A vehicle management control diversion equipment

A diversion equipment, management and control technology, applied in mechanical equipment, control valves, valve casing structures, etc., can solve problems such as no solution, unfavorable slotting, and large sealing problems at joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

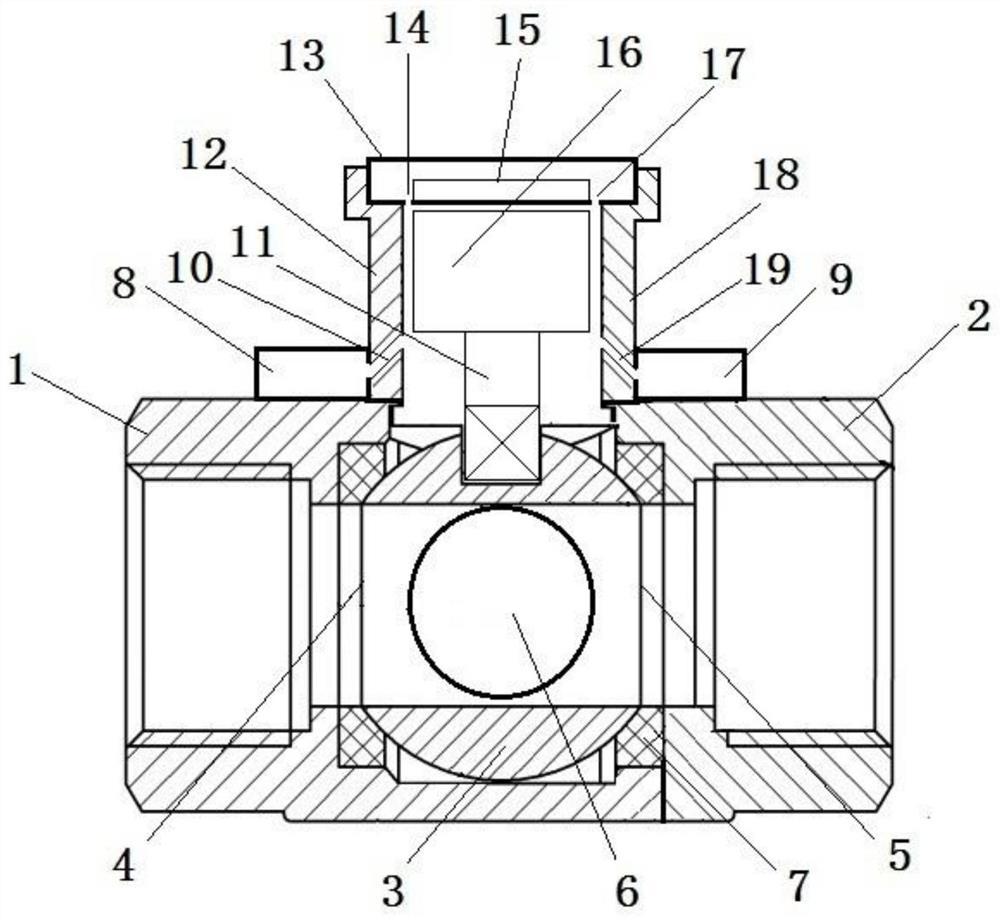

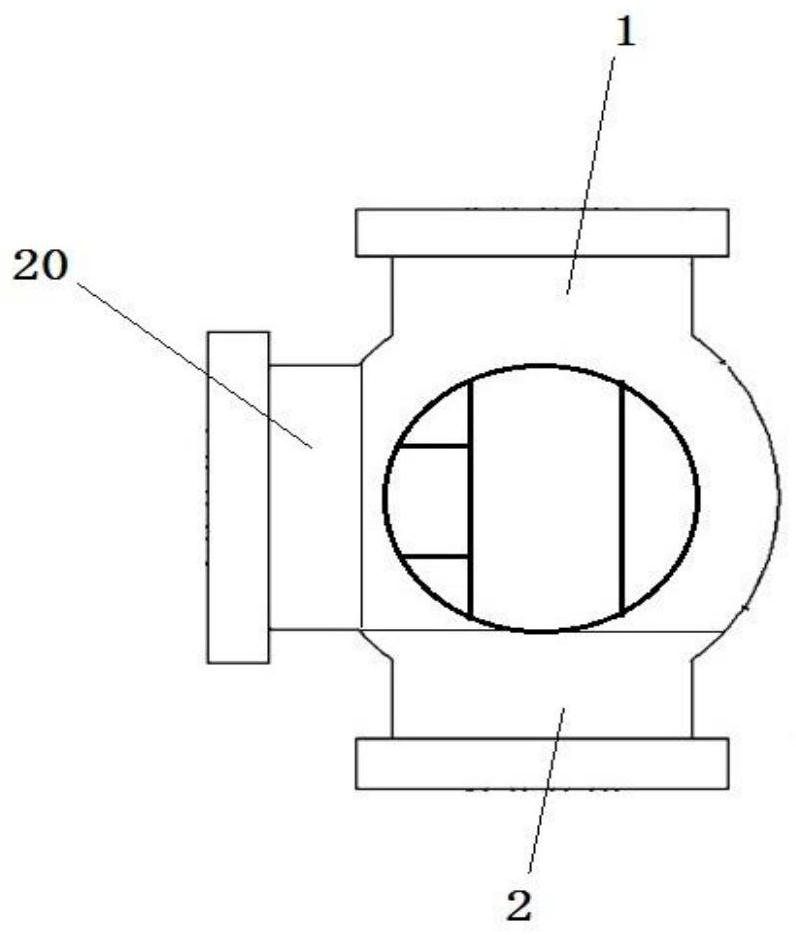

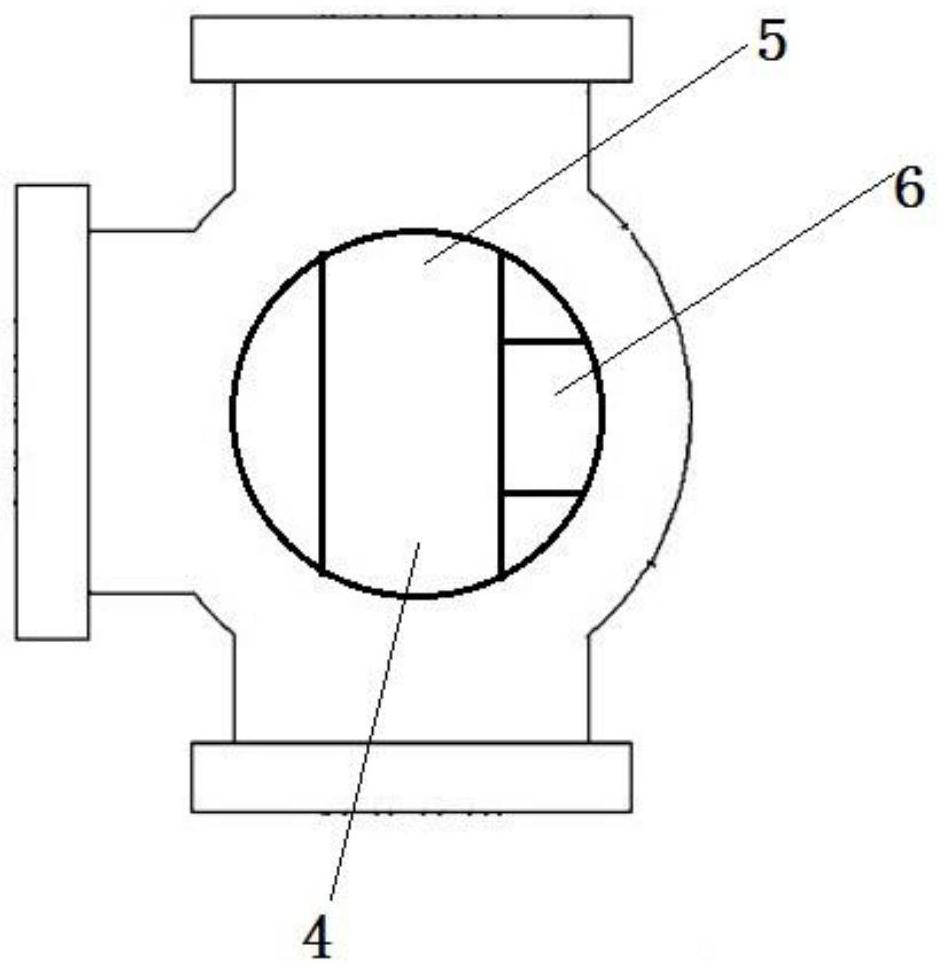

[0045]As shown in the figure: a vehicle-mounted management and control shunt device, including a first distribution valve body, a second distribution valve body, an inflow valve body, a valve core, a sealing seat, a first sensing module, a second sensing module, a transmission shaft, A strip, an electrical box, a control board, and a motor; wherein the valve core includes a first distribution channel, a second distribution channel, an inflow channel, a first half valve core, a second half valve core, an upper embedded ring, a lower embedded ring, and a butting surface , middle cavity, inflow check valve, distribution check valve 1, distribution check valve 2, upper positioning plate, lower positioning plate; the strip plate is provided with an inclined section of holes, and the lower wall of the electrical box is provided with a second section hole;

[0046] The fluid enters the shunt device from the inflow valve body, and is led out through the first distribution valve body a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com