Vehicle-mounted management and control flow dividing equipment

A shunt equipment, control technology, applied in the direction of mechanical equipment, control valves, valve housing structures, etc., can solve the problems of wire bending, failure to meet localization requirements, and large sealing problems at splicing joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

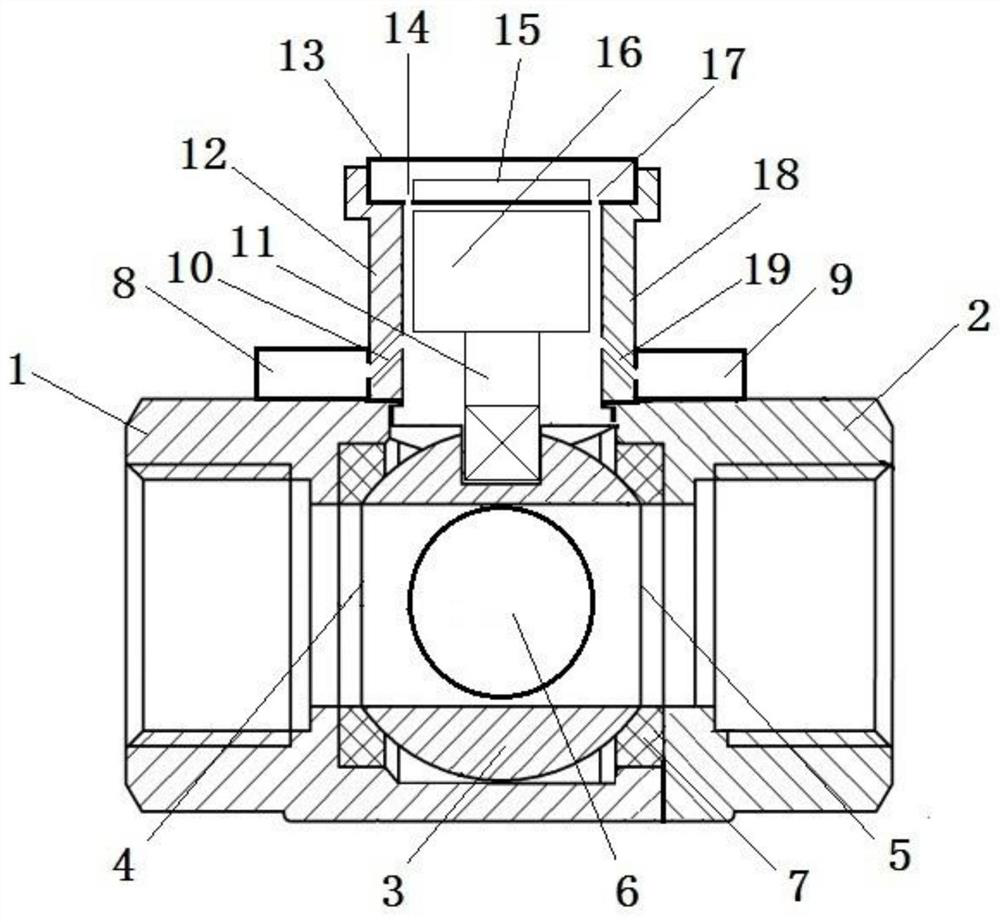

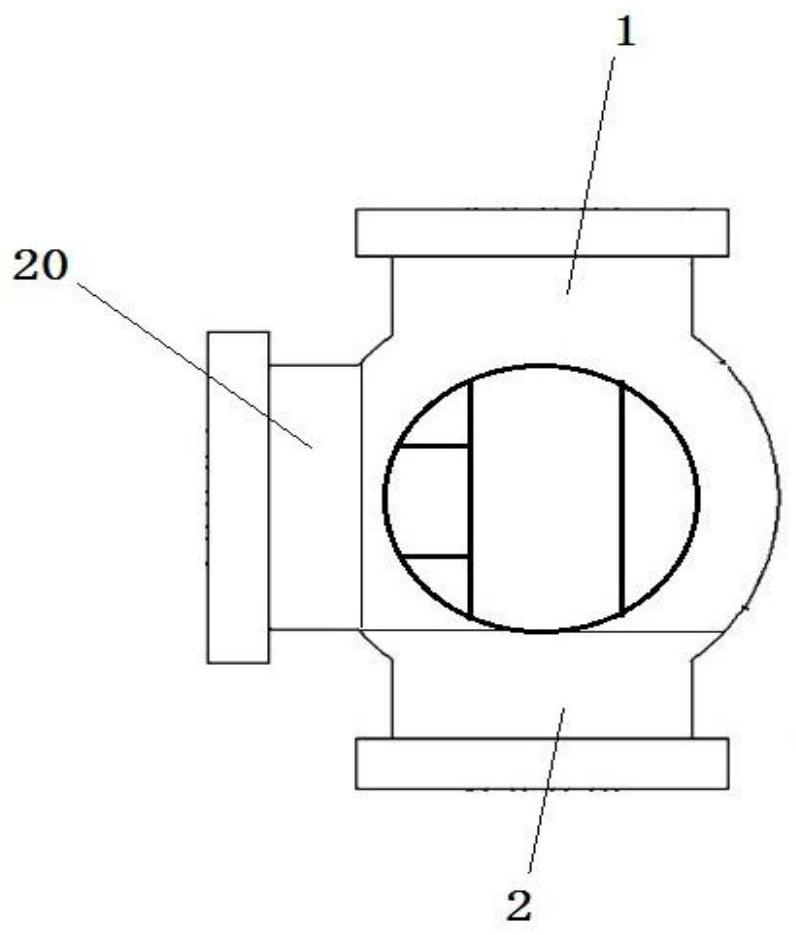

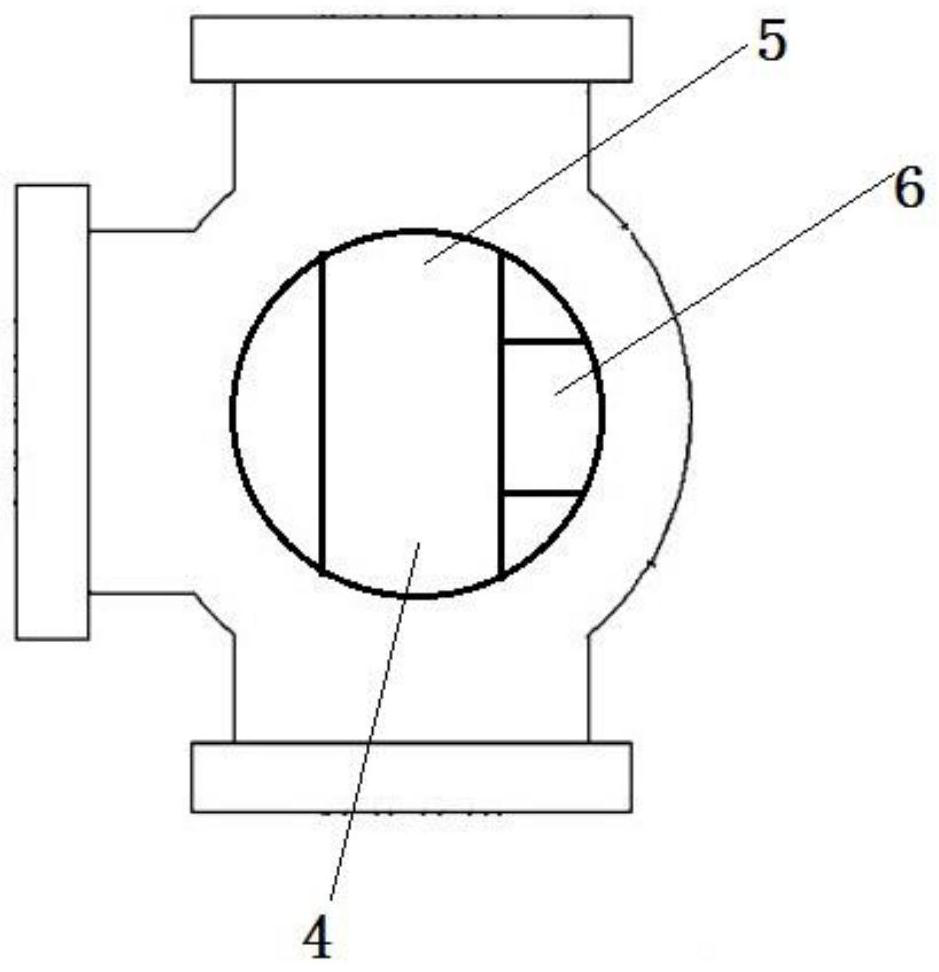

[0045]As shown: an in-vehicle control shunt device, including the first distribution valve body, a second dispensing valve body, an in-stream valve body, a spool, a seal seat, a first sensing module, a second sensing module, a drive shaft, Substrate, electrical box, control panel, motor; wherein the spool includes a first distribution channel, a second distribution channel, an incoming channel, a half-valve core, a semi-valve core, an insertion ring, a lower ring, a counter surface , Middle chamber, in-flow single-direction valve, allocated single-way valve, allocate a single-way valve two, upper positioning plate, and lower positioning plate; the strip is provided with an inclined aperture, and the lower wall of the electrical box is two segments. hole;

[0046] The fluid enters the splitter from the incoming valve body, and is exported by the first dispensing valve body, the second distribution valve body, the spool disposed inside the three parts, the valve core in the seal sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com