Intelligent hydraulic machine stroke limiting device

A stroke limit and hydraulic press technology, which is applied in the field of intelligent hydraulic press stroke limit devices, can solve problems such as affecting the use of equipment, and achieve the effect of convenient use and convenient orientation adjustment processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

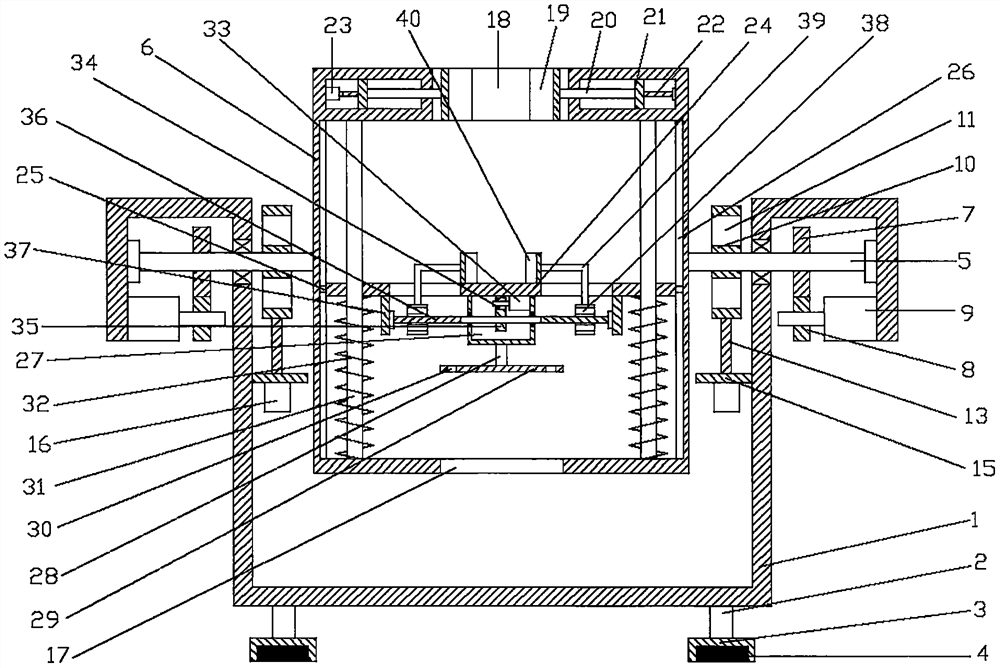

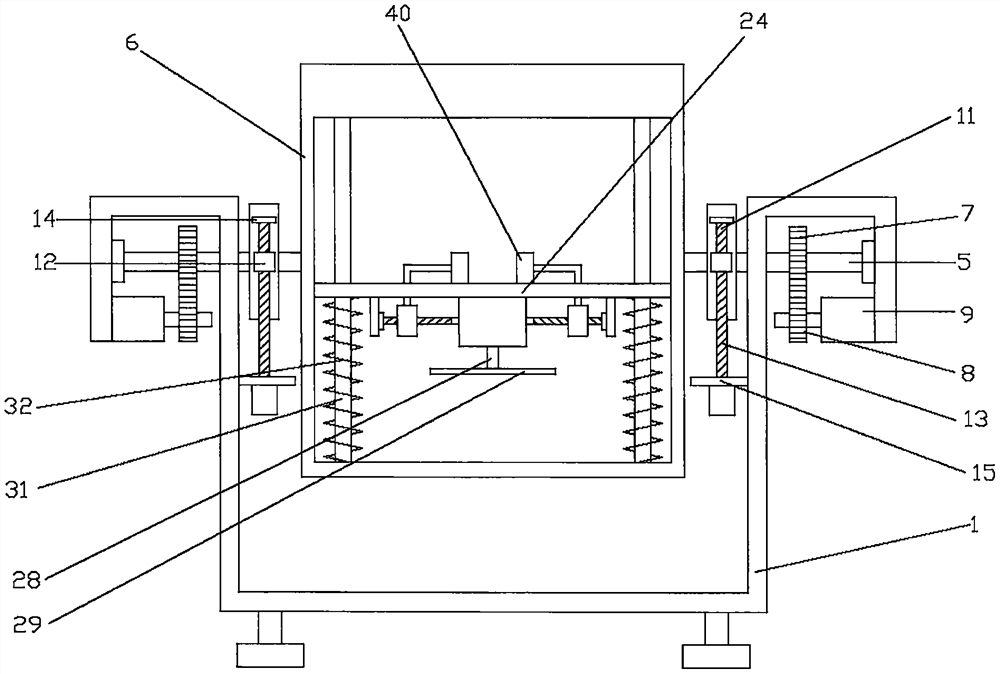

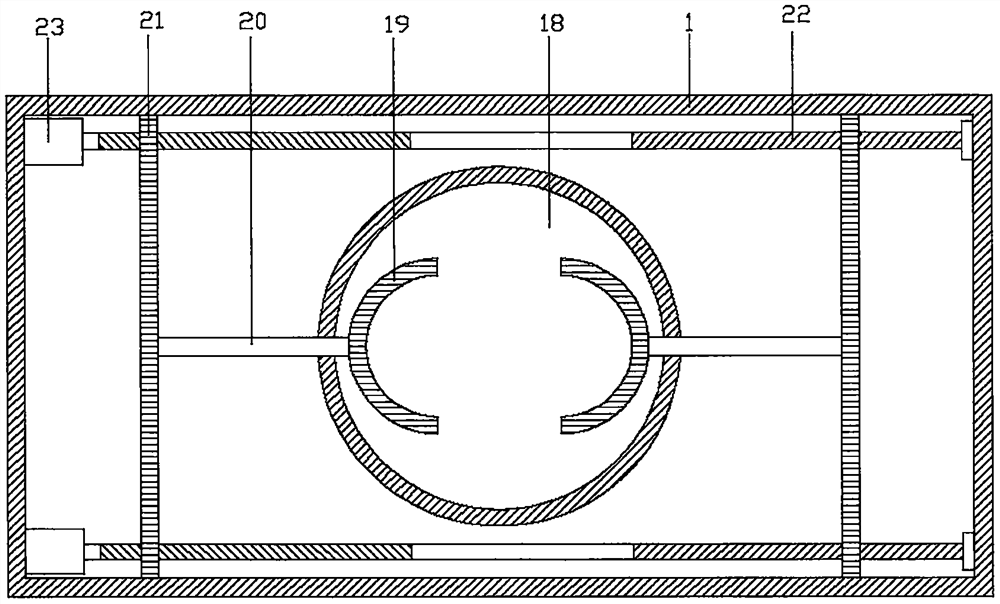

Embodiment 1

[0027] refer to Figure 1~4 , in an embodiment of the present invention, an intelligent hydraulic machine stroke limit device includes a support frame 1, and the four corners of the lower side of the support frame 1 are fixedly installed with support columns 2, and the lower side of the support column 2 is fixedly installed with support blocks 3, and the support blocks 3 The lower end is inlaid with a friction pad 4, which can effectively increase the friction between the equipment and the ground, so as to ensure the stability of the equipment. The upper end of the support frame 1 is connected with the rotating shaft 5 by connecting the bearing and the bearing seat, which can facilitate the rotation of the rotating shaft 5. The outer end of the rotating shaft 5 is provided with a first gear 7, the lower side of the first gear 7 is meshed with a second gear 8, the outer end of the second gear 8 is equipped with a first motor 9, and the first motor 9 is fixedly installed on the s...

Embodiment 2

[0032] The difference from Embodiment 1 is that a friction pad 10 is provided on the rotating shaft 5 inside the support frame 1, a brake block 11 is provided outside the friction pad 10, and first sliders 12 are fixedly installed on the front and rear sides of the brake block 11. The first slider 12, the first slider 12 is internally threaded with a one-way threaded rod 13, the upper side of the one-way threaded rod 13 is fixedly installed with a limit block 14, and the lower side of the one-way threaded rod 13 is provided with a mounting block 15, the mounting block 15 is connected with the support frame 1, a second motor 16 is installed on the lower side of the mounting block 15, and the upper side of the second motor 16 is connected with the one-way threaded rod 13, and the one-way threaded rod 13 is driven to rotate by the single machine 16, The one-way threaded rod 13 drives the brake block 11 to move upwards, so that the brake block 11 can be closely connected with the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com