Electromechanical engineering cable transfer box

A switching box and engineering technology, applied in electrical components, mechanical equipment, springs/shock absorbers, etc., can solve the problems of inconvenient maintenance, troublesome cranes, complicated wiring of the switching box, etc., to facilitate internal maintenance and reduce internal Vibration and movement stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

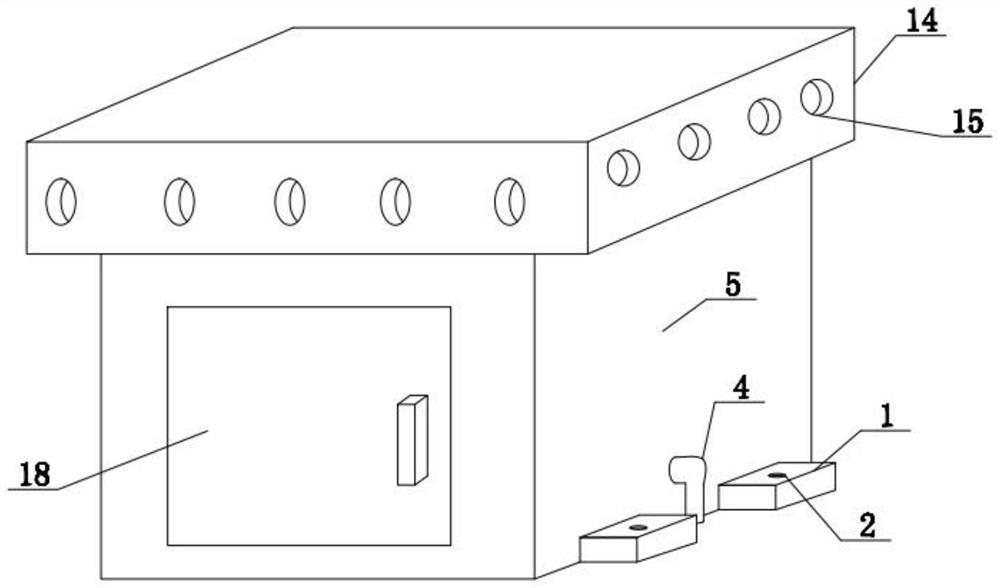

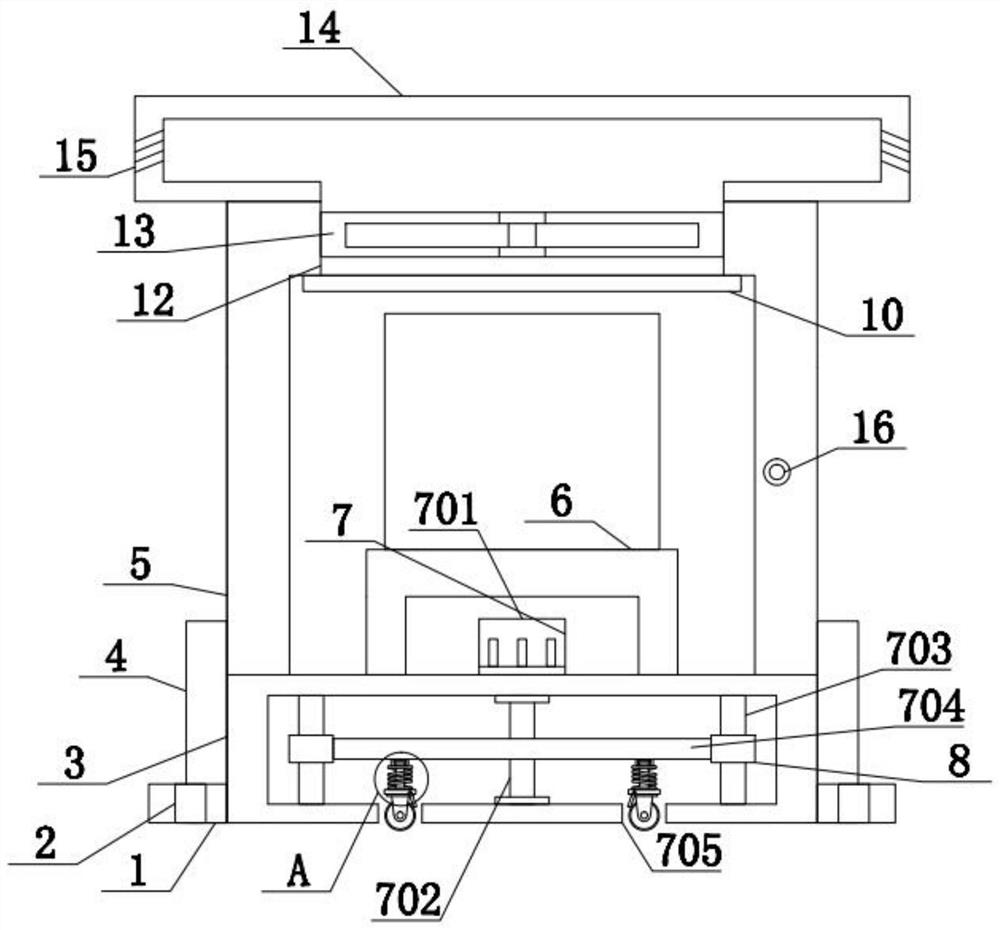

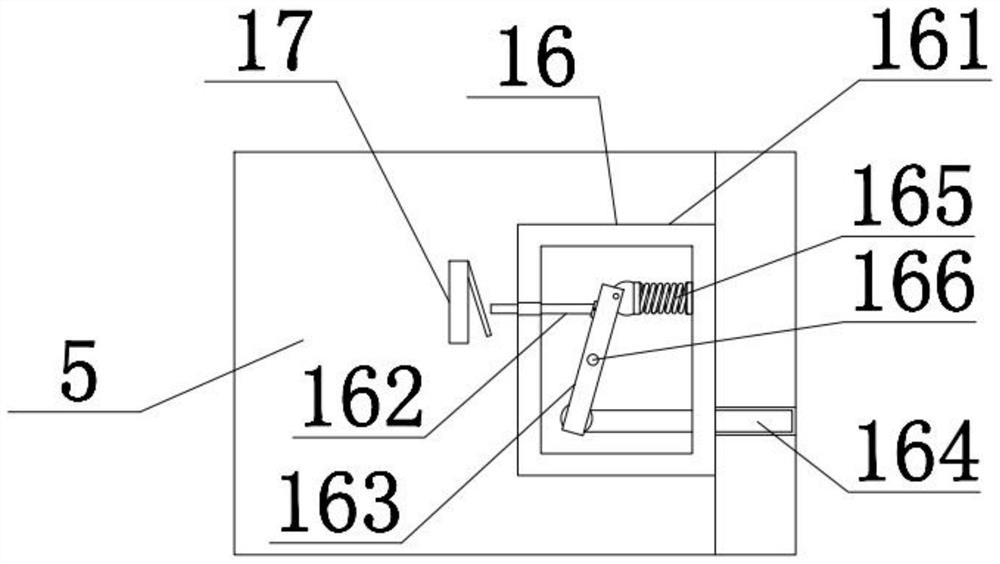

[0033] refer to Figure 1-4 , a cable transfer box for electromechanical engineering, comprising a box shell 5, the lower end of the box shell 5 is fixedly connected with a shell seat 3, the inner side of the shell seat 3 is provided with a lifting mechanism 7, and the lower end of the lifting mechanism 7 is provided There is a shock absorbing mechanism 9, the lower end of the lifting mechanism 7 is movably connected with casters 11 through the shock absorbing mechanism 9, the front right side of the box shell 5 is provided with a transmission mechanism 16, and the inner top of the box shell 5 is fixedly installed with Lighting lamp 10, a switch 17 is fixedly installed on the inner side of the box shell 5, the transmission mechanism 16 and the switch 17 are movably connected, the left and right sides of the box shell 5 are fixedly connected with the inlet pipe 4, and the shell The upper end of the seat 3 is fixedly connected with a moisture-proof frame 6, and the front of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com