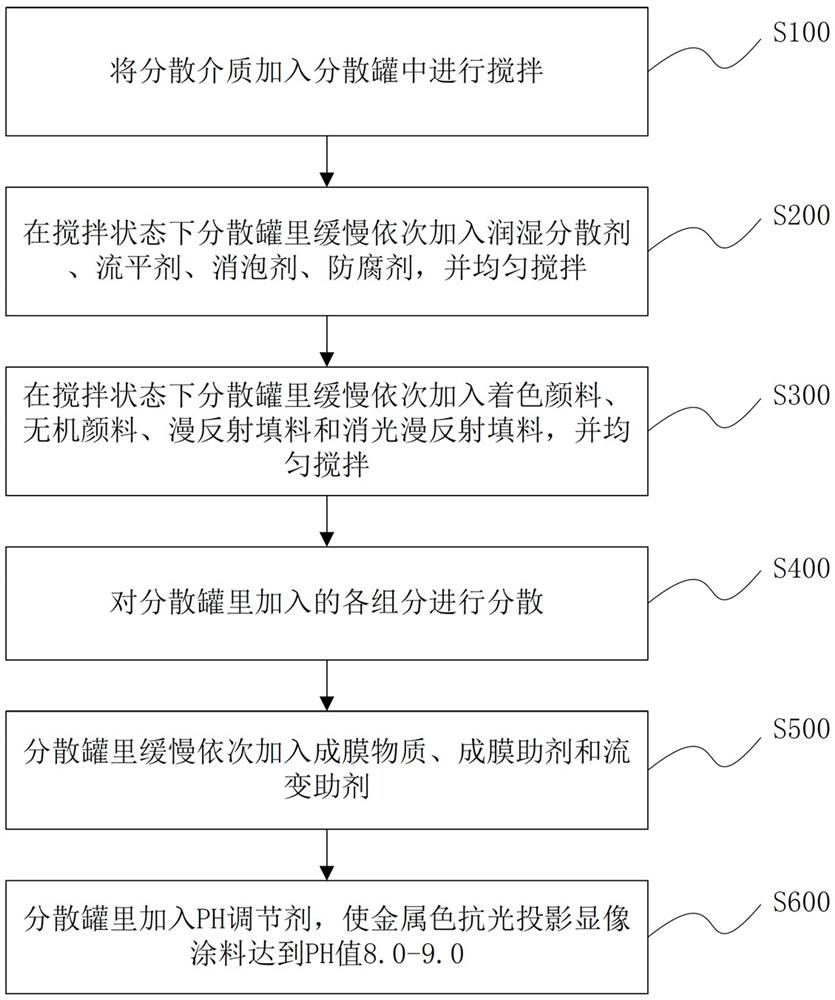

[0059] The present embodiment is a method for preparing a metal-colored anti-light projection imaging coating, and the specific steps are:

[0060] S100. Add the dispersion medium to the dispersing tank to stir;

[0061] S200. Slowly add a wetting dispersant, graft, defoamer, preservative, and mix;

[0062] S300. Slowly add colored pigments in the tank, inorganic pigment, diffuse reflective filler, and uniform stirring in the tank, inorganic pigment, diffuse reflective filler and uniform stir;

[0063] It should be noted that S100, S200 is the same as the stirring speed of S300, and the specific stirring speed is selected between 100-300 rpm, and the stirring speed at this time is 200 rpm.

[0064] S400. Disperse the components added to the dispersed tank;

[0065] It should be noted that the dispersion speed in step S400 is set to 2000 to 4000 rpm, dispersed 20-40 minutes, and the stirring speed at this time is 3000 rpm, dispersion for 30 minutes.

[0066] S. Slowly add film form...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap