Hinge actuator for torque clutch

A torque clutch and actuator technology, which is applied in the field of hinge actuators for torque clutches, can solve the problems of limitation, high cost per piece and high installation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

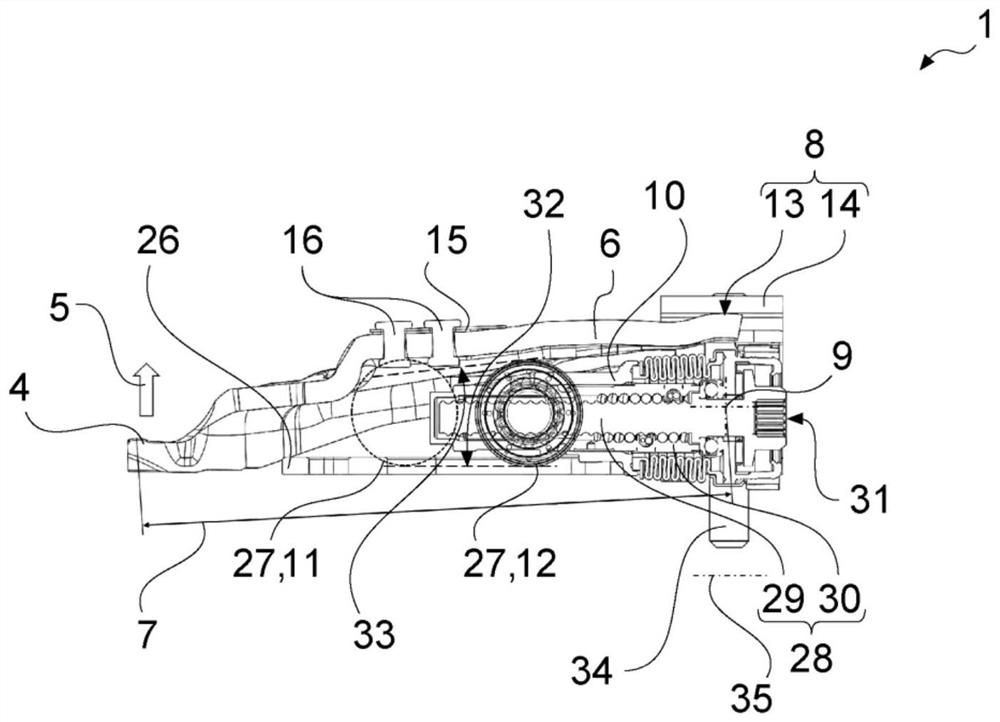

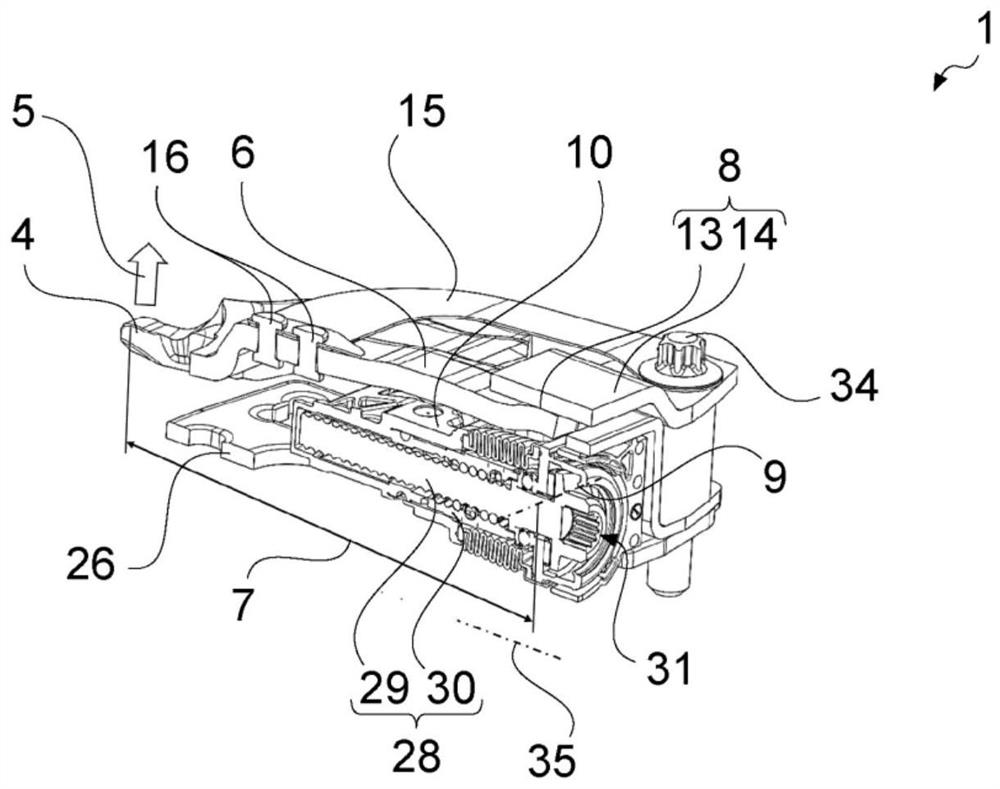

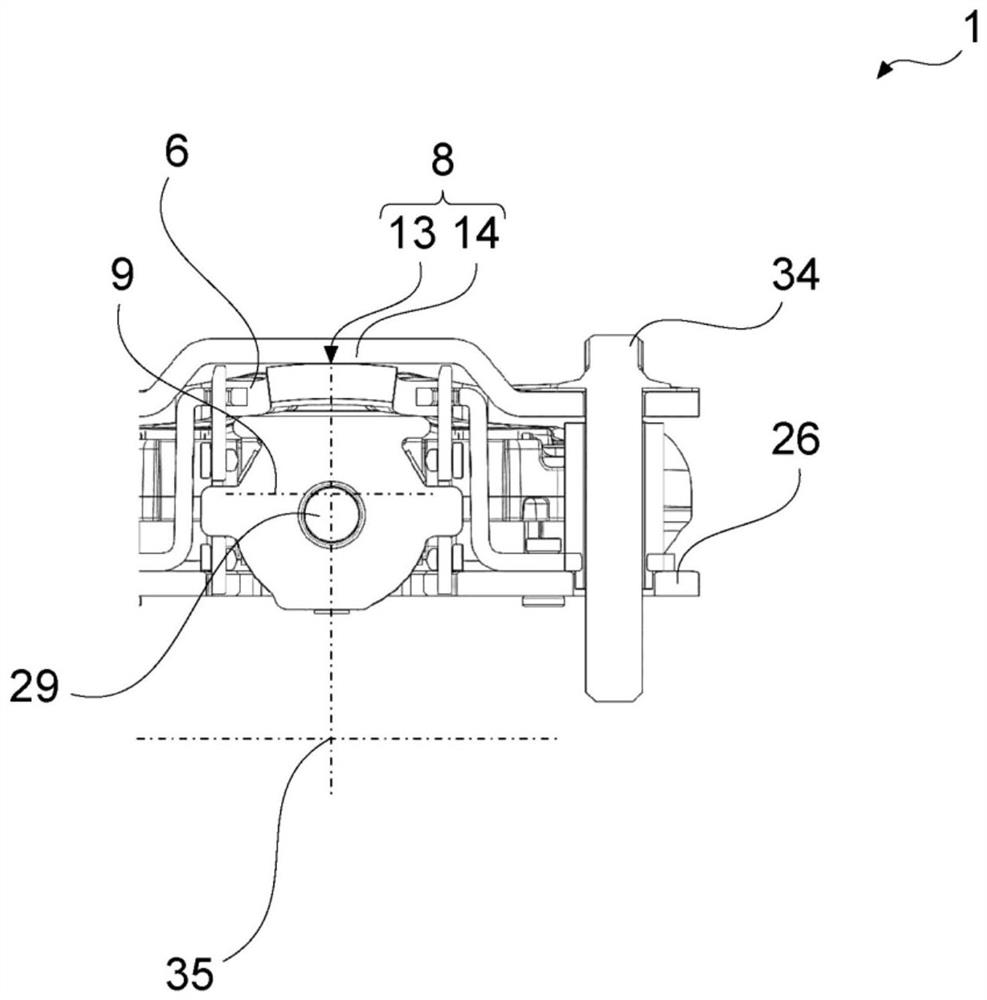

[0051] exist figure 1 A side sectional view of the hinge actuator 1 is shown in . The hinge actuator 1 has a lever 6 with a main extension 7 . The lever has two manipulation fingers 3, 4 (see Figure 4 ). Of the two operating fingers, the right operating finger 4 can be seen here. In the illustrated embodiment, the hinge actuator 1 is embodied with a base plate 26 on which at least one running track for each one of the support rollers 27 (shown here schematically in the foreground) is provided. . The illustrated supporting roller 27 is shown in the pushed-in position 12 (to the right according to the illustration) as a detail for carrying out the support and in the pushed-out position 11 as a dashed circumferential line.

[0052] The support roller 27 is a component of the crossbar 10 . The crossbar is movable along the main extension 7 by means of a screw drive 28 comprising a (rigid) spindle 29 and a spindle nut 30 (in the carriage of the crossbar 10 ). In this case, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com