Rigid connection joint of rectangular steel beam and H-shaped steel column and construction method

A technology of rigid connection and rectangular steel pipe, which is applied in construction, building structure, and construction material processing, etc., can solve the problems of rigid bolt connection, complex connection structure, technical difficulty, etc., and achieve convenient docking positioning and convenient installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

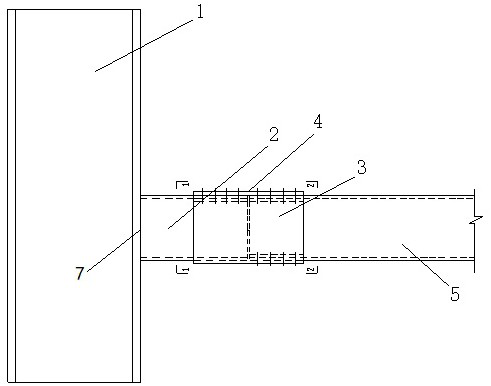

[0043] as attached figure 1 As shown, a rigid connection node between a rectangular steel beam and an H-shaped steel column provided for an embodiment of the present invention includes:

[0044] The first piece 1; the first piece 1 is an H-shaped steel column;

[0045] The second number 2; the second number 2 includes a first area and a second area; the first area is used to be fixedly connected to the first number 1 by welding;

[0046] The third part 3; the third part 3 is channel steel, including the third area and the fourth area; the third area is used to cover the second area, and is fixedly connected with the second area by welding; The fourth area is used to cover the fifth area of the fifth part 5;

[0047] The fifth part 5; the fifth part 5 is a rectangular steel beam, including the fifth area and the sixth area;

[0048] The fourth part 4; the fourth part 4 is a rectangular steel plate; when the fourth area is used to cover the fifth area of the fifth part 5,...

Embodiment 2

[0067] An embodiment of the present invention also provides a construction method for a rigid connection node between a rectangular steel pipe beam and an H-shaped steel column, comprising the following steps:

[0068] Covering the second area of the second number 2 with the third area of the third number 3, and making the third area and the second area fixedly connected by welding;

[0069] Welding connects the first area of the second part 2 and the first part 1;

[0070] Cover the fifth area of the fifth item 5 with the fourth area of the third item 3;

[0071] Put the fourth part 4 on the outside of the third part 3, and fix the third part 3, the fourth part 4 and the fifth part 5 by bolts.

[0072] In this embodiment, the first piece 1 (that is, the H-shaped steel column) and the fifth piece 5 (that is, the rectangular steel beam) form a rigid connection node by using the second piece 2 and the third piece 3 as intermediate pieces The basic form is finally rig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com