Hydraulic control device with power supply circuit

A technology of power supply circuit and hydraulic control, which is applied in the direction of valve operation/release device, flow control of electric device, valve device, etc. problem, to achieve the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

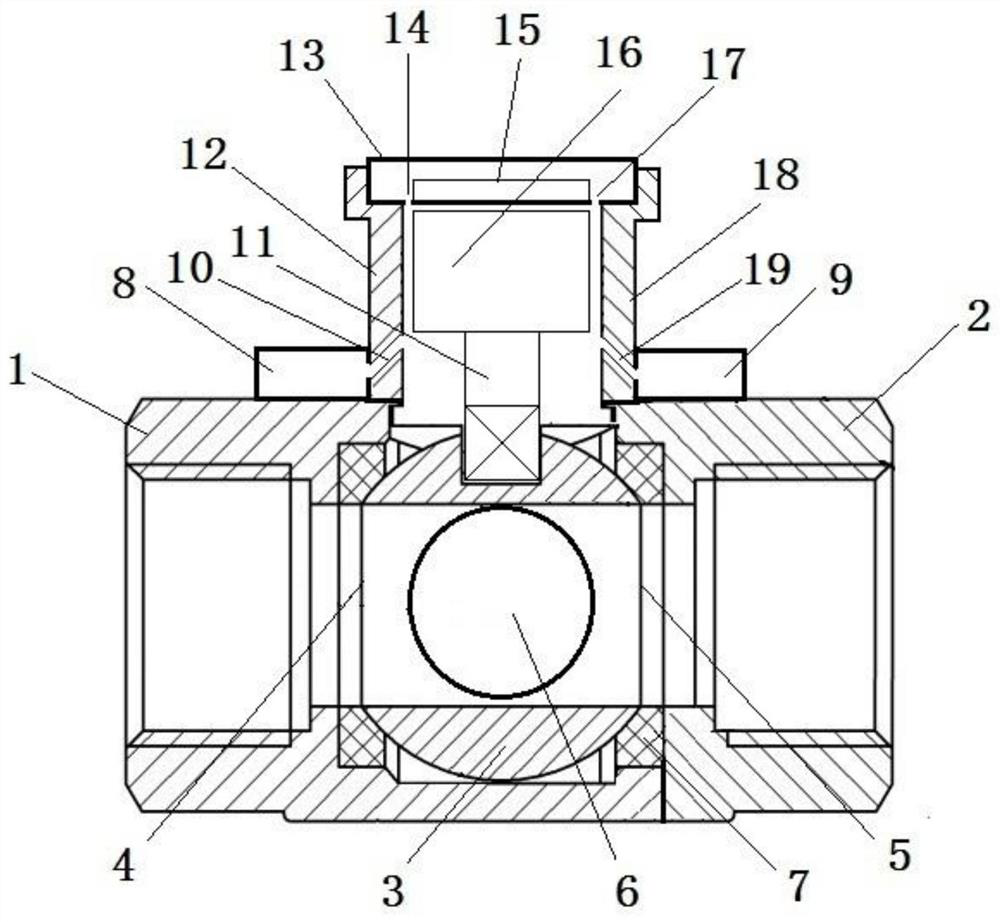

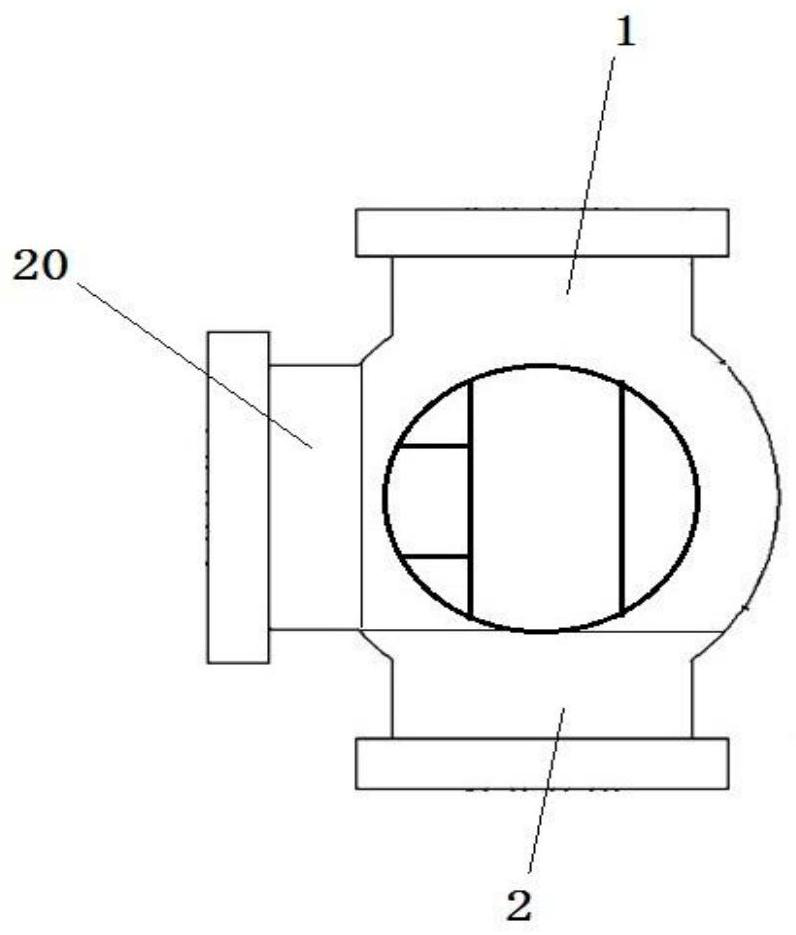

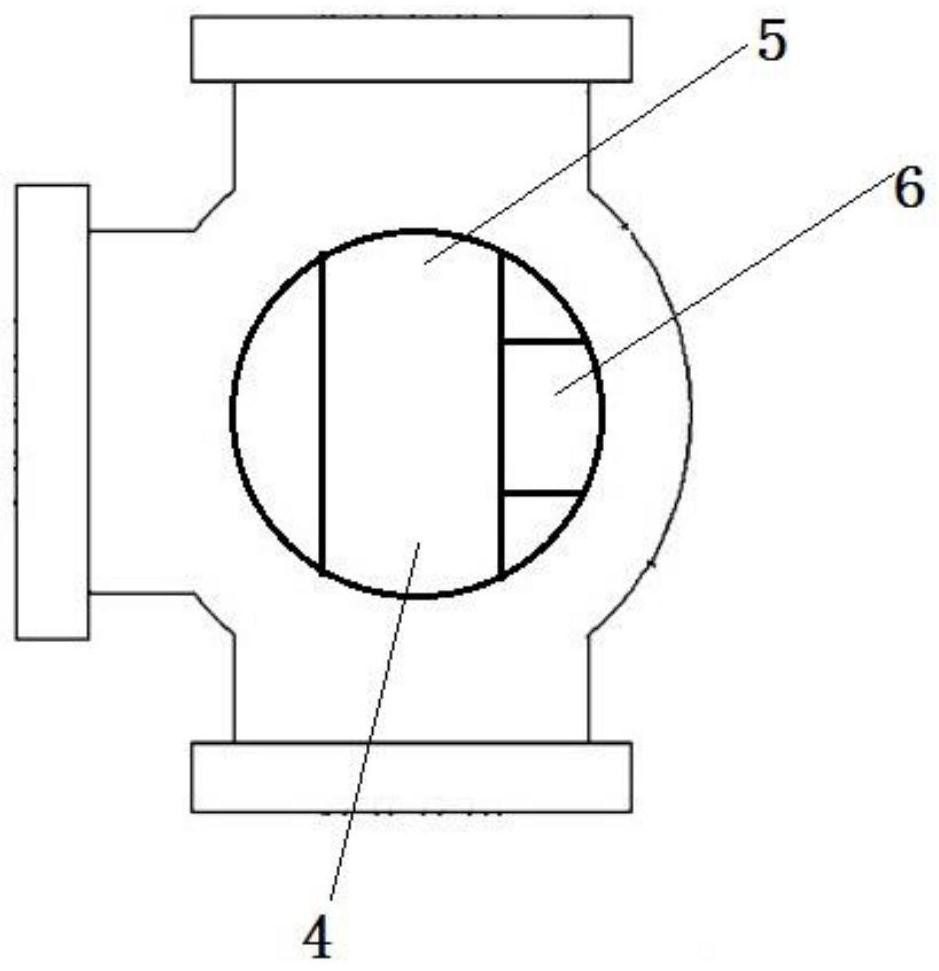

[0047] As shown in the figure: a hydraulic control device with a power supply circuit, including a first distribution valve body, a second distribution valve body, an inflow valve body, a valve core, a sealing seat, a first sensing module, a second sensing module, Drive shaft, bar, electrical box, control board, motor, power supply circuit; wherein the valve core includes a first distribution channel, a second distribution channel, an inflow channel, half valve core one, half valve core two, upper embedded ring, The lower embedded ring, the docking surface, the middle cavity, the inflow check valve, the distribution check valve 1, the distribution check valve 2, the upper positioning plate, and the lower positioning plate; The lower wall is provided with two sections of holes;

[0048] As shown in the figure: the control board and the power supply circuit are provided inside the electrical box, the power supply circuit supplies power to the control board, and the power supply ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com