Line support for municipal engineering

A line and engineering technology, applied in the municipal field, can solve the problems of increasing the force of the cable on the bracket, reducing the safety of the utility pole, and uneven force on the bracket, and achieving the effect of improving the safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1: Please refer to Figure 1-Figure 5 , the specific embodiments of the present invention are as follows:

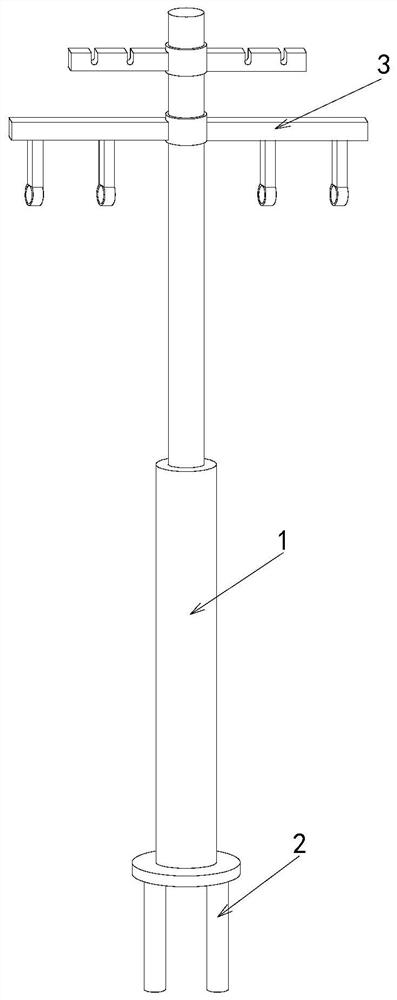

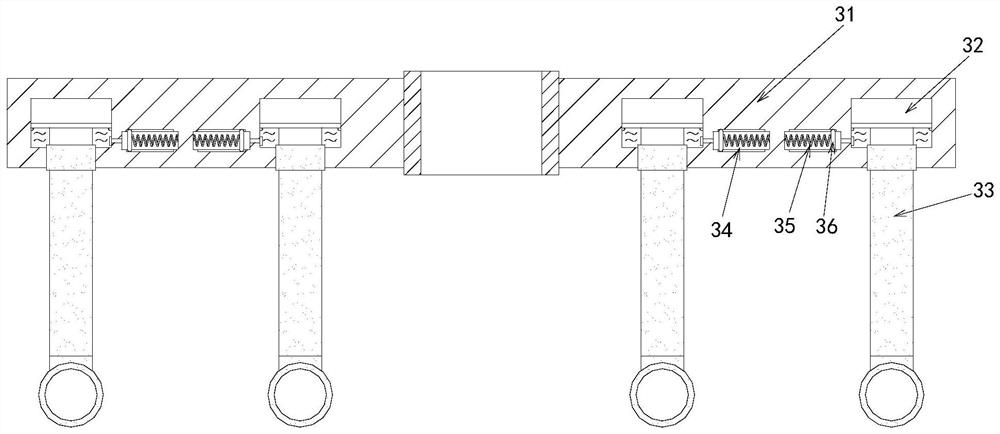

[0027] Its structure includes a utility pole 1, a base 2, and a line support 3. The bottom end of the utility pole 1 is provided with a base 2, and the line support 3 is located at the top of the utility pole 1. The line support 3 includes a support frame 31 , oil storage tank 32, wire loading device 33, movable groove 34, back-moving spring 35, oil push plate 36, described support frame 31 is provided with oil storage tank 32, and described oil storage tank 32 is connected with movable groove 34, and described wire loading The device 33 is engaged in the oil storage tank 32, the movable groove 34 is arranged at the side end of the oil storage tank 32, the return spring 35 is installed in the movable groove 34 transversely, and the oil pushing plate 36 is embedded in the end of the return spring 35 , the reset spring 35 and the oil push plate 36 are movab...

Embodiment 2

[0032] Example 2: Please refer to Figure 6-Figure 8 , the specific embodiments of the present invention are as follows:

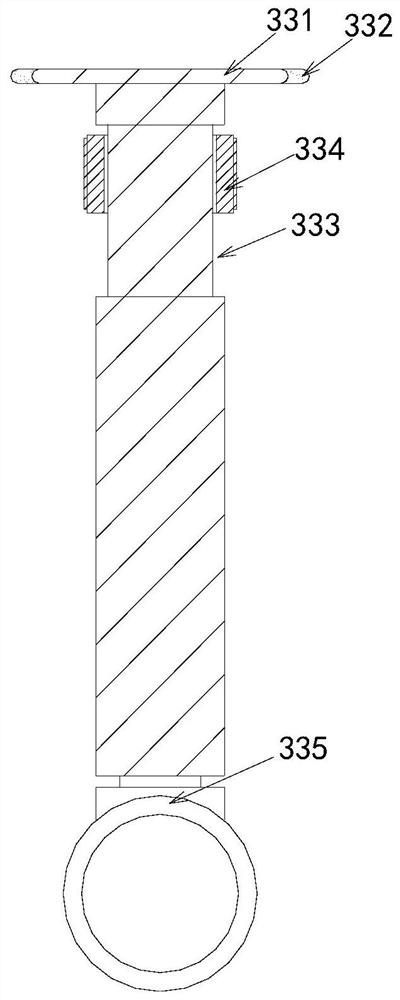

[0033] The clamping device 335 includes a mounting slot b1, a snapping head b2, a clamping frame b3, and a ball b4. The mounting slot b1 is arranged at the bottom of the wire loading device 33, and the snapping head b2 is snapped into the mounting slot. In the interior of b1, the clamping frame b3 is embedded in the bottom end of the engaging head b2, the four balls b4 are located at the upper and lower ends of the engaging head b2, and the balls b4 and the engaging head The active cooperation of b2 is beneficial to the contact between the ball b4 and the clamping head b2, thereby reducing the friction force on the clamping head b2, so that the clamping head b2 can drive the clamping frame b3 to rotate, so that it is easier for the staff to The cables are installed in the clamping frame b3.

[0034]The clamping frame b3 includes a clamping body b31, a fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com